Have you ever wondered how sheet metal parts are designed and manufactured with precision? In this blog post, we’ll dive into the fascinating world of bend allowance – a crucial concept in sheet metal fabrication. As an experienced mechanical engineer, I’ll share my insights and explain how bend allowance enables designers to create accurate flat patterns for bending operations. By the end of this article, you’ll have a solid understanding of bend allowance and its importance in producing high-quality sheet metal components.

Bend allowance is a critical concept in sheet metal fabrication, particularly in the design and manufacturing of press-bent parts. It refers to the additional length of material required to accommodate a bend in the sheet metal. This allowance ensures that the final dimensions of the bent part match the design specifications after bending.

Bend allowance is not merely statistical data; it is derived from empirical measurements and calculations accumulated by experienced mold designers over years of practice. This data is essential for accurately determining the unfolded or flat dimensions of sheet metal parts before bending. By incorporating bend allowance into their calculations, mold designers can predict the final dimensions of a part with high precision.

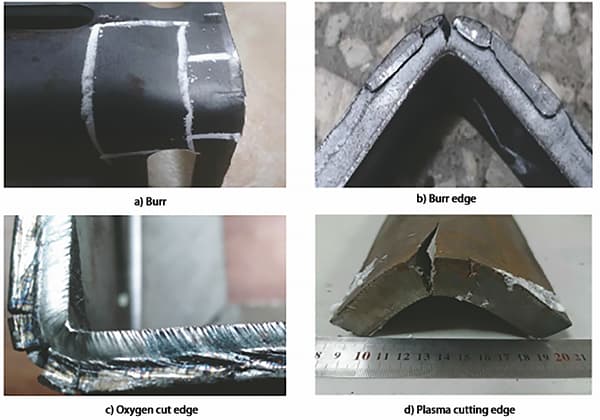

One of the biggest challenges in sheet metal fabrication is ensuring the accuracy of the unfold dimensions after bending. This involves accounting for various factors such as material type, thickness, bend radius, and bend angle. Accurate bend allowance calculations are essential to avoid discrepancies between the designed and manufactured parts.

Bend allowance is a fundamental tool for mold designers in the sheet metal industry. It allows for precise calculation of the unfold dimensions of press-bent parts, ensuring that the final product meets the design specifications and quality standards. By understanding and applying bend allowance correctly, designers can overcome the challenges associated with bending and achieve high precision in their work.

Bend allowance (BA) is crucial in sheet metal fabrication, as it measures the arc length of the neutral axis between bend lines. This calculation helps determine the exact length of material required for a bend. The formula for bend allowance is:

Here’s an example with the following parameters:

Convert the bend angle to radians:

Calculate the term

Apply the bend allowance formula:

This calculation indicates that the bend allowance for the given parameters is approximately 2.945 mm.

Consider variability in material properties and bending processes. Factors like tooling, bend method, and material type affect the K-factor and bend allowance. Perform experimental validations or consult material data sheets for accurate K-factor values.

After learning about bend allowance, the next step is to calculate it. Bend allowance is a critical factor in sheet metal fabrication, as it determines the amount of material needed to accommodate a bend. This ensures that the final dimensions of the part are accurate after bending.

One of the easiest ways to calculate bend allowance is by using a bend allowance calculator. These calculators are designed to quickly and accurately compute the bend allowance based on the input parameters such as material type, thickness, bend angle, and bend radius.

In addition to a dedicated bend allowance calculator, the above calculator can also assist in calculating various parameters related to sheet metal bending, including:

For those interested in a deeper understanding of how to calculate bend allowance manually, we have a detailed analysis available in one of our blog posts. This post covers the step-by-step method to calculate bend allowance, including the formulas and factors involved.

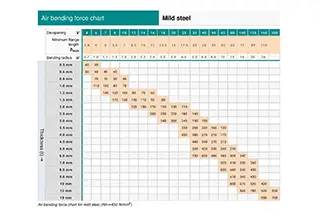

Bend allowance charts provide specific values for bend allowance based on material type, thickness, bend angle, and inside radius. These charts simplify the calculation process and ensure accurate bends.

| Material | Thickness | Deduction | Inside R | Angle | Die | Punch | ||

|---|---|---|---|---|---|---|---|---|

| R | V Width | R | Angle | |||||

| Steel Plate | 0.8 | 1.5 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° |

| 0.9 | 1.7 | 1.3 | 90° | 0.5 | 6 | 0.2 | 88° | |

| 1 | 1.8 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.2 | 1.91 | 1 | 90° | 0.4 | 6 | 0.2 | 88° | |

| 1.2 | 2.1 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.5 | 2.5 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| Cold Rolled Plate | 1.6 | 2.65 | 1.3 | 90° | 0.5 | 8 | 0.6 | 88° |

| 1.8 | 3.4 | 2 | 90° | 0.8 | 12 | 0.6 | 88° | |

| 2 | 3.5 | 2 | 90° | 0.8 | 12 | 0.6 | 88° | |

| 2.3 | 3.75 | 2 | 90° | 0.8 | 12 | 0.6 | 88° | |

| 2.5 | 4.2 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3 | 5.05 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 4 | 6.9 | 4 | 90° | 0.8 | 25 | 0.6 | 88° | |

| Hot Rolled Plate | 2.3 | 3.77 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° |

| 3.2 | 5.2 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 4.2 | 7.4 | 4 | 90° | 0.8 | 25 | 0.6 | 88° | |

| 4.8 | 8.1 | 4 | 90° | 0.8 | 25 | 0.6 | 88° | |

| Aluminum Plate | 0.8 | 1.5 | 1.3 | 90° | 0.5 | 6 | 0.2 | 88° |

| 1 | 1.6 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.2 | 2.1 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.5 | 2.45 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.6 | 2.7 | 1.3 | 90° | 0.5 | 8 | 0.6 | 88° | |

| 1.6 | 2.4 | 1.3 | 90° | 0.6 | 10 | 0.6 | 88° | |

| 2 | 3.25 | 2 | 90° | 0.8 | 12 | 0.6 | 88° | |

| 2.3 | 3.6 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 2.5 | 4.2 | 2.6 | 90° | 0.5 | 16 | 0.6 | 88° | |

| 3 | 4.7 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3.2 | 5 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3.5 | 5.9 | 4 | 90° | 0.8 | 25 | 1.5 | 88° | |

| 4 | 6.8 | 4 | 90° | 0.8 | 25 | 1.5 | 88° | |

| 5 | 8.1 | 4 | 90° | 0.8 | 25 | 3.2 | 88° | |

| Copper Plate | 0.8 | 1.6 | 1.3 | 90° | 0.5 | 6 | 0.2 | 88° |

| 1 | 1.9 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.2 | 2.15 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.5 | 2.55 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 2 | 3.5 | 2 | 90° | 0.8 | 12 | 0.6 | 88° | |

| 2.5 | 4.2 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3 | 5 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3.2 | 5.1 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3.5 | 6 | 4 | 90° | 0.8 | 25 | 1.5 | 88° | |

| 4 | 7 | 4 | 90° | 0.8 | 25 | 1.5 | 88° | |

| T | Cold-rolled steel sheet SPCC (electro-galvanized sheet SECC) | ||||||||||||||

| V | Angle | 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | Min dimension | Note |

| V4 | 90 | 0.9 | 1.4 | 2.8 | |||||||||||

| 120 | 0.7 | ||||||||||||||

| 150 | 0.2 | ||||||||||||||

| V6 | 90 | 1.5 | 1.7 | 2.15 | 4.5 | ||||||||||

| 120 | 0.7 | 0.86 | 1 | ||||||||||||

| 150 | 0.2 | 0.3 | 0.4 | ||||||||||||

| V7 | 90 | 1.6 | 1.8 | 2.1 | 2.4 | 5 | |||||||||

| 120 | 0.8 | 0.9 | 1 | ||||||||||||

| 150 | 0.3 | 0.3 | 0.3 | ||||||||||||

| V8 | 90 | 1.6 | 1.9 | 2.2 | 2.5 | 5.5 | |||||||||

| 30 | 0.3 | 0.34 | 0.4 | 0.5 | |||||||||||

| 45 | 0.6 | 0.7 | 0.8 | 1 | |||||||||||

| 60 | 1 | 1.1 | 1.3 | 1.5 | |||||||||||

| 120 | 0.8 | 0.9 | 1.1 | 1.3 | |||||||||||

| 150 | 0.3 | 0.3 | 0.2 | 0.5 | |||||||||||

| V10 | 90 | 2.7 | 3.2 | 7 | |||||||||||

| 120 | 1.3 | 1.6 | |||||||||||||

| 150 | 0.5 | 0.5 | |||||||||||||

| V12 | 90 | 2.8 | 3.65 | 4.5 | 8.5 | ||||||||||

| 30 | 0.5 | 0.6 | 0.7 | ||||||||||||

| 45 | 1,0 | 1.3 | 1.5 | ||||||||||||

| 60 | 1.7 | 2 | 2.4 | ||||||||||||

| 120 | 1.4 | 1.7 | 2 | ||||||||||||

| 150 | 0.5 | 0.6 | 0.7 | ||||||||||||

| V14 | 90 | 4.3 | 10 | ||||||||||||

| 120 | 2.1 | ||||||||||||||

| 150 | 0.7 | ||||||||||||||

| V16 | 90 | 4.5 | 5 | 11 | |||||||||||

| 120 | 2.2 | ||||||||||||||

| 150 | 0.8 | ||||||||||||||

| V18 | 90 | 4.6 | 13 | ||||||||||||

| 120 | 2.3 | ||||||||||||||

| 150 | 0.8 | ||||||||||||||

| V20 | 90 | 4.8 | 5.1 | 6.6 | 14 | ||||||||||

| 120 | 2.3 | 3.3 | |||||||||||||

| 150 | 0.8 | 1.1 | |||||||||||||

| V25 | 90 | 5.7 | 6.4 | 7 | 17.5 | ||||||||||

| 120 | 2.8 | 3.1 | 3.4 | ||||||||||||

| 150 | 1 | 1 | 1.2 | ||||||||||||

| V32 | 90 | 7.5 | 8.2 | 22 | |||||||||||

| 120 | 4 | ||||||||||||||

| 150 | 1.4 | ||||||||||||||

| V40 | 90 | 8.7 | 9.4 | 28 | |||||||||||

| 120 | 4.3 | 4.6 | |||||||||||||

| 150 | 1.5 | 1.6 | |||||||||||||

| T | Aluminum sheet L2Y2 material | ||||||||||||||

| V | Angle | 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | Min dimension | Note |

| V4 | 1.4 | 2.8 | |||||||||||||

| V6 | 1.6 | 4.5 | |||||||||||||

| V7 | 1.6 | 1.8 | 5 | ||||||||||||

| V8 | 1.8 | 2.4 | 3.1 | 5.5 | |||||||||||

| V10 | 2.4 | 3.2 | 7 | ||||||||||||

| V12 | 2.4 | 3.2 | 8.5 | ||||||||||||

| V14 | 3.2 | 10 | |||||||||||||

| V16 | 3.2 | 4 | 4.8 | 11 | |||||||||||

| V18 | 4.8 | 13 | |||||||||||||

| V20 | 4.8 | 14 | |||||||||||||

| V25 | 4.8 | 5.4 | 6 | 17.5 | |||||||||||

| V32 | 6.3 | 6.9 | 22 | ||||||||||||

| T | Copper sheet | ||||||||||||||

| V | Angle | 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | Min dimension | Note |

| 90 | 3.6 | 5.2 | 6.8 | 8.4 | 28 | ||||||||||

| 120 | |||||||||||||||

| 150 | |||||||||||||||

Note: (For C-shaped profiles with a thickness of 2.0, the V12 coefficient is 3.65, while other 2.0 sheet materials have a coefficient of 3.5.) The bending allowance coefficient for 2.0 sheet with hemming is 1.4.

| MATERLAL | SPCC | SUS | LY12 | SECC | ||||

| T | ΔT | ΔK | ΔT | ΔK | ΔT | ΔK | ΔT | ΔK |

| T=0.6 | 1.25 | 1.26 | ||||||

| T=0.8 | 0.18 | 1.42 | 0.15 | 1.45 | 0.09 | 1.51 | ||

| T=1.0 | 0.25 | 1.75 | 0.2 | 1.8 | 0.3 | 1.7 | 0.38 | 1.62 |

| T=1.2 | 0.45 | 1.95 | 0.25 | 2.15 | 0.5 | 1.9 | 0.43 | 1.97 |

| T=1.4 | 0.64 | 2.16 | ||||||

| T=1.5 | 0.64 | 2.36 | 0.5 | 2.5 | 0.7 | 2.3 | ||

| T=1.6 | 0.69 | 2.51 | ||||||

| T=1.8 | 0.65 | 3 | ||||||

| T=1.9 | 0.6 | 3.2 | ||||||

| T=2.0 | 0.65 | 3.35 | 0.5 | 3.5 | 0.97 | 3.03 | 0.81 | 3.19 |

| T=2.5 | 0.8 | 4.2 | 0.85 | 4.15 | 1.38 | 3.62 | ||

| T=3.0 | 1 | 5 | 5.2 | 1.4 | 4.6 | |||

| T=3.2 | 1.29 | 5.11 | ||||||

| T=4.0 | 1.2 | 6.8 | 1 | 7 | ||||

| T=5.0 | 2.2 | 7.8 | 2.2 | 7.8 | ||||

| T=6.0 | 2.2 | 9.8 | ||||||

| Aluminum sheet thickness | Bending angle | Bend allowance |

| AL-0.8 | 90 | 1.5 |

| AL-1.0 | 90 | 1.5 |

| 45, 135 | 0.5 | |

| AL-1.2 | 90 | 2.0 |

| 45, 135 | 0.5 | |

| AL-1.5 | 90 | 2.5 |

| 45, 135 | 0.5 | |

| 60, 120 | 1.5 | |

| AL-2.0 | 90 | 3.0 |

| 45, 135 | 1.0 | |

| 60, 120 | 2.5 | |

| 90-degree groove | 1.5 | |

| AL-2.5 | 90 | 4.0 |

| 45, 135 | 1.5 | |

| 60, 120 | 3.0 | |

| 90-degree groove | 2.0 | |

| AL-3.0 | 90 | 5.0 |

| 45, 135 | 3.0 | |

| 60, 120 | 4.5 | |

| 90-degree groove | 2.5 |

1) The bending allowance table is applicable for sheet metal bending processes where no pressure plate is used, and the width of the plate is greater than three times the thickness.

2) When bending on a press brake machine, calculations can be made according to this table.

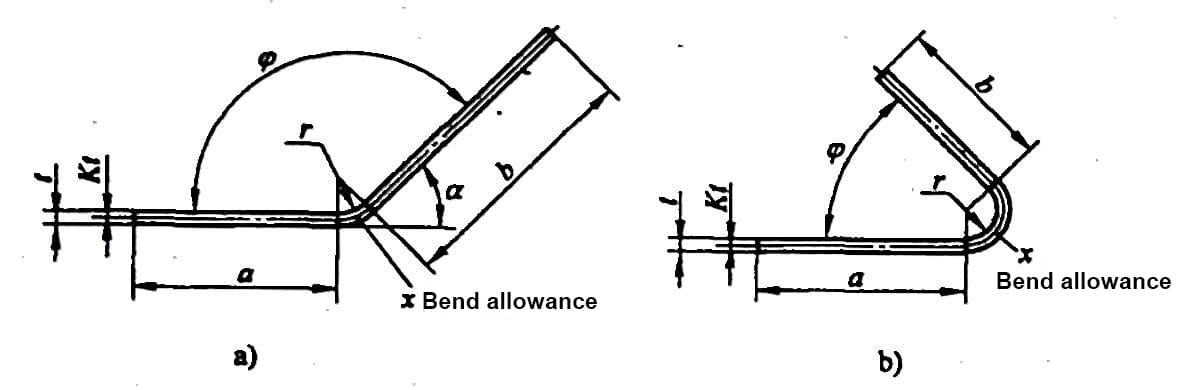

3) As per the dimensions marked in the diagram, the calculation formula for the unfolded dimensions of the bent workpiece is as follows:

L = a + b + x

In this equation,

4) Due to the numerous factors affecting sheet metal bending, this bending allowance table for sheet metal bending should be used as a reference only.

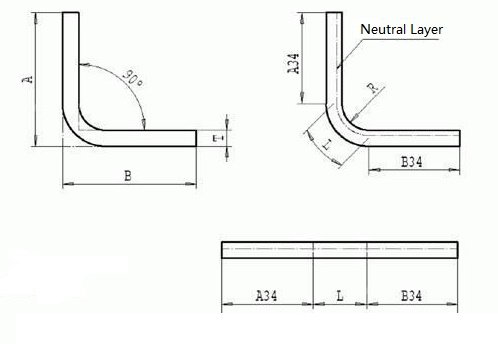

Bend forming 0°L=A+B-0.43T, T=Thickness, Deduction=0.43T

Formula: L(unfold length)=A(Outside size)+B(Outside size)-K(K-factor)

None-90° bend unfold according to the neutral layer, the distance from neutral to sheet inner side is T/3, inner R can refer to the above chart.

V-die width is 6-8 times the plate thickness

None-90°bend = 180°- Angle/90°*Deduction

The deduction is 1.8 times the steel plate thickness and 1.6 times the aluminum plate.

For plate under 2mm, K-factor is 0.432, R=plate thickness, unfold size can accurate to 0.05.

Generally, when design the sheet metal parts, the min inner R=thickness/2, if less than that, the grooving (V-cutting) will be required to solve the problem.

Further reading:

Below are answers to some frequently asked questions:

The bend allowance formula is used to calculate the length of the neutral axis between the bend lines in sheet metal bending. The formula is:

Where:

This formula helps determine the correct length of sheet metal required to achieve the desired dimensions after bending.

To use a bend allowance chart, first gather the necessary parameters: material thickness, bend angle, inside radius, and K-factor. Locate these parameters on the chart, which typically provides pre-calculated bend allowances for various configurations. Cross-reference the material thickness and inside radius with the bend angle to find the corresponding bend allowance value. Adjust the chart as needed for your specific material and process by modifying the K-factor. Use the bend allowance value to accurately calculate the flat pattern length of the sheet metal part before bending. This ensures precise bends and accurate final dimensions.

The difference between bend allowance and bend deduction lies in their purposes and applications in sheet metal bending. Bend allowance (BA) represents the additional length needed to account for the material that bends, calculated based on the arc length of the neutral axis. It is added to the flat pattern length to ensure the correct material length for bending. On the other hand, bend deduction (BD) is the amount of material to be subtracted from the total flat length to achieve the desired final dimensions after bending, compensating for material springback. Essentially, while bend allowance adds length to account for the bend, bend deduction subtracts length to adjust for the bend.

To determine the K-factor for your material in sheet metal bending, you typically need to use empirical methods involving test pieces. Here’s how you can do it:

By following these steps, you can determine the K-factor specific to your material and bending process, ensuring accurate bend allowance calculations.

To calculate bend allowance in sheet metal bending, you need the following parameters:

These parameters are essential for accurate bend allowance calculations and should be carefully measured or determined.