Intrigued by the power and precision of 5-axis machining? In this blog post, we dive deep into the fundamentals of this advanced manufacturing technique. Our expert mechanical engineer breaks down the concepts, processes, and benefits that make 5-axis machining a game-changer in the industry. Get ready to expand your knowledge and discover how this technology is revolutionizing the way we create complex parts with unparalleled accuracy and efficiency.

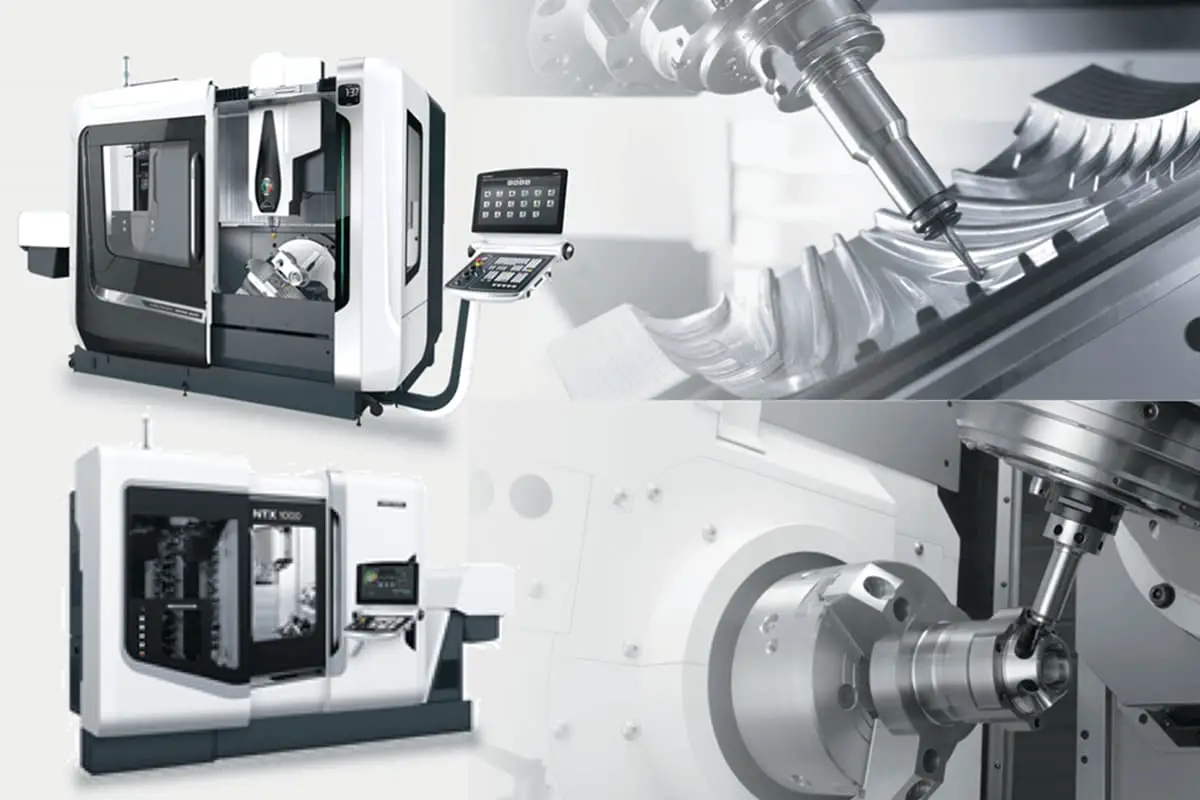

5-axis machining represents a sophisticated CNC technology that enables simultaneous movement of cutting tools or workpieces along five distinct axes. This advanced capability allows the cutting tool to approach the workpiece from virtually any angle, facilitating the production of highly complex and precise components.

