Have you ever wondered how bending technology shapes the world around us? This article dives into the various bending methods used in modern manufacturing, from die bending to CNC press brakes, and explores their applications in creating everything from elevator doors to electric control cabinets. Learn how these techniques improve efficiency and precision in production, and discover the innovations driving the future of intelligent manufacturing.

German Industry 4.0, the American Industrial Internet, and the implementation of “Made in China 2025” all confirm that the core of the Fourth Industrial Revolution in the global manufacturing industry is intelligent manufacturing. This is particularly evident in China’s sheet metal manufacturing industry, which consists of various processes such as laser cutting, sheet metal welding, cutting, and bending.

This post will primarily focus on bending technology.

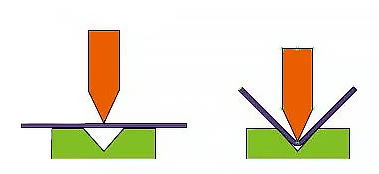

Die bending is typically performed using a press brake machine (see Figure 1), which requires the assistance of either workers or robots to complete the bending process.

The accuracy of the bending largely depends on the skill of the technicians or the quality of the robot. This method of bending is commonly used in the production of small parts with a single product type and a simple manufacturing process.

Fig. 1 Die bending

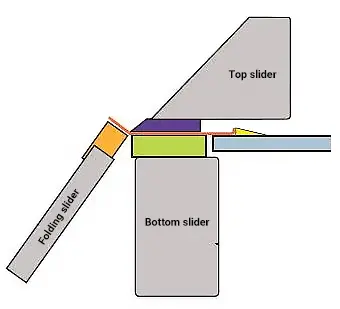

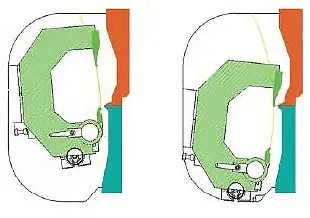

A folding machine (refer to Figure 2) can be used to bend large parts with complex structures and various shapes.

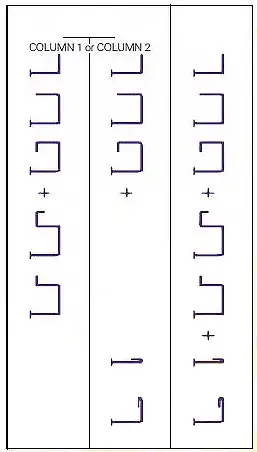

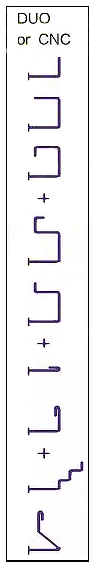

Figure 3 shows the bending shapes that can be achieved using a single-knife automatic folding machine or a double-knife automatic folding machine.

Fig. 2 Working principle of folding machine

Fig. 3 Folding shape

The double-knife bending machine is a type of folding machine (refer to Figure 4) that operates on the same principle. It is capable of bending a wide range of shapes and types, just like the folding machine.

Fig. 4 Principle of double knife bending machine

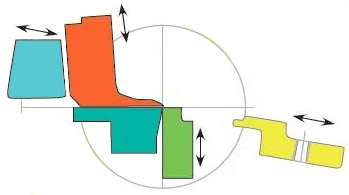

CNC press brake is the most commonly used bending machine in bending center (Fig. 5). The famous bending machine manufacturers can refer to this ranking.

Fig. 5 Principle of CNC press brake

The flexibility of the double-knife bending machine and CNC bending machine is very high, making them suitable for “universal folding” and widely used in automatic production. Until 2018, both machines were powered by hydraulic power. However, since then, CNC bending machines have begun to use servo drive and only use hydraulic drive to clamp the tooling.

There are several main differences between these machines:

(1) Bending speed.

Under the same conditions, the CNC bending machine will have a slightly faster bending speed.

For a 90° workpiece structure, it takes the CNC bending machine 1.8 to 2 seconds to bend it, whereas for the double-knife bending machine, it takes 2 to 3 seconds (depending on the size of the profile).

(2) Bending clearance.

