Have you ever wondered how modern technology can revolutionize traditional welding? This article explores the fascinating world of laser welding, highlighting its benefits, challenges, and applications in industries from aerospace to automotive. Learn how this cutting-edge technology is transforming aluminum alloy welding, offering precision and efficiency like never before.

Laser welding offers significant advantages over traditional welding methods, including minimal heat input, reduced thermal influence, high aspect ratios, and automated process control. These benefits result in improved weld quality, increased productivity, and enhanced precision in metal joining applications.

Aluminum alloys are widely favored in various industries due to their exceptional properties, including low density, high strength-to-weight ratio, excellent corrosion resistance, and superior formability. These characteristics make aluminum alloys ideal for applications in container manufacturing, machinery production, electrical power equipment, chemical industry components, and aerospace structures.

The substitution of steel with aluminum alloys in welded structures can lead to substantial improvements in overall structural performance and weight reduction. However, aluminum presents unique challenges in welding due to its high thermal conductivity, low ionization potential, and tendency to form a tenacious aluminum oxide (Al2O3) layer on its surface. This oxide film can impede fusion and contribute to weld defects such as lack of fusion, porosity, inclusions, and hot cracking, potentially compromising the mechanical integrity of the welded joint.

Compared to conventional arc welding techniques like Gas Tungsten Arc Welding (GTAW) or Gas Metal Arc Welding (GMAW), laser welding offers several distinct advantages. These include narrower weld seams, minimized heat-affected zones, reduced joint overlap requirements, precise control over welding parameters, and enhanced automation capabilities. These features contribute to improved weld quality, reduced distortion, and increased production efficiency.

Currently, laser welding technology finds extensive application in joining thin-walled electronic components, structural parts, and aerospace components. The future trajectory of laser welding research is focused on the development and implementation of high-power fiber lasers, particularly in the 10 kW range, for deep penetration welding of large-scale and thick-section materials. This advancement will expand the capabilities of laser welding to address more challenging applications in heavy industries and large-scale manufacturing.

| Performance/type | Carbon dioxide laser | NdYAG laser | YbYAG Dac laser | Fiber laser |

|---|---|---|---|---|

| Wavelength / um | 10.6 | 1.06 | 1.06 | 1-2 |

| Electric conversion efficiency/% | 12-15 | 2-6 | 20 | 8-10 |

| Power density/(MW/cm-2) | 10 | 10 | 100 | 100 |

| Maximum power/kW) | 50 | 6 | 15 | 50 |

| Beam output | Optical lens | Optical fiber | Optical fiber | Optical fiber |

| Metal absorptivity/% | 8 | 20 | 20 | 20 |

| Maintenance cycle/hr | 1000 | 1000 | 1ooo | 20000 |

| Laser brightness(103W/mm2steradian)(4kW/h) | — | 7.5(focal length:200; Fiber diameter:0.6mm) | 134.2(focal length:200; Fiber diameter:0.2mm) | 264.4 (focal length:160; Fiber diameter:0.1mm) |

CO2 Gas Laser

The CO2 laser utilizes carbon dioxide gas as its active medium, emitting at a wavelength of 10.6 μm. These lasers are categorized into cross-flow and axial-flow types based on their excitation structure. While cross-flow CO2 lasers have achieved impressive output powers up to 150 kW, their beam quality is suboptimal for precision welding applications. In contrast, axial-flow CO2 lasers offer superior beam quality, making them suitable for welding highly reflective materials such as aluminum alloys. The longer wavelength of CO2 lasers, however, can lead to increased heat-affected zones and potential thermal distortion in thin materials.

YAG Solid-State Laser

Solid-state lasers employ crystalline or glass materials as their active medium, with common types including ruby, neodymium glass, and neodymium-doped yttrium aluminum garnet (Nd:YAG). These lasers typically emit at 1.06 μm wavelength. YAG lasers offer several advantages over CO2 lasers for metal welding: higher absorption by metallic surfaces, reduced plasma shielding effects, and compatibility with fiber optic beam delivery. This fiber optic capability enables flexible welding operations and improved accessibility to complex geometries. The shorter wavelength also allows for smaller focal spots, potentially increasing power density and welding speed. These characteristics have made YAG lasers the predominant choice for aluminum alloy structural welding in many industries.

