Imagine a world where machines grind to a halt, cars stop running, and daily life as we know it collapses. This nightmare scenario underscores the critical role bearings play in modern machinery. Bearings, often overlooked, are essential components that reduce friction, ensure smooth rotation, and maintain stability in various devices. From cars to home appliances, bearings are the silent workhorses that keep everything running efficiently. This article will explore the fundamental concepts of bearings, their importance, and the technology behind them, equipping you with knowledge about these indispensable mechanical marvels.

Basic knowledge that must be understood and the function of bearings.

Do you know what kind of mechanical component a bearing is? Bearings, known as “the staple of the machinery industry,” are important components widely used in various machines. In Lesson 1 of the Bearing Column, we will explain the basic knowledge and function of bearings.

A bearing is a component that helps objects rotate. As the name implies, a bearing is a component that supports the “shaft” that rotates inside a machine.

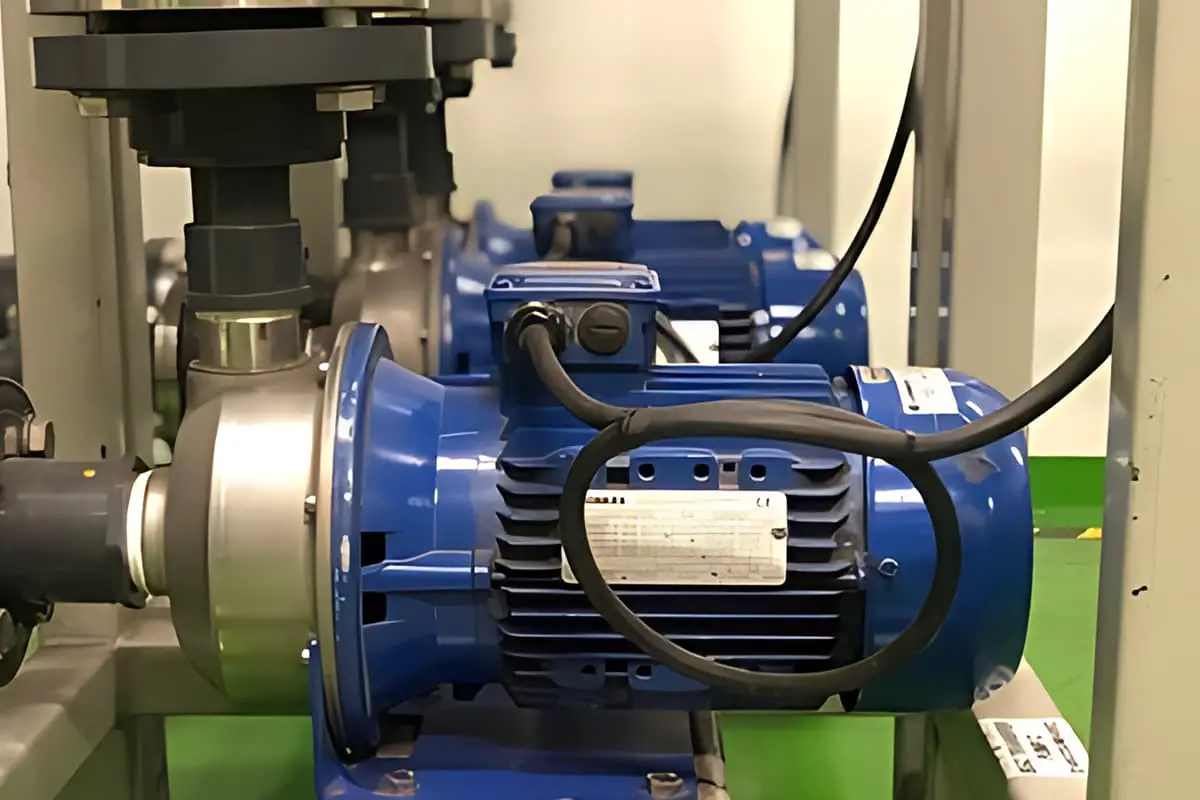

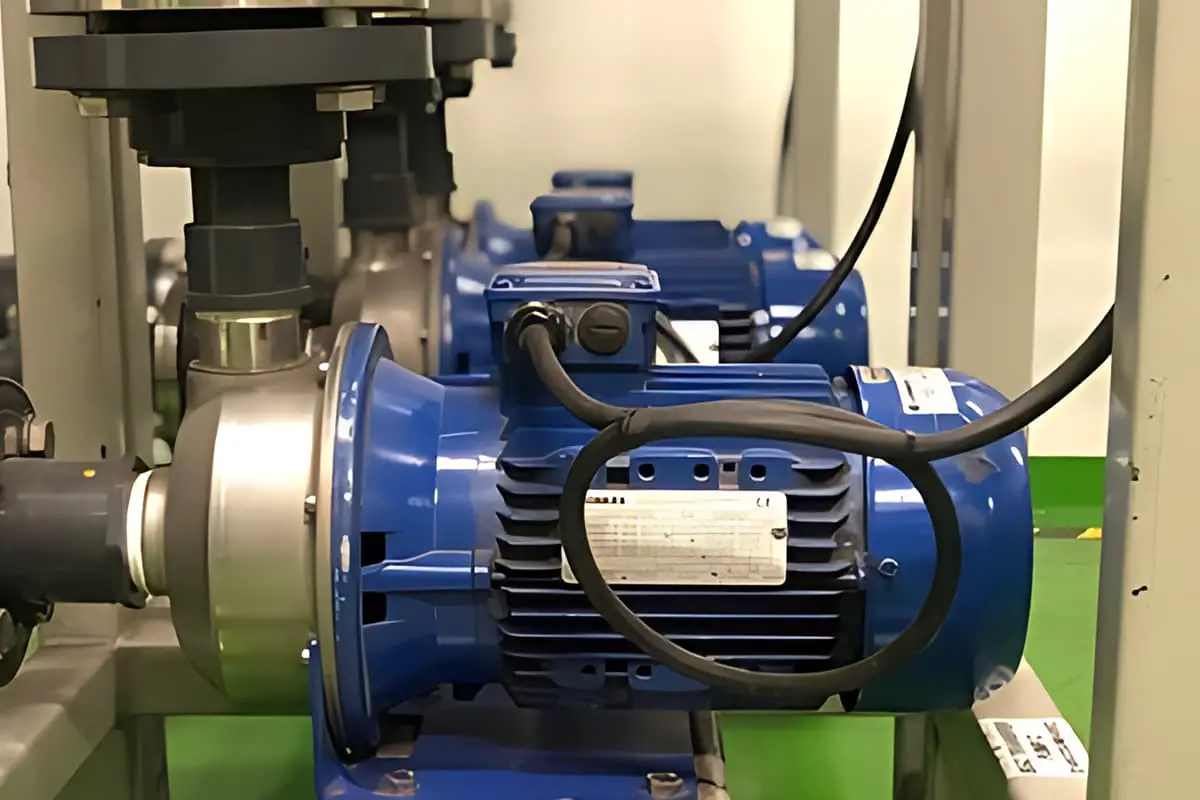

Machines that use bearings include cars, airplanes, generators, and more. Bearings are also used in household appliances such as refrigerators, vacuum cleaners, and air conditioners. In these machines, bearings are responsible for providing support to the “shaft” that has various components, such as wheels, gears, turbines, rotors, etc., installed on it, helping the shaft rotate smoothly.

Because a large number of rotating “shafts” are used in various types of machines, bearings have become an indispensable component known as “the staple of the machinery industry.” Although bearings may seem inconspicuous, they are actually essential. Without them, we would not be able to lead normal lives.

In order to operate machines smoothly, what role do bearings play exactly?

There are two main functions of bearings:

<Function 1> Reducing friction and making rotation smoother

Friction occurs between the rotating “shaft” and its support, but the bearing is installed between them to reduce friction, making the rotation smoother and reducing energy consumption. This is the function of bearings.

<Function 2> Protecting the rotating support and keeping the rotating “shaft” in the correct position

The rotating “shaft” and its support structure bear a significant amount of force. Bearings prevent damage to the rotating support due to this force and help keep the rotating “shaft” in the correct position. It is because of these functions of bearings that we can use machines repeatedly for a long time.

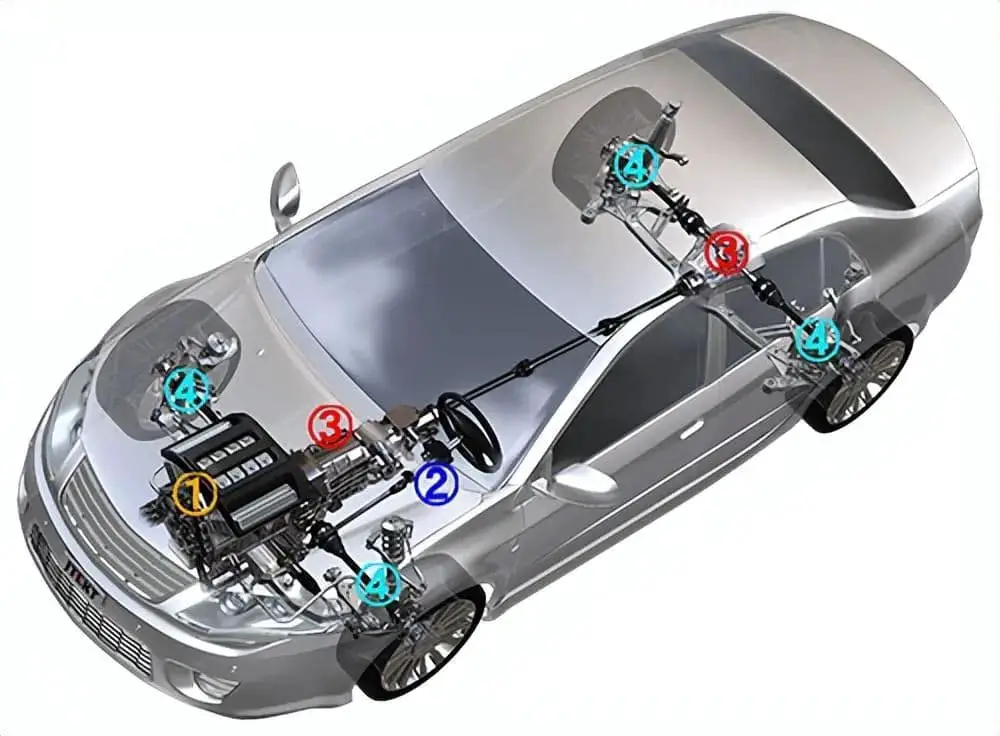

How many bearings are supporting our daily life is unimaginable, as bearings cannot be seen directly with our eyes. Let’s take a common automobile as an example. Have you played with a battery-powered racing toy when you were young? Many people may remember that a bearing was installed in the support structure of the car’s wheels. So, how many bearings does a car really need?

①Powertrain system (components)

Examples: AC generator, turbocharger, etc.

②Steering system (components)

Examples: Steering gear, pump, etc.

