Ever wondered what keeps an aircraft soaring safely through the skies? This article explores the fascinating world of aerospace materials, revealing how they withstand extreme conditions and ensure high performance. Discover the secrets behind their selection and the incredible science that makes modern aviation possible. Get ready to uncover the crucial factors that keep our planes strong, light, and reliable!

Aerospace materials must withstand extreme mechanical stresses, including high tensile, compressive, and shear forces, as well as complex dynamic loads. These materials are subjected to intense vibrations, cyclic fatigue, and impact forces during takeoff, landing, and in-flight maneuvers. The rapid rotation of turbine blades, sudden atmospheric changes, and aerodynamic loads further compound the mechanical demands on these materials.

The thermal environment for aerospace materials is equally challenging. Exposure to hot engine exhaust gases and intense solar radiation at high altitudes creates a high-temperature environment, often exceeding 1000°C in certain components. Conversely, at supersonic and hypersonic speeds, aerodynamic heating becomes a critical factor, with temperatures potentially reaching 2000°C or higher at leading edges and nose cones.

Temperature extremes are not limited to heat. Materials must maintain their integrity at cryogenic temperatures, dropping to approximately -60°C when cruising at subsonic speeds in the stratosphere, and plummeting to -80°C or lower in polar regions during winter operations. This wide temperature range (-80°C to +2000°C) demands exceptional thermal stability and resistance to thermal shock.

The chemical environment poses additional challenges. Metal components face risks of stress corrosion cracking and hydrogen embrittlement, particularly in the presence of high-temperature, high-pressure steam in engines. Elastomeric materials, such as seals and tires, must resist ozone cracking and maintain flexibility across temperature extremes. Fuels, hydraulic fluids, and de-icing agents can cause corrosion in metals and degradation or swelling in polymers and composites.

Environmental factors further accelerate material degradation. Prolonged exposure to UV radiation at high altitudes can induce photodegradation in polymers and composites. Hypersonic flight subjects materials to erosion from high-velocity particulates and atomic oxygen in the upper atmosphere. Additionally, materials must withstand long-term storage in varying humidity levels without compromising their performance or structural integrity.

To meet these multifaceted challenges, aerospace materials require a sophisticated balance of properties, including high strength-to-weight ratios, excellent fatigue resistance, thermal stability, corrosion resistance, and radiation hardness. This demanding service environment drives continuous innovation in material science, pushing the boundaries of alloy design, composite engineering, and surface treatments to ensure the safety and efficiency of aerospace systems.

Aerospace vehicles have been functioning in the atmosphere or outer space for an extended period. To ensure their high reliability, safety, and optimal flight performance, they must be designed to operate effectively in challenging environments.

To achieve these goals, optimizing the structure to meet aerodynamic, technological, and maintenance requirements is essential. However, it also requires the use of materials that possess excellent characteristics and functions.

In service, structural components must be able to handle various types of external forces without exceeding the acceptable level of deformation or breaking within a specified time frame.

One of the design goals in aerospace structures is to minimize their size and weight. In the past, the primary focus was on the static strength of the components, often neglecting or giving limited consideration to their plastic toughness. This resulted in catastrophic accidents.

