Have you ever wondered how metals transform from brittle to malleable? This article dives into the fascinating world of annealing and normalizing, two essential heat treatment processes. You’ll learn how these techniques improve metal properties, making them crucial in manufacturing.

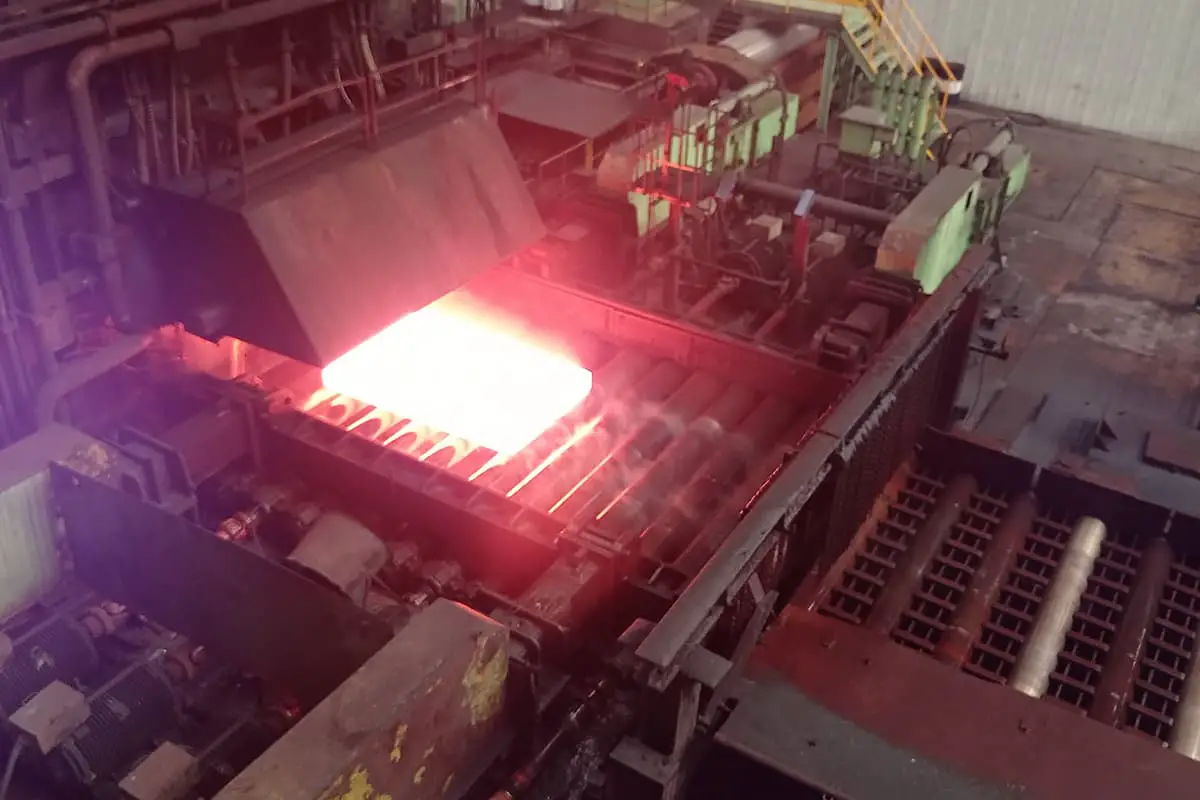

Annealing is a critical heat treatment process in metallurgy that involves a carefully controlled thermal cycle. The process consists of three key stages: slow heating of the metal to a specific temperature (typically above its recrystallization temperature), maintaining this temperature for a predetermined period (soaking), and then cooling at a controlled rate.

The primary objectives of annealing are multifaceted. It reduces hardness and increases ductility, thereby enhancing machinability and formability. This process is crucial for eliminating residual stresses that may have accumulated during previous manufacturing operations, such as forming or welding. Annealing also plays a vital role in dimensional stabilization, minimizing deformation and reducing the tendency for cracking in subsequent processing or during service.

