Ever wondered why your sheet metal projects don’t always fit together perfectly? The key lies in understanding bend allowance. This concept ensures precise bending and reduces material waste. In this article, you’ll learn how to master bend allowance in SOLIDWORKS, making your designs accurate and efficient. Get ready to transform your sheet metal fabrication process!

Concept of Bend Allowance

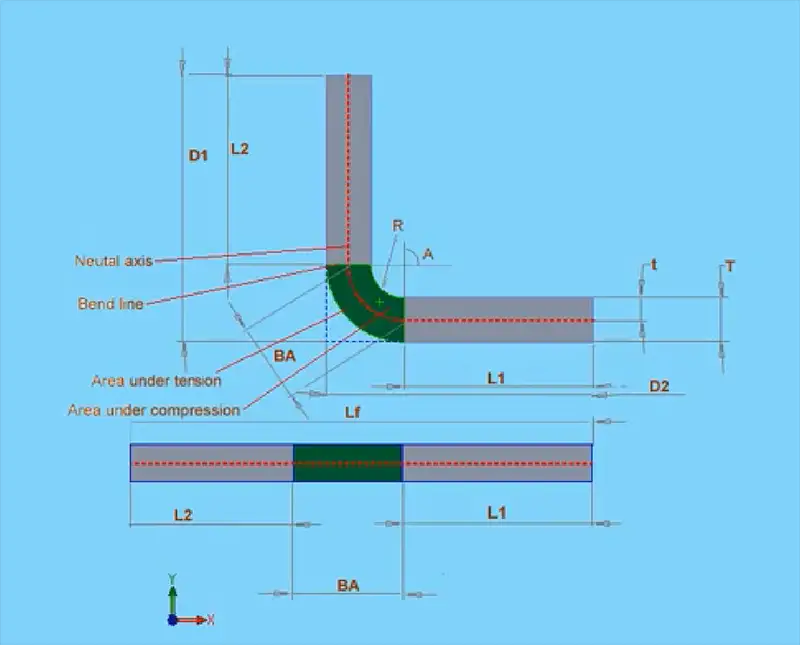

Bend allowance is a crucial parameter in sheet metal fabrication that determines the precise flat length of material required to achieve the desired dimensions after bending. It represents the arc length of the bend measured along the material’s neutral axis—an imaginary line within the bend region where the material neither stretches nor compresses during the bending process.

The calculation of bend allowance is influenced by multiple factors, including sheet metal thickness, bend radius, material properties, and bending angle. In SOLIDWORKS, users can define and manipulate bend allowance values to exert precise control over sheet metal part development, ensuring accuracy in both design and manufacturing stages.

Significance of Bend Allowance

Accurate calculation and application of bend allowance are essential for producing precisely bent sheet metal components. It ensures that the developed (flat) size of the part aligns with the design intent and guarantees that bends will be made at the correct angles and positions. This precision significantly reduces errors, material waste, and rework in the fabrication process, ultimately improving production efficiency and cost-effectiveness.

Understanding and applying appropriate bend allowance values enables designers and fabricators to:

In SOLIDWORKS, proper utilization of bend allowance facilitates more accurate simulations, streamlines the transition from design to manufacturing, and enables the creation of more complex and precise sheet metal components. It also allows for better integration with CNC bending machines and other automated fabrication processes, further enhancing production capabilities and consistency.

Material Properties

Material properties significantly impact bend allowance calculations in SolidWorks. Each metal exhibits unique elastic and plastic deformation characteristics, directly affecting its behavior during bending. For example, aluminum alloys typically have a lower yield strength and higher elasticity compared to steel, resulting in different spring-back effects and bend allowance values. Stainless steel grades, known for their work-hardening properties, require careful consideration to prevent over-bending or under-bending. The material’s Young’s modulus, yield strength, and strain-hardening coefficient are crucial parameters that SolidWorks utilizes to accurately determine bend allowance.

Bend Angle

The bend angle is a critical factor in bend allowance calculations. As the angle increases, the bend allowance generally increases non-linearly due to the complex stress-strain relationships in the material. For instance, a 90-degree bend typically requires more allowance than a 45-degree bend, but not exactly twice as much. SolidWorks employs advanced algorithms that account for this non-linear relationship, considering factors such as neutral axis shift and material thinning at the bend. The software allows designers to fine-tune bend angles and automatically recalculates allowances, ensuring precision in complex sheet metal assemblies.

Material Thickness

Material thickness plays a pivotal role in bend allowance determination. Thicker materials not only require larger bend allowances but also exhibit more complex bending behavior. As thickness increases, the neutral axis location shifts, affecting the overall bend geometry. SolidWorks incorporates sophisticated models that account for this shift, ensuring accurate allowance calculations across a wide range of thicknesses. Additionally, the software considers the k-factor (a ratio representing the location of the neutral axis) which varies with material thickness and bending method. This enables precise modeling of thin-gauge materials used in electronics enclosures as well as thick plates employed in heavy machinery components.

