Have you ever wondered how sheet metal is transformed into complex shapes? Bend deduction, a crucial concept in sheet metal fabrication, holds the key. In this blog post, we’ll dive into the intricacies of bend deduction, exploring its formulas, calculators, and practical applications. Join us as we unravel the secrets behind creating precise and beautiful sheet metal components.

Related calculators:

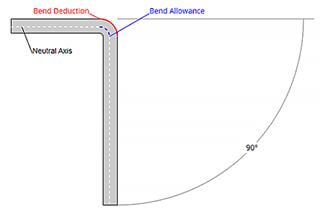

Bend deduction is a crucial concept in the field of sheet metal fabrication, particularly in the bending process. It is commonly referred to as the “back-off amount” and plays a significant role in determining the accurate dimensions of a bent part.

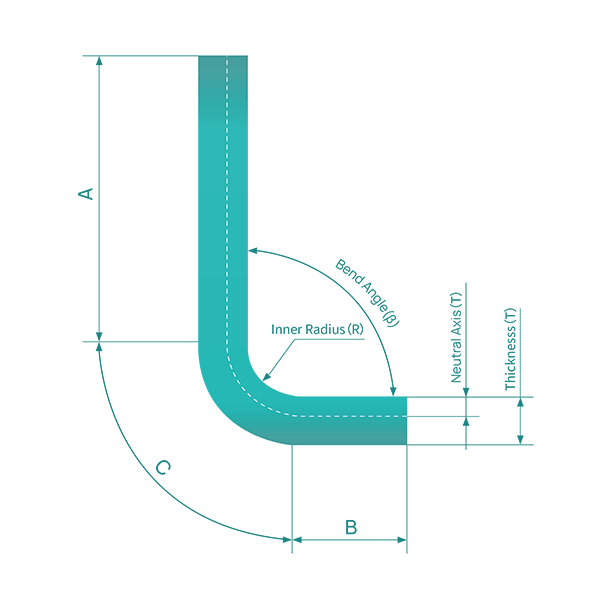

Bend deduction (BD) is the amount subtracted from the total length of the flat sheet metal to achieve the desired final dimensions after bending. It accounts for the material that is displaced during the bending process.

Importance in Sheet Metal Bending

The bend deduction is essential for accurately calculating the flat pattern of a sheet metal part before it is bent. It ensures that the final dimensions of the bent part match the design specifications. Without accounting for bend deduction, the part may end up with incorrect dimensions, leading to potential issues in assembly and functionality.

Several factors can influence the bend deduction value, including:

In practice, the bend deduction is determined through empirical data, manufacturer guidelines, or specialized software that takes into account the specific properties of the material and the bending process. Accurate bend deduction calculations are critical for ensuring that the final product meets design requirements and functions correctly in its intended application.

Bend deduction (BD) is a critical factor in sheet metal fabrication, used to calculate the flat pattern length of a sheet metal part. It accounts for the material that is displaced during the bending process. This value is essential for ensuring that the final dimensions of the bent part are accurate.

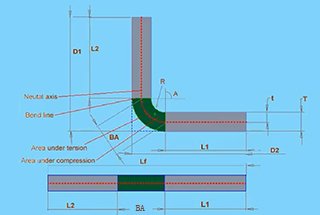

The bend deduction formula is used to determine the flat length of a sheet metal part before it is bent. The formula is as follows:

Lt=A+B−BD

Where:

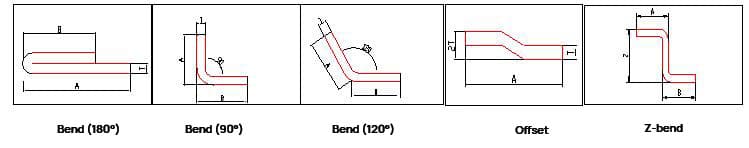

The bending deduction in Solidworks is only used for the calculation of 90-degree bends in sheet metal.