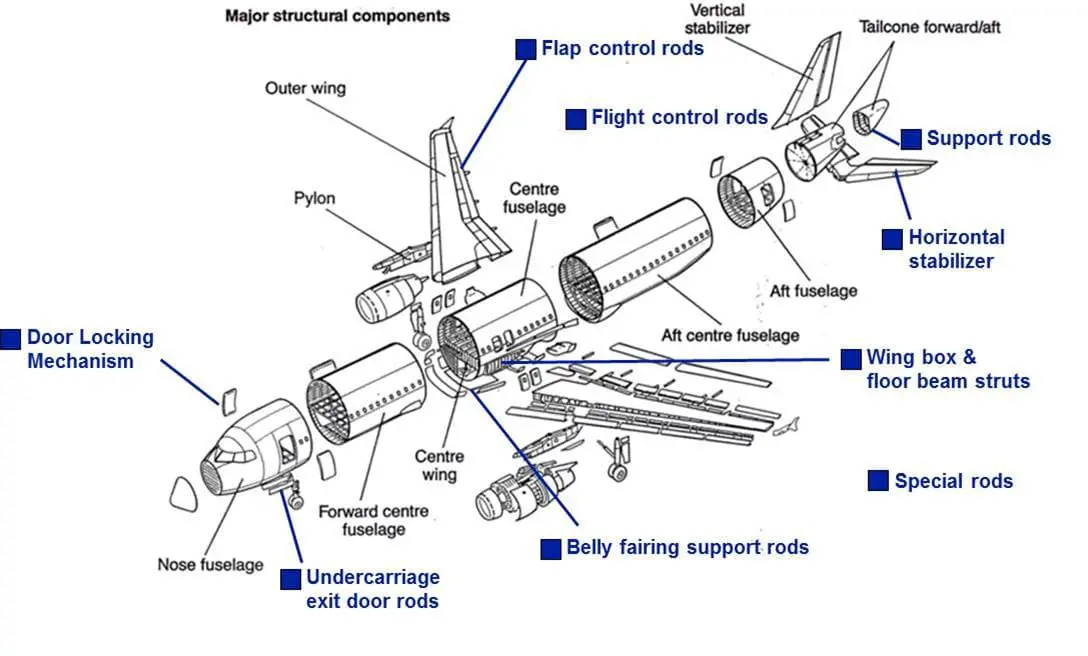

Main structural components of mainline aircraft

To ensure the safety of structural components and make the most of material performance, the design of aerospace structural parts has shifted from a “strength design principle” to a “damage tolerance design principle,” and has evolved into a “full life cycle design principle.

In the design stage, all aspects of a product’s life cycle are taken into account, and all relevant factors are comprehensively considered and optimized in the product design stage.

Materials must not only have high specific strength and stiffness, but also exhibit certain fracture and impact toughness, fatigue resistance, high and low temperature resistance, corrosion resistance, aging resistance, and mold resistance, as well as improved performance indicators.

Different material selection criteria are applied in different load areas, with materials chosen based on the specific requirements of each component. For high load areas, strength criteria are used and high-strength materials are selected. For medium load areas, stiffness criteria are used, and materials with high elastic moduli are chosen. In low load areas, dimensional stability is the primary consideration to ensure that components are larger than the minimum critical size.

When selecting and evaluating structural materials, appropriate test methods for mechanical properties (tensile, compression, impact, fatigue, low-temperature impact) should be selected based on the service conditions and stress states. A comprehensive consideration of material strength, plasticity, and toughness must be made for different fracture modes, including ductile fracture, brittle fracture, stress fatigue, strain fatigue, stress corrosion, hydrogen embrittlement, neutron irradiation embrittlement, etc.

For members under tension, the stress distribution should be uniform on both the surface and core, and the selected material should have a uniform structure and performance, with good hardenability for large members.

For members subjected to bending and torsion loads, there is a large stress difference between the surface and core, and materials with low hardenability can be used.

Fatigue limit and notch sensitivity are important evaluation criteria for material selection for components under alternating loads.

For components exposed to corrosive environments, factors such as corrosion resistance, sensitivity to hydrogen embrittlement, tendency for stress corrosion cracking, and corrosion fatigue strength are important assessment indicators for material selection.

Structure stability must be considered for materials used in high-temperature services, and low-temperature performance must be taken into account for low-temperature services.

Reducing weight has practical significance for improving aircraft safety, increasing payload and endurance, improving maneuverability and range, and reducing fuel or propellant consumption and flight costs. The faster the aircraft speed, the more significant weight reduction becomes. For example, reducing the weight of a fighter by 15% can result in a 15% reduction in taxiing distance, a 20% increase in range, and a 30% increase in payload.

For short-term disposable aircraft such as missiles or launch vehicles, it is necessary to achieve equivalent functions with the minimum volume and mass, striving to maximize material performance and selecting the smallest possible safety margin to ensure absolute reliability throughout their service life.

Reducing the structural mass can be achieved by reducing the density by 30%, which is more than the strength by 50%.

