Imagine a machine that could slice through metal like a knife through butter. That’s the power of laser cutting machines. This article delves into the fascinating world of laser cutting, highlighting its precision, speed, and versatility. Discover how these machines transform manufacturing, reduce costs, and increase efficiency. Whether you’re a seasoned engineer or a curious reader, you’ll gain valuable insights into why laser cutting technology is revolutionizing the industry.

The current processing equipment is inefficient and results in significant loss.

Although we want to upgrade the process, we are hesitant to guarantee the stability of the new process.

The production of laser cutting machines has significantly improved the processing and production of metal materials.

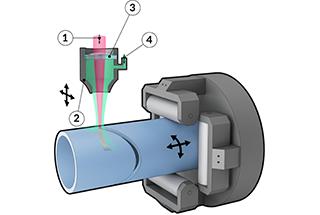

The laser cutting machine works by using a high-power laser beam to focus on the product workpiece. This causes the material to quickly melt, vaporize, burn, or reach the ignition point.

The molten chemical substances are then blown away by the rapid cyclone, which is coaxial with the light, thus separating the product workpiece. Laser cutting is a thermal cutting method.

Many customers in the processing and machinery industry are currently transitioning from old to new equipment.

When compared to the waste heat cutting method, the actual advantages of laser cutting can be summarized as follows:

Revised Version: Laser cutting can achieve excellent cutting quality due to its small laser spot, high energy, and faster cutting speed.

See also:

Laser cutting produces a narrow wound with parallel and vertical sides to the surface, resulting in high accuracy for the cutting parts’ overall dimensions.

The cutting surface is neat and visually appealing, with a surface roughness of only a few tens of microns.

Laser cutting can even eliminate the need for additional machining and manufacturing, making the parts immediately applicable.

The thermal hazard zone’s total width is minimal after the laser cutting of raw materials, and the data characteristics around the slit remain mostly unaffected.

Furthermore, the product workpiece experiences minimal thermal deformation, resulting in high-precision cutting with excellent three-dimensional geometry and a standard rectangular slit cross-section.

Due to the transmission characteristics of lasers, laser cutting machines are typically equipped with several numerical control operating tables, enabling the entire cutting process to be completed via numerical control.

During operation, only the numerical control program flow needs to be modified to facilitate cutting of different parts.

These machines can perform both two-dimensional and three-dimensional cutting.

Using the special laser cutting machine designed for intelligent steel structures as an example, the cutting speed with laser technology is 300% faster than that of plasma.

See also:

Furthermore, raw materials do not require clamping or fixing during laser cutting. This not only saves on fixture tooling, but also reduces the auxiliary time needed for feeding and cutting, resulting in a significant increase in output.

During laser cutting, the cutting torch does not come into contact with the product, and as a result, there is no damage to any special tools.

In the production and processing of parts with different styles, it is not essential to replace the “laser head. Instead, it is only necessary to adjust the main input and output parameters of the laser.

The entire process of laser cutting is characterized by low noise, minimal vibration, and zero pollution.

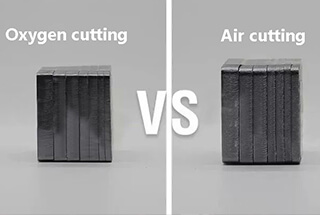

Compared to oxyacetylene cutting and low-temperature plasma cutting, laser cutting offers the advantage of being able to cut a wide variety of materials. These include metals, non-metals, metal-naphthenic non-metal composite materials, leather products, wood, and chemical fibers.

However, the adaptability of laser cutting varies depending on the type of material being used. Different materials have different thermal process performances and laser digestibility, which affects their laser cutting suitability.

The new generation of laser cutting machines is all computer numerical controlled and can be operated remotely.

Once the cutting drawing is imported, the machine will work automatically.

The process is simple, and all actions can be completed with just one or two clicks, which reduces labor costs significantly.

Moreover, many machines come equipped with automatic feeding and unloading features, making the entire process even more convenient.

One of the major advantages of using a laser cutting machine is its low usage and maintenance cost, which can greatly benefit the enterprise economy. Additionally, it requires less time for maintenance, allowing more time for cutting products and improving production.

Furthermore, in terms of usage cost, laser cutting machines have a significantly higher cutting efficiency compared to other processes, resulting in a much lower relative cost. This makes it more favorable for the development of small and medium-sized enterprises.

In summary, the laser production, processing, and sales market is continuing to grow from a market development perspective.

Despite low macroeconomic policies and industrial production requirements, the laser production and processing industry is maintaining a stable increase in business scale in the high-end production, processing, and sales market due to its work requirements.

In terms of technology, compared to traditional CNC lathe cutting, processing, and other heat treatments, laser technology offers various technical advantages, conforming to the requirements of high precision, low damage, and high efficiency in the high-end production, processing, and sales market.