However, it can also be used for the calculation of non-90-degree sheet metal unfolding, but the bending deduction value for non-90-degree bending needs to be used according to the bending coefficient table.

Each manufacturer has a different table, and there may be errors. Some sheet metal factories may not use non-90-degree bending often.

Today, I will share the calculation method for the bending deduction of 90-degree bending that I am familiar with.

Bending deduction is a crucial factor in sheet metal fabrication, particularly when using machines like press brakes. It represents the amount of material consumed during the bending process. Accurate calculation of bending deductions is essential for precise part dimensions and efficient material usage. This article discusses three common methods for calculating bending deductions.

The simplest method uses a multiplication factor based on material thickness:

This method is quick and easy but lacks precision. It’s suitable for applications with lower accuracy requirements or for initial estimations.

A more refined approach developed by the sheet metal industry:

Bending deduction = 2 × material thickness + 1/3 × material thickness

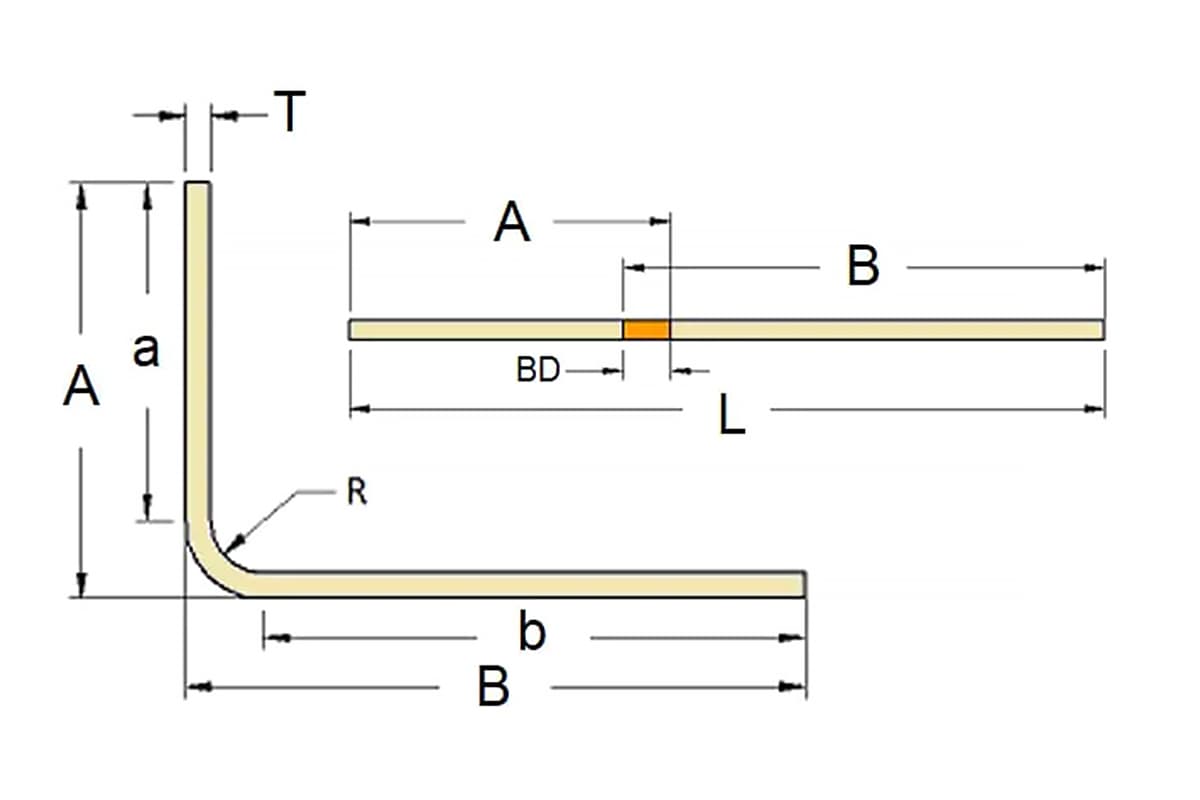

This formula accounts for material elongation during bending. It’s derived from: Unfolded length = Length A + Length B – Bending deduction

Where the bending deduction considers both material thickness and elongation.