YLR Fiber Laser

Developed post-2002, YLR fiber lasers represent a significant advancement in laser technology. These lasers use optical fibers doped with rare-earth ions as the gain medium, typically emitting at around 1.08 μm. The revolutionary double-clad fiber structure of these lasers dramatically improves pump efficiency and output power compared to traditional fiber lasers. YLR fiber lasers offer numerous advantages over YAG systems, including:

These characteristics make YLR fiber lasers increasingly popular for high-precision welding of aluminum alloys, especially in aerospace and automotive applications where weld quality and process reliability are critical.

Aluminum and aluminum alloys are categorized into seven primary series:

Based on their processing characteristics, aluminum alloys are classified into two main categories: wrought aluminum alloys and cast aluminum alloys. Wrought alloys are further subdivided into non-heat-treatable alloys and heat-treatable alloys.

The weldability of aluminum alloys varies significantly across different series:

Non-heat-treatable alloys (1000, 3000, and 5000 series) generally exhibit good weldability. The 4000 series alloys demonstrate low susceptibility to hot cracking.

However, 5000 series alloys with magnesium content exceeding 2% become prone to cracking. While increased magnesium content enhances weld performance, it adversely affects the alloy’s ductility and corrosion resistance.

Heat-treatable alloys (2000, 6000, and 7000 series) present greater challenges in welding. They are more susceptible to hot cracking, exhibit poor weld bead formation, and experience significant reduction in strength due to the dissolution of hardening precipitates in the heat-affected zone (HAZ).

To achieve high-quality welded joints in aluminum alloys, it is crucial to implement appropriate welding techniques, select suitable welding processes, and use compatible filler materials. Pre-weld surface preparation is essential and typically involves:

To maintain surface cleanliness, welding should be performed within 24 hours of surface preparation. Additionally, it is recommended to conduct welding procedure qualification tests to optimize parameters for specific alloy combinations and joint configurations.

Since the 1990s, significant advancements in laser technology, particularly the development of high-power and high-brightness lasers, have propelled laser welding to new heights of integration, intelligence, flexibility, and versatility. This evolution has sparked increased interest in applying laser welding to aluminum alloy structures across various industries globally.

In the automotive sector, several Chinese manufacturers have already incorporated laser welding technology into their latest models. As the capability to laser weld thick aluminum alloy plates continues to improve, this technology is poised for future implementation in armored vehicle structures, offering potential benefits in terms of strength-to-weight ratio and manufacturing efficiency.

The pursuit of lightweight manufacturing has made laser welding of aluminum alloy sandwich structures a key area of research for shipbuilding and high-speed rail industries. These composite structures offer an optimal balance of strength, weight reduction, and thermal management, critical for enhancing performance and energy efficiency in marine and rail applications.

Aluminum alloys remain crucial in aerospace structures, prompting intensive research into laser welding techniques by technologically advanced nations such as Japan, the United States, the United Kingdom, and Germany. The focus has shifted towards fiber laser welding and laser-arc hybrid welding, particularly for thick plate joining and dissimilar metal welding, as these methods offer superior weld quality, deeper penetration, and reduced heat-affected zones.

The evolution of fiber laser technology has positioned fiber laser welding and laser-arc hybrid welding at the forefront of aluminum alloy joining in advanced aviation manufacturing. These techniques excel in precision, speed, and the ability to weld complex geometries, making them ideal for aerospace applications. A prime example is the American NALI (National Aerospace Leadership Initiative) project, which is conducting cutting-edge research on fiber laser and laser-arc hybrid welding for combustion chamber structures in both commercial aircraft and Joint Strike Fighter (JSF) engines.

This ongoing research and implementation of advanced laser welding techniques for aluminum alloys are driving innovations in structural design, manufacturing processes, and material performance across multiple high-tech industries, paving the way for lighter, stronger, and more efficient products in the automotive, defense, marine, rail, and aerospace sectors.

Laser welding of aluminum alloys offers significant advantages over conventional fusion welding techniques, including highly focused heat input, superior weld depth-to-width ratios, and minimal structural deformation. However, this advanced process also presents unique challenges:

In conclusion, while laser welding offers compelling advantages for aluminum alloy joining, realizing its full potential requires addressing these inherent challenges. The primary focus in advancing this technology lies in developing strategies to mitigate weld defects, enhance joint properties, and improve process stability through precise control of welding parameters, innovative joint designs, and potentially the integration of real-time monitoring and adaptive control systems.