At the microstructural level, annealing refines the grain structure through recrystallization and grain growth mechanisms. It adjusts the metal’s microstructure by promoting phase transformations, homogenizing the composition, and eliminating structural defects such as dislocations and vacancies. These microstructural changes significantly influence the metal’s mechanical properties, corrosion resistance, and overall performance.

The specific annealing parameters, including temperature, soaking time, and cooling rate, are tailored to the particular metal or alloy and the desired final properties. For instance, full annealing, normalizing, and stress relief annealing are variations of the process, each designed to achieve specific outcomes in different materials and applications.

Annealing is a critical heat treatment process in metallurgy that involves carefully heating a metal to a specific temperature, maintaining it for a predetermined duration, and then cooling it at a controlled rate. This rate is typically slow but can be precisely regulated depending on the desired outcome. The process is fundamental in altering the microstructure and properties of metals and alloys.

The primary objectives of annealing are multifaceted:

Various types of annealing processes exist, each tailored to achieve specific metallurgical outcomes:

In practice, annealing can address specific metallurgical challenges:

1) To reduce hardness and enhance machinability, improving subsequent manufacturing processes and tool life;

2) To mitigate residual stresses, stabilize dimensions, and decrease tendencies for deformation and cracking, thereby enhancing the overall structural integrity and performance of the component;

3) To refine grain structures, adjust the microstructure, and eliminate structural defects, leading to improved mechanical properties and material homogeneity.

In industrial production, annealing processes are extensively utilized across various metalworking applications. The specific annealing technique is selected based on the desired material properties and the workpiece requirements. Common annealing specifications include:

The choice of annealing process is critical in optimizing material properties for subsequent manufacturing operations and end-use performance.

Normalizing, also known as normalization, is a metal heat treatment process where the workpiece is heated to a temperature 30 to 50°C above Ac3 or Accm, held for a certain period, and then removed from the furnace to cool in air or by water spray, mist, or blowing air.

Its purpose lies in refining grain size and homogenizing carbide distribution. Normalizing differs from annealing in that the cooling rate during normalizing is slightly faster than during annealing, resulting in a finer normalizing structure and improved mechanical properties.

Additionally, normalizing by cooling outside the furnace doesn’t occupy equipment, thus having a higher production rate. Therefore, normalizing is used as much as possible in production to replace annealing.

1) For low-carbon steel, the hardness after normalizing is slightly higher than after annealing, and the toughness is also better, making it suitable as a pre-treatment for machining.

2) For medium-carbon steel, it can replace tempering as a final heat treatment, and also serve as a preparatory treatment for surface hardening conducted by induction heating.

3) For tool steel, bearing steel, and carburizing steel, it can reduce or suppress the formation of network carbides, thus obtaining the ideal structure needed for spheroidizing annealing.

4) For cast steel parts, it can refine the as-cast structure and improve machinability.

5) For large forgings, it can serve as a final heat treatment, thereby avoiding a high tendency to crack during hardening.

6) For ductile cast iron, it improves hardness, strength, and wear resistance, and is used for manufacturing important components like crankshafts and connecting rods in automobiles, tractors, and diesel engines.

7) For hypereutectoid steel, performing normalizing before spheroidizing annealing can eliminate network secondary cementite, ensuring complete spheroidization of the cementite during spheroidizing annealing.

Post-normalization structure: The structure of hypoeutectoid steel is F+S, eutectoid steel is S, and hypereutectoid steel is S + secondary cementite, and is discontinuous.

The metal heat treatment process involves heating the workpiece to an appropriate temperature (Ac3 or ACcm plus 30-50°C) (see steel microstructure), and then cooling in air after insulation. Normalization is mainly used for steel workpieces.

Normalized steel is similar to annealed steel, but it cools slightly faster and has a finer structure. Some steels with a very small critical cooling rate can transform austenite into martensite by cooling in air, but this treatment is not considered normalization, rather it is called air cooling quenching.

Contrarily, some large-section workpieces made of steel with a larger critical cooling rate cannot obtain martensite even if they are quenched in water, and the effect of quenching is close to normalization.

The hardness of steel after normalization is higher than that of annealing.

During normalization, it is not necessary to cool the workpiece with the furnace as in annealing, which saves furnace time, improves production efficiency, and therefore is generally replaced by normalization as much as possible in production.