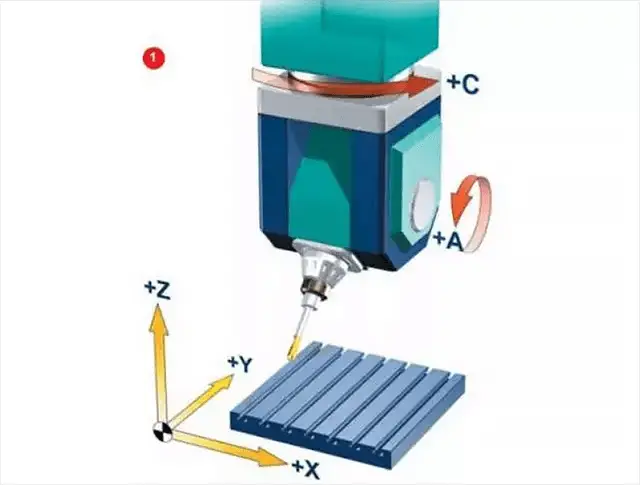

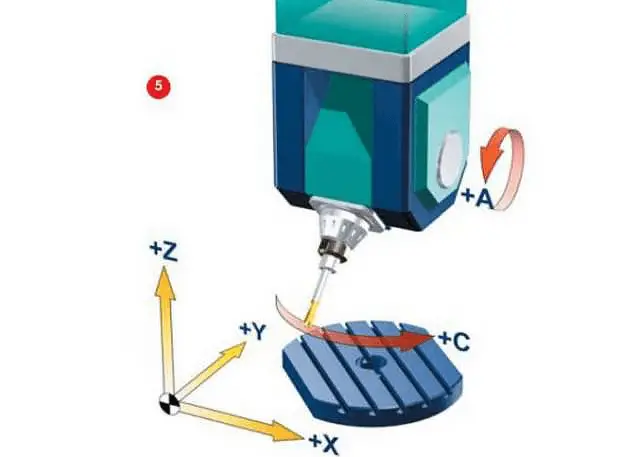

The five axes of movement in a 5-axis machining system are:

Some machines may utilize a C-axis (rotation around the Z-axis) instead of the A or B axis, depending on the specific configuration.

The incorporation of rotational movements along the A and B axes significantly enhances the machine’s capabilities. This added flexibility offers several key advantages:

Simultaneous 5-axis machining represents a cutting-edge approach in advanced manufacturing, characterized by the concurrent movement of all five axes during the machining process. Unlike conventional 3-axis systems or indexed 5-axis methods, this technique facilitates continuous multi-axis movement, resulting in a seamless and uninterrupted cutting path.

This sophisticated method enables the production of highly complex part geometries with exceptionally tight tolerances by maintaining precise control over the cutting tool’s angular position relative to the workpiece throughout the entire operation. The continuous adjustment of tool orientation allows for optimal cutting conditions, significantly reducing the risk of tool collisions and eliminating the need for multiple setups.

One of the key advantages of simultaneous 5-axis machining is the ability to utilize shorter and more rigid tooling. This reduction in tool overhang minimizes vibrations, leading to superior surface finishes and enhanced dimensional accuracy. Moreover, the technique allows for more efficient material removal rates, as the tool can maintain optimal engagement with the workpiece, reducing cycle times and improving overall productivity.

The implementation of simultaneous 5-axis machining pushes the boundaries of manufacturing capabilities, offering numerous benefits such as increased accuracy, unparalleled flexibility, and improved efficiency. It enables manufacturers to produce intricate components with complex freeform surfaces, deep cavities, and undercuts that would be challenging or impossible to achieve with traditional machining methods. This technology finds extensive applications in aerospace, medical device manufacturing, and high-precision mold and die production.

5-Axis machining revolutionizes cutting processes by employing multi-directional movements, offering unparalleled flexibility and precision in metal fabrication. This advanced technique utilizes cutting tools that operate simultaneously along five axes – the traditional linear X, Y, and Z axes, plus rotational A and B axes. This expanded range of motion enables the efficient and accurate machining of complex geometries that would be challenging or impossible with conventional 3-axis systems.

Key aspects of cutting processes in 5-Axis machining include:

Milling processes in 5-axis machining centers encompass a diverse array of sophisticated techniques that facilitate the creation of complex, high-precision geometries. These advanced processes are predominantly executed on Computer Numerical Controlled (CNC) machines, which guarantee exceptional levels of accuracy, repeatability, and operational efficiency. The most prevalent milling processes in 5-axis machining include:

Contour milling: This process involves the precise cutting along predefined geometric paths, resulting in seamless surface finishes and significantly reducing the necessity for post-machining operations. The tool follows the contour of the part, enabling the production of complex curved surfaces and intricate features with minimal tool changes.

Indexed milling: This technique allows for the strategic positioning of the cutting tool at specific angular intervals. By rotating the part or tool to predetermined positions, indexed milling facilitates the machining of complex geometries with exceptional precision. This method is particularly effective for parts with multiple flat surfaces or features that require machining from different angles.

Simultaneous 5-axis milling: In this advanced process, both the cutting tool and the workpiece undergo concurrent movement across all five axes. This synchronous motion enables the milling of highly complex and detailed parts with superior surface finish and accuracy. Simultaneous 5-axis milling excels in creating sculptured surfaces, deep cavities, and undercuts that would be impossible or highly inefficient to produce using conventional 3-axis machining.

Spiral milling: This specialized technique involves the tool following a spiral path, ideal for creating cylindrical features, helical geometries, or efficiently roughing out pockets. Spiral milling can significantly reduce machining time and improve surface finish in certain applications.