Laser welding utilizes the laser as a high-density light source that offers fast heating and instantaneous solidification, with an aspect ratio as high as 12:1. However, due to the high reflectivity and good thermal conductivity of aluminum alloys, as well as the shielding effect of plasma, defects are likely to occur during the welding process.

The two most significant defects are pores and thermal cracks. The challenge in aluminum alloy laser welding is effectively improving the material’s absorption of laser light due to its strong reflection.

The laser welding process for aluminum alloys is more complex, and it is crucial to improve and refine it due to the characteristics of the aluminum alloy itself.

The higher the material’s absorption rate of the laser, or the lower the heat transfer coefficient and temperature conductivity coefficient, the easier the laser energy is absorbed by the material’s surface, leading to a rapid increase in surface temperature and melting or evaporation of the material.

Table 1 displays the reflectivity of various metals to lasers with different wavelengths.

Table 1 The reflectivity of metals to lasers of different wavelengths at room temperature (%)

| λ/μm | Ag | Al | Cu | Cr | Ni | Steel |

|---|---|---|---|---|---|---|

| 0.7 | 95 | 77 | 82 | 56 | 68 | 58 |

| 1.06 | 97 | 80 | 91 | 58 | 75 | 63 |

| 10.6 | 99 | 98 | 98 | 93 | 95 | 93 |

The reflectivity of different metals decreases as the wavelength becomes shorter, with the reflectivity of Ag, Al, and Cu to laser light being as high as 90% or more. This significantly increases the difficulty of laser processing.

At room temperature, the absorption rate of CO2 lasers by aluminum alloys is very low, with 98% of the laser energy being reflected by the aluminum alloy surface. The reflectivity of Nd:YAG lasers is also up to 80%.

It is clear that aluminum alloys have high reflectivity to laser light and low absorption rate, due to their high density of free electrons. The strong vibration of light electromagnetic waves results in the generation of strong reflected waves and weaker transmitted waves. The reflected waves are not easily absorbed by the aluminum alloy surface, leading to its high reflectivity to lasers at room temperature.

In the laser welding process, when the laser energy density exceeds 3.5 * 106W/cm2, ions will be generated. This method of welding is done through deep penetration welding and is based on the “small hole” effect. The presence of “small holes” significantly increases the material’s absorption rate of the laser and results in a good welding effect by fusing the weldment at high energy density.

The main challenge in laser welding of aluminum alloys is inducing and maintaining the stability of small holes, which is due to both the material properties of aluminum alloys and the optical properties of the laser beam. As previously mentioned, aluminum reflects 80% of energy at room temperature and has good thermal conductivity, requiring a large laser energy density threshold to produce “small holes.”

Once the input power exceeds this value, the transmission of laser energy into the material is no longer limited by heat conduction, and the welding is carried out through deep penetration. The laser radiation causes strong evaporation of the base metal and forms an evaporation groove. The laser beam penetrates the material through this groove, resulting in a sharp increase in both weld depth and efficiency.

For highly reflective materials, such as aluminum alloys and copper alloys, a large power density is required during welding. This places certain requirements on the selection of welding models and collimating and focusing lenses.

Refinement strengthening, solid solution strengthening, and aging precipitation strengthening are three different ways to strengthen aluminum alloys. Despite these mechanisms, the large amount of evaporation of low melting point alloy elements, such as Mg and Zn, during laser welding causes the weld to sink and reduces its hardness and strength.

During the rapid solidification process, the transformation of the fine-grained strengthened structure into an as-cast structure results in a decrease in hardness and strength. Additionally, the presence of cracks and pores in the weld decreases the tensile strength.

In conclusion, joint softening is another challenge in laser welding of aluminum alloys.

There are two primary types of pores in the laser welding process of aluminum alloys: hydrogen gas pores and keyhole collapse pores.

(1) Hydrogen pores: Aluminum alloys form an oxide film on their surface at high temperatures, which easily absorbs moisture in the environment. When heated by a laser, water decomposes into hydrogen, and the solubility of hydrogen in liquid aluminum is about 20 times greater than in solid aluminum. During the rapid solidification of the alloy, the solubility of hydrogen decreases dramatically when it changes from liquid aluminum to a solid state. If the excess hydrogen in the liquid aluminum does not rise and overflow smoothly, it will form hydrogen pores. These pores are generally regular in shape and larger in size than dendrites, and the solidification patterns of dendrites can be seen on the inner surface.