For low carbon steel with a carbon content less than 0.25%, the hardness achieved after normalization is moderate, which is more conducive to cutting than annealing, and generally normalization is used to prepare for cutting.

For medium carbon steel with a carbon content of 0.25-0.5%, it can also meet the requirements of cutting after normalization.

For light-duty parts made of this type of steel, normalization can also serve as the final heat treatment.

Normalization of high carbon tool steel and bearing steel is to eliminate network carbides in the structure and prepare the structure for spheroidizing annealing.

Heat Treatment Process of Steel Parts – Normalization

Heat treatment of steel is categorized into two main types: bulk heat treatment and surface heat treatment.

Bulk heat treatments encompass processes such as annealing, normalization, quenching, and tempering, while surface heat treatments include surface quenching and thermochemical treatments.

Normalization is a critical heat treatment process where steel components are heated to a temperature 30-50°C above their upper critical point (Ac3 for hypoeutectoid steels or Acm for hypereutectoid steels), held at this temperature for a specified duration to ensure complete austenization, and then cooled in still air at room temperature.

The primary objectives of normalization are to refine the grain structure, homogenize the microstructure, eliminate internal stresses, and improve the mechanical properties of the steel. This process aims to achieve a near-equilibrium microstructure, typically consisting of fine pearlite and ferrite in hypoeutectoid steels or pearlite and cementite in hypereutectoid steels.

Compared to annealing, normalization involves a slightly faster cooling rate, resulting in a shorter overall heat treatment cycle. This accelerated cooling leads to a finer grain structure and slightly higher strength and hardness compared to annealed steel.

Due to its efficiency and favorable mechanical properties, normalization is often preferred over annealing when both processes can meet the required performance specifications. Medium and low carbon steels, particularly those used as raw materials for further processing, commonly undergo normalization heat treatment.

In contrast, general alloy steel blanks often receive annealing treatment. Normalizing these alloy steels can result in higher hardness due to the faster cooling rate, which may impede subsequent machining operations. The choice between normalization and annealing for alloy steels depends on the specific alloy composition, desired microstructure, and intended application of the final product.

The heat treatment process involves heating the workpiece to an appropriate temperature, maintaining this temperature for a period of time, and then removing it from the furnace for cooling in open air.

The difference between normalizing and annealing is that the cooling rate of normalizing is slightly faster than annealing, resulting in a finer structure in normalizing than in annealing, thereby improving mechanical properties.

Additionally, normalizing cooling outside the furnace does not occupy equipment, resulting in a higher production rate. Therefore, normalizing is used as much as possible in production to replace annealing. The main applications of normalizing include:

1. For low carbon steel, the hardness after normalizing is slightly higher than annealing, with better toughness, serving as a pretreatment for cutting.

2. For medium carbon steel, it can substitute quenching treatment as the final heat treatment, or serve as a preparatory treatment before surface hardening using induction heating.

3. For tool steel, bearing steel, and carburized steel, it can reduce or inhibit the formation of net carbides, thereby obtaining the good structure required for spheroidizing annealing.

4. For cast steel parts, it can refine the as-cast structure and improve machinability.

5. For large forgings, it can serve as the final heat treatment, thereby avoiding the greater tendency to crack during quenching.

6. For ductile iron, it can improve hardness, strength, and wear resistance, making it suitable for manufacturing important parts of vehicles, tractors, diesel engines, such as crankshafts and connecting rods.

The primary difference between annealing and normalizing lies in the cooling rate, with normalizing having a faster rate, resulting in a finer pearlite structure. Thus, for the same steel, normalizing yields higher strength and hardness than annealing.

The choice between annealing and normalizing should be based on specific situations, generally considering three aspects:

1) To improve machinability; low carbon steel should be normalized. Medium carbon steel with a carbon content between 0.25% and 0.45% can either be annealed or normalized. High carbon steel with a carbon content between 0.45% and 0.77% must be fully annealed, while hypereutectoid steel should undergo spheroidizing annealing. (Low and medium carbon structural steel – normalizing, medium and high carbon structural steel – full annealing, alloy tool steel – spheroidizing annealing)

2) Heat treatment processability; complex-shaped, large-sized or important parts should be annealed. Since annealing cools slowly, internal stress is minimized, and the workpiece is less likely to deform or crack. Normalizing can be used for general parts.