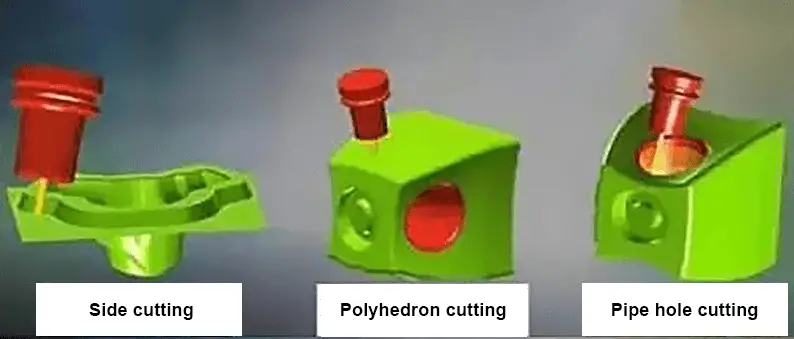

Swarf milling: A unique process where the side of the cutting tool is used to remove material along a surface. This method is particularly effective for machining ruled surfaces and can dramatically reduce cycle times compared to traditional point milling techniques.

Each of these milling processes leverages the full capabilities of 5-axis machining centers, allowing for the production of components with unprecedented complexity, accuracy, and efficiency. The selection of the appropriate milling strategy depends on the specific part geometry, material properties, and desired surface finish, often requiring a combination of these techniques to achieve optimal results.

The complexity of 5-axis machining requires advanced setups to ensure that the workpiece is accurately positioned and held securely during the processes. There are several types of setups commonly used in 5-axis machining centers, including:

To truly understand 5-axis machining, we first need to understand what a 5-axis machine tool is. 5-axis machining, as the name suggests, involves the addition of two rotary axes to the three common linear axes of X, Y, and Z.

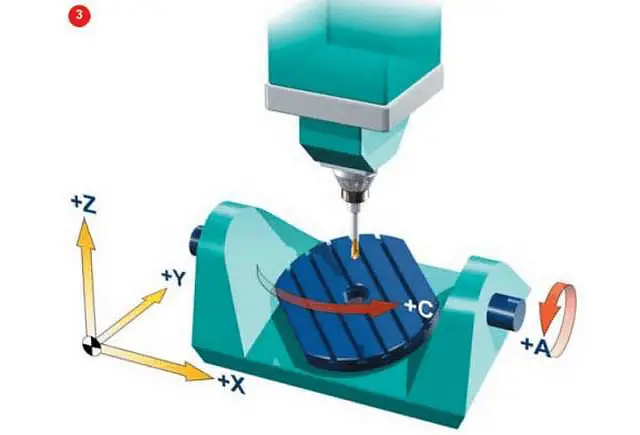

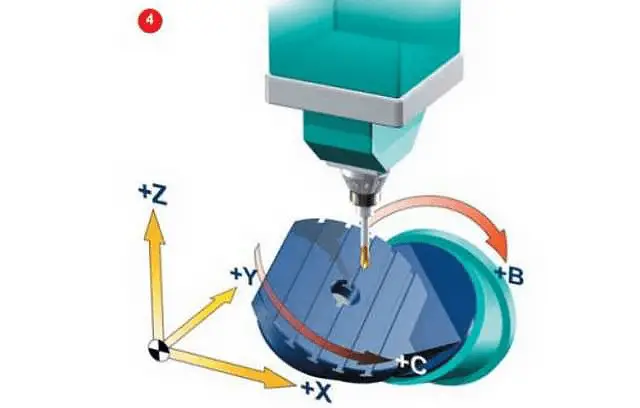

The two rotating axes (A, B, and C axis) have different motion modes to meet the technical requirements of various products.

Machine tool manufacturers continuously strive to develop new motion modes to meet various requirements in the mechanical design of 5-axis machining tools.

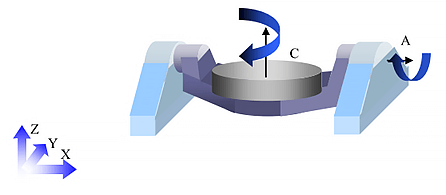

In conclusion, there are various types of 5-axis machine tools currently available in the market. Although their mechanical structures vary, the main forms include:

Two rotating coordinates directly control the direction of the tool axis (Double pendulum head form)

The two coordinate axis are at the top of the tool, but the rotation axis is not perpendicular to the linear axis (Nutate swing head form)

Two rotating coordinates directly control the rotation of the space (Double turntable form)

The two coordinate axis are on the worktable, but the rotation axis is not perpendicular to the linear axis (Nutate workbench form)

Two rotating coordinates, one acting on the tool and the other acting on the workpiece (one swing and one rotation form)

*Terms: If the axis of rotation is not perpendicular to the linear axis, it is considered a “nutate form” axis.

Having understood the 5-axis machine tools, we should now delve into their movements.

However, with such a diverse array of machine tool structures, what unique properties can they display during machining?

In comparison to traditional 3-axis machine tools, what are the benefits?

Let us now examine the highlights of the 5-axis machine tool.

Speaking of the characteristics of 5-axis machine tools, it’s important to compare them with traditional 3-axis machines.

3-axis processing equipment is more common in production, and there are several forms such as vertical, horizontal, and gantry.

The common processing methods include end cutting and side cutting with an end milling cutter, and profiling processing with a ball nose cutter, among others.

However, no matter the form or method, one common feature is that the direction of the tool axis remains unchanged during the machining process.

The machine tool can only realize movement of the tool in the spatial rectangular coordinate system through interpolation of the three linear axes X, Y, and Z.

Therefore, when faced with certain products, the disadvantages of the 3-axis machine tool are exposed, such as low efficiency, poor surface quality, and even an inability to process the product.

Compared with 3-axis CNC machining equipment, 5-axis machining centers offer the following benefits:

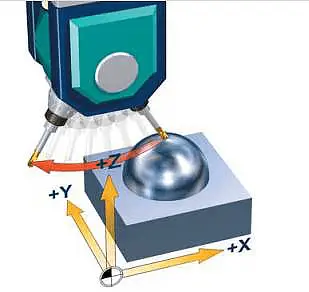

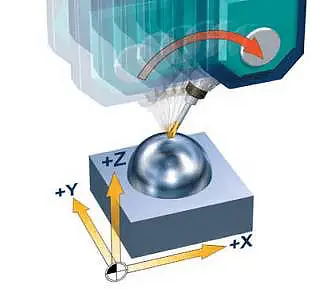

As shown in the figure, in the 3-axis cutting mode on the left, when the cutting tool moves to the tip or edge of the workpiece, the cutting conditions gradually deteriorate.

To maintain the best cutting state, the table must be rotated.

To fully process an irregular plane, the worktable must be rotated multiple times in different directions.

It can be seen that the five-axis machine tool can also prevent the situation where the linear velocity of the center point of the ball end mill is zero, resulting in a better surface quality.

As shown in the figure above, for the aerospace field components such as impellers, blades, and blisks, the 3-axis equipment fails to fulfill the processing requirements due to interference.

The 5-axis machining tool can meet this requirement.

Additionally, the 5-axis machine tool can also employ shorter tools for processing, which enhances the rigidity of the system, reduces the number of tools required, and eliminates the need for special tools.

For business owners, this translates to cost savings in terms of tool expenses with the use of 5-axis machine tools.

As can be seen from the above figure, the 5-axis machining center can also reduce bench conversion and improve machining accuracy.

In actual processing, only one clamping is required, making it easier to guarantee accuracy.

Moreover, due to the shortening of the processing chain and the reduction in the number of equipment for the 5-axis machining center, the number of fixtures, workshop area, and maintenance costs have also been reduced.

This means you can use fewer fixtures, less workshop space, and incur lower maintenance costs to achieve more efficient and higher-quality processing!

As demonstrated in the figure, the 5-axis machine tool can perform cutting through the side edge of the tool, resulting in improved processing efficiency.

The complete machining capability of the 5-axis CNC machine tool significantly shortens the production process and streamlines production management and planning.

Its advantages become increasingly apparent for more complex workpieces compared to traditional methods with dispersed processes.

For companies in the aerospace and automotive industries, the development of new products often involves complex shapes and high precision requirements.

In these cases, the use of a 5-axis CNC machining center, with its high flexibility, precision, and complete processing capabilities, can effectively address the accuracy and cycle problems in the processing of complex parts.

This, in turn, significantly reduces the development cycle and improves the success rate of new product development.

It’s important to note, however, that 5-axis machines are more complex than their 3-axis counterparts, with regards to tool attitude control, CNC, CAM programming, and post-processing.

Additionally, there are true and false 5-axis issues to consider. The distinction between true and false 5-axis lies in the presence or absence of the RTCP function.

To better understand RTCP and how it’s produced and applied, let’s dive into the machine tool structure and programming post-processing.

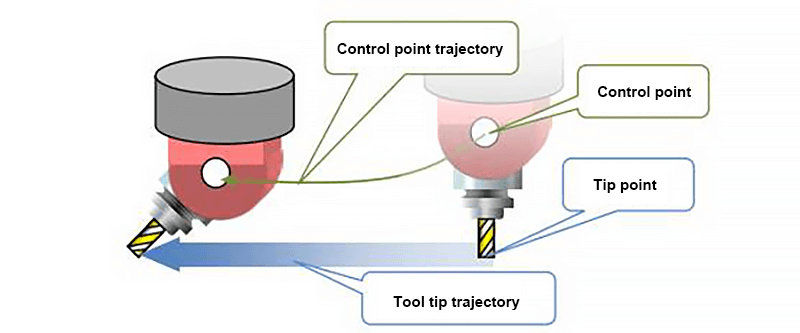

RTCP, which stands for Rotated Tool Center Point, is a crucial aspect of high-grade 5-axis CNC systems. It is also known as the tooltip follow function.

