Have you ever wondered why some aluminum die castings fail prematurely? In this article, we’ll explore the common defects found in aluminum die casting and their root causes. Drawing from the expertise of seasoned engineers, we’ll provide valuable insights into identifying and preventing these defects. By the end, you’ll have a deeper understanding of how to ensure the quality and durability of your die cast components.

Die casting is a sophisticated metal casting process that employs a precision-engineered mold cavity to rapidly inject molten metal under high pressure, creating complex shapes with exceptional accuracy. This process shares similarities with plastic injection molding but operates at significantly higher temperatures and pressures. It excels in the mass production of small to medium-sized components, making it the predominant casting method in modern manufacturing.

The die casting process yields components with superior surface finish, tighter dimensional tolerances, and enhanced mechanical properties compared to traditional casting techniques. The high-pressure injection ensures excellent metal flow, resulting in intricate details and thin-walled sections that are difficult to achieve with other methods. Moreover, die casting offers excellent repeatability, making it ideal for high-volume production runs.

However, the quality of die-cast parts heavily depends on precise process control and standardization. Variations in crucial parameters such as melt temperature, injection speed, cavity pressure, and cooling rate can lead to a spectrum of defects. Common issues include porosity, cold shuts, hot tearing, and dimensional instability. To mitigate these challenges, advanced die casting operations employ real-time monitoring systems, thermal management techniques, and computer-simulated mold filling analysis to optimize process parameters and ensure consistent, high-quality output.

Appearance inspection:

The surface of casting displays streaks that are in line with the flow direction of molten metal. Additionally, there are distinct, non-directional lines with varying hues that differ from the metal base, and these lines do not follow a particular pattern.

The causes of flow marks are as follows:

1) The mold temperature is too low;

2) The runner design is not good, and the gate position is not good;

3) The feed temperature is too low;

4) Low filling speed and short filling time;

5) The gating system is unreasonable;

6) Poor exhaust;

7) Spray is unreasonable.

Appearance inspection:

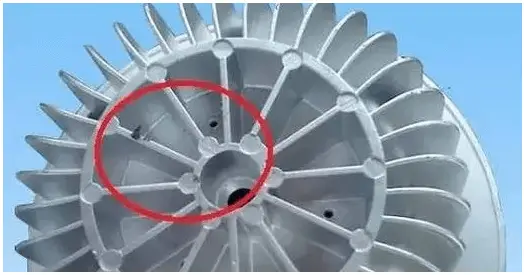

On the surface of die-cast parts, there are marks of a reticular pattern that is either convex or concave, and these marks become more prominent and extend with increasing die-casting cycles.

The causes are as follows:

1) There are cracks on the surface of die casting die cavity;

2) The preheating of die casting die is uneven.

Appearance inspection:

The surface of the die casting parts has distinctive, irregular, and depressed linear lines that are small and narrow in shape. These lines may be either penetrating or non-penetrating. On occasion, the edges of these lines may appear smooth, but they may also break under external force.

The causes are as follows:

1) The two metal flows butt with each other, but they are not completely fused and there are no inclusions between them, and the bonding force of the two metals is very weak;

2) The pouring temperature or die casting temperature is low;

3) The runner position is not right or the flow path is too long;

4) Low filling speed.

Appearance inspection:

There are smooth dents (such as discs) on the surface of most of the thick parts of the die casting.

The causes are as follows:

1) Caused by contraction

2) The design of the cooling system is unreasonable;

3) The mold was opened too early;

4) The pouring temperature is too high.

Appearance inspection:

The trace left by the contact between the surface of the casting and the surface of the die casting cavity or the step trace on the surface of the casting.

The causes are as follows:

1) Caused by ejecting element

2) Caused by splicing or moving parts

Appearance inspection:

Under the influence of external force, small flakes may peel off and appear bright or dark gray in color.

The causes are as follows:

1) There are metal or nonmetal residues on the surface of die casting die cavity;

2) When pouring, impurities are brought in first and attached to the surface of the cavity.

Appearance inspection or damage inspection:

There are obvious layers of metal in the part of the casting.

The causes are as follows:

1) The rigidity of the mold is not enough, and the template shakes during the filling process;

2) In the process of injection, the punch crawls;

3) Improper design of runner system.

Appearance inspection:

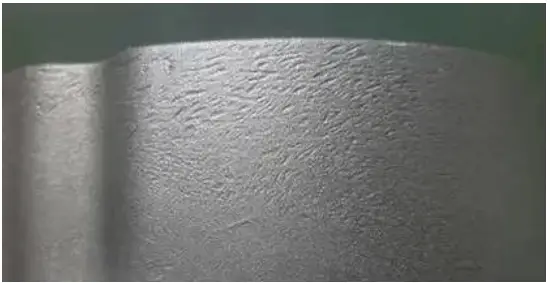

The surface of die casting has rough surface in some places.

The causes are as follows:

1) The position, direction and shape of the ingate caused by the die casting die are not proper;

2) Because of the casting condition, the molten metal in the ingate scours violently and the cooling of the part is not enough.

Appearance inspection:

There are pockmarks or convex lines in the local position of die casting parts.

The causes are as follows:

1) The position of ingate is improper;

2) The cooling condition is not good.

Appearance inspection:

The surface of the casting cracks when placed in an alkaline solution, appearing as dark gray lines. These cracks follow a linear or wavy pattern and have narrow, elongated grains that tend to worsen under external stress.

The causes are as follows:

The results show that the iron content is too high or the silicon content is too low, leading to high levels of harmful impurities in the alloy which decrease its plasticity. In Al Si alloy and Al Si Cu alloy, the content of zinc or copper is too high and in Al Mg alloy, the magnesium content is too high. The copper content in Al Si alloy and Al Si Cu alloy is also too high.

Additionally, the mold retention time is too short, the holding time is too short, and the casting’s wall thickness changes abruptly. The local clamping force is too large and the force is uneven during the ejection process.