CNC punch press and CNC bending machine are the main equipment for sheet metal processing. They are known for their convenience and flexibility and are frequently used in the processing of various metal sheet parts.

NC Punch Press

CNC punch press can perform various complex hole shape processes and shallow drawings. By using small punch dies in a step punch method, it can make large round holes, square holes, waist-shaped holes, and various curve contours. It can also perform special processes like shutters, shallow drawings, sink holes, hole flanging, reinforcement, and embossing.

Through simple mold combinations or multi-coordinate linkages, CNC punch can also process complex parts. Compared to traditional punch mold machining, CNC punch press saves on mold costs and has a larger scope and machining ability, making it better suited to changing market and product demands, with the ability to produce small, diversified batches at a low cost and short cycle.

CNC press brake can be used for sheet metal bending. Most bending parts can be machined using a combination of multi-purpose top punch and V-shaped bottom die. Additionally, most bending machines have the capability to process workpieces over 2m, offering high flexibility.

However, during the fabrication of sheet metal parts using these two types of equipment, the workpiece can often incur scratches, crush marks, and abrasions, especially when processing aluminum and stainless steel plates. These scratches can significantly impact the appearance quality of the product, especially for parts with no lacquer surface. To eliminate these scratches, a grinding process is often added, which is both time-consuming and ineffective.

In this content, I will analyze the causes of scratches and provide detailed solutions to avoid them during the handling, cutting, and bending process.

Carrying Process

Causes:

In the process of raw material inventory, logistics and parts process, the parts will inevitably collide with the surrounding objects and scratch.

Solutions:

There are several solutions to scratches during the handling process:

- To increase the operator’s sense of responsibility, inspect the surface quality of incoming materials before processing and reject those that are not suitable.

- Train operators to handle parts with care and not to stack them during fabrication.

- Use cardboard or foam board to separate workpieces during stacking and transportation, and avoid dragging the artifacts on the board. Workpieces should be placed smoothly and neatly, with consistent amounts in each layer, and the height should not exceed 1 meter.

- Avoid collisions between workpieces.

Blanking Process

Causes:

⑴ Friction scratch

a) During the fabrication of copper, aluminum, and stainless steel, the material may stick to the tool and produce tiny, hard particles similar to built-up edges on the mold. When the plate is dragged back and forth on the lower mold, it can be damaged, resulting in deep and difficult-to-remove scratches.

b) During machining, friction between the plate and the lower mold can cause scratches, especially when using special molds like shutters or plunging dies. The higher the lower die, the more severe the scratches.

c) During processing, friction between the plate and the worktable surface can cause scratches on the bottom surface of the plate.

⑵ Indentation

a) There are impurities on the surface of the incoming material, the blade, and the blade disk turret. Although the impurities are not too many, they can easily scatter on the surface of the raw material during machining. When the discharge plate presses the area where impurities are scattered, the surface of the plate will show obvious indentations.

b) The mold material is magnetic.

c) During stamping, if the unloading plate is harder than the plate, it can cause indentations when pressing onto the plate, especially when fabricating pure aluminum or copper sheets.

Solutions:

To avoid scratches during the blanking process, there are several solutions to consider:

⑴ Before processing, inspect the surface of the incoming material for debris and clean it with a jet gun and rag if necessary.

⑵ Before installing the mold, check the upper and lower mold and the turret for iron debris and clean it if found.

⑶ Grinding molds and molds that have been used for a long time must be demagnetized before reuse.

⑷ When processing viscous metals like copper, aluminum, or stainless steel, reduce the punching speed to minimize the buildup of edges. Workshops with adequate budgets can use coated molds to fabricate viscous metals to avoid buildup.

⑸ Regularly check and clean equipment.

⑹ Use air blow-injection molds, which prevent foreign bodies from entering and reduce waste and material carrying.

⑺ Machines that are not equipped with air blow-injection devices can be lubricated by brushing oil on the mold regularly.

⑻ Replace the ball table with a brush table and install anti-scratch brushes for the lower mold to change from rigid friction to soft friction between the plate and the work surface and the plate and the mold. When processing different materials and thicknesses, choose different brushes. For ease of brush replacement, the replacement should primarily be done in the lower mold mounting bracket. Use a hard brush for heavy plates and a soft brush for thin, light plates. When using special forming molds like shutter bending molds, raise the brush due to the high position of the lower mold. The scratch-proof mold with a brush is shown in the drawing.