Bend Deduction, or BD, is a terminology used in sheet metal fabrication. It refers to the difference between the bend allowance and twice the outside setback in the material. This value is a key consideration when determining the overall flat length of sheet metal parts during the bending process. It helps fabricators create accurate sheet metal components that adhere to desired dimensions.

When working with SOLIDWORKS, designers have options to choose between using bend allowance and bend deduction values in their sheet metal designs. Both are useful for determining the final flat pattern of the sheet metal part and are essential for accurate manufacturing.

Bend allowance is the arc length of the bend as measured along the neutral axis of the material. It represents the length of the sheet metal being stretched or compressed during the bending process. The neutral axis refers to the region in the material where there is no stress or strain.

| Parameter | Description |

|---|---|

| Bend Allowance | Arc length of the bend along the neutral axis of the material |

| Bend Deduction | Difference between the bend allowance and twice the outside setback |

| BD | Bend Deduction abbreviation |

When using SOLIDWORKS, it is essential to input the correct bend allowance value or bend deduction value, depending on the selected method. This ensures that the final sheet metal part will have the desired dimensions and fit properly in assemblies.

Both methods have their benefits and considerations. Bend allowance calculations give a more accurate representation of the bending process and consider material behavior during bending. Bend deduction simplifies the calculation process and is easier to understand for those new to sheet metal design.

In conclusion, understanding the differences between bend allowance and bend deduction is crucial for accurate sheet metal design within SOLIDWORKS. Accurate input of these values ensures that the final sheet metal component adheres to design specifications and fits seamlessly in the desired assembly.

You can directly use our bend allowance calculator to calculate the bending allowance. Besides, the fabrication calculator can also help you calculate K-factor, Y-factor, bend allowance, bend deduction, etc.

You may be wondering what exactly bend allowance is if you’ve never worked with sheet metal before.

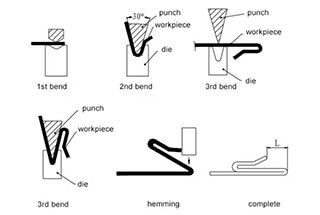

When a sheet is bent in a press brake, the part of the sheet close to and in contact with the punch elongates to compensate for the given bend.

If you compare the length of this part before and after the bending, you’ll find that they’re different.

As an engineer, if you don’t compensate for this variation, the final product won’t have accurate dimensions.

This is more critical for parts where you have to maintain a tighter allowance or precision.

In this post, I cover some of the basic problems and principles you have to deal with regularly when working with sheet metal.

Before we get started, I want to comment on something – there is not really a scientific method or formula for determining the exact calculation of the bend allowance, because there are so many factors at play during the production of your sheet metal part.

For example, actual material thickness, an infinite variety of tooling conditions, forming methods, and so on.

There are many variables here, and in reality, many methods are used to calculate the bend allowance.

Trial and error is probably the most popular method, while bend tables are another commonly used technique.

Bend tables are typically available from metal suppliers, manufacturers, and engineering textbooks. Some companies develop their own bending tables based on their standard formulas.

Now, let’s return to Solidworks. How does Solidworks calculate bend allowance exactly? Solidworks uses two methods: bend allowance and bend deduction.

I’m going to explain what these methods are and show you how they are used in Solidworks.

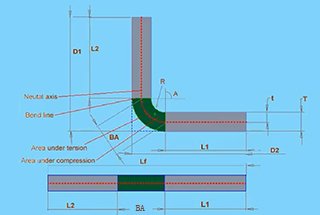

The bend allowance method is based on the formula that appears in my diagram.

The total length of the flattened sheet is equal to the sum of L1 (the first length), L2, and the bend allowance.

The bend allowance region is shown in green on my diagram. This is the region where all deformation occurs during the bending process.

Generally, the bend allowance will be different for each combination of material type, material thickness, bend radius, bend angle, and different machining processes, types, speeds, and so on. The list of potential variables is extensive.

