Ever wondered how lightweight metals power our modern world? This article dives into aluminum, exploring its unique properties and diverse applications. From aircraft to space rockets, discover how choosing the right cutting tools can make or break your aluminum projects. Get ready to enhance your knowledge and skills in handling this versatile material!

Aluminum, with a density of 2.7 g/cm³ (approximately one-third that of steel or copper), offers an excellent combination of properties. It boasts high ductility and an electrical conductivity about 61% that of copper, while weighing only one-third as much and typically being more cost-effective.

These characteristics make aluminum ideal for numerous electrical applications, including high-voltage transmission lines, cables, and components in the electronics and telecommunications industries.

While pure aluminum has relatively low strength, aluminum alloys demonstrate significantly enhanced mechanical properties, including improved strength-to-weight ratios and hardness. This versatility has led to their widespread adoption across various sectors.

In the transportation industry, aluminum alloys are extensively utilized in aircraft fuselages and structures, automotive body panels and chassis components, high-speed train carriages, and marine vessel superstructures. Their combination of light weight and high strength contributes to improved fuel efficiency and performance.

Furthermore, the aerospace sector heavily relies on advanced aluminum alloys for critical components in space rockets, spacecraft, and satellites. These alloys offer the necessary strength and thermal stability to withstand the extreme conditions of space, while their low density helps minimize launch costs.

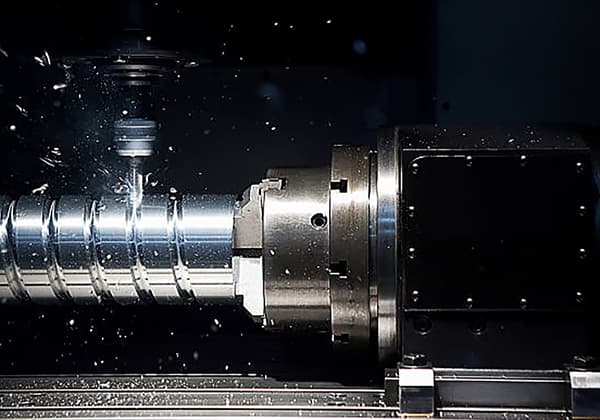

Selecting the appropriate cutting tools for aluminum is crucial for achieving high precision and superior quality in machining operations, while meeting the diverse cutting requirements of various aluminum alloy grades. The right tool choice not only ensures optimal performance but also significantly impacts the overall efficiency and cost-effectiveness of the manufacturing process.

Professional-grade cutting tools, when properly selected, enable precise material removal according to specific project needs, minimizing waste and preventing potential material losses or quality issues. This precision is particularly important when working with high-value aluminum alloys or components with tight tolerances.

Opting for cutting tools from reputable manufacturers guarantees consistent and efficient performance throughout the machining process. These tools are engineered to deliver reliable functionality and maintain stability under various cutting conditions, significantly reducing the risk of unexpected failures or safety hazards. The user-friendly design of professional-grade tools also simplifies operation, allowing for a more streamlined and worry-free production process.

Moreover, high-quality cutting tools are designed to withstand the unique challenges posed by aluminum machining, such as built-up edge formation and heat generation. They often feature specialized coatings or geometries that enhance chip evacuation, reduce friction, and extend tool life – critical factors when working with aluminum’s tendency to stick to cutting edges.

By investing in the right cutting tools, manufacturers can ensure consistent performance across a wide range of working environments and application demands. This versatility is essential for shops that handle diverse aluminum projects, from aerospace components to automotive parts.

In the following sections, we will provide comprehensive guidance to help you select the most suitable cutting tools for your specific aluminum machining projects, considering factors such as alloy properties, cutting parameters, and production requirements.

Aluminum stands out for its exceptional lightweight nature and superior corrosion resistance. This versatile metal possesses several distinctive characteristics that make it invaluable in various industrial applications:

1. Hacksaws

A hacksaw is a cutting tool consisting of a frame and a blade, commonly used in woodworking on construction sites.