(2) Keyhole collapse: The welding hole is in balance with its own gravity and atmospheric pressure. Once this balance is disrupted, the liquid metal in the molten pool cannot flow over and fill in time, resulting in irregular holes. Studies have found that the magnesium content of the inner wall of the hole is about 4 times that of the vicinity of the weld. Because the cooling rate of laser welding is too fast, the problem of hydrogen gas pores is more severe, and there are more holes caused by the collapse of small holes in laser welding.

Aluminum alloy is a common eutectic alloy that is prone to hot cracks during welding, including weld crystallization cracks and HAZ (Heat Affected Zone) liquefaction cracks. Typically, crystallization cracks appear in the weld zone while liquefaction cracks appear near the joint. Among aluminum alloys, the 6000 series Al-Mg-Si alloys are particularly susceptible to cracking.

The base metal is subjected to rapid heating and cooling, which can lead to the instantaneous solidification and crystallization process. The large degree of undercooling during this process causes the crystal grains to grow perpendicular to the center of the weld, forming low-melting eutectic compounds such as Al-Si or Mg-Si, Al-Mg2Si, and others. This weakens the bonding force of the crystal plane, making it more prone to crystal cracks under thermal stress.

In the aluminum alloy welding process, low-boiling elements such as Mg, Zn, Mn, and Si are easily evaporated and burned. The slower the welding speed, the more severe the burning, which changes the chemical composition of the weld metal. Due to component segregation in the weld zone, eutectic segregation and grain boundary melting occur, leading to liquefaction cracks at the grain boundary under stress, reducing the performance of the welded joint.

To achieve successful laser welding of aluminum alloys and address the previously mentioned issues, several approaches are commonly taken.

One of the most important factors affecting the loss of low melting point elements in aluminum alloys during welding is the pressure of the gas being expelled from the nozzle. To mitigate this issue, the nozzle diameter can be reduced, and the gas pressure and flow rate can be increased. This will reduce the burning loss of elements such as Mg and Zn during the welding process, and also increase penetration.

There are two blowing methods available: direct blowing and sideblowing. Additionally, it is possible to blow both up and down the weldment simultaneously. The choice of blowing method should be determined based on the specific circumstances during welding.

Aluminum alloy has a strong reaction to laser energy. Proper surface preparation of the aluminum alloy, such as anodic oxidation, electrolytic polishing, sandblasting, etc., can greatly improve the energy absorption of the beam on the surface.

Research has shown that removing the oxide film from aluminum alloys increases their tendency to form crystallization cracks. To avoid damaging the surface state of the aluminum alloy while simplifying the laser welding process, the workpiece surface temperature can be increased prior to welding, which will enhance the material’s absorption rate of the laser.

Laser welding is divided into two categories: pulsed lasers and continuous lasers. Pulsed lasers with a wavelength of 1064nm have a highly concentrated beam, and the pulse single point energy is greater than that of continuous lasers. However, the energy of pulsed lasers is generally limited, making them more suitable for welding thin-walled materials.

Pulse mode welding

When performing laser welding, it is important to select the appropriate welding waveform. Common pulse waveforms include square wave, spike wave, and double peak wave. Typically, pulse waves last in the milliseconds range. During a laser pulse, the reflectivity of the metal changes dramatically. Aluminum alloys have a high reflectivity to light, meaning that 60-98% of the laser energy hitting the material surface can be lost due to reflection. This reflectivity changes with the surface temperature.

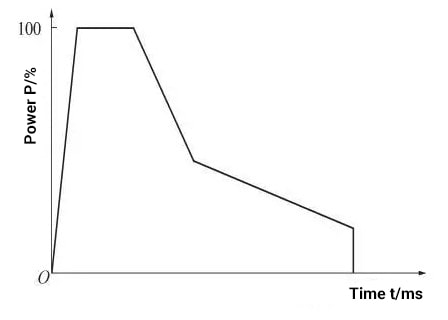

Sharp wave and double peak wave are the best options for welding aluminum alloy, as the rising phase of the waveform provides more energy to melt the aluminum alloy. Once a “small hole” is formed in the workpiece, the absorption rate of the liquid metal to the laser increases rapidly during deep penetration welding. At this point, it is important to quickly reduce the laser energy and perform the welding at a low power to avoid splashing.