In 5-axis machining, the rotary motion of the tool produces additional movements of the tooltip, which affects the cusp locus and the attitude between the tool and the workpiece.

To ensure the tooltip follows the prescribed trajectory, the CNC system must automatically correct the control point, which often does not coincide with the tooltip.

The same technology may be referred to as TCPM, TCPC, or RPCP. These names are similar in meaning to RTCP, with the main difference being in the way the technology is applied.

RTCP specifically refers to the application of the pendulum head rotation center point to compensate in the double pendulum head structure.

On the other hand, functions like RPCP are mainly used on double rotary table machines to compensate for the change in linear axis coordinates caused by the rotation of the workpiece.

In essence, these functions aim to keep the center point of the tool and the actual contact point between the tool and the workpiece surface unchanged.

For the purpose of this article, such techniques will be referred to collectively as RTCP technology.

The Origin of the RTCP Function

Years ago, when five-axis machine tools were first becoming popular in the market, the RTCP concept was heavily hyped by machine tool manufacturers.

At that time, the RTCP function was more of a technology for technology’s sake and more of a marketing tool.

However, in reality, the RTCP function is not only a good technology, but also a valuable tool that can bring benefits and create value for customers.

With a machine tool equipped with RTCP technology (also known as a true 5-axis machine tool), operators do not have to carefully align the workpiece with the turntable axis.

Instead, they can simply clamp it and the machine tool will automatically compensate for the offset, which significantly reduces preparation time and improves machining accuracy.

Additionally, post-processing is easier because the tooltip coordinates and vectors are easily output.

As mentioned before, five-axis CNC machine tools mainly come in the form of double swing heads, double turntables, or one swing and one rotation structures.

In the following section, we will use a double turntable high-end 5-axis CNC system as an example to provide a detailed explanation of the RTCP function.

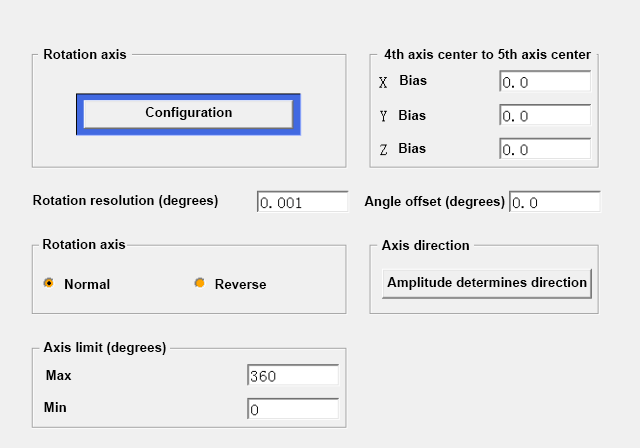

Defining the Fourth and Fifth Axes in a 5-axis Machine Tool:

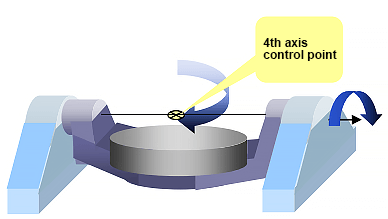

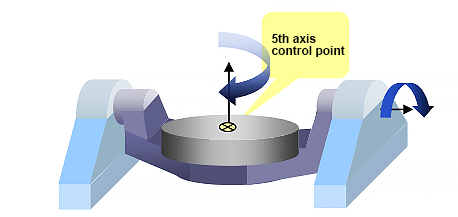

In the double-rotating table structure, the rotation of the fourth axis affects the attitude of the fifth axis, and the fifth axis is the rotary coordinate on the fourth axis.

However, the rotation of the fifth axis does not affect the attitude of the fourth axis.

Ok, let’s explain after understanding the definition.

As depicted in the figure, the fourth axis of the machine tool is labeled as the A-axis and the fifth axis is the C-axis.

The workpiece is positioned on the C-axis turntable. When the 4th axis, the A-axis, rotates, the attitude of the C-axis will be impacted as it is installed on the A-axis.

When programming the tool center cutting for the workpiece placed on the turntable, any change in the rotation coordinate will result in a change in the X, Y, and Z coordinates of the linear axis, leading to a relative displacement.

To address this displacement, the machine tool must perform compensation, which is where the RTCP function comes into play.

So, how does the machine tool compensate for the offset?

To answer that, we need to first analyze the source of the offset. As previously discussed, the linear axis coordinate shift is caused by the change in the rotating coordinate. Hence, it is crucial to analyze the center of rotation of the rotating axis.

In a machine tool with a double turntable structure, the control point of the C-axis, or the fifth axis, is typically located at the center of rotation of the machine table.

The fourth axis usually chooses the midpoint of the fourth axis as its control point.

In order to achieve five-axis control, the CNC system must have knowledge of the relationship between the control points of the fourth and fifth axes.

