Imagine a car manufacturing process where strength meets precision, and efficiency drives innovation. Laser welding technology is revolutionizing automotive production, allowing for lighter, stronger vehicles with reduced costs. This article delves into how laser welding unites diverse materials seamlessly, improving the quality and performance of car parts. Learn how this advanced technique not only enhances structural integrity but also optimizes manufacturing efficiency, setting new standards in the automotive industry. Discover the key benefits and future potential of laser welding in creating the cars of tomorrow.

Currently, the application of laser welding in the development of automotive body stamping parts is mainly reflected in the laser lap welding plate.

This allows for different materials, thicknesses, and coatings of steel to form a single material unit, thereby better satisfying the different requirements of parts regarding material properties.

With the lightest weight, optimal structure, and best performance, the body can be lightened and costs reduced through promotion and application.

At the same time, it also reduces the research and development costs of automotive stamping die development, design process analysis, and manufacturing.

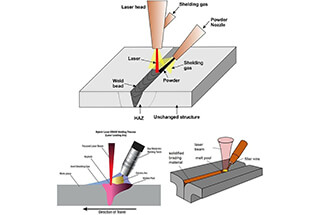

Laser welding is a type of fusion welding that completes the welding of the joint by an energy laser beam. The heat generated by the welding can be minimized, the heat-affected zone is small, and the thermal deformation is the least.

These advantages determine its importance in the production of automotive stamping parts. The flatness requirements of the plate during the production of automotive stamping parts are very high, and the welding deformation of the laser lap welding plate can meet the production needs of the stamping parts.

Stamping parts are directly formed by the edge turning process during production, so the flatness requirements of the plate are higher.

At the same time, the supply quality requirements of the laser lap welding plate will be higher. To reduce the deformation of the plate and improve production efficiency, steel mills usually adopt a welding-first-cutting-later method.

This reduces the deformation caused by welding, avoiding quality issues such as poor fusion at the welding joint, missed welds, and seam cracking.

Taking some of the commonly used laser-welded sheet metal inner parts as examples, such as the roof cross beam, the wheel arch reinforcement inner sheet, and the front surround reinforcement plate, thin and thick sheets are utilized for laser welding to meet the strength requirements of the body.

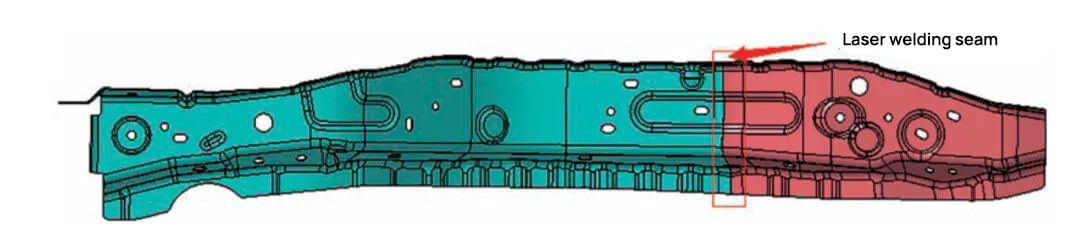

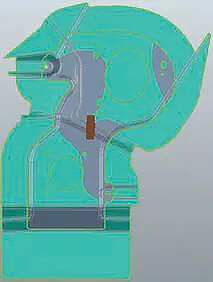

Figure 1 shows a laser-welded part of a particular model’s roof crossbeam, which consists of sheets of the same grade, 210P1, but varying thicknesses, with the thickest sheet being 1.0mm and the thinnest being 0.7mm.

Figure 2: Laser-welded inner panel reinforcement for a certain model’s wheel cover, featuring varying thicknesses, with identical plate grades of HC260YD+Z-50/50-M. The thickest plate is 1.0mm, while the thinnest is 0.8mm.

Figure 3: The laser-welded reinforcement panel for a specific vehicle model’s front surround, consisting of sheets of varying thicknesses but of the same material grade, HC420/780DP. The thickest sheet is 2.0mm, while the thinnest is 0.8mm.

The application of laser-welded plates has increased the precision of the entire vehicle’s fender, front surround, and top cover, resulting in time-saving adjustments for the whole vehicle, and reduced labor costs.

However, this production scheme brings significant difficulties to mold development, especially for the front surround reinforcing plate shown in Figure 3.

The plate has substantial thickness variance, and the spring-back of the workpiece during processing is large according to the technical analysis.

This requires a high level of Computer-Aided Engineering (CAE) analysis during the design process, as well as high demands on the designers’ spring-back compensation techniques.

During the development of this part, problems such as poor R-angle formation, insufficient strength in thin-plate areas, and deformation of the welded assembly often occur.

Solution 1: Based on the problems encountered during the production process, a specific process compensation analysis was conducted, and spring-back compensation was implemented in the early stages of development.

Solution 2: Figure 4 represents the unequal thickness stamping spring-back compensation analysis for the front surround reinforcing plate laser welded assembly of a certain car model shown in Figure 3.

The gray part of the workpiece represents the surface that requires spring-back compensation.

After complete rebound compensation, the production part can meet the required accuracy.

However, the thin sheet area faces issues of rebound and insufficient strength due to the lack of reinforcement ribs.

The deformation problem of the welded assembly caused by the thickness difference between the thin and thick plates exceeding the thickness of the thin plate requires further solutions.

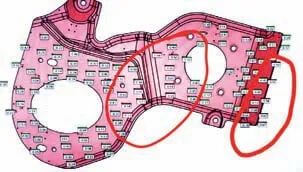

Key Issue 3: Figure 5 represents the coordinate data points for the single piece surface difference due to the welding deformation of the laser-welded assembly of the front panel reinforcement plate for a certain vehicle model depicted in Figure 3.

The parallel difference correction was performed for the area inside the red circle in Figure 5.

The final correction conclusion is a surface difference range of -0.5 to 0, which can meet the welding assembly requirements and solve the welding deformation problem.

This issue requires manual arc welding research on the mold to carry out the rebound compensation for the part production.

Summary: Through the above key problem-solving processes, this part now meets mass production welding requirements and has solved assembly welding deformation issues.

Simultaneously, it provides us with new developmental approaches and technical improvement directions for future product development, helping enhance our stamping part development quality and reduce mold development costs.

It brings cost reduction, efficiency improvement, process optimization benefits to mold manufacturers and component suppliers, while also making a significant contribution to environmental protection.

Laser tailor welding holds substantial economic value, offering a great allure to car manufacturers.

Still, it also presents more significant challenges for the development of stamped parts, demanding higher requirements in preliminary CAE analysis, process layout, and technical personnel’s capabilities.

In the future, laser welding will be applied to car body welding and will evolve to include more energy methods for welding to adapt to different scenarios and environmental requirements.

By reducing mold development costs and the investment costs for car developers, it creates more economic value for car manufacturers.

(1) Laser fusion welding technology contributes to reducing the development cost of stamped parts and die development.

(2) Laser fusion welding also aids in enhancing the technical proficiency of development engineers in the CAE analysis of part springback.

(3) Laser welding also assists in lowering vehicle body weight and overall development costs, improving the vehicle’s assembly condition and reducing deformation caused by extensive welding.