Why does your laser cutting machine sometimes fail to deliver precise cuts? The answer might lie in its optical path alignment. This guide walks you through the steps to adjust the light path, ensuring your laser maintains optimal performance. By understanding and adjusting the positions of the laser tube, reflectors, and focusing lenses, you’ll achieve cleaner, more accurate cuts. Dive into the specifics and learn how to keep your machine in peak condition.

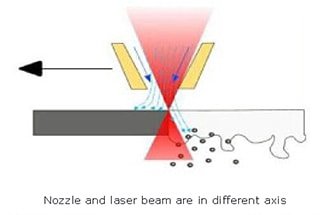

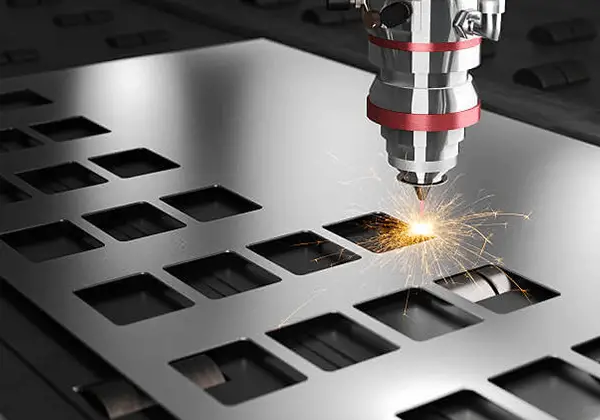

Laser cutting involves focusing a laser beam through a focusing mirror to concentrate it into a small point of light, which is then projected onto a metal surface.

The focus point attains a high power density.

At this point, the irradiated section of the material heats up rapidly and reaches the temperature of vaporization, resulting in the formation of a hole.

Through the relative linear motion of the beam and the material, the hole will continue to elongate and become a very narrow slit, ultimately achieving the goal of cutting materials.

If the laser cutting machine operates for extended periods, its optical path may deviate, leading to an adverse impact on the quality of the cuts.

Related reading: 9 Factors Affecting Laser Cutting Quality

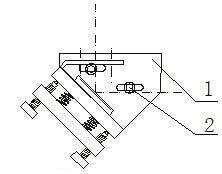

The optimal performance of a laser cutting machine relies on the perfect coordination among its key components: the laser tube, the reflector frame (A, B, C), the focusing lens, and their corresponding adjustment devices. These elements work together to produce the highest quality output and are therefore considered the core components of the laser cutting process.

Related reading: 6 Practical Functions of Laser Cutting Machine

Therefore, it is necessary to check the optical path and adjust it regularly.

After knowing the name of each component, let’s teach you how to adjust the light path of the laser cutting machine:

(1) Adjustment of the first light path

Place the masking paper on the dimming target hole of reflector A and manually adjust the light (note that the power should not be too high at this stage). Fine-tune the base of reflector A and the laser tube bracket until the light accurately hits the center of the target hole. It is important to ensure that the light is not blocked during this process.

(2) Adjustment of the second light path

Move reflector B to a remote location and use a piece of cardboard to guide the light from near to far into the cross-light target. This is because if the remote light is in the target, the near end must also be in the target.

Then, adjust the near end and remote light spot so that they are the same. This means that the deflection of the near end should match the deflection of the remote end, resulting in the cross being in the same position in both the near end and remote light spot. This will indicate whether the light path is parallel to the Y-axis guide rail.

(3) Adjustment of the third light path

(Note: The cross divides the light spot into left and right sections.) Move reflector C to the remote position to guide the light into the target. Shoot the target at the inlet and remote once and adjust the position of the contrast cross to match the position of the cross in the near-end light spot. This indicates that the beam is parallel to the X-axis.

If the optical path is inward or outward, loosen or tighten M1, M2, and M3 on mirror frame B until the light splits into left and right sections.

(4) Adjustment of the fourth light path

Place a piece of masking paper over the light outlet and press it down gently. The hole in the light outlet should leave a circular mark on the adhesive tape. Remove the masking paper and turn on the light. Next, carefully observe the position of the small hole and make adjustments to M1, M2, and M3 on the mirror frame C as necessary until the light spot appears round and straight. Finally, remove the adhesive tape from the light outlet.