What makes aluminum alloys essential in engineering? Their thermal conductivity and expansion rates play a critical role in various applications, from electronics to aerospace. This article explores the specific properties of different aluminum alloys, providing key insights into how they respond to heat. By understanding these characteristics, engineers can make informed decisions for their projects, ensuring optimal performance and durability.

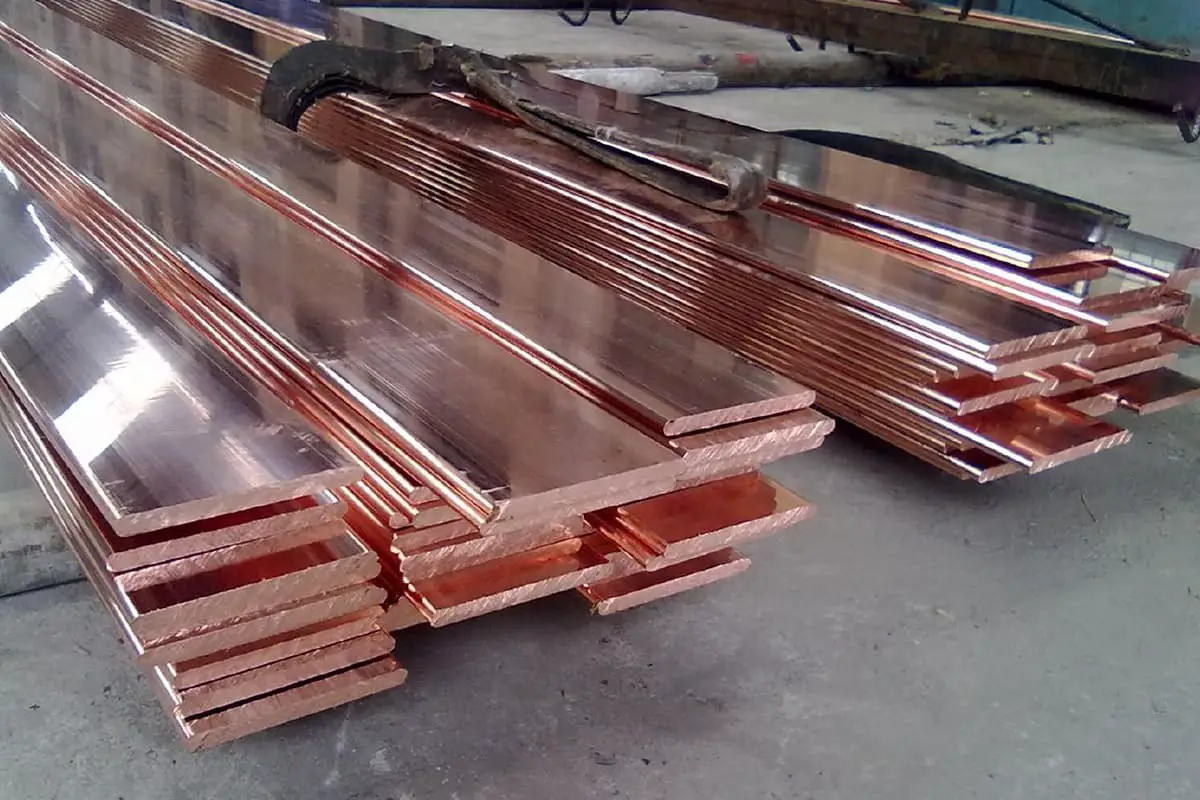

Aluminum alloys are renowned for their excellent thermal conductivity, making them ideal for applications requiring efficient heat transfer. The thermal conductivity of aluminum alloys typically ranges from 120 to 235 W/m·K, depending on the specific alloy composition. For comparison, pure aluminum has a thermal conductivity of about 235 W/m·K at room temperature.

