Have you ever wondered how those sleek, curved aluminum structures are made? This article dives into the intricate process of aluminum profile bending. From understanding the characteristics of various aluminum profiles to the specifics of bending techniques and requirements, you’ll discover how precision and expertise come together to shape aluminum for construction and industrial uses. Get ready to learn the key factors that ensure successful bending and the detailed steps involved in this fascinating manufacturing process.

1. According to the structure of profiles: general profiles and thermal break profiles (also known as insulated profiles).

2. According to surface treatment: anodized profiles and painted profiles.

3. By hardness state: aged (high-temperature homogenization) and non-aged profiles, provided the material (chemical composition) remains the same.

4. According to usage: industrial and construction.

Based on the drawings and descriptions, the profiles selected for this project are for construction use. The balcony uses anodized general profiles, and the doors and windows use thermal break painted profiles. The material is 6063, typically in T5 hardness state.

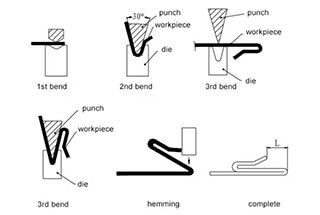

1. Bending refers to the process of deforming a profile through plastic deformation, under the premise of applying a pre-stressing force (within the yield limit) and utilizing rotation and mold changes to alter the interface of the profile cross-section deformation (inward movement).

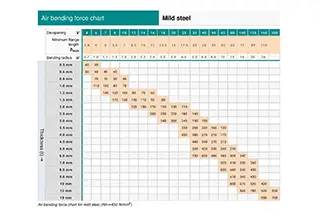

2. Regarding preparation length: Generally, the preparation length should be the sum of the effective arc length of the required bending material and the process section. The process section equals 2.1 times the deformation width (t), and the deformation width (t) equals the outer radius (Rout) minus the inner radius (Rin).

Preparation length = Effective arc length + 2.1t

Of course, the specific preparation length can be adjusted according to the actual situation in order to save the process section.

3. Regarding preparation quantity: Generally, 1-2 additional pieces should be prepared based on the actual quantity needed, considering different cross-sections, radii, and arc lengths. These will be used for mold adjustment. This does not account for potential losses during transportation, processing, and installation after bending.

4. Regarding the requirement of the effective arc length for each bend: it should not exceed 180 degrees under normal circumstances.

5. Regarding the material hardness requirement: when the elongation rate of the profile bending meets the deformation requirement, the T5 state should be chosen (ð≤10%). The national standard for aluminum profiles is ð≥ 8%.

ð = t / Rin × 100% = (Rout-Rin) ÷ Rin × 100%

Otherwise, states T0~T4 should be chosen. However, profile manufacturers are generally reluctant to produce T1~T4 state profiles for customers.

6. Regarding the profile surface treatment requirement: usually, anodizing or painting can be chosen after bending (the elongation rate of the coating is much larger than that of the profile). Because there’s no relative displacement between the profile and the mold during bending, the profile won’t be damaged.

If the coating falls off during the bending process, it’s because of insufficient adhesion, which is mainly caused by poor pre-treatment before spraying, insufficient heating, or inadequate heating time. For convenience in transportation and installation, appropriate surface protection should be done.

The above introduction is just general knowledge. Specific circumstances should be determined based on project requirements, partitioning, nodes, and material selection characteristics.

The national production standard for aluminum profiles (6063, T5) requires ð (Elongation Rate) ≥ 8%.

1. Aluminum Profiles (6063, T5): All typical aluminum profiles can be bent when the required ð (Elongation Rate) ≤ 10%.

2. Aluminum Profiles (6063, T5): For cases requiring ð (Elongation Rate) ≥ 10%, if the aluminum profile has a thicker wall, a closed cavity, a relatively simple geometric shape, symmetrical force in the bending direction, and a width-to-height ratio less than 1, its bending elongation rate can generally range between 10% ~16%.

3. If the bending of the aluminum profile is not permitted under the above conditions, other hardness states of the aluminum profile, such as T0~T4, should be considered. Generally, the elongation rate of aluminum profiles (6063) in the T0 state can reach 20% ~28%.

4. In conclusion, the requirement for the elongation rate in aluminum profile bending should be specifically determined based on the specific design requirements and material selection conditions (geometric shape, wall thickness, degree of cavity closure, symmetry of force in the bending direction, tensile strength, etc.).