③Power transfer system (components)

Examples: Transmission, differential gears, etc.

④Suspension system (components)

Examples: Wheels, suspension, etc.

High-end automobiles may use up to 150 bearings, and all of them play an essential role. If there were no bearings in automobiles, the components would not rotate smoothly, consume more energy, and the parts that support rotation would soon be damaged, which would result in the vehicle being unable to operate safely and comfortably. Therefore, countless bearings work silently behind our wonderful lives.

Bearing components are operating for our lives. Because bearings are essential components that provide support for our lives, high durability and precision have been demanded of them throughout history. Moreover, with the continuous development of mechanical technology, more and more specialized new bearings will be developed and applied to adapt to harsh environments.

In the future, bearings will continue to improve and develop to keep our lives running.

As we have already introduced in Lesson 1, bearings are tools that reduce friction and help objects move smoothly. But when and how were they first invented, and how did they evolve and become widespread? This lesson will introduce the unexpected history of bearings.

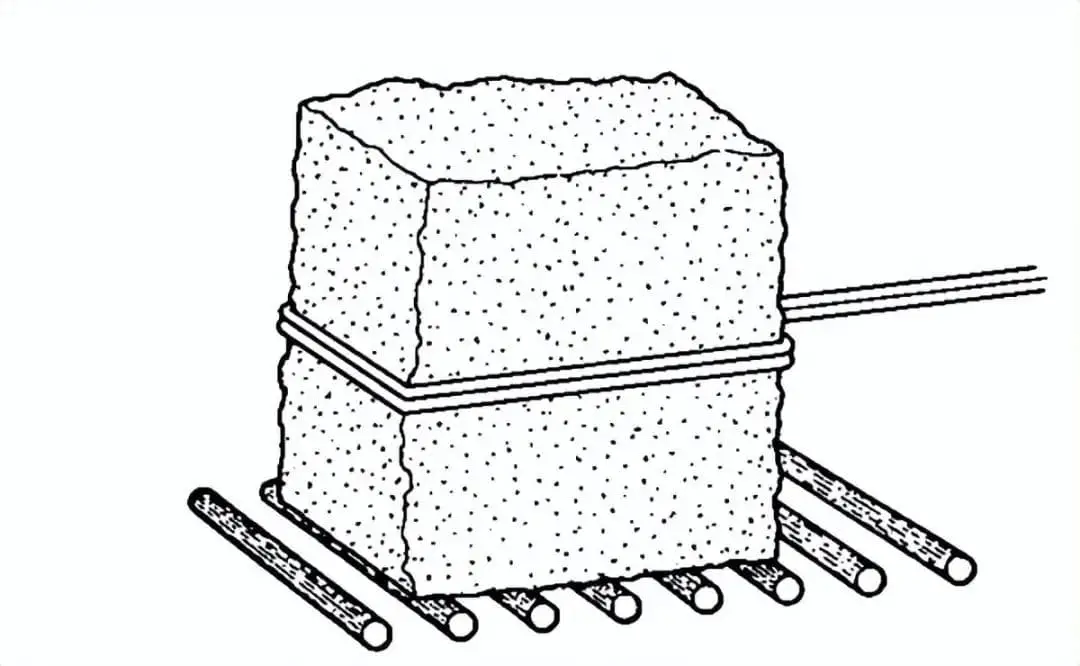

In ancient times, humans came up with many ways to reduce friction, and we can look at an example from the construction of the Egyptian pyramids.

The enormous pyramids, which were built by accumulating huge “heavy stone blocks,” are still awe-inspiring to countless people around the world today. So, how did the people of ancient times move these “heavy stone blocks”? The answer has been roughly inferred from numerous wall paintings found in ancient Egypt.

Several wall paintings in ancient Egypt depict the construction of the pyramids, with some showing scenes of people placing circular wooden objects under the “heavy stone blocks” and rolling them. It can be inferred that the ancient Egyptians reduced friction and moved the “heavy stone blocks” with less force by using rolling wooden objects.

This method of transport is reminiscent of the use of rolling elements (rollers) in bearings.

Records of humans attempting to reduce friction can be found worldwide, although they vary in terms of time period and methods employed. This demonstrates the significant value placed on smooth transportation of goods through the reduction of friction throughout human history.

Leonardo da Vinci was a genius artist from Italy during the Renaissance period. He had a deep connection with bearings and was rightly called the “Father of Modern bearings.”

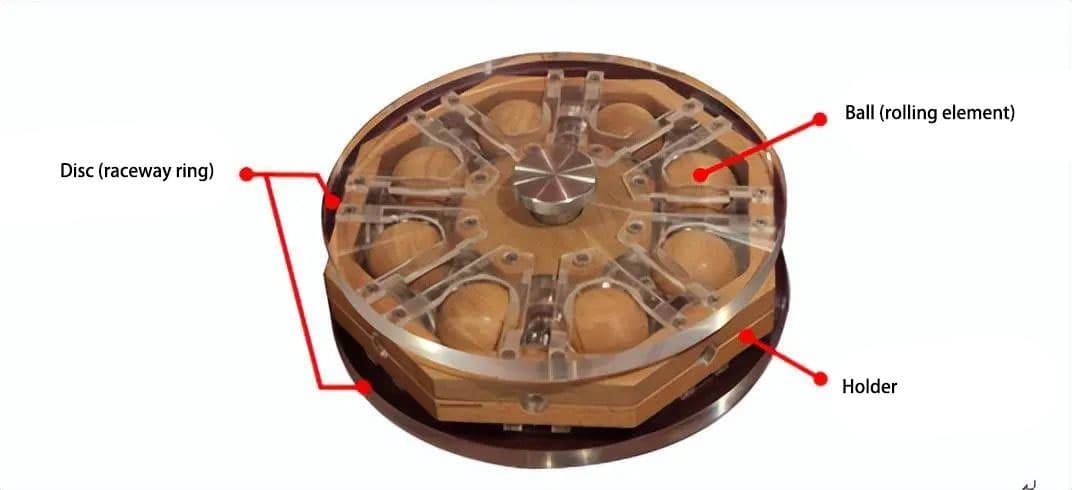

Da Vinci was deeply curious about everything and made significant contributions to mechanical design. His manuscript contained design sketches of bearings that are indispensable for mechanical devices.

With unparalleled creativity, he created a bearing structure that significantly reduced friction. The structure is a device that sandwiches a rolling ball (rolling element) between two circular plates (raceway rings). Surprisingly, the design sketch of the bearing also included a “retaining cage” that prevents the rolling balls from contacting each other.

This structure is almost identical to the one used in modern bearings.

Therefore, the “basic structure of bearings” consisting of raceway rings, rolling elements (such as “balls” or “rollers”), and a retaining cage was invented approximately 500 years ago. The brilliant Leonardo da Vinci revolutionized bearings with his creativity.

However, even after the invention of the basic structure of bearings, actual manufacturing and mass production were not easy. It was not until the Industrial Revolution that bearings were widely used in machinery.

During the Industrial Revolution from the mid-18th to the 19th century, steel began to be produced on a large scale. Therefore, high-strength steel bearings could be mass-produced and widely used in various fields.

One of the great inventions that emerged during the Industrial Revolution was the “vehicle axis that uses bearings.” The first widely used rolling bearings were multi-purpose ball bearings used in bicycle axles. Subsequently, roller bearings for carriage axles using rollers as rolling elements were also invented.

The emergence of “vehicle axis that uses bearings” greatly improved mobility and transportation efficiency. As a result, many industrial machinery at that time also actively introduced bearings and made great contributions to industrial development.

Through the Industrial Revolution, bearings became an important component supporting industrial development behind the scenes and an indispensable tool in people’s lives.

The history of the development of bearings is the history of human civilization’s progress. Without the invention of bearings, humans would still be struggling to move heavy objects, and our lives would not have so many machines to provide us with convenient and comfortable services.

The birth and progress of bearings have had a tremendous impact on civilization’s development. It can be said that bearings are the crystallization of the wisdom and technology of our predecessors and the unsung heroes behind the “history of industrial development.”

In Lecture 3, we will introduce the structure of the bearing and the function of each component.

