Metal is a kind of material with luster and ductility. Therefore, most metals can be made into beautiful and exquisite handicrafts or jewelry, such as gold rings, silver necklaces, iron handicrafts, etc. The initial absorptivity of metal to 10.6um laser beam is only 0.5% ~ 10%. However, when the focused laser beam with power density […]

Metal is a kind of material with luster and ductility.

Therefore, most metals can be made into beautiful and exquisite handicrafts or jewelry, such as gold rings, silver necklaces, iron handicrafts, etc.

The initial absorptivity of metal to 10.6um laser beam is only 0.5% ~ 10%.

However, when the focused laser beam with power density exceeding 106W / cm2 irradiates the metal surface, the surface can start melting quickly in microsecond time.

The absorptivity of most metals in the molten state increases sharply, generally by 60% ~ 80%.

Laser cutting uses a high-density laser beam to scan the material surface, heat the material to thousands to tens of thousands of degrees Celsius in a very short time, melt or gasify the material, and then blow the melted or gasified material away from the cutting seam with high-pressure gas to achieve the purpose of cutting the material.

Laser cutting technology is widely used in the processing of metal and non-metallic materials, which can reduce processing time, reduce processing cost and improve workpiece quality.

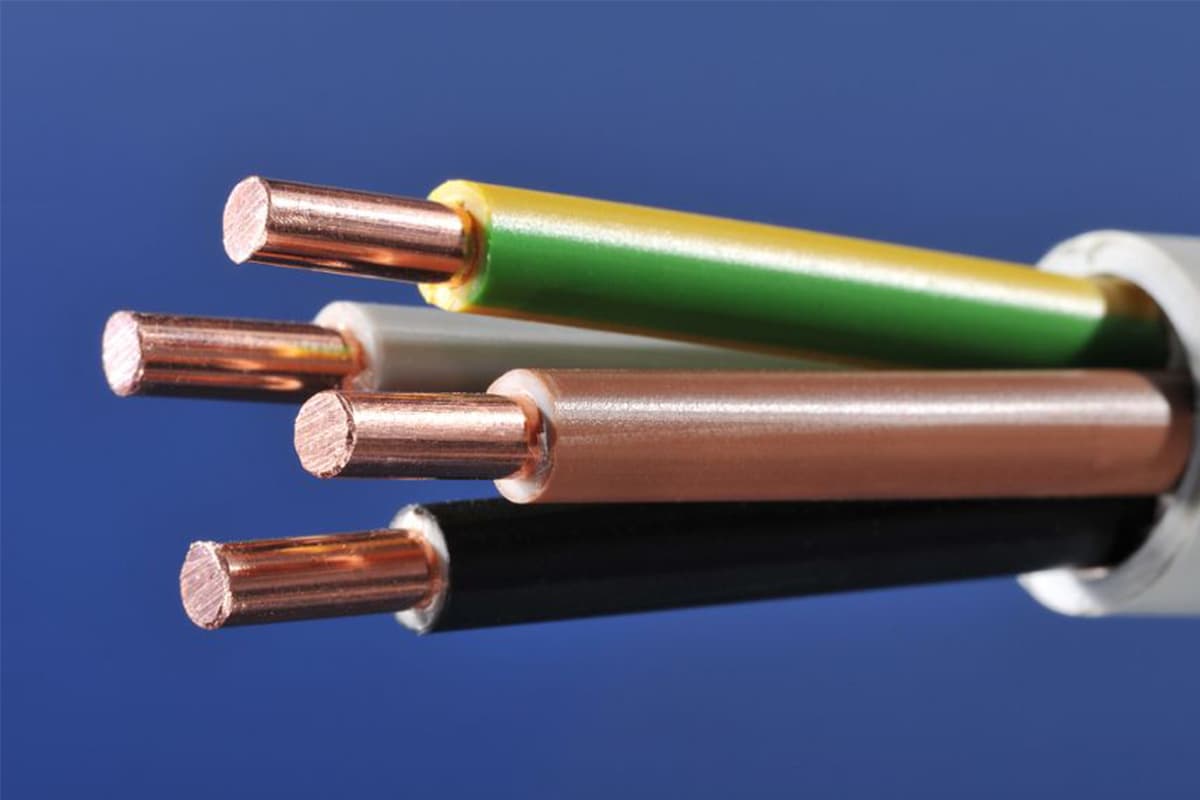

Next I will analyze several metal materials cut by laser cutting machine, including the following seven types:

Modern laser cutting system can cut the maximum thickness of carbon steel plate up to 20mm. The cutting seam of carbon steel cut by oxidation melting laser cutting machine can be controlled within a satisfactory width range, and the cutting seam of thin plate can be narrowed to about 0.01mm.

Fiber laser cutting machine is an effective processing tool for manufacturing industry.

Under the strict control of heat input in the laser cutting process, the heat affected zone of trimming can be limited to become very small, so as to maintain the good corrosion resistance of this kind of material more effectively.

Pure titanium can well couple the heat energy converted by focused laser beam.

When oxygen is used as auxiliary gas, the chemical reaction is intense and the cutting speed is fast, but it is easy to form oxide layer on the cutting edge and cause over burning accidentally.

For the sake of safety, it is better to use air as auxiliary gas to ensure the cutting quality.

The laser cutting quality of titanium alloy commonly used in aircraft manufacturing industry is good.

Although there will be a little slag at the bottom of the cutting seam, it is easy to remove.

Aluminum cutting belongs to melting cutting, and the auxiliary gas is mainly used to blow away the molten products from the cutting area, which can usually obtain better cutting quality.

For some aluminum alloys, attention should be paid to prevent intergranular microcracks on the slit surface.

Pure copper (red copper) cannot be cut with CO2 laser beam due to its high reflectivity.

Only specific fiber laser cutting machines resistant to high counterforce can be used.

Brass (copper alloy) uses a high-power laser cutting machine, and the auxiliary gas adopts air or oxygen, which can cut thinner plates.

Nickel base alloy, also known as super alloy, has many varieties. Most of them can perform oxidation melting cutting.

Most alloy structural steel and alloy tool steel can obtain good edge cutting quality by laser cutting.

Even for some high-strength materials, as long as the process parameters are properly controlled, straight and slag free cutting can be obtained.

However, for tungsten containing high-speed tool steel and hot die steel, melting corrosion and slag sticking will occur during laser cutting.

With the rapid development of laser industry, related laser technology and laser products are becoming more and more mature.

In the field of laser cutting machine, optical fiber laser cutting machine has low maintenance cost and high cutting quality for the sheet metal processing industry.

Compared with YAG and CO2 laser cutting machines, it has more market share.

As the founder of MachineMFG, I have dedicated over a decade of my career to the metalworking industry. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your business.