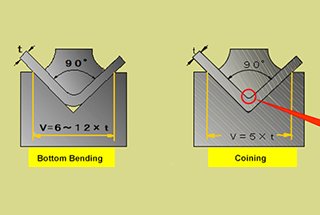

A more sophisticated formula derived from empirical studies:

Bending deduction = 2 × t – (0.72t – 0.075V – 0.01)

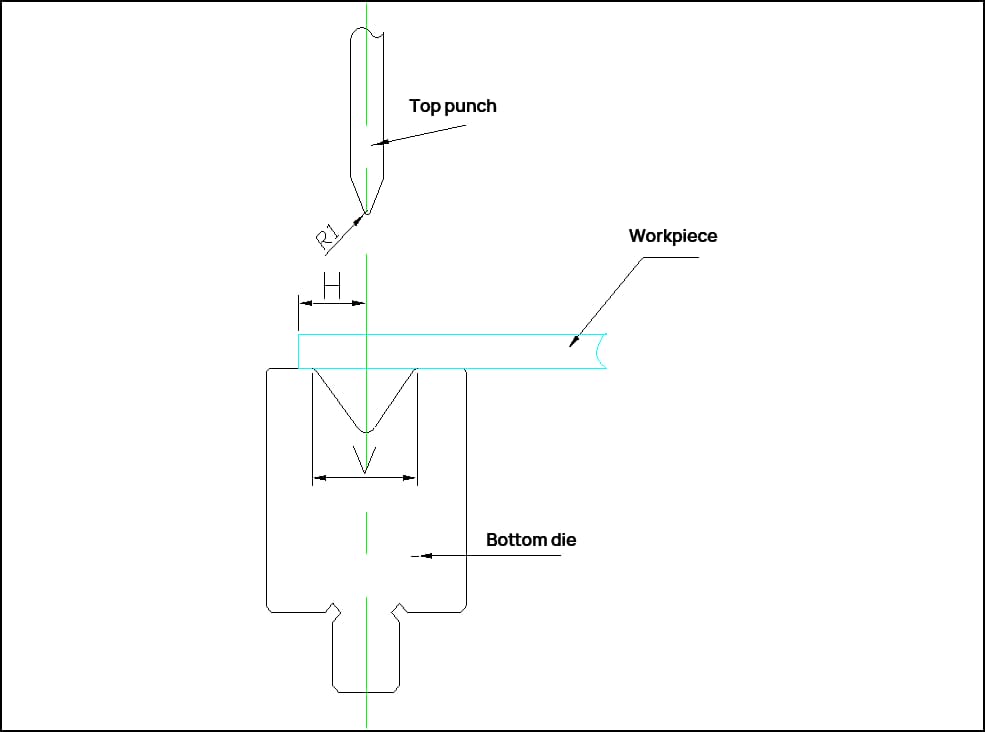

Where:

This formula accounts for the influence of the lower die width on bending deduction. It’s particularly accurate for carbon steel plates but has shown good results with other materials like aluminum when the die width is about 4 times the material thickness.

Important Considerations

Conclusion

Choosing the appropriate bending deduction calculation method depends on the required accuracy, material type, and available tooling information. For high-precision work, the advanced formula (Method 3) is recommended, while the simpler methods can be useful for quick estimates or less critical applications.

