Are you struggling with inconsistent bends on your CNC press brake? This article demystifies the critical adjustments needed for perfect synchronization and precision. From fine-tuning the electro-hydraulic servo system to ensuring guide rail clearance, it covers essential steps to optimize your machine’s performance. Expect to learn practical tips for achieving accurate Y-axis sampling and maintaining uniform guide rail gaps, all aimed at enhancing your press brake’s efficiency.

The electro-hydraulic synchronous servo system controls the position synchronization of the ram during movement and positioning at the end of the stroke.

The correct installation of the grating ruler is crucial for accurate Y-axis sampling.

To install the grating ruler correctly, perform horizontal alignment of the CNC press brake, ensuring that the grating ruler and guide rail are perpendicular to the ground (check with the frame leveler).

If the ram of the CNC press brake is not parallel to the workbench at the bottom dead center, adjust it by changing the reference zero value of the two Y-axes.

Note: This adjustment is a fine-tuning process and may need to be repeated. It is recommended that the user assign a dedicated person to be responsible for the adjustment. If necessary, seek assistance from relevant experts or the manufacturer to guide the adjustment.

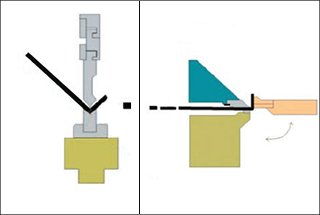

Adjust the set screw of the guide rail and check it with a feeler gauge to ensure that the guide rail gap is approximately 0.1mm. The guide rail gap should be uniform both vertically and horizontally.

Fill the lubricating oil at the lubricating point at the upper end of the guide rail. Then, start the machine to run the ram up and down and recheck whether the guide rail clearance meets the requirements. If not, readjust it.

After repairing or replacing the nylon guide plate, check the motion accuracy of the ram. Refer to the machine tool certificate of conformity for the inspection methods and accuracy requirements. If there is any error, adjust and repair it accordingly.