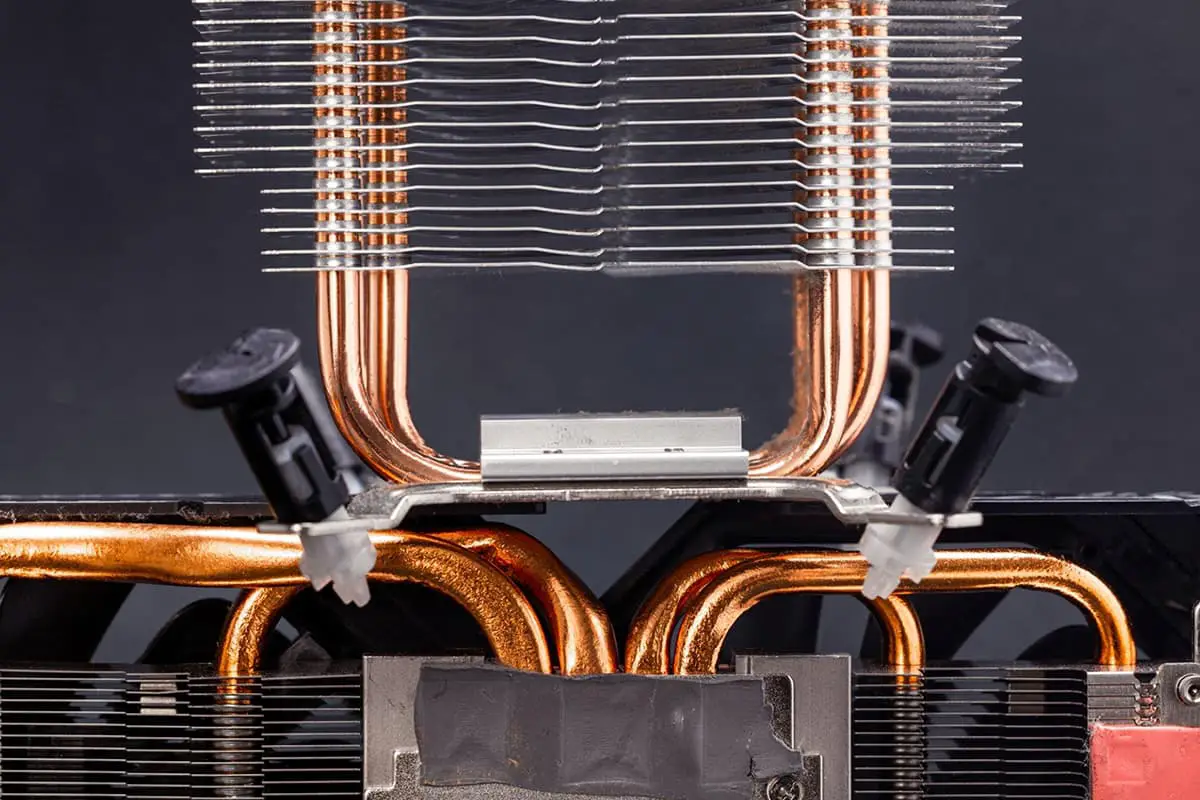

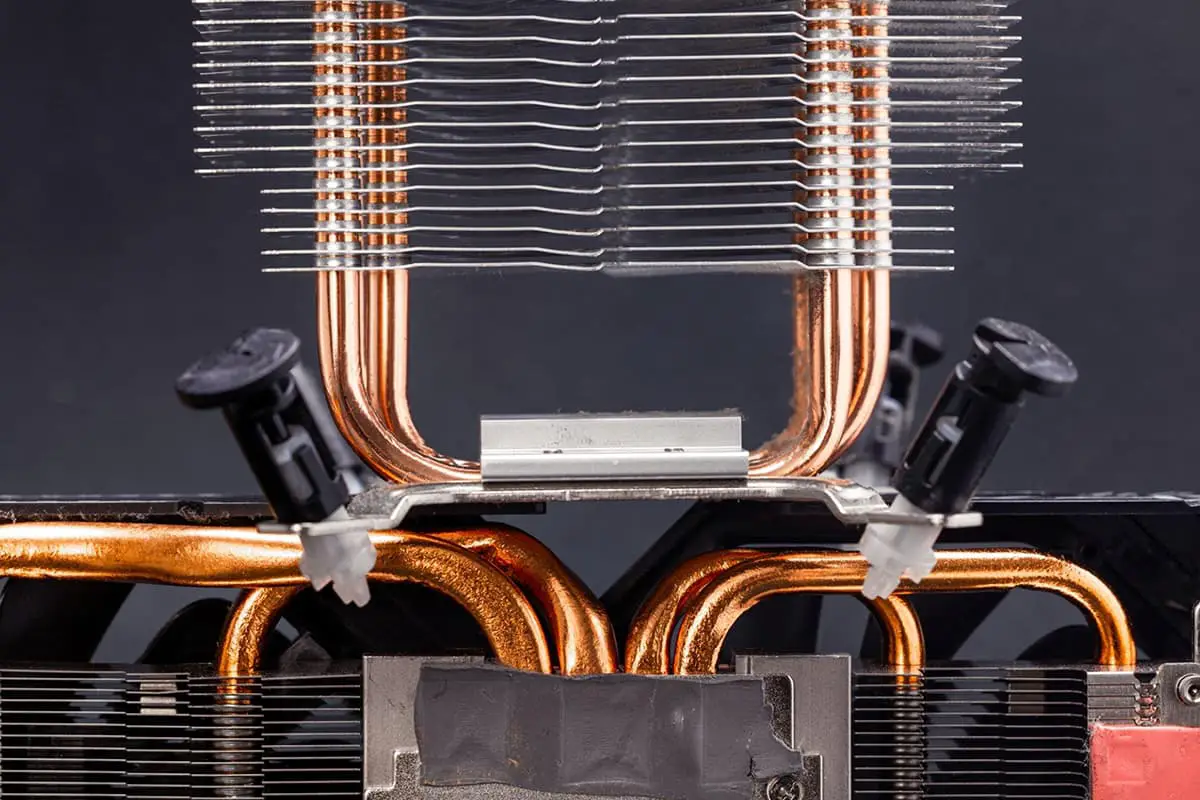

This high thermal conductivity allows aluminum alloys to rapidly dissipate heat, making them suitable for heat sinks, radiators, and other thermal management components in various industries, including automotive, aerospace, and electronics.