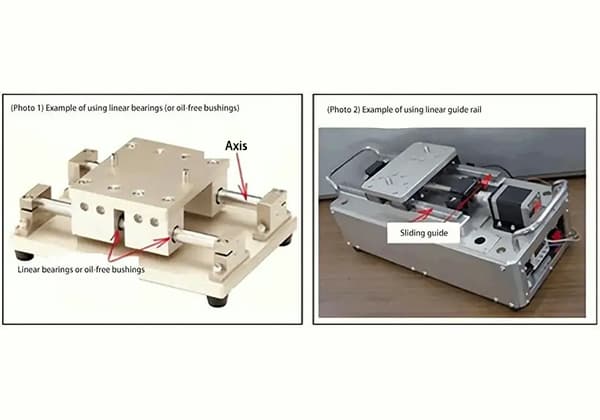

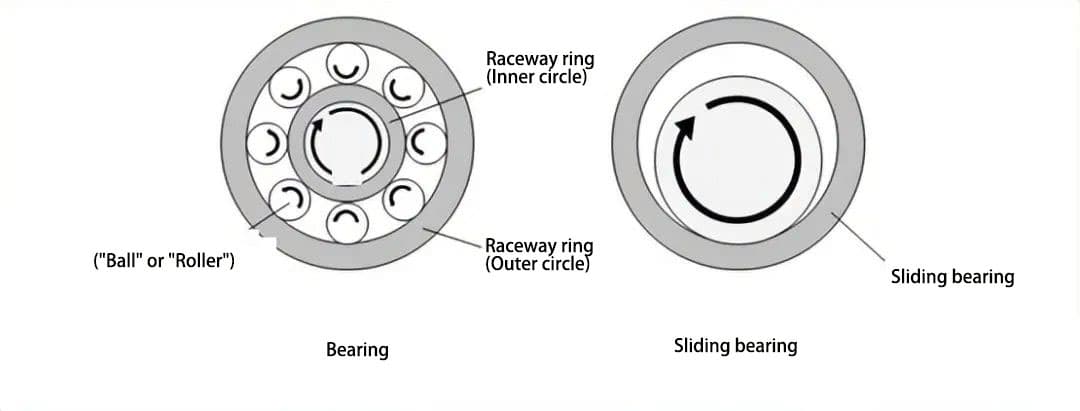

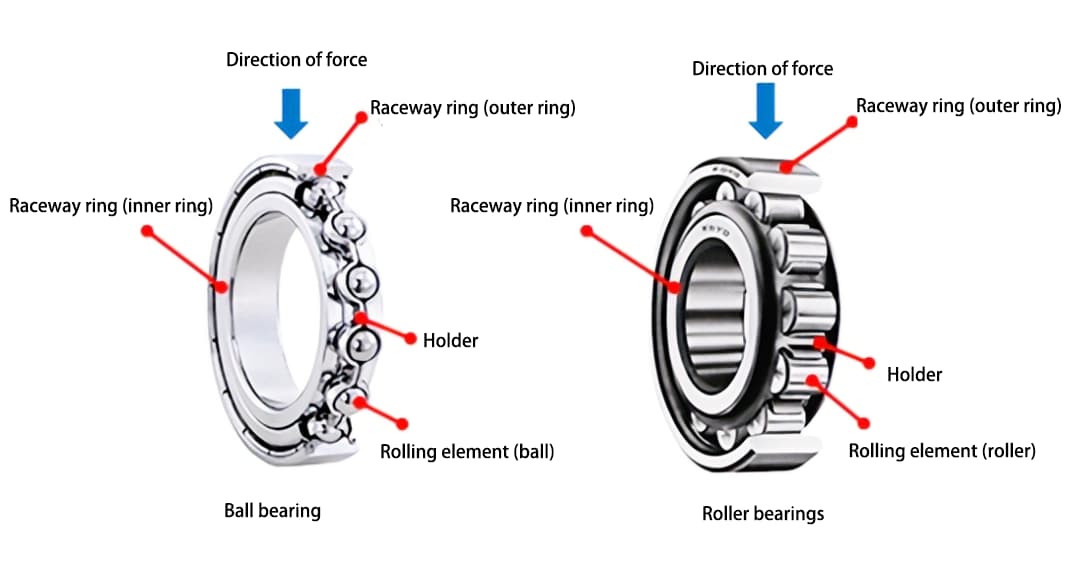

Bearings reduce friction by using rolling motion. As shown in Figure 1, when the “shaft” begins to rotate, multiple “rolling elements” (such as “balls” or “rollers”) in the bearing will begin to roll. Bearings reduce friction by utilizing this rolling motion.

Compared with “sliding motion” plain bearings, bearings that utilize “rolling motion” are better at reducing friction and minimizing the consumption of rotational energy. So, what is the structure of bearings? Below, we will provide a detailed introduction.

Although there are many types of modern bearings, their basic structure is similar to the bearing structure conceived by Leonardo da Vinci about 500 years ago.

The components of a bearing include:

Race rings

Race rings support the force acting perpendicular to the shaft in the case of “radial bearings” shown in Figure 2. In ball bearings, the rolling elements are balls, while in roller bearings, the rolling elements are rollers.

The raceway ring is used for this type of radial bearing.

The raceway ring assembled on the inner side of the shaft is called the inner ring.

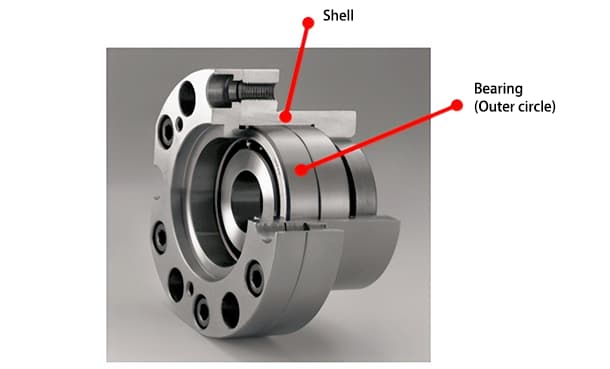

The raceway ring on the outer side is called the outer ring, which is assembled into the housing (※1: refer to Figure 3).

Housing

The housing refers to the part that comes into contact with the outer ring of the bearing when the bearing is assembled.

Raceway ring

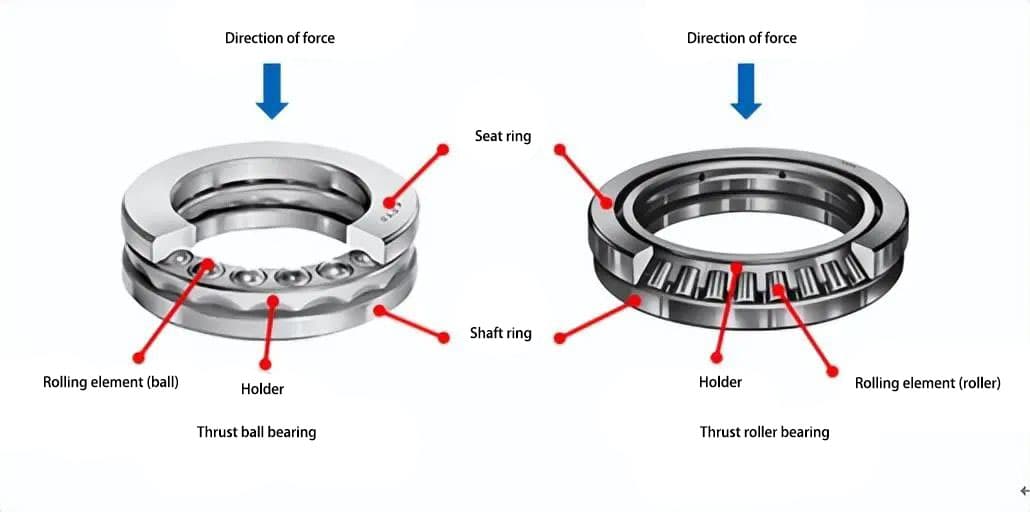

The bearing shown in Figure 4 is called a “thrust bearing,” which supports force in the same direction as the axis.

The raceway ring is used for this type of thrust bearing.

The raceway ring assembled on the shaft side is called the shaft ring.

The raceway ring assembled on the housing side is called the seat ring.

To achieve smooth rotation, the surface on which the rolling elements of the bearing raceway ring roll is meticulously smoothed.

Rolling element

As shown in Table 1, rolling elements include “balls” and “rollers”.

Table 1 Types of rolling elements

| Ball | Ball bearings | |

| Cylindrical roller | Cylindrical roller bearings | |

| Needle roller | ||

| Tapered roller (conical) | ||

| Spherical roller (barrel-shaped) |

Depending on usage conditions such as load capacity and rotational speed, various types of rolling elements are available for selection. We will discuss the types of bearings in the bearings section of Lecture 4, and interested learners can refer to the next page.

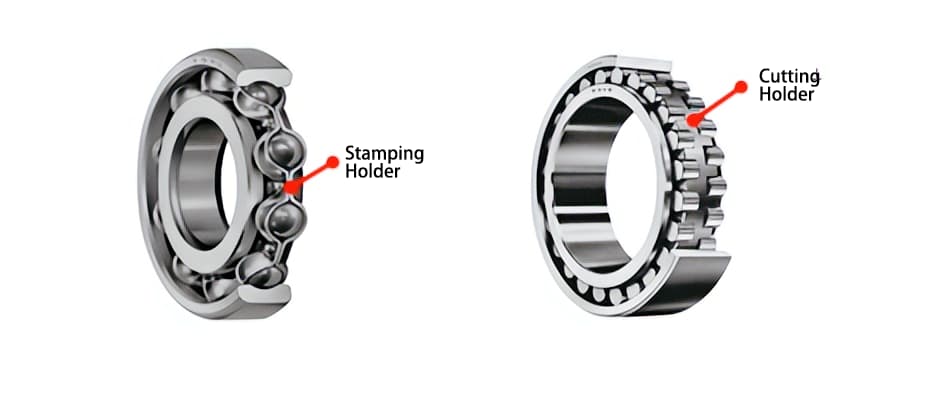

Holder

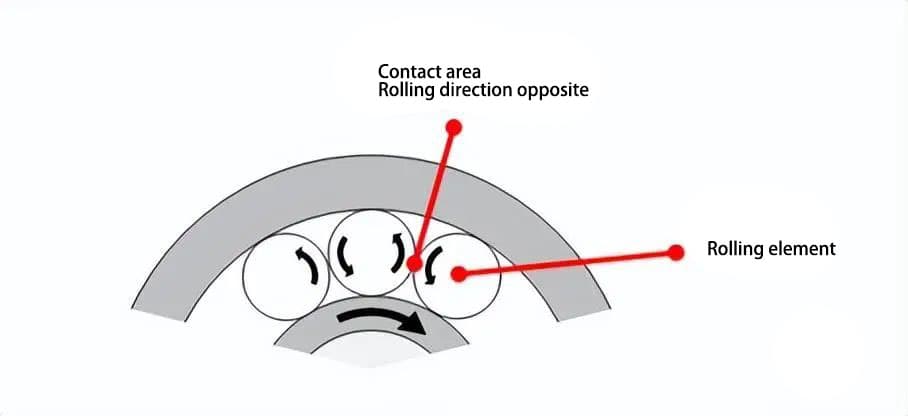

As shown in Figure 5, when the inner ring of the bearing rotates, the rolling elements also begin to roll. If there is no retainer in the bearing, adjacent rolling elements will come into contact with each other.

When the rolling direction of two rolling elements on a contact surface is opposite, it hinders the rolling motion of the rolling elements.

To prevent this from happening, a retainer is used to keep the adjacent rolling elements separated so that they can roll smoothly. Various types of retainers are available for selection depending on usage conditions such as load capacity and rotational speed of the bearing. Figure 6 shows a representative type of retainer.

It is evident that the raceway ring, rolling elements, and retainer respectively play different roles. These roles complement each other for the bearing to rotate smoothly.

However, with only these constituent parts, the bearing still cannot rotate continuously and smoothly with stability. Next, we will introduce another important component of bearings.

To ensure stable and smooth rotation of bearings, the friction of rolling movement must be reduced, and parts wear must be prevented. That is where lubricants come in.

The lubricants used in bearings are mostly semi-solid (paste-like) “grease” and liquid “oil.”

In addition, lubricants also reduce internal heat inside the rotating bearing and prolong bearing life. Therefore, lubricants are also an “important component” for ensuring stable and smooth rotation of bearings.

Components and lubricant are required to ensure stable and smooth rotation of bearings.

The components of bearings include the raceway ring, rolling elements, and retainer, each playing a different role. These roles complement each other to enable the bearing to rotate smoothly.

Moreover, “lubricants” help reduce friction in rolling movement and prevent parts wear. Each component plays its critical role, allowing the bearing to rotate continuously and smoothly with stability.