| V | Die width w | Bend Radius | T | 30° | 45° | 60° | 90° | 120° | 150° | 180° | 90°double bend outer layer | Minimum bending size H | Minimum size of Z-bend (Z) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8.0 | 12.0 | R1 | 0.6 | 0.2 | 0.5 | 0.9 | 1.0 | 0.7 | 0.2 | 0.3 | 1.9 | 6.0 | 10.0 |

| 0.8 | 0.3 | 0.6 | 1.0 | 1.6 | 0.8 | 0.3 | 0.4 | 2.2 | |||||

| 1 | 0.3 | 0.7 | 1.1 | 1.7 | 0.9 | 0.3 | 0.5 | 2.5 | |||||

| 1.2 | 0.4 | 0.8 | 1.3 | 2.2 | 1.1 | 0.4 | 0.6 | 2.8 | |||||

| R2 | 0.6 | 0.2 | 0.5 | 0.9 | 1.6 | 0.7 | 0.2 | 0.3 | 1.9 | ||||

| 0.8 | 0.3 | 0.6 | 1.2 | 1.8 | 0.8 | 0.3 | 0.4 | 2.2 | |||||

| 1 | 0.3 | 0.7 | 1.2 | 2.0 | 0.9 | 0.3 | 0.5 | 2.5 | |||||

| 1.2 | 0.4 | 0.8 | 1.4 | 2.3 | 1.1 | 0.4 | 0.6 | 2.8 | |||||

| 10.0 | 14.0 | R1 | 1.5 | 0.7 | 1.2 | 1.6 | 2.5 | 1.3 | 0.5 | 0.7 | 3.2 | 7.0 | 11.0 |

| R2 | 1.5 | 0.6 | 1.0 | 1.5 | 2.7 | 1.3 | 0.5 | 0.7 | 3.5 | ||||

| 12.0 | 16.0 | R1 | 2 | 0.6 | 1.3 | 2.0 | 3.4 | 1.7 | 0.6 | 0.9 | 4.4 | 8.5 | 13.0 |

| R2 | 2 | 0.9 | 1.4 | 2.0 | 3.6 | 1.7 | 0.6 | 0.9 | 4.5 | ||||

| 16.0 | 26.0 | R1 | 2.5 | 0.7 | 1.5 | 2.4 | 4.3 | 2.2 | 0.8 | 1.1 | 5.6 | 12.0 | 20.0 |

| 3 | 0.8 | 1.7 | 2.8 | 5.1 | 2.8 | 0.8 | 1.3 | 5.8 | |||||

| R2 | 2.5 | 0.8 | 1.6 | 2.5 | 4.8 | 2.3 | 0.9 | 1.1 | 6.2 | ||||

| 3 | 1.0 | 2.0 | 3.0 | 5.2 | 2.8 | 1.0 | 1.3 | 6.4 | |||||

| 22.0 | 32.5 | R1 | 4 | 1.0 | 2.4 | 3.5 | 6.5 | 3.3 | 1.1 | 16.0 | 26.0 | ||

| R2 | 4 | 1.2 | 2.6 | 4.0 | 6.8 | 3.5 | 1.1 | ||||||

| 32.0 | 50.0 | R1 | 5 | 1.2 | 3.2 | 4.8 | 8.6 | 4.6 | 1.4 | 24.0 | 38.0 | ||

| 6 | 1.5 | 3.5 | 4.5 | 9.5 | 5.0 | 1.8 | |||||||

| R2 | 5 | 1.5 | 3.4 | 5.0 | 8.8 | 4.5 | 1.6 | ||||||

| 6 | 1.8 | 3.8 | 5.5 | 9.8 | 5.2 | 2.0 |

Explanation:

| Formula | 0.2t | 0.4t | 0.6t | 0.8t | 1.0t | 1.2t | 1.4t | 1.6t |

| Angle | 155-165° | 145-155° | 135-145° | 125-135° | 115-125° | 105-115° | 95-105° | 85-95° |

| Thickness (t) | 15-25° | 25-35° | 35-45° | 45-55° | 55-65° | 65-75° | 75-85° | |