2. Aviation snips

Aviation snips are made from tough alloy steel and are suitable for cutting thin sheet metal, aluminum, plastic, and other materials. They come in left-cutting, right-cutting, and straight-cutting varieties. The quality of the snips affects the type of blades they have.

3. Nibblers

Nibblers are mechanical tools commonly used in model making to cut plastic or metal at connection points, saving time and effort compared to hand twisting.

They have a scissor-like shape with smaller, thicker heads than regular scissors, similar to the back half of pliers. Some nibblers are designed for cutting wires, while others have a wire stripping function.

1. Circular saws

A circular saw is a toothed tool used for cutting steel. Metal circular saws can easily cut through steel, just like cutting through 2×4’s with a traditional pipe.

Compared to earlier products, circular saws use unique materials and tooth designs that allow for faster metal cutting, better chip handling, and no heat transfer during the cutting process.

2. Jigsaws

Jigsaws are sawing machines in which the blade is mounted on a sliding guide (or roller) that moves along the track. The sawing process is achieved through a feeding mechanism.

3. Band saws

Band saws are machine tools used for cutting various metal materials. They are classified into horizontal and vertical types according to their structure, and semi-automatic, fully automatic, and CNC types according to their function.

Horizontal band saws can be further divided into double-column and scissors types.

4. CNC routers

CNC routers can perform relief carving, flat carving, hollow carving, and other tasks on aluminum alloys, copper, electric wood, wood, jade, glass, plastic, acrylic, and other materials. They have high carving speed and precision.

1. High-speed steel (HSS)

High-speed steel is a type of high-alloy tool steel with added alloy elements such as tungsten, molybdenum, chromium, vanadium, etc. It has high strength and toughness, as well as certain hardness and wear resistance, making it suitable for various cutting tool requirements.

The manufacturing process of HSS tools is simple, and they can be easily sharpened to a sharp cutting edge.

Therefore, despite the emergence of various new types of tool materials, HSS tools still account for a large proportion in metal cutting. They are suitable for machining non-ferrous metals and high-temperature alloys.

Because of its above-mentioned properties, milling cutters for casting risers, milling cross-grooves, and milling expansion grooves in piston machining use HSS material, while drill bits are made of HSS.

2. Carbide

Carbide is made by powder metallurgy from hard-to-melt metal carbides (such as WC, TiC, TaC, NbC, etc.) and metal binders (such as Co, Ni, etc.).

Since carbides have high melting points, high hardness, good chemical stability, and thermal stability, the hardness, wear resistance, and heat resistance of carbide materials are very high.

The commonly used hardness of carbide is 89~93HRA, higher than that of HSS (83~86.6HRA). At 800~1000℃, it can still perform cutting. At 540℃, the hardness of carbide is 82~87HRA, and at 760℃, the hardness can still be maintained at 77~85HRA.

Therefore, the cutting performance of carbide is much better than that of HSS, and the durability of the tool can be improved several times to tens of times. When the durability is the same, the cutting speed can be increased 4~10 times.

Currently, our company mainly uses YG6 and YGX in the WC-TiC-Co class of carbide tools. YT15 and other carbides in the WC-TiC-Co class are used for rough machining, semi-finishing, and some finishing processes in piston machining.

3. Polycrystalline diamond (PCD)

Diamond is currently the hardest mineral material known, with the best thermal conductivity. Its wear when paired with various metals and non-metal materials under friction is only 1/50 to 1/800 of that of carbide, making it the ideal material for making cutting tools.

However, natural single-crystal diamonds are only used for ultra-precision machining of jewelry and certain non-ferrous metals.

Although industrial production of artificial large-particle single-crystal diamonds has been achieved by companies such as De Beers and Sumitomo Electric, they have not yet entered a stage of extensive application.

The cutting edge of a diamond tool is extremely sharp (which is important for cutting very small cross-sectional chips), and the roughness of the blade is small, with a low friction coefficient. The cutting process does not easily produce chip lumps, resulting in high surface quality during machining.