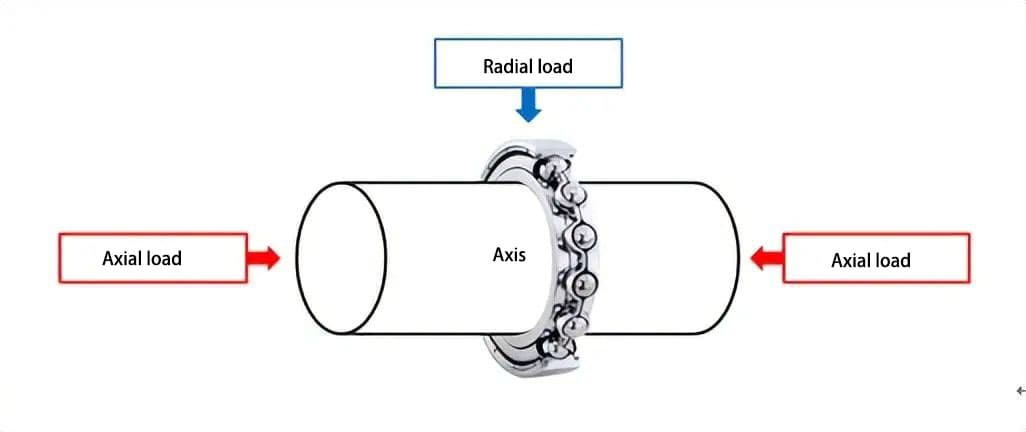

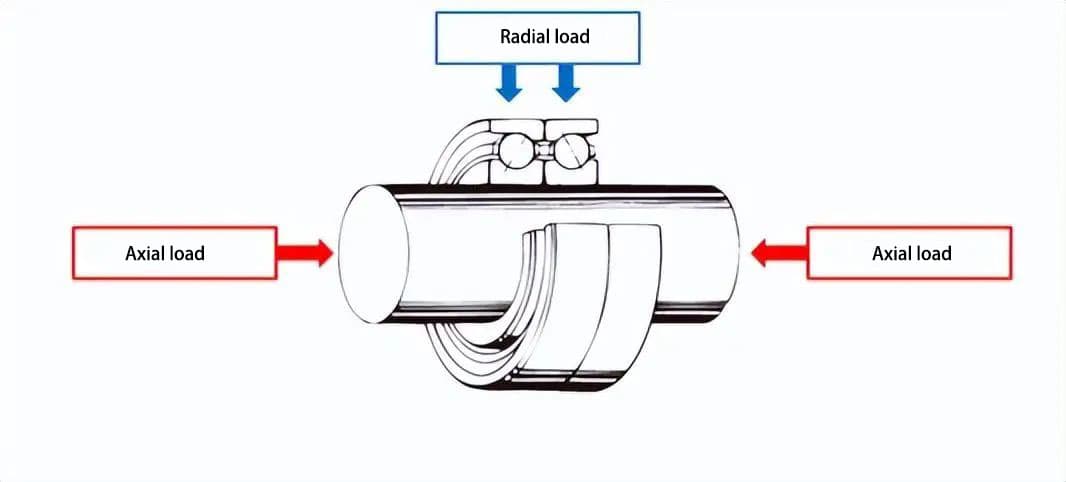

Bearings will receive forces from different directions, so they can be classified according to the “direction of force”.

First, let’s introduce the force on the bearing.

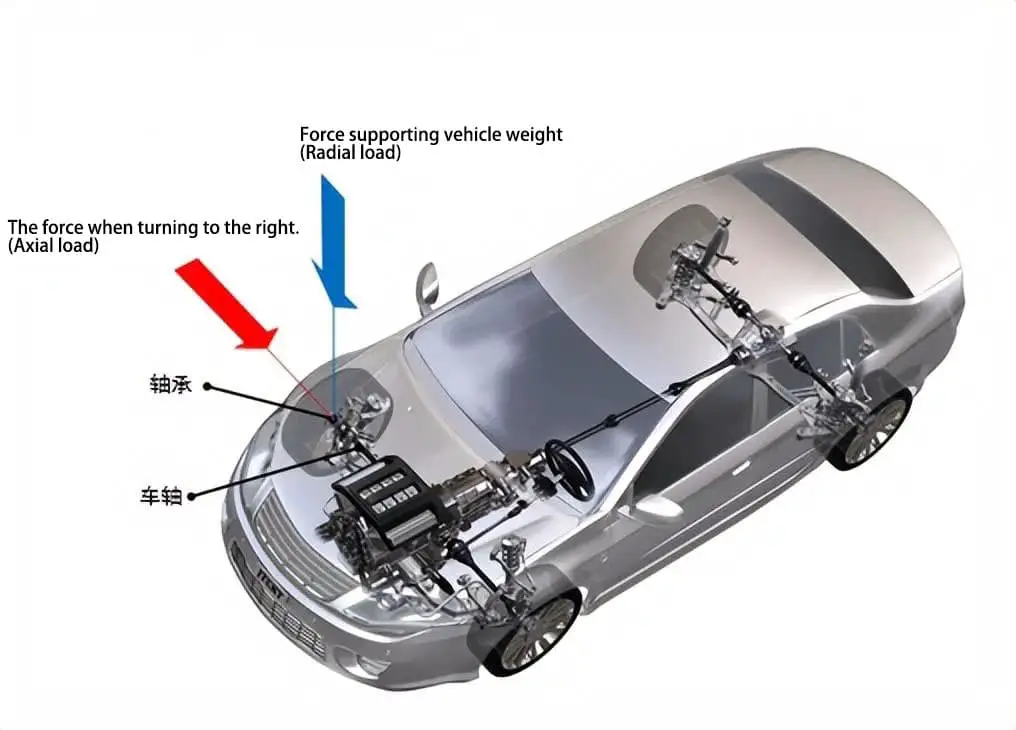

Figure 1 shows the force on the bearing used for the car wheel with a tire installed. One is the force that supports the weight of the car (shown by the blue arrow in Figure 1), and the bearing must bear the force perpendicular to the axle of the car wheel.

In addition, centrifugal force occurs when the car turns (shown by the red arrow in Figure 1), and the bearing will bear the force in the same direction as the car axle.

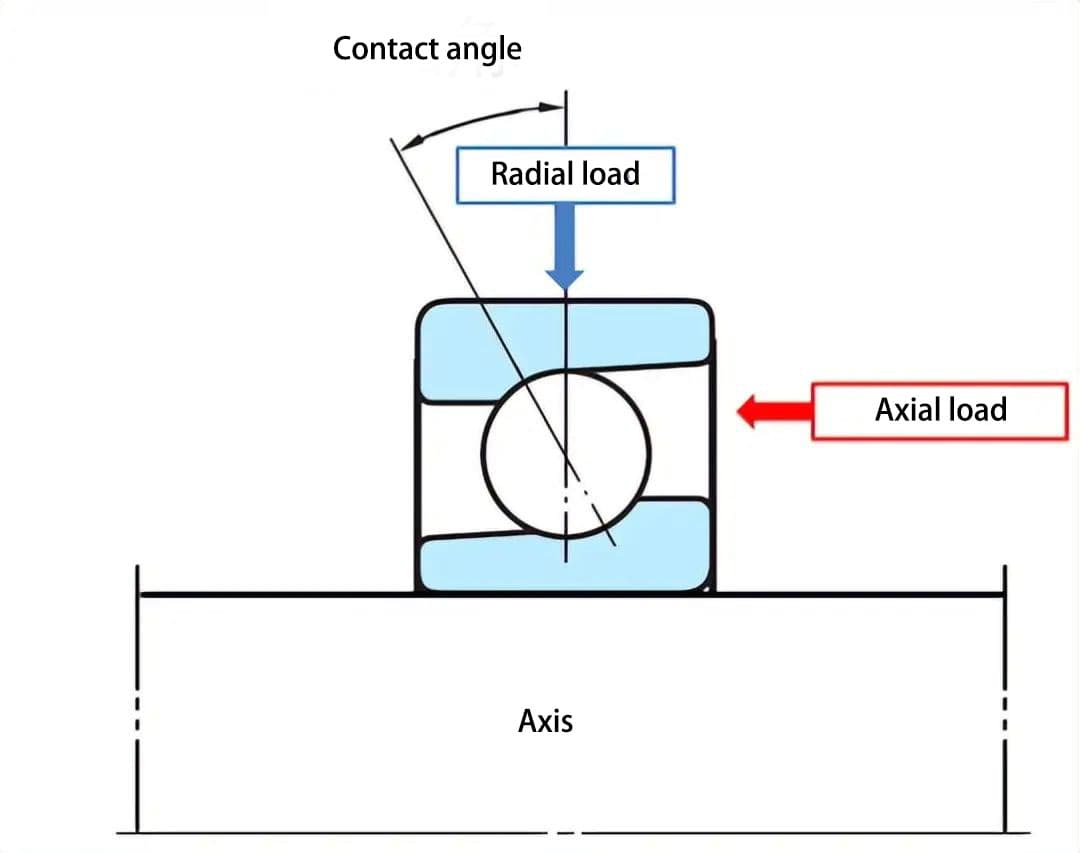

As shown above, bearings usually withstand forces from different directions. Therefore, bearings can be classified according to the direction of force and bearing capacity. Bearings withstand radial loads and axial loads; the force that bearings withstand is called “load”; the force perpendicular to the shaft is called “radial load”; the force in the same direction as the shaft is called “axial load”.

Classification of Bearings

According to the direction of the force that the bearing can bear and the shape of the rolling element, the bearings can be divided into the four types shown in Table 1.

Table 1: Classification of Bearings

| Rolling Element | |||

| Ball | Roller | ||

| Main Direction of Force | Perpendicular to the Shaft (Radial Load) | Radial Ball Bearings | Radial Ball Bearings |

| Same Direction as the Shaft (Axial Load) | Thrust Ball Bearings | Thrust Ball Bearings | |

Radial Ball Bearings

Radial Ball Bearings are “ball” bearings that bear the force “perpendicular to the direction of the shaft”. Deep Groove Ball Bearings (Ball Bearings) are a type of radial ball bearing.

Deep groove ball bearings are commonly used types of bearings.

Deep groove ball bearings can not only withstand radial loads, but also withstand a certain degree of bidirectional axial loads. When bearing a larger axial load, angular contact ball bearings, which will be introduced later, should be used.

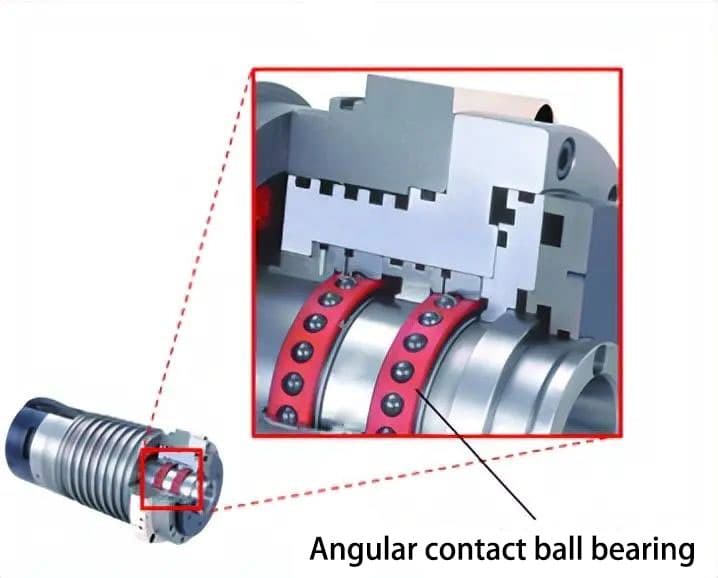

Angular Contact Ball Bearings

Angular contact ball bearings can simultaneously withstand radial loads and one-way axial loads. When bearing bidirectional axial loads, two or more angular contact ball bearings should be used in combination.

When bearings bear “radial load” and “axial load”, the angle between the direction of the load borne by the raceway ring and the rolling element and the direction perpendicular to the shaft is called the contact angle.

The contact angle is generally divided into 15°, 30°, and 40°, which are represented by the letters C, A, and B, respectively.

Radial roller bearings are “roller” bearings that bear the force “perpendicular to the direction of the shaft”. Radial roller bearings withstand larger loads than radial ball bearings and have different types based on the type of roller, such as cylindrical roller bearings, needle roller bearings, tapered roller bearings, and spherical roller bearings.

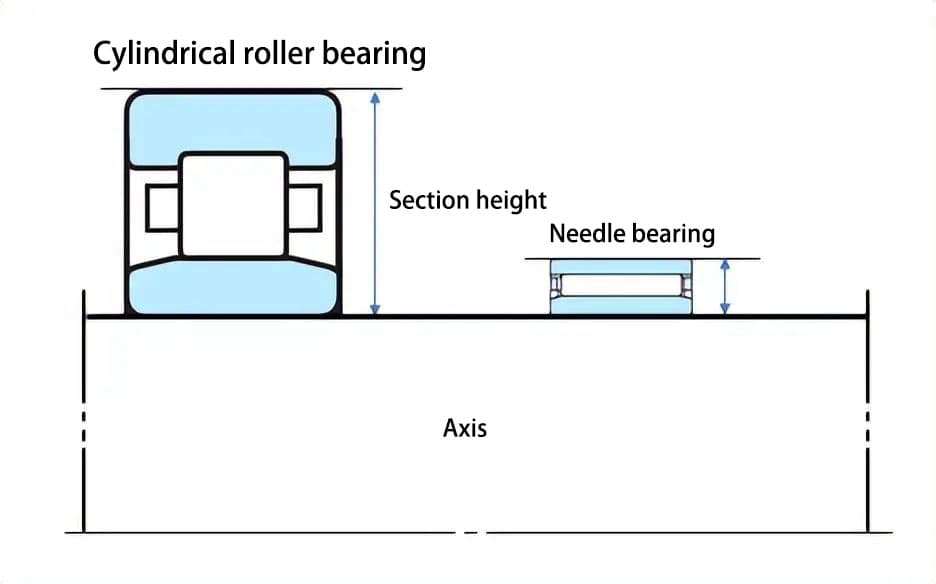

Cylindrical Roller Bearings

Roller bearings use “cylindrical rollers”. Cylindrical roller bearings withstand larger radial loads than deep groove ball bearings and can be used in machines that generate impact force.

Needle roller bearings

Roller bearings use “needle-shaped rollers”. Needle roller bearings use needle-shaped rollers with a smaller diameter than cylindrical rollers, as shown in Figure 5. The low cross-section height of this type of bearing helps achieve miniaturization and lightening of machines.

Tapered Roller Bearings

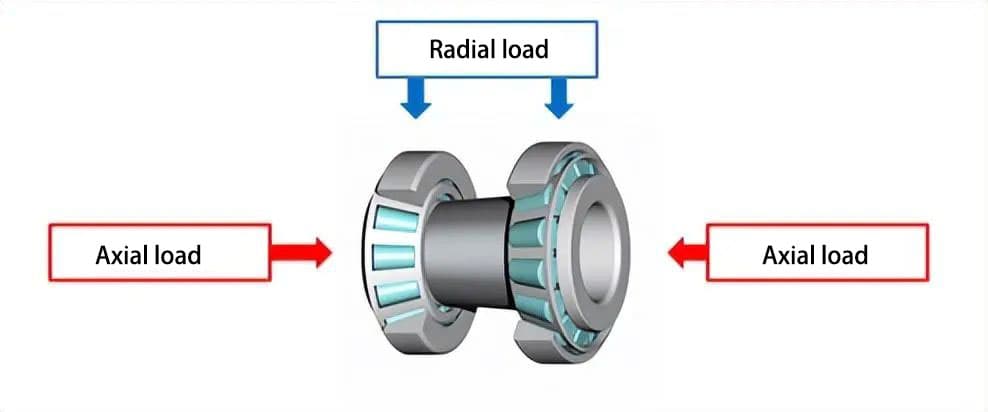

Tapered roller bearings use conical “tapered rollers”.

Tapered roller bearings are widely used in radial roller bearings and can simultaneously withstand radial loads and unidirectional axial loads. When bearing bidirectional axial loads, two or more tapered roller bearings should be combined.

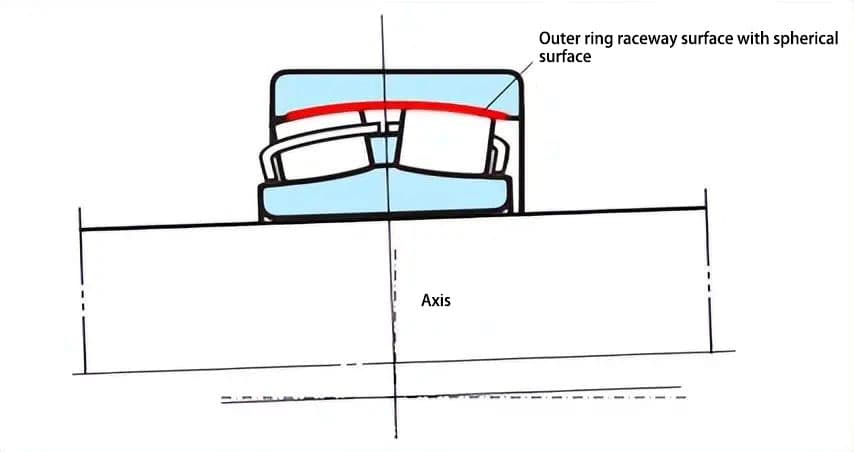

Spherical Roller Bearings

Spherical roller bearings use barrel-shaped “spherical rollers”, as shown in Figure 7, assembled between the “outer ring raceway surface with spherical” and the “inner ring raceway surface”. Therefore, the inner ring, rolling element, and cage of the spherical roller bearing can rotate while tilted to the outer ring.

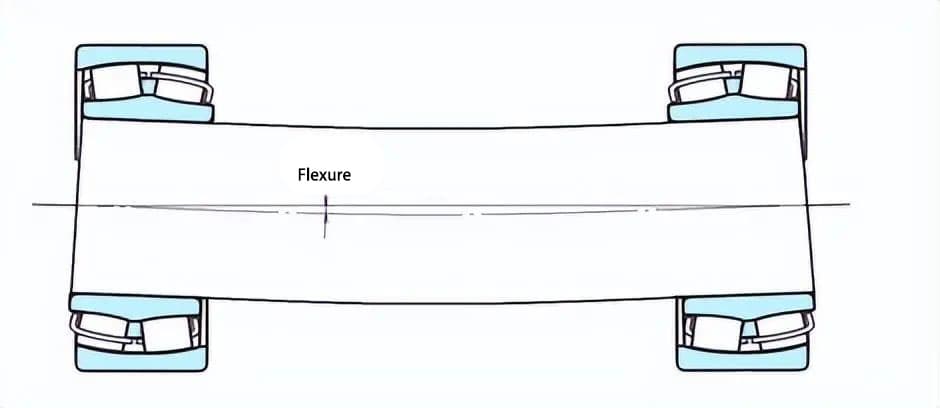

As shown in Figure 8, spherical roller bearings are used in machines that bear large loads and have shafts that are prone to bending. Figure 8: Application of Spherical Roller Bearings.

There are various types of “bearings” available depending on the direction and magnitude of the applied load. The appropriate “bearing” type should be chosen based on the machine structure or usage. In addition to the types introduced here, there are many other “bearing” types.

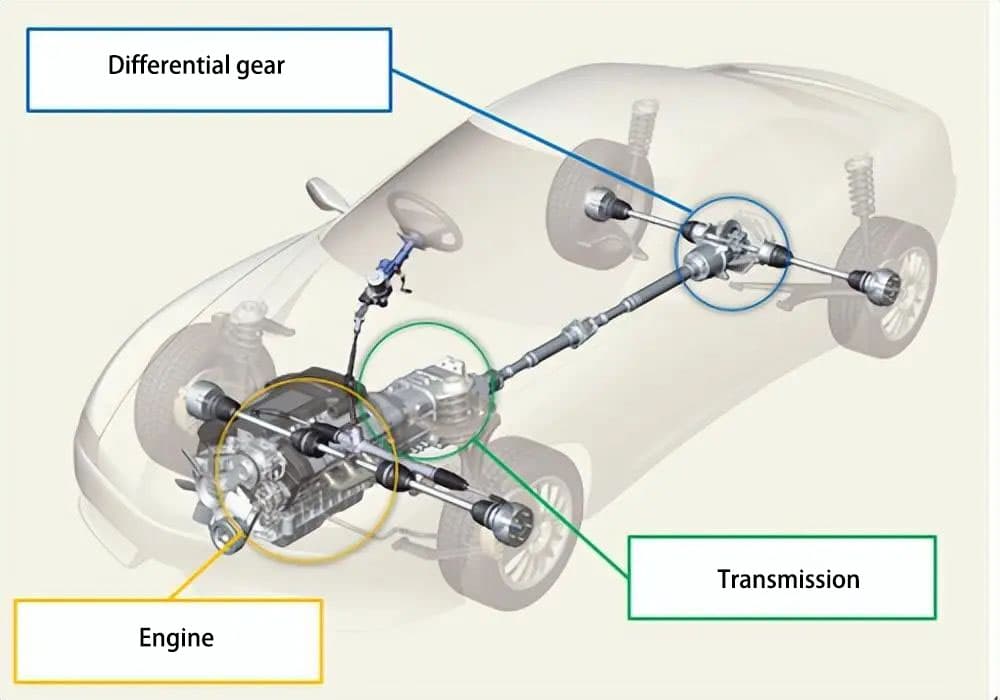

The areas of automotive application for bearings.

In this column, we will explain how bearings are used with the example of the transmission and differential gears that transmit engine power to the vehicle’s axles in automobiles.

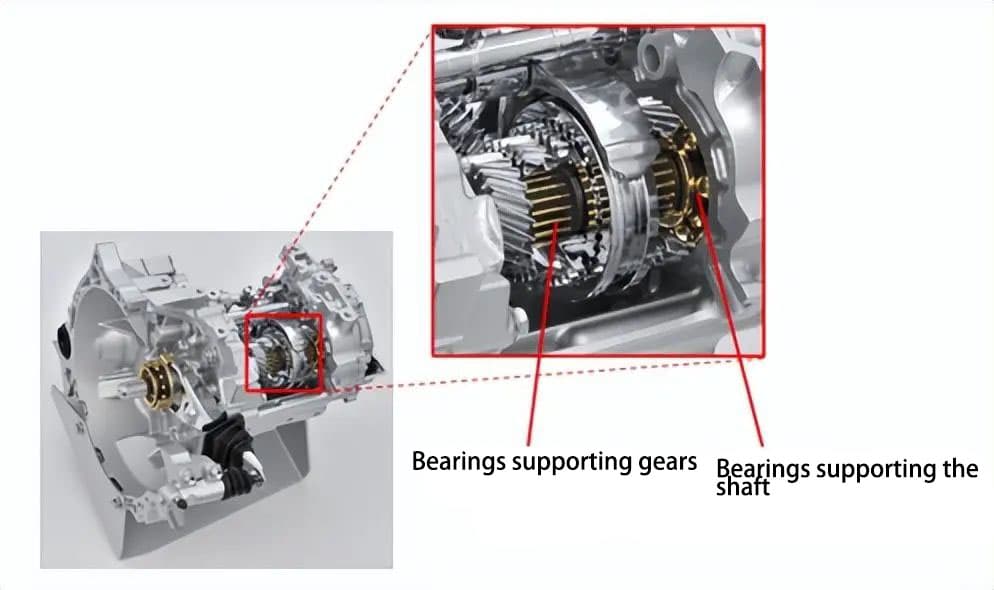

The driving force required for automobiles depends on the driving conditions, such as high-speed driving or the need for greater driving force on slopes, etc. The transmission is a device that converts the engine power into driving force suitable for driving and transmits it to the axle. Inside the transmission, different types of bearings are used to play their respective roles, and many bearings are used in the automobile parts as well.

The transmission can be roughly divided into two types: manual and automatic. In cars that use a manual transmission, the gearshift lever is located on the driver’s side.

The operator manually operates the gearshift lever to convert the engine power into driving force suitable for driving conditions. The manual transmission is composed of shafts and gears. Below, we introduce the bearings that support these components.

Bearings supporting the shafts

Suitable types of bearings are chosen based on the size of the engine’s power to support the rotation of the shaft and the force generated by the gears.

Table 1. Bearings supporting the shafts.

| Radial load | Axial load | Types of bearings |

| Small | Small | Deep groove ball bearing (ball bearing) |

| Large | Small | Cylindrical roller bearing |

| Large | Large | Tapered roller bearing |

Bearings for supporting gears

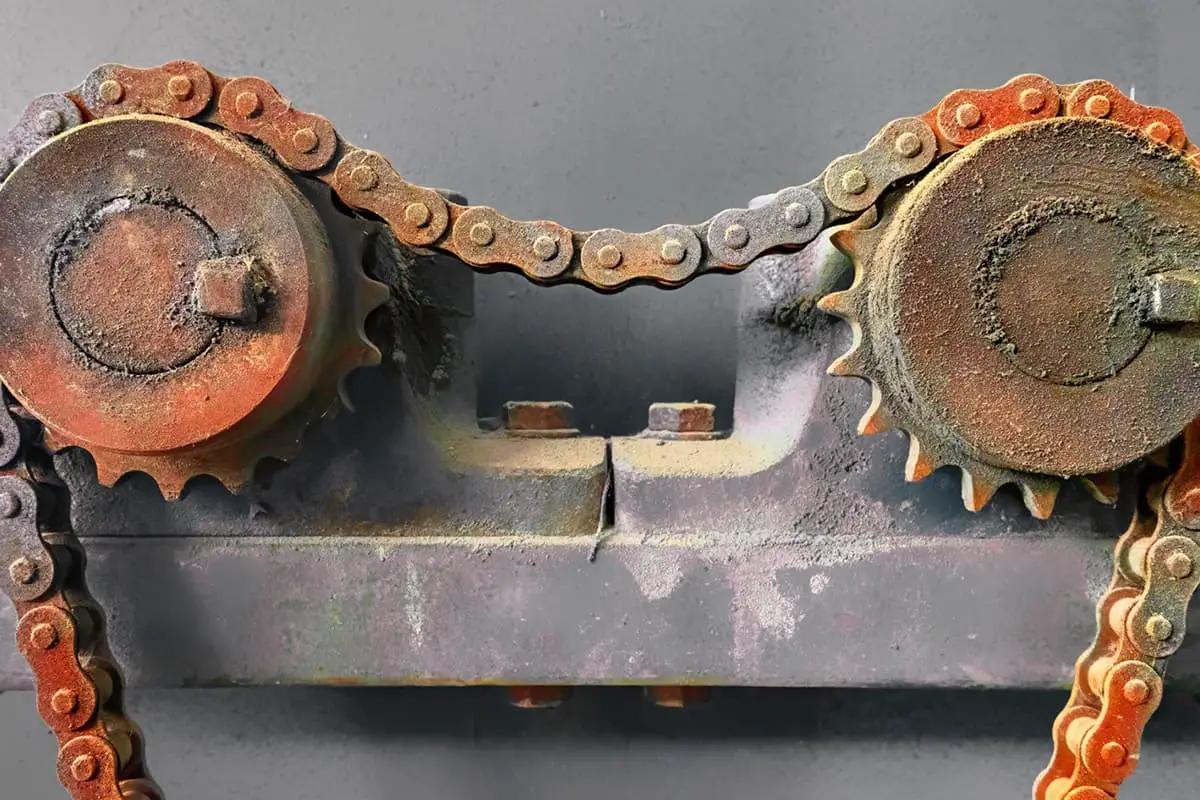

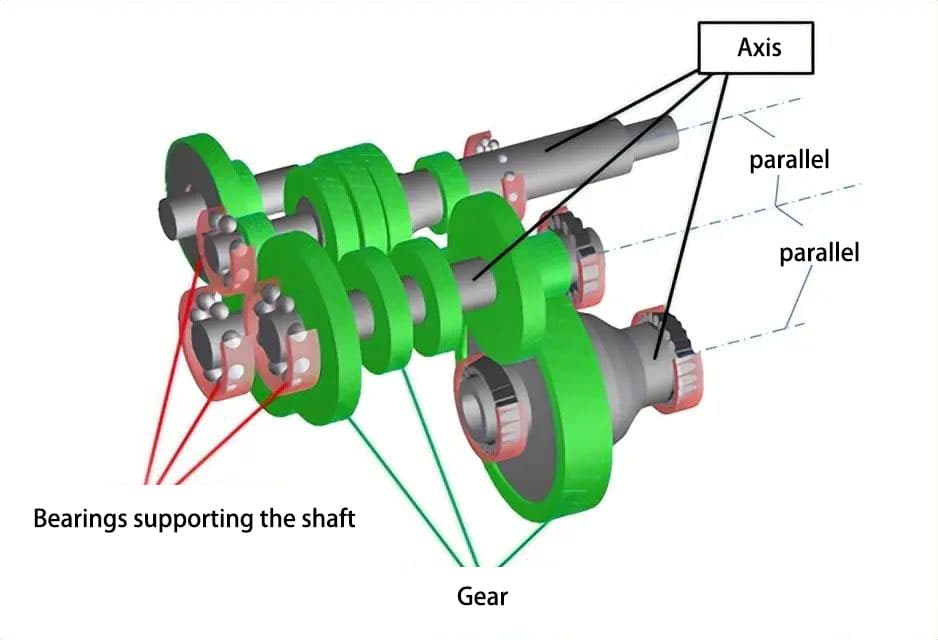

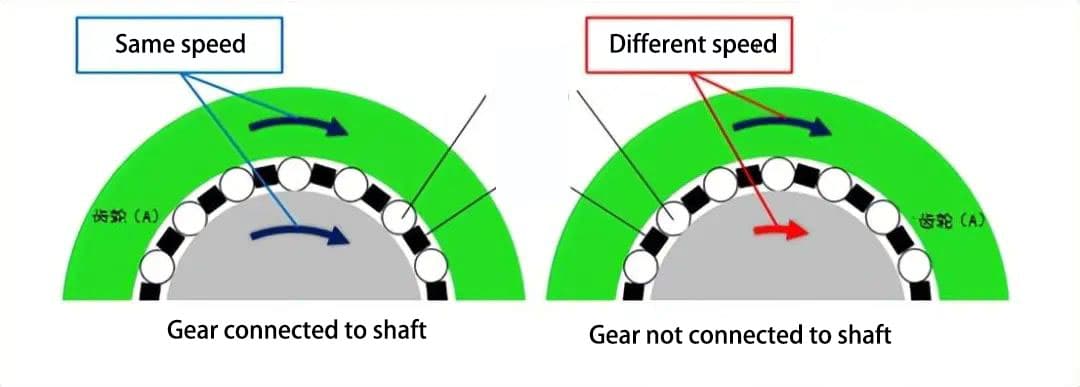

In a manual transmission, gears are always meshing with each other and rotating.

To transmit the driving force suitable for driving, select the appropriate gear (A) by operating the lever. The selected gear (A) is then connected to the shaft and rotates at the same speed as the shaft.

When the driving condition changes and a different driving force needs to be transmitted to the wheels, the gear (A) connected to the shaft is lifted off the shaft by operating the lever and the gear (B) suitable for the different driving force is selected. The selected gear (B) is then connected to the shaft and rotates at the same speed as the shaft.

At this time, the gear (A) that is lifted off the shaft rotates at a different speed compared to the shaft. To allow the gear and shaft to rotate at different speeds, needle roller bearings (components with needle rollers and cages) are installed between the gear’s inner surface (inner side) and the shaft’s outer surface (outer side) to roll between them.

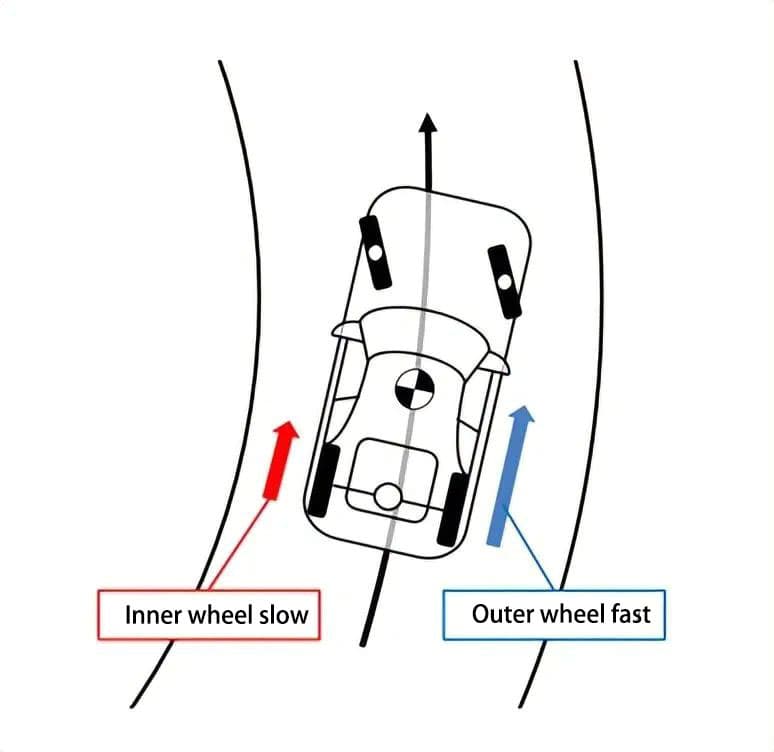

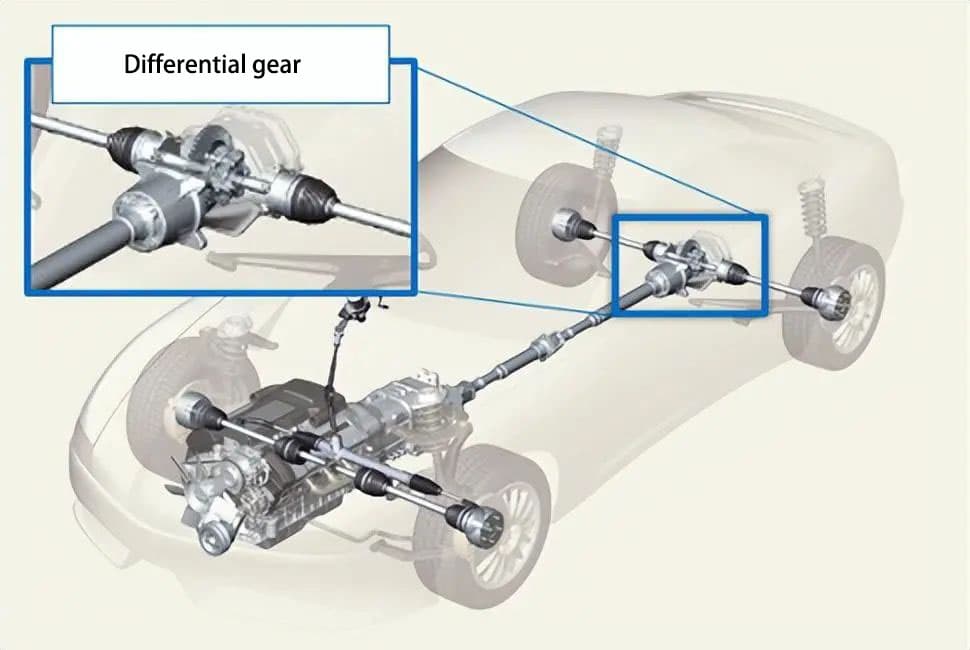

When a car turns left or right, the speed of the inner wheel axle is reduced, while the speed of the outer wheel axle is increased. The differential gear is a device that converts the driving force from the transmission into a larger driving force and transmits it to the left and right wheel axles to achieve different speeds.

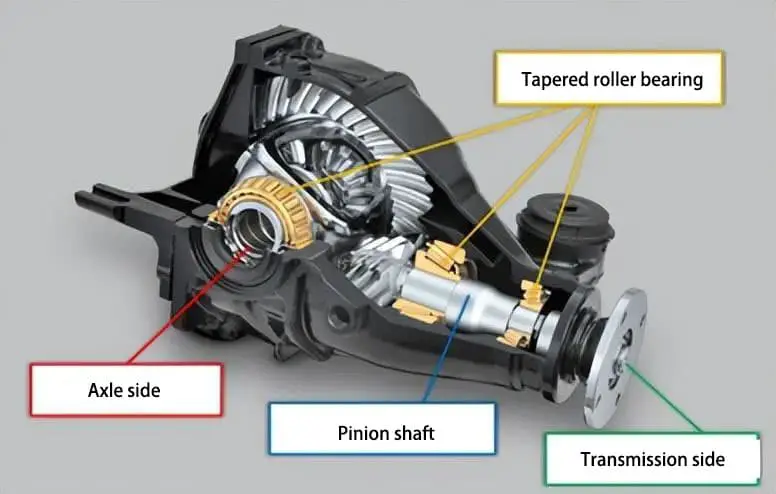

The differential gear is installed with the small gear axle (the shaft on the transmission side) and the gear on the axle side that mesh vertically. The bearings support the rotation of the shaft and the force generated by the gears.

Tapered roller bearings for supporting shaft

The combination of tapered roller bearings supports both radial and bi-directional axial loads, ensuring proper meshing of gears and transmitting large driving forces to the left and right wheel axles.

Summary

This article introduced the bearings used in devices that transmit power from the engine to the wheel axles, but in automobiles, many other parts also use a large number of bearings.

Each bearing plays its own role and improves the driving performance and safety of the vehicle. In order to further improve the safety and comfort of automobiles, the requirements for the performance and reliability of bearings will continue to increase in the future.

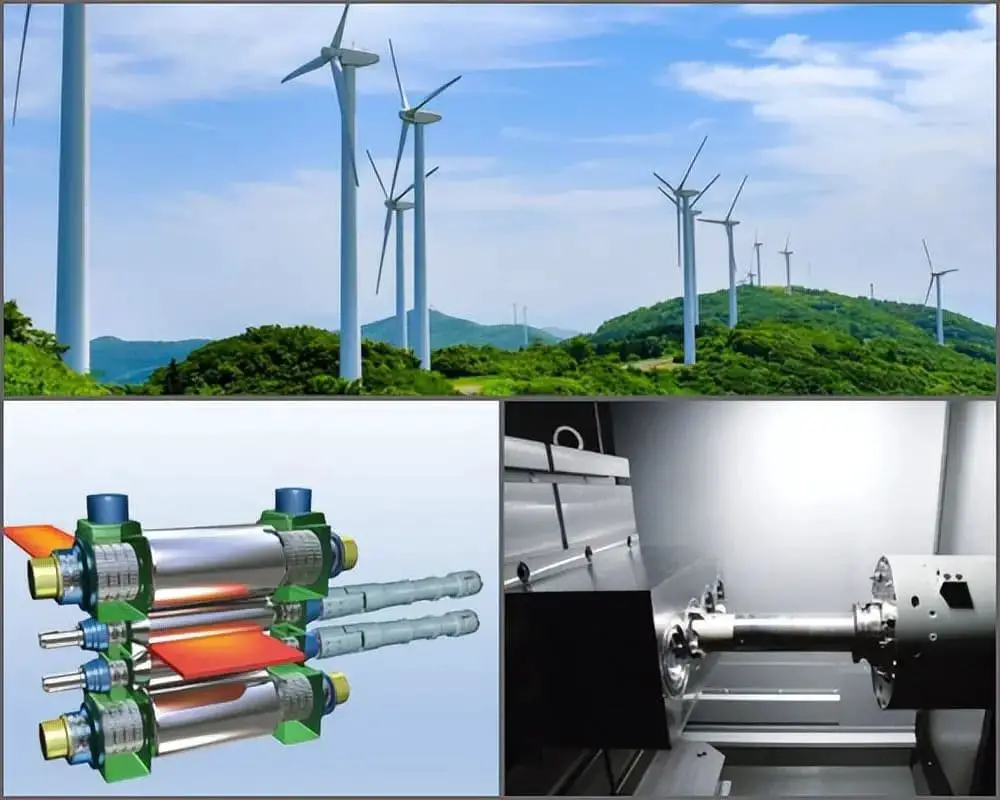

We will introduce the bearings used in machines in the three fields of “energy manufacturing,” “raw material manufacturing,” and “product processing”.

Generators are crucial machines for producing energy to power our daily lives. Wind turbines have gained immense popularity around the world.

However, due to the high installation location of wind turbines, they pose significant challenges in maintenance. Thus the bearings used in wind turbines must possess high reliability with minimal failure rates and long service life.

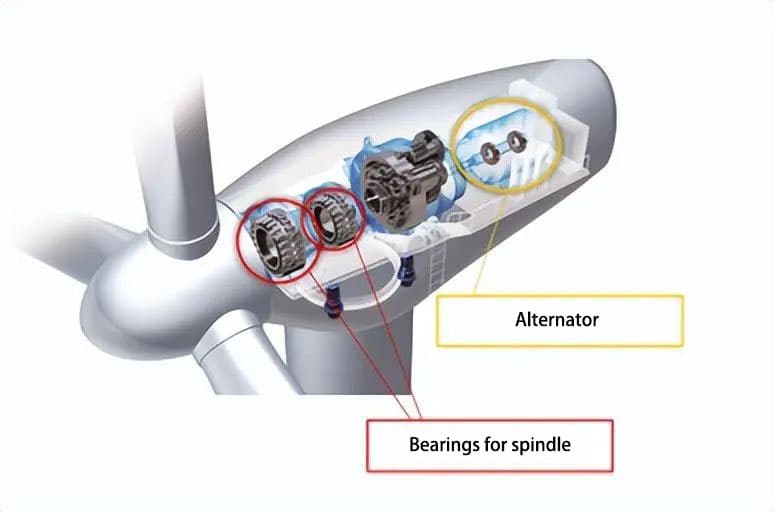

There are many bearings used in wind turbines, and here we will be discussing the main spindle bearings responsible for accepting the rotational force from the wind and transmitting it to the generator.

Main Spindle Bearings

Wind turbines utilize wind power to rotate its main spindle and transmit rotational energy to the generator for power generation.

The main spindle bearing is responsible for supporting the weight of the blades and rotating components while also withstanding irregular wind forces that vary in size and direction. Due to these severe functional requirements, Spherical Roller Bearings are the primary choice for main spindle bearings, known for their ability to support large forces and excellent self-alignment characteristics.

■ What is the self-alignment property?

Self-alignment refers to the quality of the inner ring, rolling elements, and cage to rotate smoothly even when the outer ring is tilted.

To support the significant load, main spindle bearings typically employ large Spherical roller bearings, generally larger than 1 meter in size.

Steel rolling mills are machinery that form the backbone of raw material manufacturing by producing steel materials of various shapes for different uses. Let us introduce this equipment.

Bearings Used in Raw Material Manufacturing – Steel Rolling Mill In a rolling mill, steel materials are pressed and rolled between two counter-rotating rolls.

Furthermore, as the saying goes, “strike while the iron is hot,” steel materials are often rolled at high temperatures. Thus, bearings used in this situation must withstand high temperatures and forces to allow the rollers to rotate.

Work Roll Bearings

Working rolls in steel rolling mills are supported by four-row tapered roller bearings to withstand the extremely high radial loads and two-directional axial loads generated during the rolling process.

Backup Roll Bearings

Despite the tendency for work rolls to deform under the significant loads generated during rolling, backup rolls effectively suppress this phenomenon. Backup rolls use four-row cylindrical roller bearings supporting large radial loads and multi-row tapered roller bearings supporting axial loads.

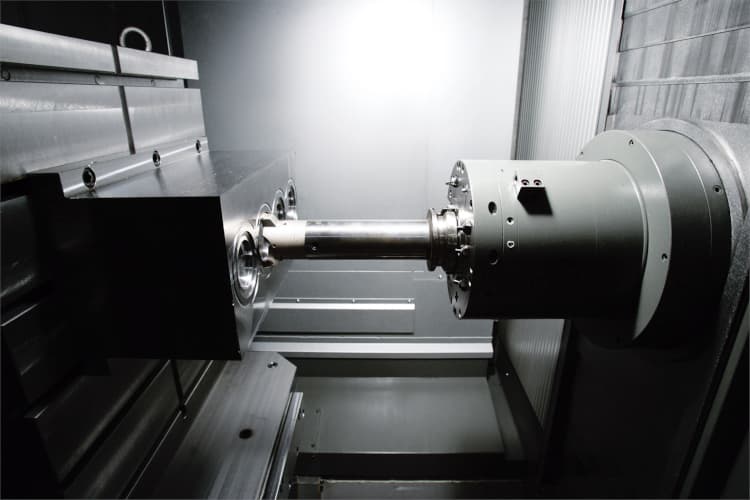

Finally, we will introduce the equipment commonly used in product processing.

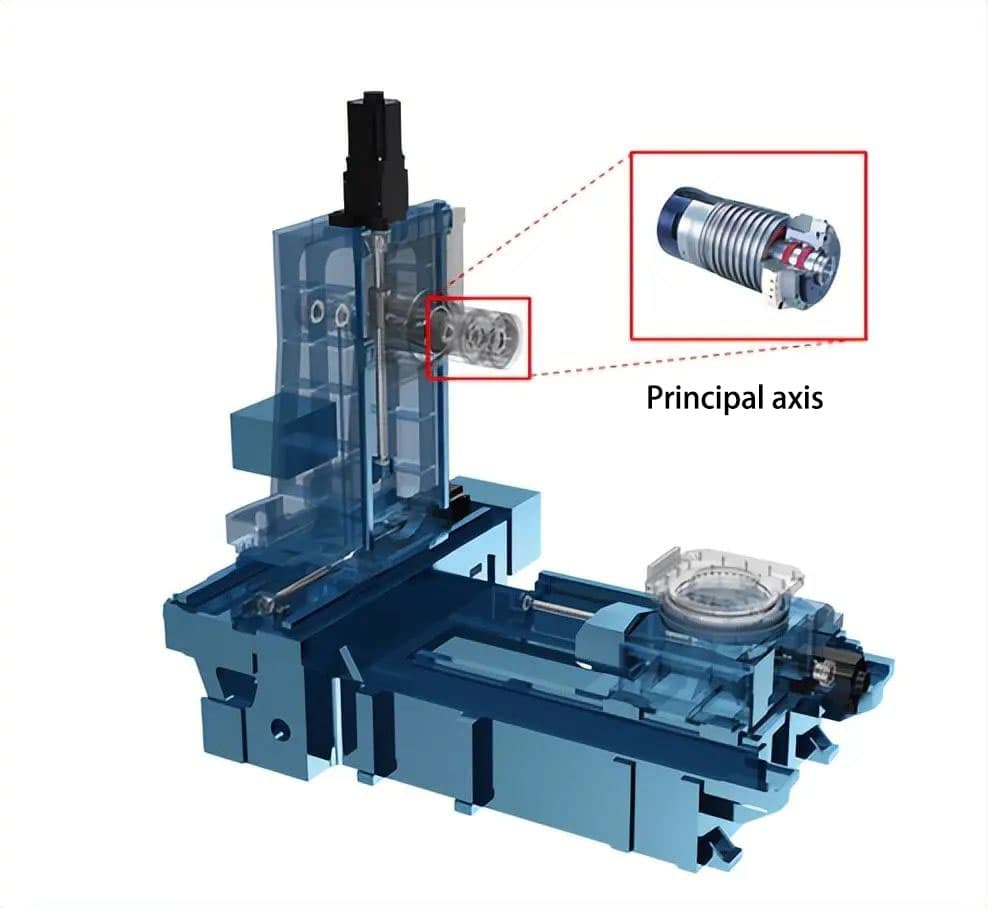

Equipment used for processing various products and parts according to their specific use is known as “machine tools.” In recent years, machining centers that perform computer-controlled processing have increasingly become more popular.

Machining centers can achieve precision and fine processing that is difficult to achieve manually, while significantly reducing processing time.

To avoid changes in workpiece dimensions and reduced processing precision due to heat generated during machining, the main spindles (where the tool is installed) in machining centers require bearings with low thermal expansion properties.

Main Spindle Bearings

The main spindle of a machining center uses angular contact ball bearings to withstand both radial and axial loads during processing.

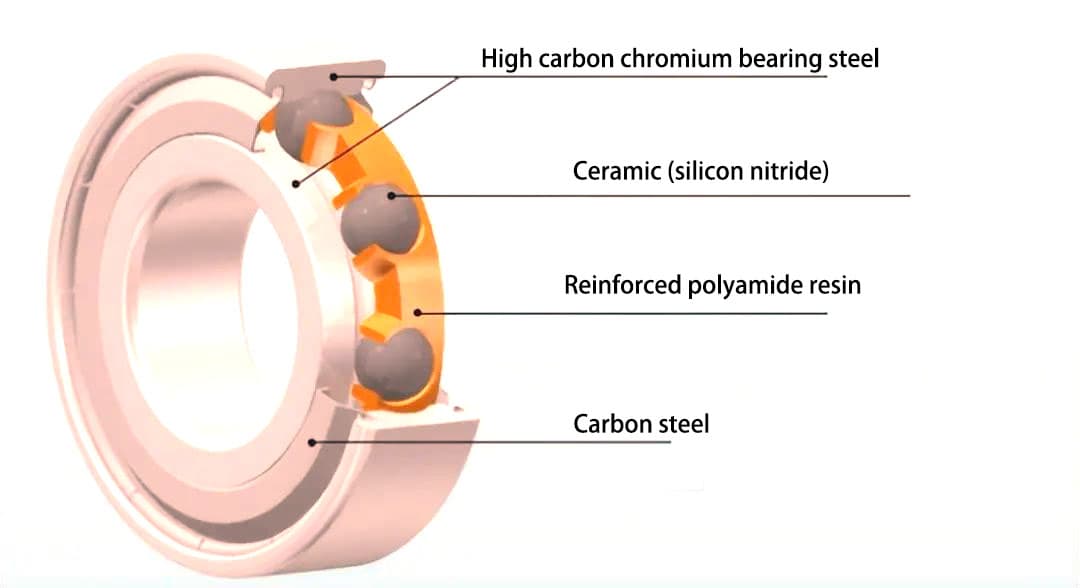

This type of bearing uses ceramics as a bearing material. These ceramic bearings can suppress changes in workpiece sizes by exhibiting low thermal expansion during high-speed rotation.

Moreover, these bearings can supply the necessary lubricant only to the appropriate locations where heat occurs and quickly discharges it, which helps prevent overheating.

Summary: Bearings that Support Our Life

Machines used in manufacturing energy, materials, and products may seem uncommon in our daily lives; however, as we have seen, many bearings support the operation of these machines. These bearings not only support machine rotation but also provide valuable support to our daily activities.

The components of ordinary bearings are made of metal materials and use lubricating oil or grease as lubricants. However, if these ordinary bearings are used in environments where electricity is generated, magnetism is generated, and they are susceptible to corrosion by acid and alkali, they will quickly be damaged and unable to rotate smoothly.

To ensure their use in the above conditions, bearings with special materials and lubricants for special use environments are developed.

The air conditioner outdoor unit is equipped with a fan that sends air outside, and bearings support this fan. In recent years, motors that can control the rotational speed of the fan (frequency conversion) have become more and more prevalent. However, due to its characteristics, the motor can generate voltage from high-frequency current during operation.

When the voltage accumulates to a certain level, the current flows through the inside of the bearing, which may cause bearing failure. This phenomenon is called “electrical erosion.” Therefore, ceramic bearings with excellent insulation performance (not easily conductive) are needed as the rolling elements of the bearing.

In addition, ceramic bearings are also used in critical equipment such as mechanical motors for infrastructure-related facilities and hospitals to prevent sudden equipment failures.

Image 3 – MRI (Magnetic Resonance Imaging Device)

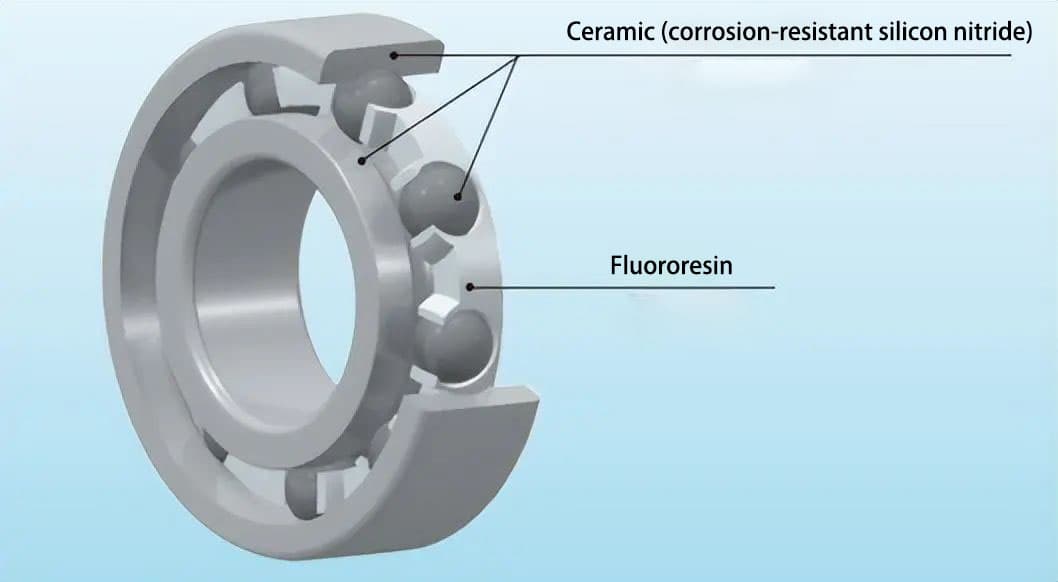

As aging becomes more severe, people’s attention to health is increasing, and medical equipment is constantly increasing worldwide. MRI (Magnetic Resonance Imaging Device) uses strong magnetic force to capture organs and blood vessels for internal examination.

If ordinary bearings are used under the strong magnetism of the MRI, it will interfere with the magnetic field, and precise examination cannot be performed. Additionally, bearings cannot rotate smoothly.

Therefore, when used for MRI, bearings that are not affected by strong magnetism are required.

The raceway ring and rolling elements of the bearing liner use ceramic, which is not easily affected by magnetism. The cage uses resin with excellent lubrication performance, contributing to precise medical examination.

In skateboards used by Olympic athletes, bearings have been newly developed according to the expectations of the athletes. Each of the four wheels of the skateboard uses two bearings (a total of eight).

The skateboard is equipped with bearings that use ceramic balls and have a special surface treatment on the raceway ring and cage, enhancing the feeling of “light and smooth rotation” and “comfortable ride.

Additionally, it enables athletes to maintain speed until the end of the race, allowing them to challenge more difficult skills. Therefore, it contributes to successfully completing difficult skill movements such as the “heel flip.”