| 0.5 | 0.10 | 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.70 | 0.80 |

| 0.6 | 0.12 | 0.24 | 0.36 | 0.48 | 0.60 | 0.72 | 0.84 | 0.96 |

| 0.8 | 0.16 | 0.32 | 0.48 | 0.64 | 0.80 | 0.96 | 1.12 | 1.28 |

| 1.0 | 0.20 | 0.40 | 0.60 | 0.80 | 1.00 | 1.20 | 1.40 | 1.60 |

| 1.2 | 0.24 | 0.48 | 0.72 | 0.96 | 1.20 | 1.44 | 1.68 | 1.92 |

| 1.5 | 0.30 | 0.60 | 0.90 | 1.20 | 1.50 | 1.80 | 2.10 | 2.40 |

| 2.0 | 0.40 | 0.80 | 1.20 | 1.60 | 2.00 | 2.40 | 2.80 | 3.20 |

| 2.5 | 0.50 | 1.00 | 1.50 | 2.00 | 2.50 | 3.00 | 3.50 | 4.00 |

| 3.0 | 0.60 | 1.20 | 1.80 | 2.40 | 3.00 | 3.60 | 4.20 | 4.80 |

| 4.0 | 0.80 | 1.60 | 2.40 | 3.20 | 4.00 | 4.80 | 5.60 | 6.40 |

| 4.5 | 0.90 | 1.80 | 2.70 | 3.60 | 4.50 | 5.40 | 6.30 | 7.20 |

| 5.0 | 1.00 | 2.00 | 3.00 | 4.00 | 5.00 | 6.00 | 7.00 | 8.00 |

| 6.0 | 1.20 | 2.40 | 3.60 | 4.80 | 6.00 | 7.20 | 8.40 | 9.60 |

| Formula | 0.3t | 0.5t | 0.7t | 0.9t | 1.1t | 1.3t | 1.5t | 1.7t |

| Angle | 155-165° | 145-155° | 135-145° | 125-135° | 115-125° | 105-115° | 95-105° | 85-95° |

| Thickness (t) | 15-25° | 25-35° | 35-45° | 45-55° | 55-65° | 65-75° | 75-85° | |

