What makes water quenching and oil quenching so different for 35CrMo steel? This article explores the distinct effects of these two methods on steel hardness and mechanical properties. By comparing the results of both techniques, the article sheds light on which method better suits specific manufacturing needs. Readers will gain insights into the optimal quenching process, understanding the balance between strength and flexibility, and the economic benefits of each approach.

35CrMo steel, a common material used in our company’s parts, is usually quenched and tempered through either oil cooling or water quenching with oil cooling. However, since the production line’s multi-purpose furnace has been put into use, it is unable to complete the water quenching oil cooling process.

As a result, the oil-quenched workpiece, particularly those with rolled bars without surface processing, show low hardness and fail to meet drawing requirements. This requires a secondary quenching, which negatively impacts the performance of the parts, increases production costs, and results in unnecessary losses.

An analysis has revealed that the low hardness is primarily due to insufficient cooling speed. Based on relevant data and other heat treatment plants’ production experience, cooling the 35CrMo steel bars with brine can increase the cooling rate.

Since our company has not previously used water quenching in the production of 35CrMo steel bars, we need to test both the water quenching and oil quenching methods and compare their mechanical properties before deciding to implement water quenching for 35CrMo steel bars.

The test material is 35CrMo steel bar produced by our company( φ 60mm), see Table 1 for chemical composition.

Table 1 Chemical Composition of 35CrMo Steel Bar (Mass Analysis) (%)

| Project | C | Si | Mn | Cr | Mo | S | P | Cu | Ni |

| National standard | 0.32~0.40 | 0.17~0.37 | 0.40~0.70 | 0.80~1.10 | 0.15~0.25 | ≤0.035 | ≤0.035 | ≤0.30 | ≤0.30 |

| Test materials | 0.36 | 0.26 | 0.56 | 0.99 | 0.17 | 0.03 | 0.02 | 0.1 | 0.1 |

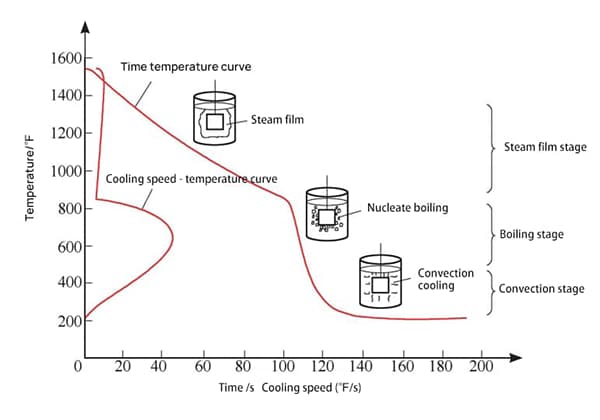

The production line for multi-purpose furnace test equipment is depicted in Figure 1. The electronic universal testing machine is controlled using the Rockwell hardness tester and CMT8202 microcomputer.

Fig. 1 Multi purpose furnace production line

The test consists of two parts: a comparison of the depth of the hardened layer between two quenching methods.

The samples of both quenching methods undergo a tensile test, and the results of their tensile strength and elongation are compared.

Take φ60mm bar as test sample, and conduct oil quenching and water quenching.

(1) Oil quenching process

Quenching 860 ℃, holding for 45min, oil cooling to 150 ℃;

Temper at 200 ℃, hold for 180min, and air cool to room temperature.

(2) Water quenching process

Quench at 860°C, hold for 45 minutes, and then water cool to 150°C.

Heat to 200°C, hold for 180 minutes, and air cool to room temperature.

No quenching cracks are observed on the surface of the treated sample.

Measure the hardness of the machined surface every 2.5mm from the surface to the center, as illustrated in Figure 2.

The hardness results are presented in Table 2.

Table 2 shows that the hardness after water quenching is high, and the hardened layer is deep.

Fig. 2 Hardness Test of Hardened Layer

Table 2 Hardness of Hardened Layer

| Distance to surface/mm | 0 | 2.5 | 5 | 7.5 | 10 | 12.5 | 15 | 17.5 | 20 | 22.5 | 25 | 30 |

| Water quenching hardness HRC | 53 | 52 | 50 | 46 | 40 | 37.5 | 35 | 33 | 32 | 30 | 28 | 25.5 |

| Oil quenching hardness HRC | 33 | 32 | 31 | 30.5 | 30 | 28 | 27.5 | 26 | 24 | 23 | 23 | 22.5 |

35CrMo steel bars can undergo oil and water quenching, and the hardness can be adjusted to reach 28-30HRC through tempering temperature adjustment.

(1) Oil quenching process

Quenching 860 ℃, holding for 45min, oil cooling to 150 ℃;

Temper at 520 ℃, hold for 90min, and air cool to room temperature. The process curve is shown in Fig. 3.

Fig. 3 Oil quenching process curve

(2) Water quenching process

Quenching 860 ℃, holding for 45min, water cooling to 150 ℃;

Temper at 580 ℃, hold for 90min, and air cool to room temperature. The process curve is shown in Fig. 4.

Fig. 4 Water quenching process curve

The test bar is processed into a tensile sample for tensile test, and the results are shown in Table 3.

It can be seen from Table 3 that the strength after water quenching is relatively high and the toughness is relatively low, with little difference overall.

Table 3 Mechanical Properties

| Quenching cooling medium | Tensile strength/MPa | Elongation (%) |

| brine | 880 | 14 |

| oil | 814 | 19 |

Based on the test results, it can be deduced that while the tensile strength has significantly improved, the elongation has decreased at the same surface hardness. This is due to the fast water quenching cooling speed, which results in a deep hardened layer and high hardness.

This solution addresses the issue of insufficient hardness in 35CrMo steel bars after oil quenching.

Changing some 35CrMo steel parts to a water quenching process can not only meet production requirements and reduce the rework rate, but also save costs. The electricity savings equal the electricity cost for rework plus the electricity cost saved by the existing process. The calculation is as follows: Electricity saving = (209 × 1.5 + 78 × 3) × 120 (approx. 120 heats of 35CrMo steel production per year) × 10% × 1.2 + 91 (power of washer) × 0.5 × 120 × 1.2 yuan = 14436 yuan.

Labor cost saved = (time saved+rework time) × number of operators × annual production furnace × unit price of man hour=(0.5+4.5×10%)×2×120×8.571yuan = 1954yuan.

Material cost saved = (quenching oil loss per furnace+cleaning fluid loss) × annual production heats=(50+20) × 120 yuan = 8400 yuan.

The annual total is about 24790 yuan.

35CrMo steel bars can be quenched by water instead of oil.

Not only can the hardness meet the requirements, but also have little impact on the comprehensive mechanical properties.

Related reading: Metal Mechanical Properties Chart

In addition to these benefits, the rework rate has significantly decreased, leading to an improvement in labor efficiency and a reduction in production costs. Furthermore, the use of a lower quenching temperature and the elimination of oil smoke generated in the oil cooling quenching process of the material result in improved economic benefits, as well as energy savings and reduced emissions.