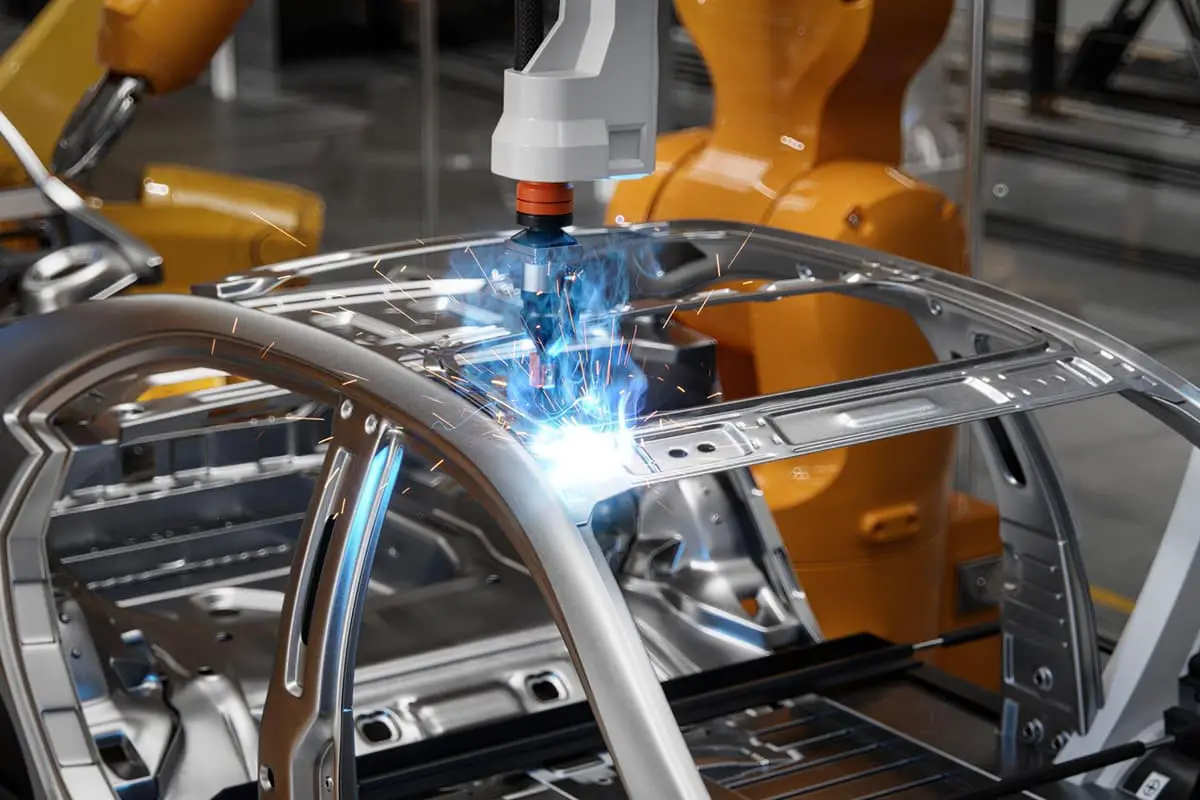

Welding robots primarily consist of the robot body, automated welding equipment (welding power supply), wire feeder (for arc welding), welding torch (or tongs), and a control cabinet. Welding robots can be categorized into arc welding robots and spot welding robots. Since there are some differences between arc welding robots and spot welding robots, allow me […]

Welding robots primarily consist of the robot body, automated welding equipment (welding power supply), wire feeder (for arc welding), welding torch (or tongs), and a control cabinet.

Welding robots can be categorized into arc welding robots and spot welding robots.

Since there are some differences between arc welding robots and spot welding robots, allow me to share some technical knowledge on this subject.

