How do advanced CNC machines achieve precision and complexity in manufacturing? This article explores the differences between 4-axis and 5-axis CNC machining, highlighting their unique capabilities and applications. Readers will learn how these machines enhance production efficiency, improve accuracy, and expand the possibilities of machining complex parts. Dive in to discover the nuances that make multi-axis machining a cornerstone of modern manufacturing.

Compared to traditional manual machining, CNC machining is significantly faster. The finished product has high dimensional accuracy and low error, as long as the computer code is correct and meets the design specifications.

CNC manufacturing is an excellent method for rapid prototyping. While it can also be used for end-use products and components, it is typically cost-effective only for short-term production runs in small quantities.

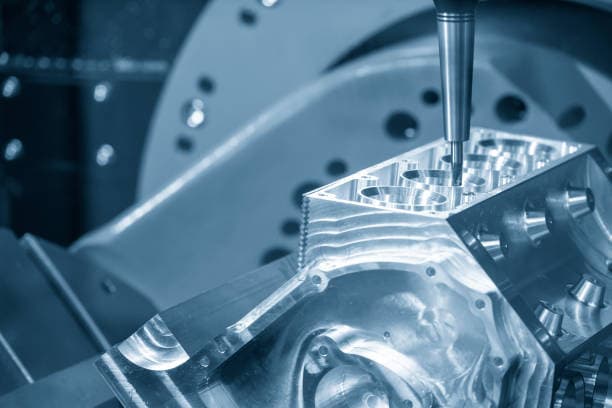

CNC milling is a process where material is removed using rotating tools. The workpiece can either remain stationary while the tool moves onto it, or it can be positioned at a predetermined angle within the machine tool. The more axes of motion a machine has, the more complex the shaping process and the faster the speed.

In 4-axis CNC milling, a fourth axis is added to the cutting tool‘s motion, allowing for rotation around the X-axis. This results in four axes of motion: the X-axis, the Y-axis, the Z-axis, and the A-axis (rotation around the X-axis).

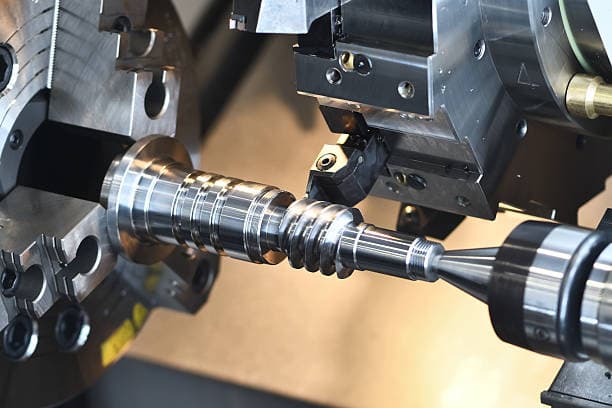

Many 4-axis CNC machines also allow the workpiece to rotate, referred to as the B-axis, allowing the machine to function as both a milling machine and a lathe.

Definition of 4-axis: A 4-axis machine tool has at least four coordinates, which include three linear coordinates and one rotational coordinate.

Features of 4-axis machining:

(1) It is used when a 3-axis machine tool cannot effectively process a workpiece, or when the workpiece needs to be clamped for an extended period of time.

(2) It enhances the accuracy, quality, and efficiency of processing free-form surfaces.

(1) Enhanced tooling capabilities;

(2) Shorter clamping times through advanced processing technology;

(3) No need for clamps;

(4) Improved surface quality;

(5) Extended tool life;

(6) Streamlined production processes;

(7) Significant increases in processing and production efficiency.

Above the four axes is another axis of rotation, typically with a full 360-degree rotation in the vertical plane.

The 5-axis system allows for complete processing and clamping in one setup, reducing clamping costs and minimizing the risk of surface scratches.

It is ideal for processing multi-faceted holes and surfaces, as well as parts with high precision requirements, particularly in mold machining.

During motion along the entire path, the tool direction can be optimized and the tool can move in a linear fashion, allowing for optimal cutting conditions to be maintained throughout the entire process.

4-axis and 5-axis linkage refer to the number of controlled axes in the control system of machining centers, CNC milling machines, or engraving machines.

A 4-axis linkage system requires four controllable axes that can be controlled simultaneously through interpolation motion. The motion speed is the combined speed of the four axes, not each axis’s individual motion control. This results in the simultaneous movement of one point in space to another point through four axes. The motion speed of each axis is calculated internally through the controller’s motion interpolation algorithm.

In a 4-axis machining center, the axes are X, Y, Z, and either A (rotating around X axis), B (rotating around Y axis), or C (rotating around Z axis). The 4-axis can move independently or in conjunction with other axes. However, some 4-axis machine tools can only move independently and only serve as indexing axes, meaning they rotate to a certain angle and then stop and lock the axis, not participating in cutting.

Similarly, a 4-axis linkage machine tool can have more than four axes, but the maximum number of linked axes is still four. The same applies to 5-axis linkage machine tools, which are more complex than 4-axis and 3-axis linkage. Currently, some CNC systems in China claim to have five axes, but some of them are fake. A true 5-axis linkage system has RTCP (Real-Time Compensation of Position) function.