Fiber laser marking machines, controlled by computers, are used to etch characters, patterns, or barcodes on card surfaces. They offer advantages like aesthetically superior marking, no consumption of materials, and maintenance-free operation. Fiber laser marking is primarily used in the telecommunication industry for mobile card engraving, and city public utility IC card marking. Its application […]

Fiber laser marking machines, controlled by computers, are used to etch characters, patterns, or barcodes on card surfaces. They offer advantages like aesthetically superior marking, no consumption of materials, and maintenance-free operation.

Fiber laser marking is primarily used in the telecommunication industry for mobile card engraving, and city public utility IC card marking. Its application spans numerous sectors, including public transportation, taxis, rail transit (subway), water supply, heating, gas, landscaping, digital communities, toll roads, and parking management.

A smart card, also known as an IC card, is a portable plastic card with an integrated circuit chip adhered or embedded into it. It resembles a regular card and features a microprocessor and high-capacity memory.

Smart cards have emerged with the advancement of semiconductor technology and the increasing societal need for secure and capacious data storage. Today, they have become a new star in the information society, commonly found in forms like telephone IC cards, identity IC cards, transportation tickets, and storage cards.

China’s IC card industry is growing at an astonishing pace. Particularly in recent years, the annual card issuance has exceeded 100 million, with applications spanning telecom, social security, banking, taxation, public transit, highway cards, and fuel cards.

With the expansion of IC card applications, card packaging, printing, and marking have industrialized. As the IC card industry progresses and card-making standards rise, printing methods have gradually shifted from ink printing and thermal transfer to laser printing.

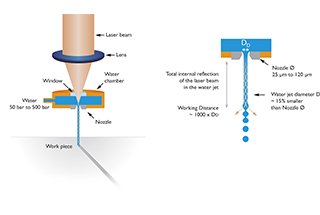

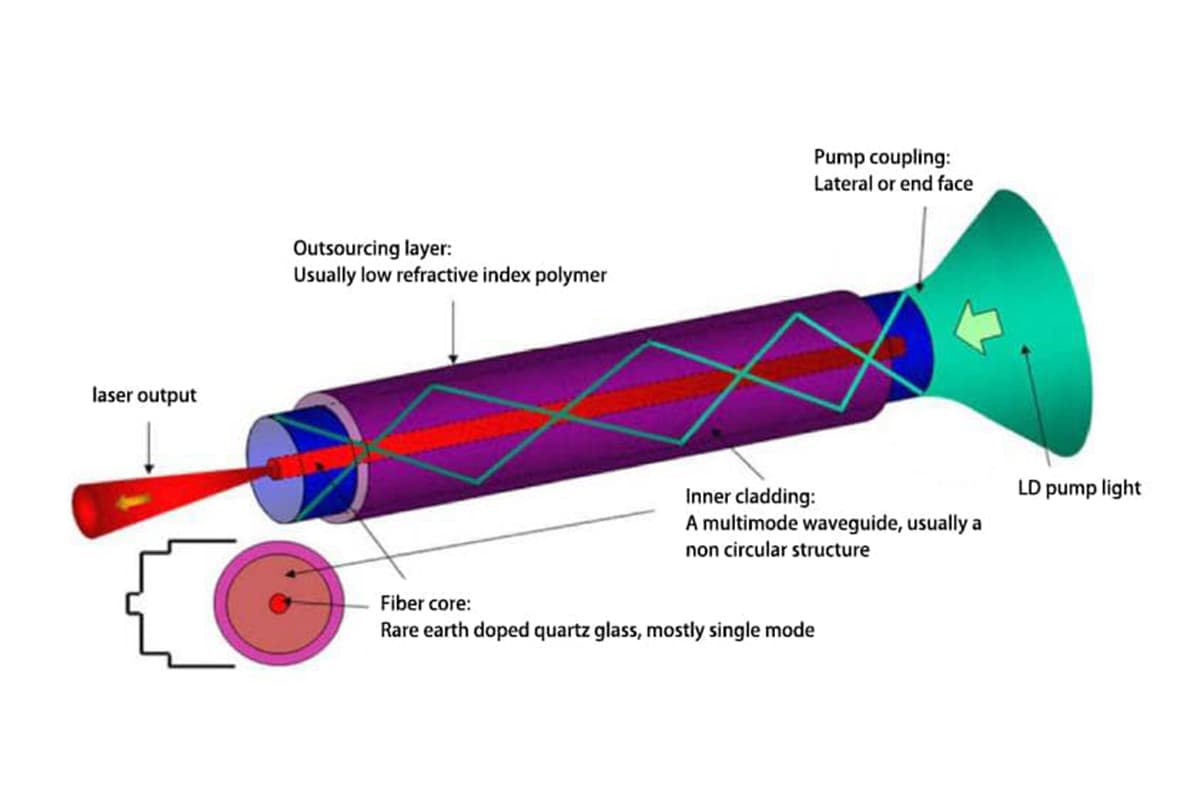

Laser marking, with its unmatched advantages of permanent marking and no material consumption, is increasingly replacing traditional card-making technologies. Moreover, with the rapid development of laser technology and market demand for high-output power, compact size, and low-maintenance laser products, the laser module integrated into card issuing machines has evolved from lamp-pumped and diode-pumped marking machines to fiber laser marking machines.

Fiber laser marking machines are integrated into compact card issuers. For instance, a 10W fiber laser marking machine integrated into the PT3080 system can mark 750 cards per hour. When integrated into the MPR series of large card issuers, a fiber laser marker can mark 4000-6000 cards per hour.

Fiber laser marking can mark a wide range of materials, primarily PVC, PC, high-temperature resistant plastic, Teslin, ABS, PET, PET-G, and PET-F.

Smart cards have permeated various sectors of our current socio-economic structure. According to international professional organizations, billions of smart cards are currently in use worldwide, and their use in major Chinese cities is steadily increasing.

In some regions, local governments even view the development of a city-wide universal card or citizen card project as a “people-oriented project,” which has indeed achieved positive results in real life, promoting overall harmonious societal construction. Hence, as the smart card industry progresses, the application of laser technology within it will inevitably broaden.