| 0.5 | 0.15 | 0.25 | 0.35 | 0.45 | 0.55 | 0.65 | 0.75 | 0.85 |

| 0.6 | 0.18 | 0.30 | 0.42 | 0.54 | 0.66 | 0.78 | 0.90 | 1.02 |

| 0.8 | 0.24 | 0.40 | 0.56 | 0.72 | 0.88 | 1.04 | 1.20 | 1.36 |

| 1.0 | 0.30 | 0.50 | 0.70 | 0.90 | 1.10 | 1.30 | 1.50 | 1.70 |

| 1.2 | 0.36 | 0.60 | 0.84 | 1.08 | 1.32 | 1.56 | 1.80 | 2.04 |

| 1.5 | 0.45 | 0.75 | 1.05 | 1.35 | 1.65 | 1.95 | 2.25 | 2.55 |

| 2.0 | 0.60 | 1.00 | 1.40 | 1.80 | 2.20 | 2.60 | 3.00 | 3.40 |

| 2.5 | 0.75 | 1.25 | 1.75 | 2.25 | 2.75 | 3.25 | 3.75 | 4.25 |

| 3.0 | 0.90 | 1.50 | 2.10 | 2.70 | 3.30 | 3.90 | 4.50 | 5.10 |

| 4.0 | 1.20 | 2.00 | 2.80 | 3.60 | 4.40 | 5.20 | 6.00 | 6.80 |

| 4.5 | 1.35 | 2.25 | 3.15 | 4.05 | 4.95 | 5.85 | 6.75 | 7.65 |

| 5.0 | 1.50 | 2.50 | 3.50 | 4.50 | 5.50 | 6.50 | 7.50 | 8.50 |

| 6.0 | 1.80 | 3.00 | 4.20 | 5.40 | 6.60 | 7.80 | 9.00 | 10.20 |

| No. | Angle /Thickness | 0.8 | 1.0 | 1.2 | 1.5 | 2.0 | 2.5 | 3.0 | 4.0 | 5.0 |

| 1 | 0 | 3.00 | 3.60 | 4.00 | 5.00 | 7.00 | 8.40 | 10.00 | 14.00 | 20.00 |

| 2 | 5 | 2.92 | 3.50 | 3.89 | 4.86 | 6.81 | 8.17 | 9.72 | 13.61 | 19.44 |

| 3 | 10 | 2.83 | 3.40 | 3.78 | 4.72 | 6.61 | 7.93 | 9.44 | 13.22 | 18.89 |

| 4 | 15 | 2.75 | 3.30 | 3.67 | 4.58 | 6.42 | 7.70 | 9.17 | 12.83 | 18.33 |

| 5 | 20 | 2.67 | 3.20 | 3.56 | 4.44 | 6.22 | 7.47 | 8.89 | 12.44 | 17.78 |

| 6 | 25 | 2.58 | 3.10 | 3.44 | 4.31 | 6.03 | 7.23 | 8.61 | 12.06 | 17.22 |

| 7 | 30 | 2.50 | 3.00 | 3.33 | 4.17 | 5.83 | 7.00 | 8.33 | 11.67 | 16.67 |

| 8 | 35 | 2.42 | 2.90 | 3.22 | 4.03 | 5.64 | 6.77 | 8.06 | 11.28 | 16.11 |

| 9 | 40 | 2.33 | 2.80 | 3.11 | 3.89 | 5.44 | 6.53 | 7.78 | 10.89 | 15.56 |

| 10 | 45 | 2.25 | 2.70 | 3.00 | 3.75 | 5.25 | 6.30 | 7.50 | 10.50 | 15.00 |

| 11 | 50 | 2.17 | 2.60 | 2.89 | 3.61 | 5.06 | 6.07 | 7.22 | 10.11 | 14.44 |

| 12 | 55 | 2.08 | 2.50 | 2.78 | 3.47 | 4.86 | 5.83 | 6.94 | 9.72 | 13.89 |

| 13 | 60 | 2.00 | 2.40 | 2.67 | 3.33 | 4.67 | 5.60 | 6.67 | 9.33 | 13.33 |

| 14 | 65 | 1.92 | 2.30 | 2.56 | 3.19 | 4.47 | 5.37 | 6.39 | 8.94 | 12.78 |

| 15 | 70 | 1.83 | 2.20 | 2.44 | 3.06 | 4.28 | 5.13 | 6.11 | 8.56 | 12.22 |

| 16 | 75 | 1.75 | 2.10 | 2.33 | 2.92 | 4.08 | 4.90 | 5.83 | 8.17 | 11.67 |

| 17 | 80 | 1.67 | 2.00 | 2.22 | 2.78 | 3.89 | 4.67 | 5.56 | 7.78 | 11.11 |

| 18 | 85 | 1.58 | 1.90 | 2.11 | 2.64 | 3.69 | 4.43 | 5.28 | 7.39 | 10.56 |

| 19 | 90 | 1.50 | 1.80 | 2.00 | 2.50 | 3.50 | 4.20 | 5.00 | 7.00 | 10.00 |