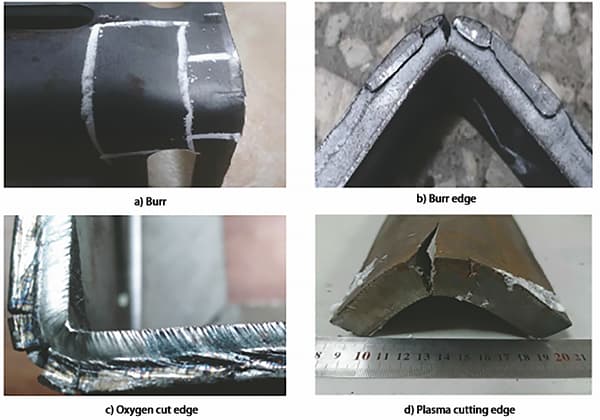

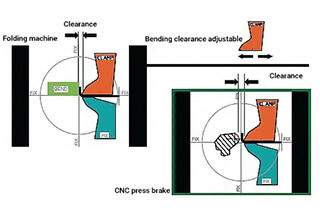

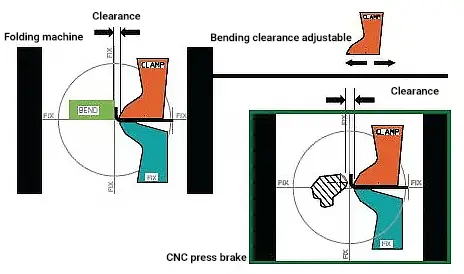

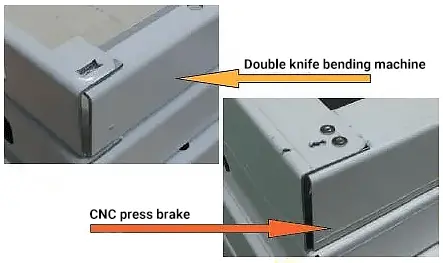

The cutting shape of the double knife bending machine differs from that of the CNC bending machine (see Fig. 6).

In cases where the clamping device is adjustable, the force area of the CNC bending machine is relatively small, which can lead to damage or scratching on the workpiece surface (see Fig. 7).

Fig. 6 Bending clearance

Fig. 7 Surface scratch

(3) Bending shape.

Figure 8 shows the bending shape of the double knife bending machine and CNC bending machine.

Fig. 8 Bending shape

Nowadays, punching technology has become more mature, especially with the popularity of punching units such as Trumpf and Amada. As a result, laser drilling and cutting technologies have also become increasingly popular.

Despite advancements in various sheet metal production processes, bending remains a major bottleneck that significantly affects the overall workflow balance and limits workshop capacity improvements.

The elevator hall door panel has a relatively simple structure with a small number of punching holes.

Most manufacturers typically use punching centers and bending centers to complete production. However, the production process bottleneck lies in bending.

During bending, the workpiece needs to rotate three times, and the corresponding tool needs to be adjusted to complete the bending process. This takes about 35 to 45 seconds per piece.

To increase production speed and efficiency, manufacturers can add a bending center to the production line. Although this can reduce the production time to 20 seconds per piece, it also increases the production cost.

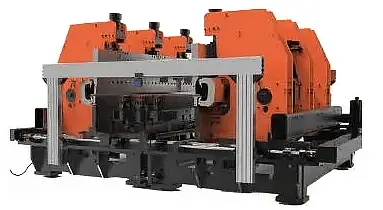

Alternatively, manufacturers can adopt a double knife bending machine (as shown in Figure 9) that allows both sides of the workpiece to be bent simultaneously. This reduces the workpiece’s rotation to only once, with a production rhythm of 12-15 seconds per piece.

As an example, consider a workpiece with the section shape shown in Figure 10 and a length of 2m. The calculated production beats are presented in Table 1.

Fig. 9 Double knife bending machine

Fig. 10 Cross-section of the hall door

Table 1 Production rhythm

| Action | Time/s | Note |

|---|---|---|

| Transmission | 2 | speed 1m/s |

| Alignment | 1.8 | |

| Bending | 7.2 | 4×1.8s (CNC press brake) |

| +/-Changes | 1 | 1s |

| Cycle Time | 12 |

An automatic hall door bending line equipped with a double knife bending machine offers highly flexible production capabilities while also ensuring accuracy and repeatability. This production line can continuously and stably complete the bending process for hall doors at the highest output rate.

The production of electric control cabinets is a highly intricate process, and its structure and materials vary greatly. Many manufacturers opt for the combination of a material warehouse, punching and shearing machines, and robot bending units to complete the production.

The main advantage of this method is that as the production capacity increases, manufacturers can add more robot bending units to improve production efficiency. Moreover, if a group of bending units get damaged, it will not affect the production of other units, ensuring uninterrupted production.

However, there are also some manufacturers who use turret punch and panel bender to produce electric control cabinets. This approach yields higher production efficiency than robot bending but comes with relatively high equipment costs.

In the cabinet industry, the box parts shown in Figure 11 must be taken into account.

Fig. 11 Box shape

The box shape is designed to enhance the strength of sheet metal structures. However, when using a CNC bending machine, the height of the box cannot be adjusted automatically, and manual adjustment is necessary.

To enable automatic height adjustment of the box, a double-knife bending machine can be used, but an additional module installation is required.

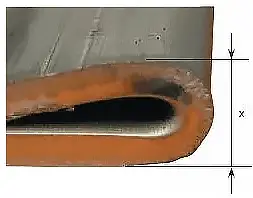

In many cabinets, hemming, which refers to double-layer materials, is often used.

If folding 1.8-2.5mm material using a CNC bending center, the situation depicted in FIG. 12 may occur. However, if a robot and press brake machine are utilized, this situation can be avoided.

Fig. 12 Water drop shape

Furthermore, the worktable size of press brake machines available in the market is limited to 4m. Therefore, if the length of the workpiece is more than 4m, the accuracy requirements for the bending flatness become exceedingly high.

Bending is an art, and choosing the right bending machine is an independent decision for the customer.

Signing a contract hastily can lead to regrettable situations and cause immeasurable losses for the enterprise.

Lastly, we aspire to assist every customer in constructing a satisfactory production line by offering powerful components in a modular manner.