In the initial state, when the A and C axes are at position 0, the fourth axis control point is the origin in the fourth axis rotation coordinate system and the fifth axis control point is represented by the position vector [U, V, W].

The CNC system also needs to be aware of the distance between the A and C axis.

For double turntable machine tools, an example can be seen in the accompanying figure.

It can be seen that for machines with RTCP capability, the control system is designed to keep the tool center always at the position specified in the programming. This means that programming is not affected by the machine’s movement.

When programming on the machine, you won’t need to consider machine movement or tool length. Simply focus on the relative movement between the tool and the workpiece. The job control system will handle the rest for you.

For example:

As illustrated in the figure, when the RTCP function is absent, the control system disregards the tool length.

As a result, the tool rotates around the center of its shaft, causing the tip to deviate from its position and become unfixed.

As demonstrated in the figure, when the RTCP function is activated, the control system only adjusts the direction of the tool, while the position of the tool tip remains constant.

The necessary compensations along the X, Y, and Z axes have been calculated automatically.

Regarding the issue of linear axis coordinate offset in 5-axis machine tools and CNC systems that lack RTCP, it is worth noting that many five-axis CNC machine tools and systems in China are considered “fake 5-axis”.

This term refers to machine tools without the RTCP function. It is not determined by appearance or whether the 5 axes are linked, as false five-axis can still be used for 5-axis linkage.

The main distinction between fake 5-axis is the absence of a real 5-axis RTCP algorithm, meaning that programming for fake 5-axis must account for the spindle’s swing length and the position of the rotating table.

This implies that when using fake five-axis CNC systems and machine tools in programming, it’s necessary to utilize CAM programming and post-processing technology to pre-plan the tool path.

If the machine tool or tool is altered for the same part, CAM programming and post-processing must be performed once again.

The fake 5-axis machine tool must also ensure that the workpiece is positioned at the center of rotation of the worktable when clamping.

This results in a considerable amount of time spent on clamping and aligning for the operator, and accuracy cannot be guaranteed.

Even for index processing, the fake 5-axis is problematic.

On the other hand, the true 5-axis only requires setting up one coordinate system and only one tool calibration to complete the machining process.

The following figure uses the NX post-processing editor settings as an illustration to demonstrate the coordinate transformation of the fake 5-axis.

As depicted in the figure, the fake 5-axis relies on post-processing technology to compensate for the displacement of the rotary axis to the linear axis coordinate by showing the center position relationship between the fourth and fifth axes of the machine tool.

The CNC programs generated for X, Y, and Z axis not only include approach points but also the necessary compensation on these axes.

This method leads to reduced processing accuracy, low efficiency, non-universal programs, and high labor costs.

Moreover, each machine tool has different rotation parameters, requiring a separate post-processing file, causing production inconvenience.

Fake five-axis programming cannot be altered and manual 5-axis programming is almost impossible.

The lack of RTCP function also limits its ability to use advanced derivative 5-axis functions, such as compensation.

In conclusion, the choice of 5-axis machine tool is not about true or false, but about the method used to achieve processing results. In terms of cost-effectiveness, true 5-axis machine tools are a more viable option.

CNC Technology

5-axis CNC machining leverages advanced computer numerical control (CNC) technology to orchestrate precise, simultaneous movements along five distinct axes. This sophisticated control system enables the machining of complex geometries with unprecedented flexibility and efficiency. By integrating real-time feedback loops and adaptive control algorithms, modern 5-axis CNC systems can dynamically optimize cutting parameters, compensate for tool wear, and adjust for thermal expansion. This level of automation not only minimizes human intervention but also significantly enhances process repeatability, reduces setup times, and virtually eliminates operator-induced errors. Furthermore, the integration of Industry 4.0 principles allows for seamless connectivity with CAM software, digital twins, and production management systems, facilitating smart manufacturing practices.

Machining Accuracy

The hallmark of 5-axis machining is its exceptional accuracy, with state-of-the-art systems capable of achieving tolerances as tight as ±0.0001 inches (±2.54 micrometers). This level of precision is made possible through a combination of rigid machine construction, advanced motion control systems, and thermal compensation techniques. High-precision linear scales and rotary encoders provide real-time position feedback, while advanced error mapping and compensation algorithms correct for geometric inaccuracies. For industries demanding utmost precision, such as aerospace and medical device manufacturing, this accuracy enables the production of complex components with intricate features, tight tolerances, and superior surface finishes in a single setup. The ability to machine parts to near-net shape significantly reduces the need for secondary operations, streamlining production workflows and minimizing overall manufacturing costs.

Tool Center Point

The Tool Center Point (TCP) management in 5-axis machining is a critical technology that ensures optimal tool positioning and orientation throughout the machining process. Advanced TCP control algorithms continuously calculate and adjust the relative position between the tool tip and the workpiece surface, maintaining consistent cutting conditions even during complex simultaneous movements. This dynamic control enables the machining of intricate contours, deep cavities, and undercut features that would be impossible with conventional 3-axis systems. Modern 5-axis machines often incorporate tool length measurement systems and automatic tool offset compensation, ensuring that the TCP remains accurately positioned even as tools wear or are changed. Some advanced systems also feature real-time collision avoidance algorithms that simulate the machine’s movements and automatically adjust toolpaths to prevent potential collisions between the tool, workpiece, and machine components, significantly enhancing operational safety and reducing the risk of costly machine crashes.

Aerospace Industry

5-axis machining is a cornerstone technology in the aerospace industry, enabling the production of high-precision, complex components essential for aircraft and spacecraft. This advanced machining technique excels in crafting intricate geometries such as turbine blades, impellers, and structural airframe components with unparalleled accuracy and superior surface finish. The ability to manipulate the cutting tool along five simultaneous axes allows for the efficient machining of compound curves and undercuts in a single setup, significantly reducing production time and potential for error.

Moreover, 5-axis machining is particularly valuable when working with the exotic materials common in aerospace applications, such as titanium alloys, Inconel, and other heat-resistant superalloys. These materials often present challenges in terms of machinability, but 5-axis CNC machines can optimize tool paths and cutting strategies to maintain consistent cutting forces, extend tool life, and achieve the tight tolerances required for aerospace certification.

Defense Industry

The defense sector leverages 5-axis machining to produce mission-critical components that demand extreme precision, durability, and performance under harsh operational conditions. This technology is instrumental in manufacturing:

5-axis machining enables the defense industry to achieve the stringent tolerances and surface finishes necessary for these sophisticated systems. It also facilitates the production of lightweight yet robust structures, enhancing the mobility and effectiveness of military equipment. The ability to machine complex shapes in hardened materials with high accuracy is crucial for ensuring the functionality, reliability, and performance of defense industry products in high-stakes scenarios.

Transportation Industry

In the transportation sector, particularly automotive and high-performance vehicle manufacturing, 5-axis machining has revolutionized component production. This technology enables the creation of lightweight, high-strength parts that contribute to improved fuel efficiency, enhanced performance, and increased safety. Key applications include:

The superior surface finish achievable with 5-axis machining often eliminates the need for secondary finishing operations, streamlining production processes. Additionally, this technology facilitates the implementation of design for manufacturability (DFM) principles, allowing for the creation of parts with optimized geometries that were previously impossible or impractical to produce. This capability is particularly valuable in the rapidly evolving EV market, where innovative designs and manufacturing efficiency are crucial for competitiveness.

Cutting Tools

In 5-axis machining, cutting tools are critical components for efficient and precise manufacturing. The selection of tool materials is paramount to achieving optimal performance and longevity. While carbide and high-speed steel (HSS) remain popular for their versatility, advanced materials such as cermet and ceramic tools are gaining traction for their superior heat resistance and hardness.

For machining aluminum and titanium, tools with excellent wear resistance, thermal stability, and chemical inertness are essential. Polycrystalline diamond (PCD) tools excel in aluminum machining due to their exceptional hardness and thermal conductivity, allowing for high cutting speeds and superior surface finishes. For titanium, cubic boron nitride (CBN) tools are often preferred, particularly in finishing operations, due to their ability to maintain edge sharpness at high temperatures.

Tool coatings play a crucial role in enhancing performance and tool life. Beyond traditional titanium nitride (TiN) and titanium aluminum nitride (TiAlN) coatings, multi-layer coatings like TiSiN and AlCrN are increasingly utilized for their improved oxidation resistance and toughness. These advanced coatings can significantly reduce tool wear, especially in high-speed and dry machining conditions.

Material Profiling

Accurate material profiling in 5-axis machining is fundamental for achieving consistent results in complex geometries. The creation of impellers, turbine blades, and medical implants exemplifies the need for precise geometric profiling to ensure optimal functionality and performance.

Aluminum alloys, particularly series 6000 and 7000, are extensively used in aerospace and automotive applications due to their excellent machinability, high strength-to-weight ratio, and corrosion resistance. 5-axis machining of aluminum can achieve exceptional surface finishes (Ra < 0.8 μm) and tight tolerances (±0.025 mm) when employing appropriate cutting strategies and tool paths.

Titanium, specifically Ti-6Al-4V alloy, presents unique challenges in 5-axis machining due to its low thermal conductivity and high chemical reactivity. To mitigate heat buildup and tool wear, strategies such as high-pressure coolant delivery, trochoidal milling, and variable helix end mills are employed. These techniques allow for increased material removal rates while maintaining tool life and part quality.

The integration of advanced CAM software with 5-axis machines enables sophisticated toolpath generation, including adaptive roughing and smooth finish strategies. These algorithms optimize cutting conditions, minimize tool load, and enhance surface quality, particularly for complex freeform surfaces common in aerospace and medical components.

Improving Surface Quality

5-axis machining offers significant advantages in enhancing surface quality through its ability to produce complex geometries with minimal setups, thereby reducing error risks and ensuring superior part integrity. The continuous 5-axis motion allows for optimized tool orientation, maintaining constant contact angles between the cutting tool and workpiece. This results in more uniform chip loads, reduced tool deflection, and ultimately, smoother surface finishes with improved dimensional accuracy.

Advanced probing systems play a crucial role in achieving excellent surface quality in 5-axis machining. In-process measurement and adaptive control strategies enable real-time monitoring of surface parameters, detecting deviations, and implementing immediate corrective actions. This closed-loop approach not only enhances surface finish but also ensures tight tolerances, reduces scrap rates, and enables consistent quality across production runs.

Boosting Productivity

5-axis machining significantly outperforms traditional 3-axis methods in terms of productivity:

Reduced cycle times: Simultaneous motion across all five axes allows for complex operations to be executed in a single setup, dramatically reducing non-cutting time associated with multiple setups and tool changes. This can lead to cycle time reductions of up to 50% for intricate parts.

Enhanced machine versatility: Modern 5-axis machining centers offer multi-tasking capabilities, seamlessly integrating milling, turning, and drilling operations. This consolidation of processes eliminates inter-machine transfers, reducing work-in-progress and improving overall manufacturing efficiency.

Optimized tool utilization: The ability to maintain optimal tool engagement angles throughout the cutting process results in more evenly distributed tool wear. This not only extends tool life by up to 30% but also allows for the use of shorter, more rigid cutting tools, enabling higher cutting speeds and feeds.

Improved part accuracy: 5-axis kinematics allow for machining complex features in a single setup, minimizing cumulative errors associated with multiple setups. This approach, combined with on-machine probing and real-time compensation, can achieve tolerances as tight as ±0.0001 inches (2.54 micrometers) on complex components.

Furthermore, the integration of advanced CAM software with 5-axis machines enables sophisticated toolpath optimization, including trochoidal and high-efficiency milling strategies. These techniques maximize material removal rates while maintaining consistent tool loads, further boosting productivity and tool life.

Innovation in Fixturing

In the realm of 5-axis machining, advancements in fixturing technology have revolutionized the production process. Fixturing, the critical system for securing, supporting, and positioning workpieces during machining operations, has undergone significant improvements. These innovations enable machinists to tackle increasingly complex geometries and surfaces with unprecedented efficiency and precision.

A groundbreaking development in fixturing is the integration of advanced vacuum systems. These systems provide secure workpiece retention without traditional mechanical clamps, dramatically enhancing tool accessibility and allowing for more aggressive cutting strategies. Furthermore, the advent of composite materials and topology-optimized designs has led to fixtures that are not only lighter but also more rigid and vibration-resistant. This combination results in reduced setup times, increased production rates, and improved machining accuracy.

Cutting Condition Trends

The optimization of cutting conditions in 5-axis machining continues to be a crucial factor in achieving superior product quality. Recent years have seen the emergence of data-driven approaches and intelligent algorithms that are reshaping the industry’s approach to cutting parameter selection and optimization.

Key cutting condition trends revolutionizing 5-axis machining include:

Adaptive cutting strategies: Leveraging real-time monitoring and machine learning algorithms, these strategies dynamically adjust cutting parameters based on instantaneous tool load, material properties, and part geometry. This approach not only reduces tool wear and minimizes vibrations but also optimizes material removal rates and surface finish quality simultaneously.

High-speed machining (HSM) with advanced toolpaths: Modern HSM goes beyond simply increasing spindle speeds and feed rates. It incorporates sophisticated toolpath generation algorithms that maintain consistent chip loads and optimize tool engagement angles. This results in improved productivity, enhanced surface quality, and extended tool life, even when machining hard materials or thin-walled components.

Spline interpolation and AI-driven motion control: Advanced spline interpolation techniques, coupled with artificial intelligence-driven motion control systems, enable smoother and more precise tool movements. In 5-axis machining, this combination facilitates the production of complex, free-form surfaces with exceptional accuracy and surface finish, while maintaining high feed rates and minimizing machine vibrations.

Cryogenic and minimum quantity lubrication (MQL) cooling strategies: These environmentally friendly cooling methods are gaining traction in 5-axis machining. Cryogenic cooling using liquid nitrogen and MQL systems that deliver precisely controlled amounts of lubricant significantly reduce thermal distortion, extend tool life, and enable higher cutting speeds, particularly when machining difficult-to-cut materials like titanium alloys and heat-resistant superalloys.

By integrating these cutting-edge advancements and trends, 5-axis machining continues to expand the frontiers of manufacturing capabilities. The synergy between innovative fixturing solutions and optimized cutting conditions is unlocking new levels of efficiency, precision, and complexity in modern manufacturing, paving the way for the production of increasingly sophisticated components across various industries.