Aluminum alloys, titanium alloys, and composite materials are the primary materials used in aerospace structures due to their high specific strength and stiffness, which can improve the payload, maneuverability, and endurance of aircraft while reducing flight costs.

The use of ultra-high strength steel (with a yield strength greater than 1380 MPa) in aerospace engineering is limited to less than 10%.

For modern aircraft such as supersonic fighter, the amount of ultra-high strength steel is stable at 5% ~ 10%, the tensile strength is 600 ~ 1850MPa, sometimes as high as 1950mpa, and the fracture toughness KIc = 78 ~ 91MPa · m1 / 2.

High-strength corrosion-resistant steel is typically used for the fuselage load-bearing structure in environments with active corrosion, while carbon-free corrosion-resistant steel is used for components in aircraft equipped with hydrogen fuel engines using liquid hydrogen and hydrogen medium.

The main structural materials used in aircraft fuselages in the 21st century are aluminum alloys, including the 2XXX series, 7XXXX series, and aluminum-lithium alloys. Adding lithium to aluminum alloys can improve their strength and reduce their density, thus enhancing their specific strength and stiffness.

Aluminum-lithium alloys have been used in large transport aircraft, fighter planes, strategic missiles, space shuttles, and launch vehicles, and are used in components such as headshells, load-bearing components, liquid hydrogen and liquid oxygen storage tanks, pipelines, and payload adapters. They are considered a promising material for aerospace development.

The third and fourth-generation aluminum-lithium alloys no longer prioritize low density and have better overall properties. Compared to the third-generation aluminum-lithium alloys, the fourth-generation alloys have higher static strength (especially yield strength) and fracture toughness, while maintaining equivalent crack growth rate, fatigue performance, corrosion performance, and elastic modulus.

Titanium alloys have a higher specific strength than aluminum alloys and are used for aircraft components such as the frame, flap guide rail and bracket, engine base, landing frame parts, and heating parts like the exhaust hood and fire shield. For supersonic aircraft with Mach numbers greater than 2.5, the surface temperature can reach 200 to 350°C, and titanium alloys can be used as the skin.

The high-purity, high-density titanium alloys prepared by rapid solidification/powder metallurgy methods have good thermal stability and maintain their strength at 700°C, similar to their strength at room temperature. The high-strength, high-toughness β-type titanium alloys developed have been selected by NASA as the matrix material for SiC/Ti composite materials used in aircraft fuselage and wing panels.

The proportion of titanium alloys used in aircraft is gradually increasing, with 20% being used in civil aviation fuselages and 50% being used in military aircraft fuselages.

Metal matrix composites, high-temperature resin matrix composites, ceramic matrix composites, and carbon/carbon composites are playing an increasingly important role in the aerospace industry.

Carbon/carbon composite materials combine the refractory properties of carbon with the high strength and rigidity of carbon fibers. They have excellent thermal stability and conductivity, as well as high strength and toughness at 2500°C with a density that is only one-fourth of high-temperature alloys.

Hybrid composites have gained significant attention, such as adding glass fiber to carbon fiber composites to improve impact performance or adding carbon fiber to glass fiber reinforced plastics to increase stiffness.

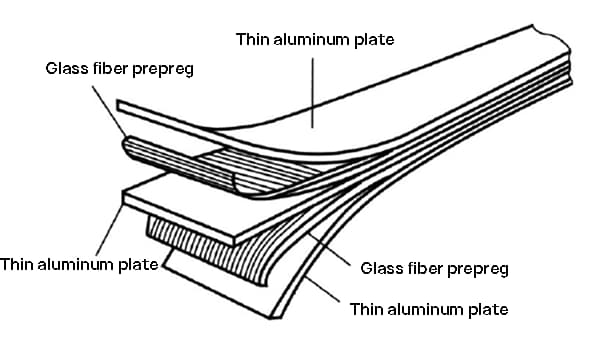

Layered composite materials are also becoming more widely used in aerospace engineering, such as the 3% use of GLARE, a new laminate, in the A380. Laminate is a composite material made by stacking two different materials together under pressure.

A laminate typically consists of an upper panel, upper bonding layer, core material, lower bonding layer, and lower panel. Its strength and rigidity are higher than those of the individual panel or core material. It has been used in transport and fighter aircraft.