3) Processing cost; normalizing is less costly than annealing. To reduce costs and improve production efficiency, normalizing should be used as much as possible while ensuring quality.

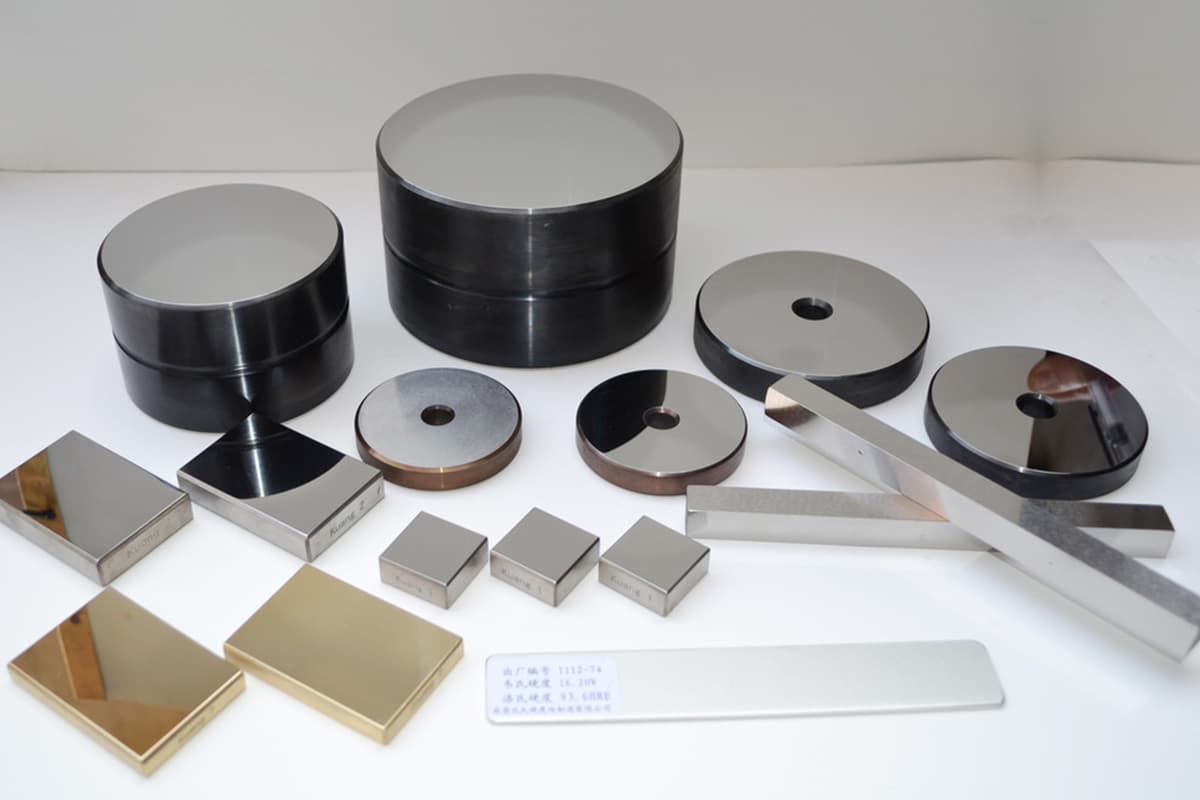

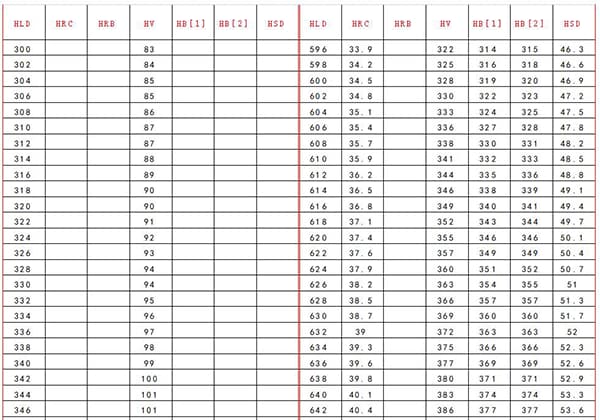

Annealing and Hardening Processes Table

| Process Name | Objective | Application Scope | Note |

| Full Annealing | (1) Refine the grain structure. (2) Eliminate Widmanstätten and banded structures. (3) Reduce hardness and increase plasticity to enhance machinability. (4) Mitigate internal stress. (5) For castings, remove coarse grains to improve impact toughness, plasticity, and strength. | (1) For small to medium-sized castings, forgings, and hot-rolled steel of hypo-eutectoid steel. (2) For the preliminary heat treatment of hypo-eutectoid steel. | (1) Usage in hyper-eutectoid steel is not advisable as it leads to the formation of mesh-like carbides, thereby reducing the material’s toughness. (2) For large castings and forgings, full annealing is employed; however, due to the effects of stress, deformation and cracking may occur, necessitating prompt stress relief. |

| Incomplete Annealing | (1) Decrease hardness, enhance plasticity, and improve machinability. (2) Eliminate internal stress. (3) Achieve spheroidized pearlite. | (1) Hyper-eutectoid steels, featuring a non-networked carbide structure, are seldom used for hypo-eutectoid steels. (2) Pre-heat treatment is employed for high carbon steels and bearing steels. | When network carbides exist in hypereutectoid steel, it must be normalized first, and then subjected to incomplete annealing. |

| Spheroidizing Annealing | (1) Obtain spheroidized pearlite and eliminate slight network structures in hypereutectoid steel. (2) Reduce hardness, enhance plasticity and toughness. (3) Improve machinability. (4) Serve as the preparatory heat treatment before quenching. | This process is employed to improve the structure of carbon tool steel, alloy tool steel, and bearing steel with an ωc greater than 0.65%. It enhances their machinability and prepares the structure for the final heat treatment, thereby ensuring superior performance. | Spheroidizing annealing is a specific case and progression of incomplete annealing. |