When machining non-ferrous metals, the surface roughness can reach Ra0.012µm, and the machining accuracy can reach IT5 or higher.

There are three types of diamond tools: natural single-crystal diamond tools, integral artificial polycrystalline diamond tools, and diamond composite tools.

Due to their high cost, natural diamond tools are less commonly used in actual production. Artificial diamonds are formed by the transformation of graphite under high temperature and pressure through the action of alloy catalysts.

Diamond composite blades are formed by sintering a layer of diamond approximately 0.5~1µm thick onto a cemented carbide substrate using advanced processes such as high temperature and high pressure.

This material uses cemented carbide as the substrate, and its mechanical properties, thermal conductivity, and expansion coefficient are similar to those of cemented carbide.

The diamond crystals in the artificial polycrystalline diamond abrasive on the substrate are arranged irregularly, and their hardness and wear resistance are uniform in all directions.

Polycrystalline diamond (PCD) is formed by sintering screened artificial diamond microcrystals under high temperature and pressure. During the sintering process, the addition of additives allows the formation of binding bridges between diamond crystals, mainly composed of TiC, SiC, Fe, Co, and Ni.

The diamond crystals are tightly embedded in a strong skeleton formed by the structure bridge, which is held together by covalent bonds, greatly improving the strength and toughness of the PCD.

Its hardness is about 9000HV, bending strength is 0.21~0.48GPa, thermal conductivity is 20.9J/cm·sµ℃, and coefficient of thermal expansion is 3.1×10-6/℃.

Most of the PCD cutting tools used now are composites of PCD and cemented carbide substrates, with a layer of PCD sintered onto the cemented carbide substrate.

The thickness of PCD is generally 0.5mm and 0.8mm, and due to the conductivity of the PCD binding bridge, it is easy to cut into various shapes and make various tools, and the cost is much lower than that of natural diamonds.

Polycrystalline diamond (PCD) can machine various non-ferrous metals and extremely wear-resistant high-performance non-metal materials, such as aluminum, copper, magnesium and their alloys, carbide, fiber-reinforced plastics, metal-based composite materials, wood-based composite materials, etc.

The average size of diamond particles in PCD tool material is different, which affects its performance differently.

The larger the particle size, the higher its wear resistance. Under similar cutting edge processing amounts, the smaller the particle size, the better the quality of the cutting edge.

PCD tools with particle sizes of 10~25µm can be used for high-speed cutting of silicon-aluminum alloys with Si content of 12~18 at speeds of 500~1500m/min, while PCDs with particle sizes of 8~9µm are used to process aluminum alloys with Si content less than 12%.

For ultra-precision machining, PCD tools with smaller particle sizes should be selected. The wear resistance of PCD weakens at temperatures above 700℃ because its structure contains metal Co, which promotes the “reverse reaction” of diamond transforming into graphite.

PCD has good fracture toughness and can perform intermittent cutting. It can end mill aluminum alloy with Si content of 10% at a high speed of 2500m/min.

The high hardness, wear resistance, thermal conductivity, and low friction coefficient of diamond materials can achieve high precision, high efficiency, high stability, and high surface smoothness in processing non-ferrous metals and wear-resistant non-metal materials.

When cutting non-ferrous metals, the life of PCD cutting tools is dozens or even hundreds of times that of cemented carb

4. Cubic boron nitride (CBN)

Cubic boron nitride (CBN) is a new type of artificial synthetic material developed in the 1950s. It has high hardness and good wear resistance, and is widely used in the machining industry.

Polycrystalline cubic boron nitride (PCBN) is made by sintering CBN micro-powder with a small amount of binder phase (Co, Ni or TiC, TiN, Al203) and a catalyst at high temperature and pressure.

It has high hardness (second only to diamond) and heat resistance (1300~1500℃), excellent chemical stability, much higher thermal stability (up to 1400℃) and thermal conductivity than diamond tools, low friction coefficient, but lower strength.

Compared with diamond, PCBN’s outstanding advantages are much higher thermal stability, up to 1200℃ (diamond is 700~800℃), and can withstand higher cutting speeds; another outstanding advantage is its great chemical inertness, which does not react with ferrous metals at 1200~1300℃ and can be used for processing steel.

Therefore, PCBN tools are mainly used for efficient processing of black difficult-to-machine materials.

In addition to the above characteristics, PCBN tools also have the following advantages:

(1) high hardness, especially suitable for machining quenched and hardened steel with an HRC of 50 or more, heat-resistant alloys with an HRC of 35 or more, and gray cast iron with an HRC of 30 or less that are difficult to machine with other tools;

(2) compared with cemented carbide tools, they have high cutting speed and can achieve high-speed and efficient cutting;

(3) good wear resistance, high durability of the tool (10-100 times that of cemented carbide tools), and able to obtain better surface quality of the workpiece, achieving grinding by turning.

The disadvantage of PCBN tools is that their impact resistance is worse than that of cemented carbide tools, so when using them, attention should be paid to improving the rigidity of the process system and avoiding impact cutting.

PCBN can be made into integral blades or composite blades combined with cemented carbide. PCBN composite blades have a layer of 0.5~1.0mm thick PCBN sintered on a cemented carbide substrate, which has both good toughness and high hardness and wear resistance.

The performance of PCBN mainly depends on the particle size of CBN, the content of CBN, and the type of binder.

According to its structure, it can be roughly divided into two categories: one is directly bonded by CBN crystals, with high CBN content (above 70%), high hardness, and suitable for cutting processing of heat-resistant alloys, cast iron, and iron-sintered metals;

The other is based on CBN crystals, sintered by ceramic binders (mainly TiN, TiC, TiCN, AlN, Al203, etc.), with low CBN content (below 70%), low hardness, and suitable for cutting machining of quenched and hardened steel.

Cubic boron nitride tools are used in the turning of cast iron ring grooves inlaid with piston rings, as well as in the machining of piston solid contact molds.

5. Ceramic

The main advantages of ceramic cutting tools are: high hardness and wear resistance, with a room temperature hardness of 91-95HRC; high heat resistance, with a hardness of 80HRC at a high temperature of 1200℃; and minimal reduction in flexural strength and toughness under high temperature conditions.

They also exhibit high chemical stability as ceramics have low affinity with metals, good high-temperature oxidation resistance, and do not interact with steel even at melting temperatures.

Therefore, there is less bonding, diffusion, oxidation, and wear on the cutting tool. They have a lower coefficient of friction, making it difficult for chips to stick to the tool and form chip nests.

The disadvantages of ceramic knives are their brittleness, low strength, and toughness, with only 1/2 to 1/5 of the flexural strength of hard alloys.

Therefore, appropriate geometric parameters and cutting amounts must be selected when using them to avoid impact loads that could cause blade chipping or breakage.

Additionally, ceramic knives have low thermal conductivity, only 1/2 to 1/5 that of hard alloys, with thermal expansion coefficients 10-30% higher than hard alloys, resulting in poor heat shock resistance.

Currently, ceramic cutting tools have not been applied to the aluminum piston processing.

1. High Hardness and Wear Resistance

Hardness is a fundamental characteristic that cutting tool materials should possess. To cut chips from a workpiece, the tool’s hardness must be greater than that of the workpiece material. The cutting edge hardness of tools used to cut metals is generally above 60HRC. Wear resistance refers to a material’s ability to resist wear.

Generally, the higher the hardness of the cutting tool material, the better its wear resistance. Hardness points in the structure (such as carbides and nitrides) with higher hardness, more quantity, smaller particles, and more uniform distribution have better wear resistance.

Wear resistance is also related to the material’s chemical composition, strength, microstructure, and the temperature of the frictional area. Wear resistance WR can be expressed by the formula:

WR = KIC0.5E-0.8H1.43

Where H is the material’s hardness (GPa). The higher the hardness, the better the wear resistance.