⑼ Using polyurethane as the unloading device, change the rigid pressure material to an elastic pressure material or a special plastic discharge plate.

The causes of scratches in the blanking manufacturing process are complex. This is just a preliminary analysis, and the most effective solution can only be determined through further research and analysis.

Bending Process

Causes:

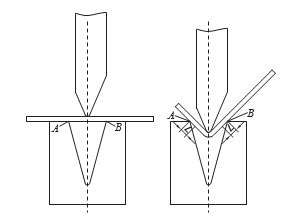

In most of the bending process, V-shaped die bending is adopted. See below diagram:

In the bending process, points A and B are the areas of stress on the plates, resulting in indentations. During fabrication, the punch moves downward, causing the plate to slide along points A and B. In the sliding range L, the surface of the plate will show visible signs of abrasion.

To prevent this issue, some factories use a protective film on the plate surface, which helps to some extent. However, if the bending force is strong, the indentations will be deep and the protective film will not effectively eliminate them.

Solutions:

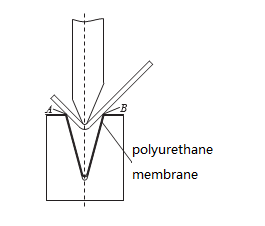

⑴ Use a pressure-resistant, wear-resistant, reusable film in an ordinary mold.

Place a polyurethane membrane mat on the V-shaped die, and use a polyurethane membrane cushion between the sheet and mold during the process to avoid direct contact between the sheet metal and die, thereby avoiding indentations and scratches.

The cushion membrane protection process is shown in the figure.

⑵ Design anti-indentation mold. There are three commonly used forms of anti-scratch molds:

a) Hard rubber V-shaped mold.

This material has low hardness, so it won’t cause indentations or scratches on the plate during processing. Due to its low hardness, the mold is typically made into a single V shape.

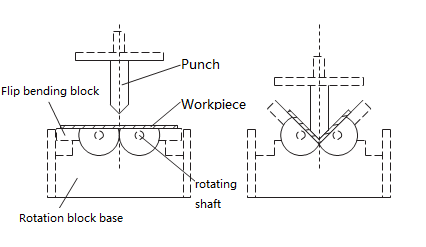

b) Flip bending V die.

This kind of mold uses rotary forming and turning as the main motion, and its core component is the turning bending block and turning pivot. During processing, when the press brake punches downward to contact the workpiece and continues moving downward, the right end of the bending block rotates along the axis of rotation, driving the bending of the workpiece.

Due to this rotation, there is almost no relative slipping of the workpiece surface, avoiding indentation and abrasion. The mold structure is suitable for bending plates with thickness t ≥ 1mm, but when the thickness is greater than 1mm, the root segment can’t be fully bent. Therefore, I suggest using the first method for scratch-free sheet metal fabrication.

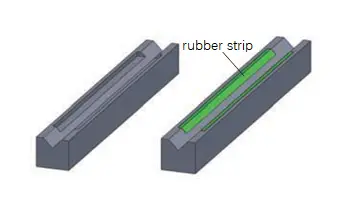

c)Replaceable rubber strip V die

The principle of the mold involves opening the gap on the traditional V-shaped die and mounting a rubber strip on the gap. During the bending process, the force-bearing point of the workpiece contacts the flexible rubber strip. Since the rubber’s hardness is lower than that of the workpiece, it will not produce indentation or scratches. This type of scratch-resistant mold does not have widespread use and is mainly used in the reconstruction of old molds.

In Conclusion

In sheet metal processing, the causes of scratches are diverse. The above analysis and solutions are the result of years of technical work and have shown significant results in factory practice. Sheet metal craftspeople can adopt the appropriate solution based on the actual situation.

Thank you for clarifying that there is a lot of factors that may cause scratches on metal during processing. My classmates and I purchased metal sheets from a manufacturer for a school project and we were told that it underwent annealing, so we wondered why it has scratches. Since you assured that it is not purpose, we might purchase again from the same manufacturer if any need arises in the future.