The GLARE laminate is formed by hot pressing multiple thin aluminum plates and unidirectional glass fiber pre-impregnated with epoxy adhesive under pressure or in a hot press tank, as shown in Figure 1. The aluminum plates must be properly pre-treated to facilitate adhesion to the fiber pre-impregnated layer.

Table 1 shows the types of commercially produced GLARE laminates, which can be made into plates of different thicknesses as needed. The fibers can be 2, 3, 4 layers, or more, and their content and direction can meet the requirements in the table. Each type of GLARE laminate can have different forms and can be adjusted to meet specific needs.

Fig. 1 Schematic diagram of glare laminate

Table 1 types of commercially available glare laminates

| Laminate | Aluminum layer | Fibrous layer | Typical density / (g / cm 3) | ||

| aluminium product | Single layer thickness / mm | orientation | Single layer thickness / mm | ||

|

GLARE1 GLARE2 GLARE3 GLARE4 GLARE5 GLARE6 |

7475-T76 2024-T3 2024-T3 2024-T3 2024-T3 2024-T3 |

0.3~0.4 0.2~0.5 0.2~0.5 0.2~0.5 0.2~0.5 0.2~0.5 |

Unidirectional Unidirectional 0°/ 90° orthogonal 0°/ 90°/0° orthogonal 0°/ 90°/90°/0° orthogonal +45 ° / – 45 ° orthogonal |

0.25 0.25 0.25 0.375 0.5 0.25 |

2.52 2.52 2.52 2.45 2.38 2.52 |

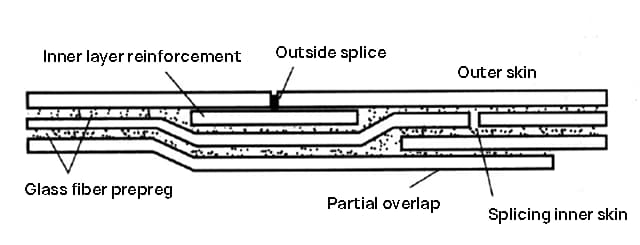

The splicing technology of GLARE laminates addresses the problem of limited plate width. As shown in Figure 2, there is a narrow seam between the same layer of aluminum plates, with joints between different layers located at different positions. These joints can be connected to other layers of aluminum plates through fiber layers, allowing for the manufacture of wall plates or the entire fuselage skin with excellent fatigue resistance, corrosion resistance, and fire resistance, eliminating the need for rivet holes and the resulting stress concentrations.

To ensure the safe transfer of load, a reinforcing layer can be added at the splice, such as a layer of metal plate or a layer of glass fiber pre-impregnated with resin.

Fig. 2 splicing diagram of glare laminate

Honeycomb sandwich composite materials are composed of a sandwich core and skin (panel). The skin can be made of aluminum or carbon/epoxy composite materials, while the sandwich core resembles a honeycomb and is made up of a series of hexagonal, quadrilateral, or other shaped cells made of metal, glass fiber, or composite materials. The upper and lower surfaces of the sandwich are bonded or brazed to the thinner panels.

The core material of aluminum honeycomb sandwich composites is made by gluing aluminum foil in different ways and forming honeycombs of various specifications through stretching. The performance of the core material is primarily determined by the thickness of the aluminum foil and the size of the cells.

These materials have high specific strength and stiffness, good impact resistance, vibration reduction, microwave transmission, and strong designability. Compared to riveted structures, the structural efficiency can be increased by 15% to 30%.

Honeycomb sandwich structures can be used for various wall panels, such as wing surfaces, cabin surfaces, cabin covers, floors, engine covers, muffler plates, heat insulation plates, satellite star shells, paraboloid antennas, rocket propellant storage tank bottoms, and more. However, honeycomb sandwich structures are susceptible to corrosion in certain environments.

When subjected to impact, the honeycomb sandwich will experience permanent deformation and become separated from the skin.

Table 2 shows the percentage of structural materials used in military aircraft in the United States. The trend is that the usage of composite materials and titanium alloys is gradually increasing, while the use of aluminum alloys is decreasing.

Table 2 percentage of structural materials for US military aircraft

| Type | Steel | Alloy | Titanium alloy | Combined material |

| F-16 | 5 | 8 | 2 | 3 |

| F-18A/B | 15 | 50 | 12 | 9.5 |

| F-18C/D | 16 | 50 | 13 | 10 |

| F-18E/F | 14 | 31 | 21 | 23 |

| F-22 | 5 | 16 | 41 | 24 |

| F-35 | – | – | 27 | 36 |

| F117 | 5 | 20 | 25 | 10 |

| B-1 | 9 | 41 | 21 | 29 |

| B2 | 6 | 19 | 26 | 38 |

| C17 | 12.3 | 69.3 | 10.3 | 8.1 |

Table 3 shows the breakdown of materials used in typical mainline aircraft. The B787 has 50% composite materials and the A350 has 52% composite materials. The use of composite materials is becoming a trend in the aerospace industry due to its ability to reduce weight, increase damage resistance, provide corrosion protection, and enhance durability.

However, composite materials also have disadvantages, such as high cost, limited impact resistance, lack of plasticity, increased technical difficulty, poor maintainability, and difficulty in recycling. As a result, the use of composite materials has not increased in the A320neo and B737MAX compared to the A320 and B737.

Table 3 proportion of typical mainline aircraft materials (%)

| Type | Aluminum alloy | Steel | Titanium alloy | Combined material | Other |

| B373 | 79 | 12 | 5 | 3 | 1 |

| B747 | 79 | 13 | 4 | 3 | 1 |

| B757 | 78 | 12 | 6 | 3 | 1 |

| B767 | 80 | 14 | 2 | 3 | 1 |

| B777 | 70 | 11 | 7 | 11 | 1 |

| B787 | 20 | 10 | 15 | 50 | 5 |

| A300 | 76 | 13 | 4 | 5 | 2 |

| A310 | 74 | 8 | 5 | 6 | 7 |

| A320 | 66 | 6 | 5 | 15 | 8 |

| A330/A340 | 66 | 5 | 5 | 16 | 8 |

| A380 | 61 | 5 | 5 | 22 | 7 |

| A350 | 20 | 7 | 14 | 52 | 7 |

| MD-82 | 74.5 | 12 | 6 | 7.5 | – |

| MS-21 | 33 | 5 | 19 | 38 | 5 |

| C919 | 63 | 8 | 8 | 21 | – |

Most of the cabin sections of manned spacecraft are made of aluminum alloys, titanium alloys, and composite materials. For instance, the orbiters of the space shuttle are primarily constructed of aluminum alloys, while the thrust structure supporting the main engine is made of Qin alloy. The main frame of the middle fuselage is composed of a metal matrix composite material reinforced with boron fiber-reinforced aluminum alloy, and the cargo compartment door is made of a special paper honeycomb sandwich structure with graphite fiber-reinforced epoxy resin composite material as the panel.

Ablative materials are used for the outer surface of the missile head, re-entry capsule of the spacecraft, and inner surface of the rocket engine. Under heat flow, these materials can undergo physical and chemical changes, including decomposition, melting, evaporation, sublimation, and erosion. This results in the mass consumption of the material surface, which takes away a large amount of heat, preventing heat flow during re-entry into the atmosphere from entering the aircraft and cooling the combustion chamber and nozzle of the rocket engine.

To maintain the proper temperature in the cabin, radiation heat protection measures are taken for the re-entry section. The outer skin is made of high-temperature-resistant nickel-base alloy or beryllium plate, and the inner structure is composed of heat-resistant alloy. The outer skin and inner structure are filled with materials with good thermal insulation properties, such as quartz fiber and glass fiber composite ceramics.

With the implementation and ongoing advancement of space projects like manned spaceflight, lunar exploration, deep space exploration, high-resolution satellites, high-speed vehicles, reusable vehicles, and space mobile vehicles, new and more demanding requirements are being placed on materials, offering new opportunities and driving the development of new aerospace materials.

Significant breakthroughs have been achieved in the independent assurance of key raw materials and engineering applications in the field of materials.