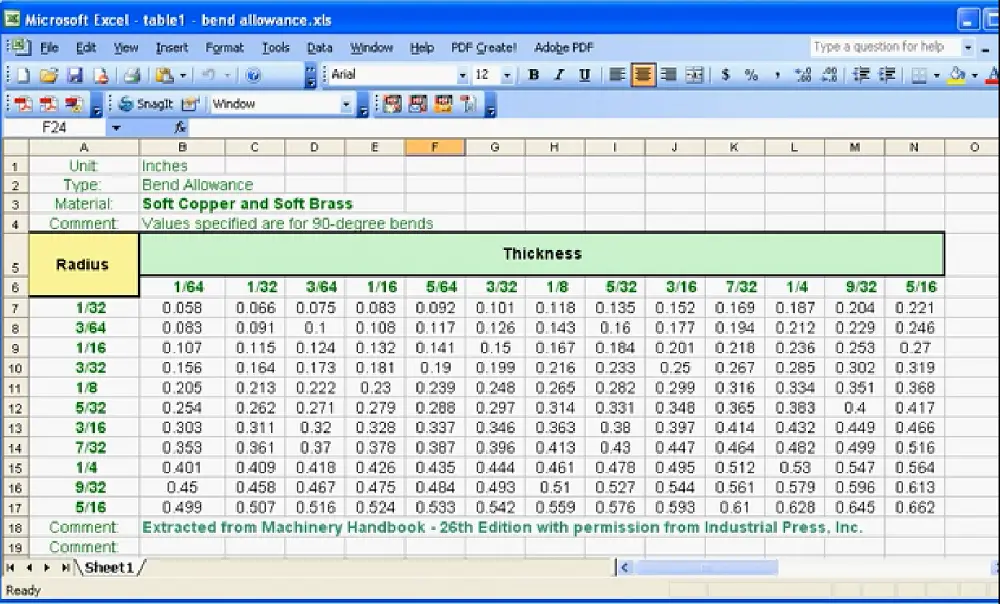

The value of the bend allowance from sheet metal suppliers, manufacturers, and engineering textbooks is provided in bend tables. A bend table looks like the following Excel spreadsheet.

The bend table approach is probably the most accurate method for calculating bend allowance.

You can input your data manually into a matrix of the bend angle and bend radius. If you are not sure of the bend allowance value, you can run some tests.

You need a piece of the exact same sheet metal you will use to manufacture your part, and then you bend it using the same processes you will use during your machining. Simply take some measurements before and after bending, and based on the same information, you can adjust the necessary bend allowance.

Another method that Solidworks uses is the bend deduction method.

The formula is as follows:

The flattened length of the parts, Lf, equals D1 plus D2 minus the bend deduction.

Like bend allowance, bend deduction comes from the same sources: tables and manual testing.

As you can see, it is easy to understand how these values are related to each other based on the information provided by these formulas.

Another method for calculating bend allowance uses the K-factor.

K represents the neutral axis offset.

The general principle of this formula is as follows: the neutral axis (shown in red in my diagram) does not change during the bending process. During the bending process, the material inside the neutral axis will compress, and the material outside the neutral axis will stretch. The neutral axis will be closer to the inside bend (indicated in blue in the diagram). The more the part bends, the closer the neutral axis will be to the inside of the part.

The bend allowance calculation formula with the K-factor is shown below:

BA = 2πA(R+KT)/360

The K-factor equals t, which is the offset distance to the neutral axis, divided by big T, which is the thickness of the material.

In this formula, the bend allowance equals 2 times pi multiplied by A (the angle) multiplied by the sum of R (the bend radius) and the K-factor multiplied by T (the thickness of the material). Then, you divide all of this by 360.

In theory, the K-factor can be anywhere between 0 and 1, but for practical purposes, it is typically between 0.25 and 0.5.

For example, hard materials like steel have a higher K-factor, such as 0.5, while soft materials like copper or brass will have a lower K-factor closer to 0.

And don’t worry, this is the last formula we will be walking through in this lesson. It might seem a little confusing now, but with some practice, it will become second nature.

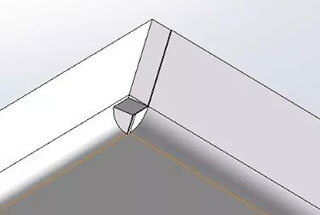

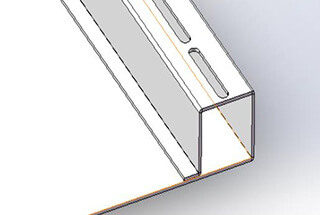

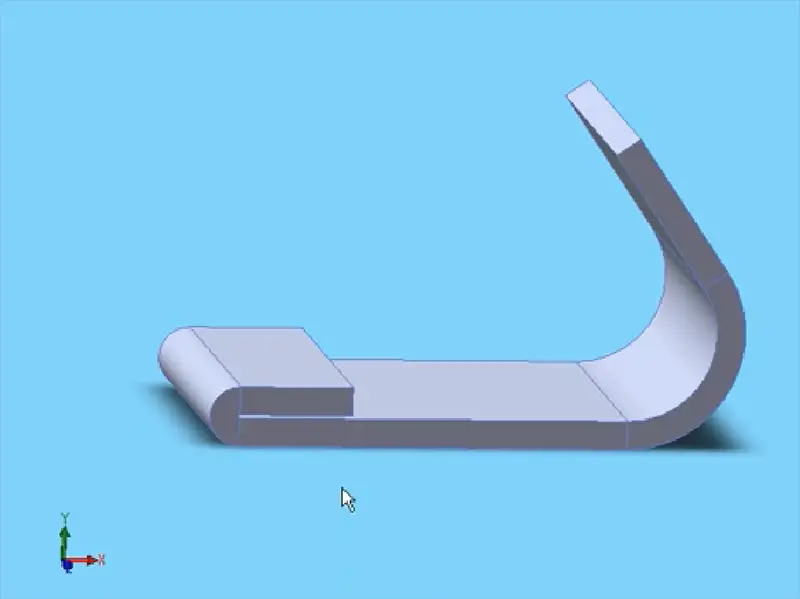

One last point: let’s take a look at the example. There is a hem on this part that has a K-factor of around 0.3. On the other hand, a soft bend, such as the gradual bend on the other side of this part, has a higher K-factor of about 0.5. And this concludes our lesson on bend allowance.

Further reading: