Have you ever wondered why some welds fail while others hold strong? The secret often lies in preheating. In this article, we’ll explore how proper preheating can prevent cracks, reduce stress, and ensure a durable weld. By understanding these techniques, you’ll gain insights into creating stronger, more reliable welds.

Preheating is a commonly used technique in welding. It involves heating the workpiece to be welded to a temperature above the ambient temperature before or during the welding process.

Most modern specifications require specific preheating temperature ranges, depending on the standard and type of material being welded.

In this article, we will discuss the importance of proper preheating, its benefits, and the consequences of improper preheating using examples.

Preheating is the process of heating the workpiece to be welded to a temperature higher than the ambient temperature, either before or during welding.

Preheating is a mandatory requirement in welding, and specific preheating temperature ranges are outlined in pre-welding and post-welding specifications. However, in certain conditions, alternative preheating methods may also be used.

Preheating offers several advantages, regardless of whether it is mandatory or not:

The amount of preheating required for welding is not solely determined by the minimum standard outlined in the specification. Instead, one or more of the following methods may be used:

The preheating temperature range is generally appropriate for various weld groove sizes and constraints.

While many specifications specify a minimum preheating temperature, in some cases, a lower preheating temperature may be used, while in others, a higher preheating temperature may be necessary.

There are several “preheating calculation tables” available that use either linear or circular rulers to determine the preheating temperature. These tables allow you to predict the required preheating temperature based on the identification of the base metal’s material and thickness.

Carbon equivalent (CE) is a useful measure for determining whether preheating is necessary and to what extent. Here are the guidelines:

If the CE is higher than 0.5, it’s advisable to delay the final non-destructive testing (NDE) for at least 24 hours to determine if any delayed cracks are present.

The Ito & Bessyo Parameter Crack Detection (PCM) method can be utilized when the carbon equivalent is equal to or less than 0.17 wt-% or when high-strength steel is used. This approach is helpful in accurately determining when preheating is necessary, as well as when to apply forced preheating and what temperature to use. Here are the guidelines:

The spark test has been in use for many years as a method of estimating the carbon content in carbon steel. The quality of the spark produced indicates the level of carbon content, with higher carbon content resulting in a better spark and a greater need for preheating.

While this method is not the most accurate, it is simple and can provide a general indication of the required preheating temperature. By examining the quality of the spark produced, the relative level of preheating temperature required can be determined.

Another effective but less precise method for selecting the preheating temperature is to increase it by 100°F (50°C) for every 10 points based on the carbon content (0.10 wt-%). For example, if the carbon content is 0.25 wt-%, the preheating temperature should be at least 250°F (125°C), or higher.

However, if there are coatings or other components near the weld, the preheating temperature specified in the original production specification may not be appropriate.

If the welding heat input is near the maximum range allowed by the standard process, the heat transferred to the welded components may be sufficient to balance the preheating requirement. As a result, the affected metal may be heated to or above the minimum value of preheating requirements. In such cases, external methods can be used to reduce preheating requirements.

It should be noted that this approach involves ranges and imprecise conversions (e.g., °F to °C), as preheating is not an exact science.

In many cases, it is also common to continuously increase the preheating temperature until the problem, such as crack disappearance, is resolved.

On the other hand, in some specific situations, it may be possible to achieve the intended purpose even if the preheating temperature is lower than the recommended value or the temperature specified in the production specification.

To avoid material softening caused by preheating, it is important to pay attention to actual operation skills.

Choose welding processes and electrodes that introduce hydrogen rarely.

There are certain techniques that can help reduce or alleviate residual stress.

Careful monitoring is necessary to ensure correct usage of the preheating method.

The following descriptions are crucial for successfully implementing these techniques.

Welding skills have a significant impact on welding shrinkage, residual stress, heat input control, and crack avoidance.

Short welds have less longitudinal shrinkage than long welds.

Backhand welding or special welding sequences can be employed to reduce residual stresses.

Heat input should be controlled or reduced.

Linear welds with small oscillations should be used instead of those with large oscillations.

Appropriate manufacturing processes can help reduce or eliminate craters and weld cracks.

Based on experience, to avoid cracks due to insufficient weld deposit material (which is also a requirement in many production specifications), the amount of deposited metal should be at least 3/8 inch (10 mm) or 25% of the weld groove thickness.

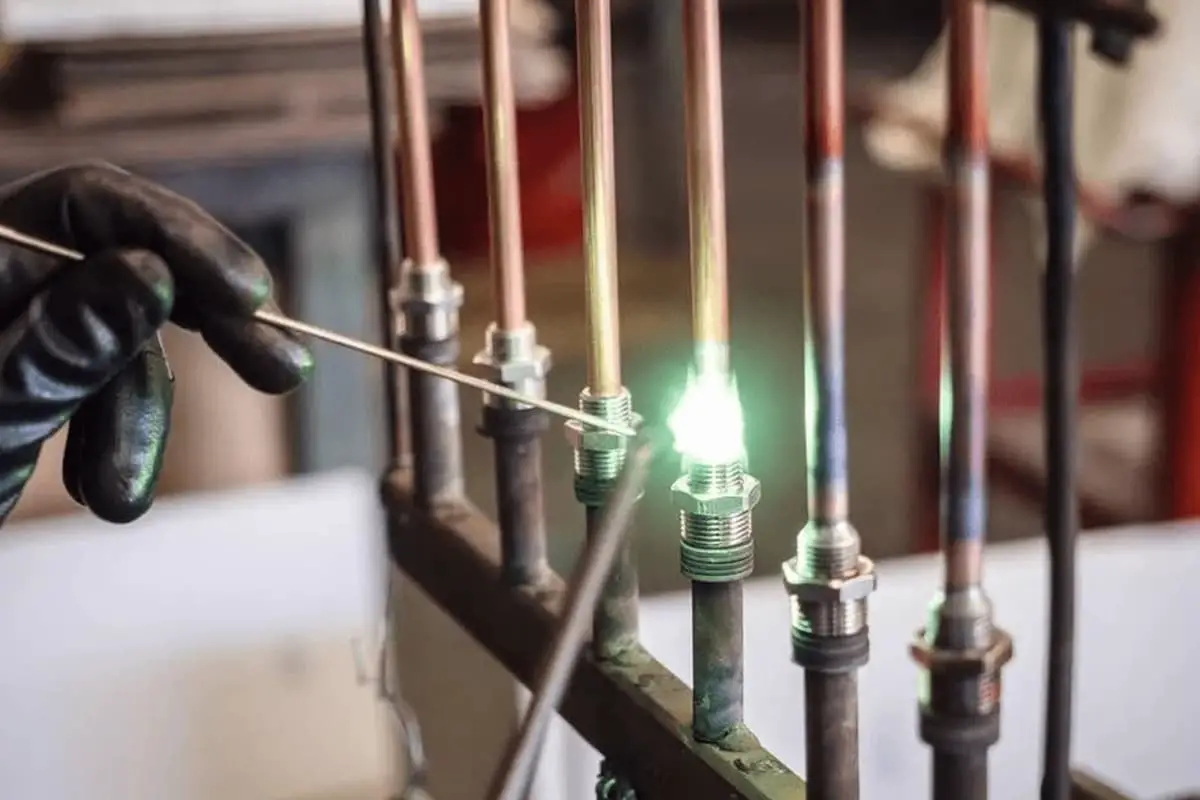

In workshops or fields, preheating can be achieved using flame heating (air-fuel or acetylene fuel), resistance heating, electronic induction heating, and other methods.

Regardless of the method used, preheating must be uniform.

Unless there are specific requirements, preheating should penetrate the entire thickness of the weldment.

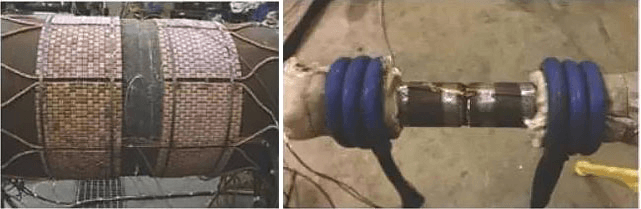

Figure 1 displays equipment that uses resistance heating (without insulation, later application) and induction heating.

Fig. 1 – resistance heating (left) and induction heating (right)

Various devices can be used to measure and monitor temperature.

Components or weldments that are to be welded should be preheated until the material is fully saturated with heat.

Whenever possible, the degree of thermal penetration should be tested or evaluated.

For most welding applications, it is usually sufficient to monitor the temperature at a distance from the weld’s edge.

Temperature monitoring or reading should not contaminate the welding groove.

Indicating pens or pencil-like tools are used to determine the minimum temperature reached during preheating. These tools melt at a specific temperature, which allows for a simple and cost-effective method of determining the melting temperature of the pen.

However, if the temperature of the workpiece exceeds the melting temperature of the indicator pen, it will not function properly. In such cases, multiple indicating pens with varying melting temperatures may need to be used to ensure accurate temperature readings.

For preheating and welding operations, direct measuring equipment such as contact pyrometers or direct-reading thermocouples with analog or digital readings can also be used. These instruments should be calibrated or have their ability to measure the temperature range verified in some manner.

The thermocouple, in particular, has the advantage of continuously monitoring and storing data. As a result, it can be used with a curve recorder or data acquisition system during preheating or post-weld heat treatment (PWHT) operations.

The American Welding Society (AWS) D10.10 provides various schemes and examples of appropriate thermocouple placement positions.

For many years, various “indigenous methods” have been used to determine if the preheating temperature is sufficient. One such method is to spray saliva or smoke directly on the workpiece. The sound made by the saliva is used as an indicator of temperature, although this method is not very accurate. Some experienced individuals still use this technique.

A more accurate way to determine preheating temperature is to use an acetylene torch. The flame is adjusted to produce high carbonization, creating a layer of gray smoke in the area to be preheated. The welding torch is then adjusted to produce medium smoke and is used to heat the gray smoke area. When the gray smoke disappears, it indicates that the surface temperature has reached over 400°F (200°C).

It is important to ensure that the preheating temperature is reached throughout the entire thickness of the workpiece and weldment area. Most monitoring is only for the outer surface of the workpiece, but AWS D10.10 provides recommended practices for the soaking zone and requires that the entire thickness of the workpiece be heated during pipe welding.

Careful observation is necessary during preheating to avoid overheating of the base metal, especially when using resistance heating or induction heating methods. Many shippers now require thermocouples to be placed under each resistance heating plate or induction coil assembly to monitor and prevent overheating.

Regardless of whether preheating is required and which preheating method is used, preheating provides several benefits, including:

When preheating, it is best to evenly heat the entire welding thickness to the specified preheating temperature. Overheating a local area may cause material damage, so it should be avoided as much as possible.