Imagine transforming industries with a simple beam of light. Blue laser technology is revolutionizing fields from automotive manufacturing to medical treatments. This article explores five exciting applications, including enhanced welding for new energy vehicles and advanced underwater communication. Discover how this powerful tool is shaping the future and improving efficiency across various sectors. Dive in to learn how blue lasers can offer superior performance and innovative solutions.

Lasers, alongside atomic energy, semiconductors, and computers, were among the “four new inventions” of the 20th century and have had a profound impact on the development of human civilization.

The emergence of the laser not only transformed optics but also influenced other scientific systems, including physics.

Moreover, its impact extends to all aspects of life, particularly industrial production and computers.

It can be said that lasers are ubiquitous in modern processing industries.

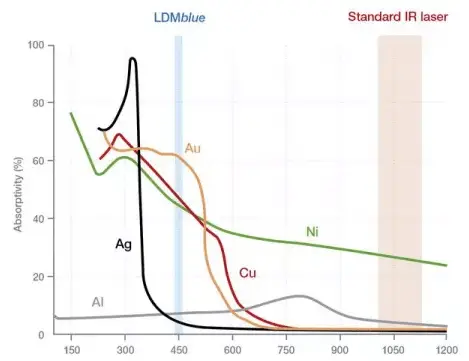

In industrial laser applications, infrared lasers are widely employed for cutting, cladding, and welding operations. However, when processing non-ferrous metals such as copper, aluminum, gold, and silver, these materials exhibit low absorption rates for infrared wavelengths. This poor absorption often leads to erratic welding processes, resulting in production errors and increased scrap rates.

To overcome this challenge, blue light lasers with a wavelength of 450 nm offer an ideal solution. The shorter wavelength of blue light significantly enhances the absorption rate for these reflective metals, providing superior processing capabilities.

Compared to traditional infrared lasers, blue light lasers demonstrate approximately 2 to 10 times better metal processing performance, particularly for cutting, cladding, and welding highly reflective materials like copper and aluminum. This improved absorption translates to several key advantages:

Additionally, blue light lasers offer improved beam focus ability due to their shorter wavelength, allowing for finer feature processing and potentially higher power densities. This makes them particularly suitable for applications requiring high precision, such as electronics manufacturing and micro-welding.

In the field of new energy vehicle manufacturing, blue light lasers have a wide range of applications in the production of automotive batteries and parts.

① Power battery positive and negative pole pillar welding

The materials of the power battery poles of new source vehicles are copper and aluminum

② Welding of motor stator

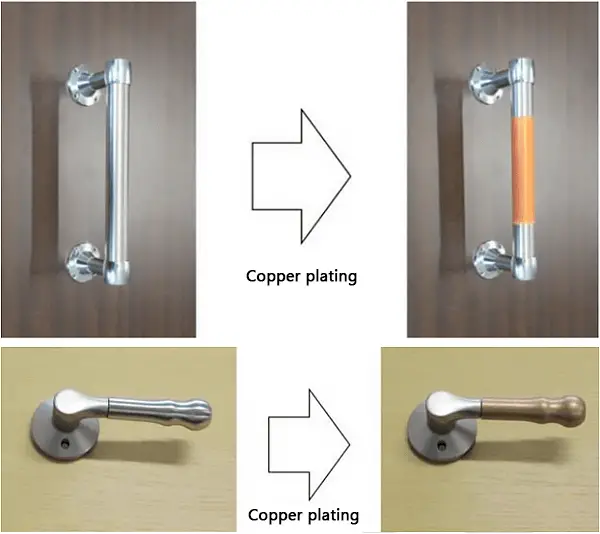

Since ancient times, people have used copper to transport and store water, and to make pipes and barrels, as observed by the Egyptians and Greeks. They noticed that items made of copper had the ability to prevent water from deteriorating and protect wood from parasites.

Recent studies have shown that copper and copper alloys possess bactericidal and antibacterial properties, even in non-engineered metals. These materials have been found to be 99% efficient in killing viruses within 2-6 hours.

The use of blue light lasers to copper-plate frequently touched surfaces like handrails and door handles in facilities such as hospitals, nursing homes, schools, and public transportation can create a healthier environment by reducing the risk of bacterial and viral infections.

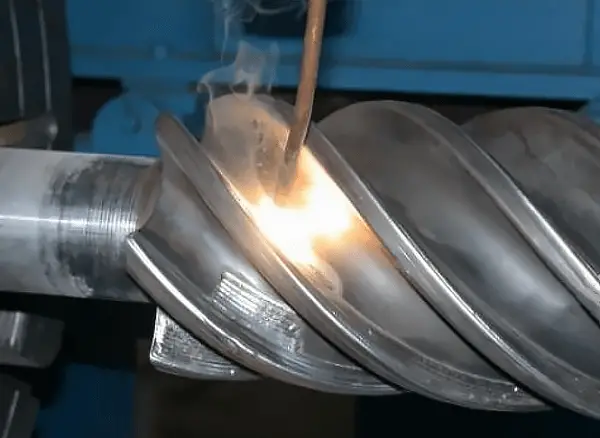

Laser cladding technology meets a broad range of engineering needs for repairing high-tech engineering components that have long production cycles, high processing costs, and high prices. It also enables optimization of resource allocation while saving precious and rare metal materials, reducing energy consumption, and saving money.

Laser cladding repair is mainly used to repair the mold by laser cladding alloy powder.

Mood disorders treatment

According to the results of relevant foreign studies, blue light laser can have miraculous effects in treating depression, insomnia, and other diseases, as well as suboptimal health conditions, under certain levels of irradiation intensity and duration.

Heart disease treatment

Laser myocardial revascularization is currently considered as an effective alternative to conventional treatments for heart disease.

The thermal effect of laser light on myocardial tissue is utilized to create multiple micro-holes in the ischemic myocardial area using a high-intensity laser beam. This process directs blood from the heart chambers to the ischemic myocardial area, enhancing myocardial blood micro-circulation, and achieving the desired treatment outcome.

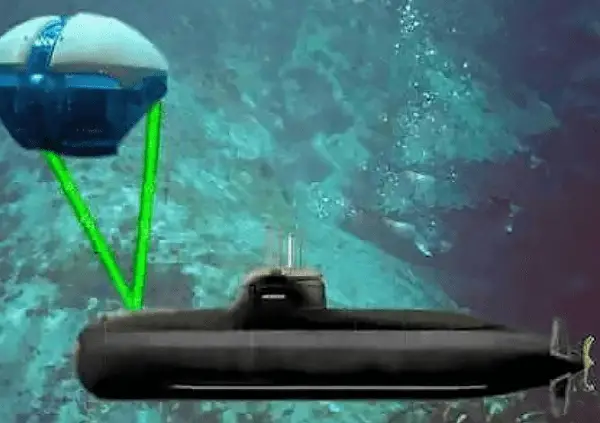

When light enters the sea, its energy is attenuated by the action of seawater.

Seawater has varying attenuation coefficients for different wavelengths of light. Among the visible light wavelengths ranging from 200 to 800 nm, blue light between 400 to 450 nm has the smallest attenuation coefficient.

This principle has led to the widespread use of blue lasers for underwater communication, detection, and other applications. Blue lasers are also useful for detecting marine fisheries resources and undersea military activities.

Moreover, blue lasers can also detect the ideal ozone level.