| Isothermal Annealing | (1) Using isothermal annealing results in a uniform pearlite structure due to the constant-temperature decomposition of austenite, especially for parts with a large cross-section. This leads to consistent mechanical properties. (2) Isothermal annealing enables steel, which is difficult to transform into pearlite through conventional annealing methods, to achieve a pearlite structure. This facilitates machining and shortens the production cycle. | (1) Isothermal annealing, widely adopted in production due to its purpose, is especially utilized for hypo-eutectoid steel and eutectoid steel. (2) The annealing of alloy steel is nearly entirely replaced by isothermal annealing, as opposed to the traditionally used full annealing. | The grain size and hardness obtained at different isothermal temperatures vary. At higher isothermal temperatures, the grain is coarser and the hardness is lower. Conversely, at lower temperatures, the grain is finer and the hardness is higher. |

| Diffusion Annealing | Eliminate dendritic segregation in ingots and castings to unify the composition and structure, thus enhancing performance and facilitating machining operations. | (1) Primarily used for casting ingots and large-scale cast parts. (2) For high-alloy steel forgings, diffusion annealing is implemented to prepare the microstructure for subsequent heat treatment and machining. | Due to the long production cycle and substantial consumption of electricity or fuel in diffusion annealing, parts with less stringent requirements generally do not undergo this process. |

| Recrystallization Annealing | (1) Metals subjected to cold deformation can be relieved of work hardening by recrystallization annealing. This process eliminates internal stress, reduces hardness, and enhances ductility, thereby facilitating further mechanical processing. (2) After hot processing, due to the rapid cooling, the recrystallization is not complete, resulting in high internal stress and hardness, necessitating recrystallization annealing. | (1) Utilized to restore the structure and performance prior to cold deformation (for instance, cold rolling, cold drawing, and cold punching parts) while eliminating internal stress. (2) Implemented as an intermediate operation in cold deformation to facilitate further processing. | When steel parts undergo uneven cold deformation, or are subjected to critical deformation amounts approximately between 5% and 15%, performing recrystallization annealing can easily result in coarse-grained structure. |

| Stress Relief Annealing | (1) Eliminate internal stress and stabilize dimensions to reduce deformation during machining and usage. (2) Lower hardness for easier cutting and machining. | (1) Used for cast and forged pieces, such as bed frames, engine blocks, and transmission casings. (2) Used for high-alloy steel, primarily to reduce hardness and enhance machinability. (3) For high-precision parts, in order to eliminate stress after machining and stabilize dimensions, a lower temperature (200-400℃) is maintained for an extended period. | (1) For large workpieces and when the furnace load is substantial, it’s appropriate to extend the insulation time accordingly. (2) When relieving stress from standard castings, to prevent a reduction in strength due to secondary graphitization, the heating temperature should not exceed 600℃. |

| High-Temperature Annealing | Eliminate white mouth and free cementite, decompose cementite to enhance machinability, and increase plasticity and toughness. | Used for gray iron and ductile iron parts (when white mouth occurs). | Generally, malleable cast iron is not used. |

| Malleabilizing Annealing | By causing the decomposition of the cementite, flake graphite is obtained, which significantly enhances the strength and plasticity. | Used for converting white cast iron into malleable cast iron. | During the annealing cooling process, if air cooling occurs before reaching 650°C, the material retains good toughness. However, brittleness may occur during furnace cooling. |

| High-Temperature Graphitizing Annealing | Eliminate free cementite in the as-cast structure, enhance machinability, reduce brittleness, and improve mechanical properties. | Commonly used for ductile iron (when a certain amount of free cementite causes white mouth). | During cooling, brittleness appears if the temperature is gradually reduced within the range of 600 to 400 degrees Celsius. Therefore, after the annealing temperature is maintained, the furnace should be cooled to approximately 600 degrees Celsius and immediately removed for air cooling. |

| Low-Temperature Graphitizing Annealing | To obtain ductile iron with a high-toughness ferritic matrix. | Often used for ductile iron (when only pearlite appears in the cast structure, with no free cementite). | When the presence of pearlite is not allowed in the base structure, the heat preservation duration should be appropriately extended; otherwise, it can be slightly reduced. |

| Low-Temperature Annealing | Reduce the brittleness of castings, enhance machinability, and improve toughness. | Commonly used for gray cast iron and ductile iron (when no cementite appears, only pearlite is present). | If free cementite is present in the as-cast structure, high-temperature annealing is used instead of this annealing process. |

| Normalizing | (1) Enhance the hardness of low carbon steel to improve its machinability. (2) Refine the grain structure (such as eliminating Widmanstätten structure, banding, large ferrite grains, and networked carbides) to prepare for the final heat treatment. (3) Relieve internal stress, boosting the performance of low carbon steel as a prerequisite for the final heat treatment. | (1) Primarily used for low carbon steel, medium carbon steel, and low alloy steel. High carbon steel and high carbon alloy steel are not commonly utilized, except when there are netted carbides, as these materials undergo martensitic transformation after normalizing. (2) Employed for quenching repair parts, this technique mitigates internal stress and refines the structure to prevent deformation and cracking during re-quenching. | Compared to annealing, normalizing has a shorter production cycle and higher equipment utilization. Additionally, it can enhance the mechanical properties of steel. Therefore, depending on the material and technical requirements, normalizing can be used as a substitute for annealing in certain situations. |

| High-Temperature Normalizing | Enhancing uniformity within the structure, improving machinability, increasing strength, hardness, and wear resistance, or eliminating white mouth and free carbides. | Primarily used for ductile iron parts requiring high strength and excellent wear resistance. | When free cementite is present in the as-cast structure, the annealing temperature should be set at the upper limit. Castings with high silicon content should be cooled at a faster rate to prevent graphitization. |

| Low-Temperature Normalizing | Attaining excellent strength, toughness, and ductility. | Primarily used for ductile iron components where high strength and toughness are required, but the demand for wear resistance is not particularly high. | During the process of utilizing local pig iron to cast ductile iron, it’s challenging to ensure adequate plasticity and toughness due to high sulfur and phosphorus content. Employing a low-temperature annealing can effectively compensate for the lack of plasticity and toughness induced by this issue. |