The slowing down part of the welding waveform has a longer pulse width, which effectively reduces the formation of pores and cracks. This waveform causes the weld to be melted and solidified repeatedly, reducing the solidification rate of the molten pool. The waveform can be adjusted as needed when welding different types of samples.

Figure 1 Pulse waveform of welding aluminum alloy

Selecting the appropriate amount of defocus can also minimize the formation of pores. The change in defocus has a significant impact on the formation of the weld surface and penetration. Negative defocus can increase penetration, while positive defocus in pulse welding can make the weld surface smoother and more visually appealing.

Due to the high reflectivity of aluminum alloys to laser energy, the welding head is usually angled to prevent the laser beam from being reflected vertically and damaging the laser focusing lens. The diameter of the solder joint and effective bonding surface increase as the laser tilt angle increases. The largest solder joint and effective bonding surface are achieved when the laser tilt angle is 40°. However, the welding point penetration and effective penetration decrease with the increase in laser tilt angle, and when it exceeds 60°, the effective welding penetration decreases to zero. Tilting the welding head to a certain angle can increase the penetration depth and width of the weld.

Additionally, it is important to note that the faster the welding speed, the greater the risk of cracking. This is because a fast welding speed leads to a large degree of undercooling, causing the grains in the weld zone to be refined and a large number of “beam crystals” growing in the same direction, which increases the likelihood of cracks forming on the crystal plane between these beam crystals. If the welding speed is too fast, the penetration depth of the weldment will be relatively shallow.

Continuous mode welding

Traditional laser welding can result in embrittlement or cracks. In contrast, continuous laser welding does not have the same sudden cooling and heating process as pulse laser welding, leading to fewer cracks during the welding process. Additionally, fiber laser welding of most aluminum alloys results in improved toughness after welding and reduces the risk of brittleness.

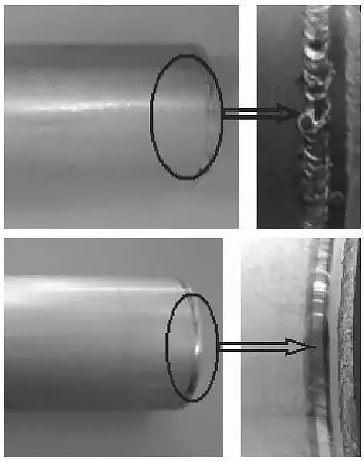

Pulsed laser welding is suitable for welding industrial pure aluminum, with little risk of cracks after welding. However, some industries may require post-welding surface polishing, and pulsed laser welding can cause dents and increase the amount of polishing required, leading to increased processing time and production costs. Continuous lasers can address these problems.

As shown in Figure 2, the comparison of the battery shell welding seam after pulse laser welding and continuous laser welding demonstrates the advantages of continuous laser welding. The impulse solder joints are uneven and have undercut and dented surfaces, with many spatters, and a lower post-weld strength. In contrast, continuous laser welding results in a smooth and uniform weld seam surface, free of defects and spatter, with no cracks found in the weld seam.

Figure 2 Pulse and continuous welding of Al-Mn alloy

Arc craters are a common occurrence during argon arc welding, and the same can occur during laser welding. To minimize the appearance of small craters, a slow rise and slow fall stage can be set in the waveform during welding, and the welding speed can be increased as needed.

Continuous laser welding has numerous advantages when welding aluminum alloys. Compared to traditional welding methods, continuous laser welding is more efficient and eliminates the need for wire filling. In comparison to pulse laser welding, continuous laser welding eliminates defects such as cracks, pores, and spatter, and ensures that the aluminum alloy has good mechanical properties after welding. Additionally, there will be no dents after welding and the amount of polishing and grinding required is reduced, saving on production costs.

However, it is important to note that continuous lasers have a relatively small spot size, so the workpiece assembly accuracy must be high.

Preventing thermal cracks is a critical technology for laser welding of aluminum alloys, especially for the 6000 series alloys which are highly sensitive to cracks. If the content of ω(Mg2Si) reaches 1%, hot cracks are likely to occur. To reduce the risk of cracks, suitable alloying elements can be added to adjust the chemical composition of the molten pool, such as adding Al-Si or Al-Mg-Si powder.