KIC is the material’s fracture toughness (MPa·m½). The larger the KIC value, the smaller the material’s fracture caused by stress and the better the wear resistance.

E is the elastic modulus of the material (GPa). When E is small, it helps produce lower stresses caused by micro-strains due to abrasive grains, leading to improved wear resistance.

2. Adequate Strength and Toughness

To prevent blade chipping or breakage during use when subjected to large pressures, impacts, and vibrations during the cutting process, cutting tool materials must have sufficient strength and toughness.

3. High Heat Resistance (Thermal Stability)

Heat resistance is the primary indicator for measuring the cutting performance of cutting tool materials. It refers to a cutting tool material’s ability to maintain a certain level of hardness, wear resistance, strength, and toughness under high-temperature conditions.

Cutting tool materials should also have the ability to resist oxidation, bonding, and diffusion at high temperatures, meaning they should exhibit good chemical stability.

4. Good Thermophysical Properties and Heat Shock Resistance

The better the thermal conductivity of the cutting tool material, the easier it is for cutting heat to diffuse away from the cutting area, which helps reduce cutting temperature.

During intermittent cutting or when using a cutting fluid, the tool often undergoes severe heat shock (rapid temperature changes), resulting in cracks inside the tool that can cause breakage.

The material’s ability to withstand heat shock can be expressed by its heat shock resistance coefficient R:

R = λσb(1-µ)/Eα

Where λ is the thermal conductivity coefficient, σb is the tensile strength, µ is Poisson’s ratio, E is the elastic modulus, and α is the coefficient of thermal expansion.

A higher thermal conductivity coefficient makes it easier for heat to dissipate, reducing the temperature gradient on the tool surface.

A lower coefficient of thermal expansion reduces thermal deformation, and a smaller elastic modulus can lower the magnitude of alternating stresses resulting from thermal deformation, thereby helping improve the material’s heat shock resistance.

Cutting tool materials with good heat shock resistance can use cutting fluids during machining processes.

5. Good Processability

To facilitate tool manufacturing, cutting tool materials require good processability, such as forging properties, heat treatment properties, high-temperature plastic deformation properties, and grinding processing properties.

6. Economic Efficiency

Economic efficiency is one of the important indicators of cutting tool materials. Although high-quality cutting tool materials may have high unit costs, their longer lifespan might not necessarily result in high costs per component.

Therefore, when selecting cutting tool materials, their economic impact should be considered comprehensively.

Aluminum profiles, characterized by their lower hardness compared to steel, offer relatively easy cutting. However, this property also increases their tendency to adhere to cutting tools. To ensure clean cuts and extend blade life, use carbide-tipped blades with a high tooth count (60-80 teeth for a 10-inch blade) and a negative hook angle. These features prevent chip welding and reduce burr formation. Regularly inspect and replace blades to maintain cutting efficiency and quality.

Proper lubrication is crucial when cutting aluminum to prevent burr formation, improve surface finish, and prolong tool life. Use a dedicated aluminum cutting fluid or a high-quality synthetic lubricant. For optimal results, consider a minimum quantity lubrication (MQL) system, which provides precise lubricant application without excessive waste. This approach not only improves cut quality but also supports environmentally friendly practices.

While most industrial aluminum profile cuts are perpendicular, complex designs often require angled cuts, such as 45-degree miters. For precise angle control, utilize a CNC sawing machine equipped with a rotary table or a dedicated miter saw with digital angle readout. When programming cuts, account for material thickness and blade kerf to ensure dimensional accuracy. For repetitive angled cuts, consider creating custom jigs or fixtures to maintain consistency across multiple pieces.

Safety in production is a collective responsibility that extends throughout the factory. It necessitates strict adherence to processing protocols and principles, regular employee safety training, and proactive measures to mitigate unnecessary risks.

Given the substantial weight of aluminum profiles, cutting operations should be performed by a team of at least two people to ensure safe handling and smooth cutting processes. This approach minimizes the risk of strain injuries and improves overall operational efficiency.