However, the high thermal conductivity of aluminum alloys is accompanied by a relatively high coefficient of thermal expansion (CTE). The CTE for most aluminum alloys ranges from 20 to 25 μm/m·K (microns per meter per degree Kelvin). This means that for every 1°C increase in temperature, an aluminum component will expand by approximately 20-25 microns per meter of length.

The thermal expansion characteristics of aluminum alloys are crucial considerations in design and engineering, particularly in applications where dimensional stability is critical or where aluminum components interface with materials having different expansion rates. Engineers must account for this expansion to prevent stress, warping, or failure in assemblies, especially in environments with significant temperature fluctuations.

Some key points to consider regarding aluminum alloy thermal properties:

| Grade | Heat Treatment Method | Coefficient of Thermal Expansion | Thermal Conductivity |

| 1060 | O | 23.6 | 234 |

| H18 | 230 | ||

| 1100 | O | 23.6 | 222 |

| H18 | 218 | ||

| 1350 | All | 23.75 | 234 |

| 2011 | T3 | 22.9 | 151 |

| T8 | 172 | ||

| 2014 | O | 23 | 193 |

| T4 | 134 | ||

| T6 | 154 | ||

| 2017 | OH | 23.6 | 193 |

| T4 | 134 | ||

| 2018 | T61 | 22.3 | 154 |

| 2024 | O | 23.2 | 193 |

| T3,T4,T361 | 121 | ||

| T6,T81,T861 | 151 | ||

| 2025 | T6 | 22.7 | 154 |

| 2036 | T4 | 23.4 | 159 |

| 2117 | T4 | 23.75 | 154 |

| 2124 | T851 | 22.9 | 152 |

| 2218 | T72 | 22.3 | 154 |

| 2219 | O | 22.3 | 172 |

| T31,T37 | 112 | ||

| T6,T81,T87 | 121 | ||

| 2618 | T6 | 22.3 | 147 |

| 3003 | O | 23.2 | 193 |

| H12 | 163 | ||

| H14 | 159 | ||

| H18 | 154 | ||

| 3004 | All | 23.9 | 163 |

| 3105 | All | 23.6 | 172 |

| 4032 | O | 19.4 | 154 |

| T6 | 138 | ||

| 4043 | O | 22.1 | 163 |

| 4045 | All | 21.05 | 172 |

| 4343 | All | 21.6 | 180 |

| 5050 | All | 23.75 | 200 |

| 5005 | All | 23.75 | 193 |

| 5052 | All | 23.75 | 138 |

| 5056 | O | 24.1 | 117 |

| H38 | 108 | ||

| 5083 | O | 23.75 | 117 |

| 5086 | All | 23.75 | 125 |

| 5154 | All | 23.9 | 125 |

| 5252 | All | 23.75 | 138 |

| 5254 | All | 23.9 | 125 |

| 5356 | O | 24.1 | 117 |

| 5454 | O | 23.6 | 134 |

| H38 | 134 | ||

| 5456 | O | 23.9 | 117 |

| 5457 | All | 23.75 | 176 |

| 5652 | All | 23.75 | 138 |

| 5657 | All | 23.75 | 205 |

| 6005 | T1 | 23.4 | 180 |

| T5 | 190 | ||

| 6053 | O | 23 | 172 |

| T4 | 154 | ||

| T6 | 163 | ||

| 6061 | O | 23.6 | 180 |

| T4 | 154 | ||

| T6 | 167 | ||

| 6063 | O | 23.4 | 218 |

| T1 | 193 | ||

| T5 | 209 | ||

| T6,T83 | 200 | ||

| 6066 | O | 23.2 | 154 |

| T6 | 147 | ||

| 6070 | T6 | – | 172 |

| 6101 | T6 | 23.4 | 218 |

| T61 | 222 | ||

| T63 | 218 | ||

| T64 | 226 | ||

| T65 | 218 | ||

| 6105 | T1 | 23.4 | 176 |

| T5 | 193 | ||

| 6151 | O | 23.2 | 205 |

| T4 | 163 | ||

| T6 | 172 | ||

| 6201 | T81 | 23.4 | 205 |

| 6253 | – | – | |

| 6262 | T9 | 23.4 | 172 |

| 6351 | T6 | 23.4 | 176 |

| 6463 | T1 | 23.4 | 193 |

| T5 | 209 | ||

| T6 | 200 | ||

| 6951 | O | 23.4 | 213 |

| T6 | 198 | ||

| 7049 | T73 | 23.4 | 154 |

| 7050 | T74 | 24.1 | 157 |

| 7072 | O | 23.6 | 222 |

| 7075 | T6 | 23.6 | 130 |

| 7175 | T74 | 23.4 | 156 |

| 7178 | T6 | 23.4 | 125 |

| 7475 | T61,T651 | 23.2 | 138 |

| T76,T761 | 147 | ||

| T7351 | 163 | ||

| 8017 | H12,H22 | 23.6 | – |

| H212 | – | ||

| 8030 | H221 | 23.6 | 230 |

| 8176 | H24 | 23.6 | 230 |