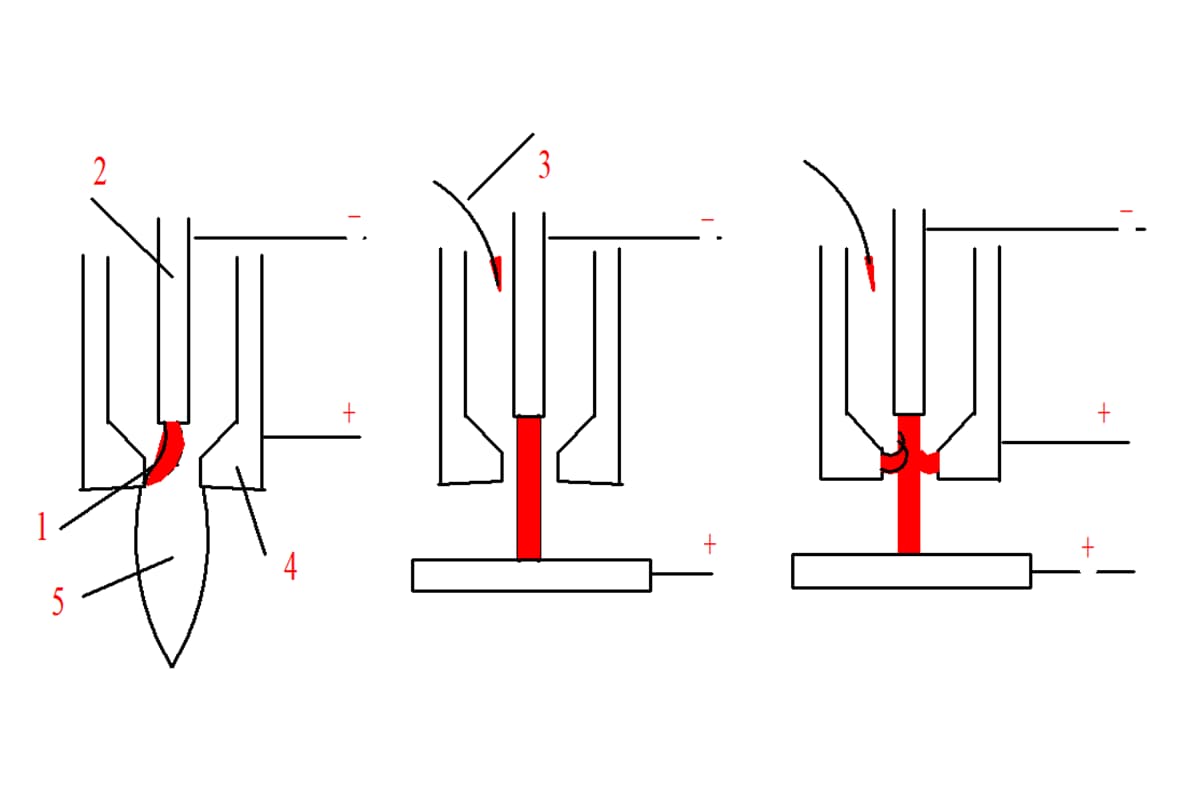

Firstly, the welding process of arc welding robots is far more complex than that of spot welding robots, requiring precise control of the Tool Center Point (TCP), which is the movement trajectory of the wire tip, the welding torch posture, and the welding parameters.

Therefore, in addition to the aforementioned features, arc welding robots must also possess functionalities that cater to the requirements of arc welding.

Theoretically, a five-axis welding robot can be utilized for arc welding tasks. However, for complex-shaped weld seams, using a five-axis robot can be highly challenging.

Unless the weld seam requirements are simple, it is recommended to use a six-axis welding robot if possible.

When an arc welding robot performs a “Z” shaped corner weld or a small diameter circular weld seam, it should not only closely follow the instructed trajectory but also have software functions for different swing styles to choose from during programming.

This is to facilitate swing welding, and the robot should automatically stop moving forward at the pause points in each swing cycle to meet the process requirements.

Additionally, it should have functionalities such as touch positioning, automatic detection of weld seam start points, arc tracking, and automatic re-ignition.

The precise positioning of the spot and the workpiece is crucial in a spot welding robot’s operation due to the contact between them.

There are no strict technical guidelines for the movement trajectory of the spot welding robot.

Not only does it have a high load capacity, but it also moves swiftly and smoothly between spots, with precise positioning, to minimize transition time and enhance work efficiency.

The load capacity required for a spot welding robot depends on the type of welding tongs used. For tongs used for transformer separation, a spot welding robot with a 30-45kg load capacity is sufficient.

However, these tongs, due to their long secondary cable, result in substantial power loss and hinder the robot from extending the tongs into the workpiece for welding operations.

In addition, the constant swinging of the electric cable with the movement of the spot welding robot leads to rapid wear and tear.

Therefore, there is an increasing trend towards the use of integrated tongs, which, along with the transformer, weigh around 70kg.

Considering the need for the spot welding robot to have sufficient load capacity to deliver the tongs to the welding position at a high speed, heavy-duty spot welding robots with a load capacity of 100-150kg are typically chosen.

To cater to the requirement of swift short-distance repositioning of the tongs during continuous spot welding, new heavy-duty spot welding robots have been equipped with the ability to complete a 50mm displacement within 0.3 seconds.

This imposes higher demands on the motor’s performance, the microcomputer’s calculation speed, and the algorithm.

A laser cutting and welding robotic system should also be equipped with a sensory system, such as laser or visual sensors, along with their corresponding control systems.