In addition, wire feeding can improve the welding effect and produce a uniform weld seam with improved hardness. The introduction of filler material increases the content of Mg and Si in the dendrite in the fusion zone, leading to an increase in the strength of the joint due to the β” solid solution strengthening effect.

Typically, 6063 and 6082 aluminum alloys are filled with Al-5Si and Al-7Si welding wires, while 6013 and 6056 plates are welded with CO2 and Nd: YAG lasers, respectively, and filled with Al-12Si welding wires.

Aiming for stability and quality in aluminum alloy laser welding.

The current research focus in aluminum alloy laser welding is the use of a composite process that combines the high energy density of laser beams with the wider heating range of arcs, utilizing the strengths of both heat sources and enhancing their characteristics of high energy density and stable arcs.

For materials with high reflectivity such as aluminum alloy, hybrid laser welding can preheat or melt the material surface using arc energy, significantly improving the absorption of laser energy by the aluminum alloy.

Shida et al. successfully used a 10 kW CO2 laser in conjunction with TIG and MIG arcs to weld aluminum alloys. The introduction of arcs improved the laser energy utilization rate and increased the weld penetration ratio by 5-20%. The result was a smooth, well-formed weld surface.

Laser hybrid welding enlarges the molten pool size and modifies the material flow conditions in the molten state through the coupling of laser beams and arcs, which is beneficial in eliminating pores.

Elimination of air holes in aluminum alloy welding can also be achieved through dual-beam welding. A 6 kW continuous fiber laser was used for dual-beam butt welding of 5052 aluminum alloy, and the effects of two-beam parallel and serial welding modes and different welding speeds on seam morphology and structure were studied. The research found that parallel dual-beam welding resulted in large holes in the welds, while serial welding of aluminum alloys produced good weld formation without pores.

Under the influence of high-power lasers, the main defects in laser deep penetration welding of aluminum alloys are porosity, surface collapse, and undercut. Surface collapse and undercut defects can be improved through laser wire filling welding or laser arc hybrid welding. However, controlling porosity defects is challenging.

Research has shown that there are two types of characteristic pores in laser deep penetration welding of aluminum alloys. One type is metallurgical pores, caused by material contamination or air intrusion during the welding process, similar to arc fusion welding. The other type is process porosity, which is caused by the unstable fluctuation of small holes inherent in the laser deep penetration welding process.

During laser deep penetration welding, the small hole often lags behind the beam movement due to the viscosity of the liquid metal, and its diameter and depth fluctuate under the influence of plasma/metal vapor. As the beam moves and the molten pool metal flows, incomplete deep penetration welding is closed due to the flow of the molten pool metal, causing bubbles to appear at the tip of the small hole. In full penetration deep penetration welding, bubbles appear in the waist of the small hole in the middle.

These bubbles migrate and roll with the flow of liquid metal, escape from the molten pool surface, or are pushed back into the small hole. When the bubbles are solidified by the molten pool and captured by the metal front, they become weld pores.

Metallurgical pores can be controlled through pre-welding surface treatment and proper gas protection during the welding process. The key to controlling process pores is to ensure stability during the laser deep penetration welding process.

According to research on domestic laser welding technology, controlling air holes in aluminum alloy laser deep penetration welding requires consideration of all links, including before welding, the welding process, and post-welding treatment. This can be achieved through the following new processes and technologies.

Pre welding treatment method

Pre-welding surface treatment is an effective method for controlling metallurgical pores in aluminum alloy laser welding. Common surface treatment methods include physical mechanical cleaning and chemical cleaning. Recently, laser impact cleaning has also emerged, which further enhances the automation of laser welding.

Parameter stability optimization control

The process parameters of aluminum alloy laser welding typically include laser power, defocus, welding speed, and the composition and flow of gas protection. These parameters not only impact the protective effect of the welding area, but also affect the stability of the laser deep penetration welding process, which in turn affects weld porosity.

Through laser deep penetration welding of aluminum alloy sheets, it has been found that the stability of small hole penetration influences the stability of the molten pool, which then impacts weld formation and results in porosity defects. Additionally, the stability of laser deep penetration welding is related to the matching of laser power density and linear energy.

Therefore, determining reasonable process parameters for stable weld formation is an effective method for controlling the porosity of aluminum alloy laser welding. Research results on full penetration stable weld forming characteristics have shown that the ratio of weld back width to weld surface width (weld back width ratio) can be used to evaluate the weld formation and stability of aluminum alloy sheets.

By appropriately matching the laser power density and line energy during thin plate laser welding, a certain weld back width ratio can be ensured, effectively controlling weld porosity.

Double spot laser welding

Double spot laser welding refers to a welding process where two focused laser beams simultaneously act on the same weld pool. In laser deep penetration welding, one of the major causes of weld porosity is the closing of gas in the small hole in the weld pool.

By using double spot laser welding, the opening of the small hole is increased due to the influence of two light sources, making it easier for internal metal vapor to escape and improving the stability of the small hole, thereby reducing weld porosity.

Studies on laser welding of A356, AA5083, 2024, and 5A90 aluminum alloys have shown that double spot laser welding can significantly reduce weld porosity.

Laser arc hybrid welding

Laser arc hybrid welding is a welding method in which both laser and arc influence the same molten pool. Usually, the laser is the primary heat source, and the interaction between laser and arc enhances the penetration and welding speed of laser welding while reducing welding assembly accuracy.

The use of filler wire helps control the microstructure and properties of the welded joints, and the auxiliary effect of arc improves the stability of laser welding holes, contributing to reducing weld porosity.

In the process of laser arc hybrid welding, the arc affects the metal vapor/plasma cloud generated by the laser process, promoting the absorption of laser energy and stability of small holes.

Studies on laser arc hybrid welding of aluminum alloys have confirmed its effectiveness in reducing weld porosity.

Fiber laser welding

The keyhole effect in laser deep penetration welding occurs due to the strong vaporization of metal under the influence of laser. The force of metal vaporization is tightly connected to laser power density and beam quality, affecting both the penetration of laser welding and the stability of keyholes.

Seiji et al. studied SUS304 stainless steel high power fiber laser and showed that:

During high-speed welding, the molten pool elongates, spatter is controlled, small hole fluctuations are stable, and there are no bubbles at the tip of the small hole. When a fiber laser is used for high-speed welding of titanium alloys and aluminum alloys, a weld without pores can also be produced.

Research on shielding gas control technology for titanium alloy fiber laser welding by Allen et al. shows that:

By controlling the position of the welding shielding gas, it is possible to prevent gas involvement, decrease the small hole closing time, stabilize the welding small hole, and alter the solidification behavior of the molten pool, thereby reducing weld porosity.

Pulsed laser welding

Compared to continuous laser welding, the pulse mode of laser output can enhance the periodic and steady flow of the molten pool, which helps in the release of bubbles and reduces weld porosity.

T.Y. Kuo and S.L. Jeng investigated the impact of the YAG laser welding power output mode on the porosity and characteristics of welds made from SUS 304L stainless steel and Inconel 690 superalloy.

The results indicate that for square wave pulse laser welding, as the base power increases to 1700W, the weld porosity decreases with the increase in pulse amplitude ΔP. Specifically, the porosity of the stainless steel decreases from 2.1% to 0.5%, and that of the superalloy decreases from 7.1% to 0.5%.

Post weld composite treatment technology

In practical engineering applications, despite strict surface treatment before welding and a stable welding process, porosity is still a common issue in aluminum alloy laser welding.

Therefore, post-weld treatment methods to eliminate porosity are crucial.

Currently, the main method used is modified welding.

One such method to eliminate internal and shrinkage porosity in aluminum alloy castings is hot isostatic pressing technology.

By combining this with stress heat treatment after aluminum alloy laser welding, a composite process of hot isostatic pressing and heat treatment of aluminum alloy laser welding components is formed. This not only eliminates weld porosity, but also enhances the performance of the joint.

The application of high-power laser welding in aluminum alloys still poses many challenges due to its unique characteristics.

One of the main challenges is controlling weld porosity defects and improving welding quality.

To improve the stability of the welding process and control porosity in aluminum alloy laser welding, a comprehensive approach that considers all aspects, from pre-welding to welding process and post-welding treatment, is essential.

To address this challenge, several new technologies and processes have been developed, including laser cleaning before welding, optimization of welding process parameters through back width ratio control, double beam laser welding, laser-arc hybrid welding, pulse laser welding, and optical fiber laser welding.