| 20 | 95 | 1.42 | 1.70 | 1.89 | 2.36 | 3.31 | 3.97 | 4.72 | 6.61 | 9.44 |

| 21 | 100 | 1.33 | 1.60 | 1.78 | 2.22 | 3.11 | 3.73 | 4.44 | 6.22 | 8.89 |

| 22 | 105 | 1.25 | 1.50 | 1.67 | 2.08 | 2.92 | 3.50 | 4.17 | 5.83 | 8.33 |

| 23 | 110 | 1.17 | 1.40 | 1.56 | 1.94 | 2.72 | 3.27 | 3.89 | 5.44 | 7.78 |

| 24 | 115 | 1.08 | 1.30 | 1.44 | 1.81 | 2.53 | 3.03 | 3.61 | 5.06 | 7.22 |

| 25 | 120 | 1.00 | 1.20 | 1.33 | 1.67 | 2.33 | 2.80 | 3.33 | 4.67 | 6.67 |

| 26 | 125 | 0.92 | 1.10 | 1.22 | 1.53 | 2.14 | 2.57 | 3.06 | 4.28 | 6.11 |

| 27 | 130 | 0.83 | 1.00 | 1.11 | 1.39 | 1.94 | 2.33 | 2.78 | 3.89 | 5.56 |

| 28 | 135 | 0.75 | 0.90 | 1.00 | 1.25 | 1.75 | 2.10 | 2.50 | 3.50 | 5.00 |

| 29 | 140 | 0.67 | 0.80 | 0.89 | 1.11 | 1.56 | 1.87 | 2.22 | 3.11 | 4.44 |

| 30 | 145 | 0.58 | 0.70 | 0.78 | 0.97 | 1.36 | 1.63 | 1.94 | 2.72 | 3.89 |

| 31 | 150 | 0.50 | 0.60 | 0.67 | 0.83 | 1.17 | 1.40 | 1.67 | 2.33 | 3.33 |

| 32 | 155 | 0.42 | 0.50 | 0.56 | 0.69 | 0.97 | 1.17 | 1.39 | 1.94 | 2.78 |

| 33 | 160 | 0.33 | 0.40 | 0.44 | 0.56 | 0.78 | 0.93 | 1.11 | 1.56 | 2.22 |

| 34 | 165 | 0.25 | 0.30 | 0.33 | 0.42 | 0.58 | 0.70 | 0.83 | 1.17 | 1.67 |

| 35 | 170 | 0.17 | 0.20 | 0.22 | 0.28 | 0.39 | 0.47 | 0.56 | 0.78 | 1.11 |

| 36 | 175 | 0.08 | 0.10 | 0.11 | 0.14 | 0.19 | 0.23 | 0.28 | 0.39 | 0.56 |

| 37 | 180 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

1) The bending deduction table is applicable for sheet metal bending processes where no pressing plate is used and the sheet width is more than three times the thickness (t).

2) When bending on the bending machine, calculations can be made according to this table.

3) According to the dimensions indicated in the diagram, the calculation formula for the unfolded size of the bent workpiece is as follows:

L=a+b-y

Where:

4) Due to the numerous factors influencing sheet metal bending, this sheet metal bending deduction value table is provided for reference only.

The dimensional accuracy of bent workpieces is related to the positional precision of the press brake’s back gauge and the precision of the sheet metal cutting machine. Utilizing reliable machines for both cutting and bending processes can address these issues.

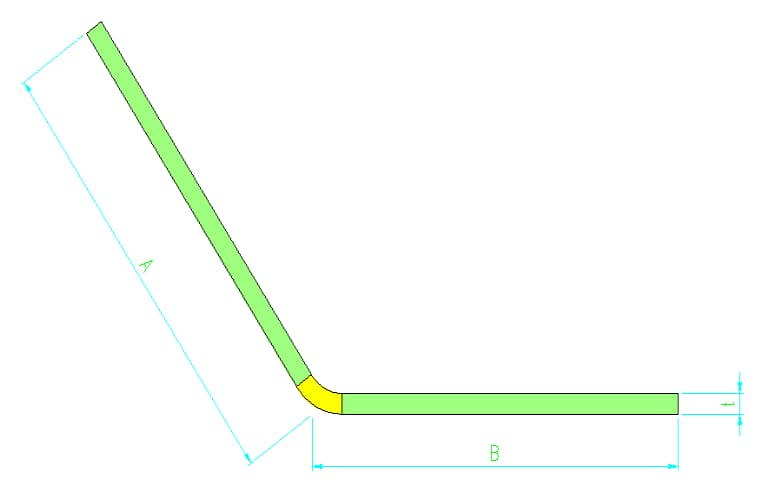

A critical factor affecting the dimensional accuracy of bent workpieces is the accuracy of the sheet metal’s flat pattern development. When a flat sheet is bent into a workpiece with a specific angle, measuring the dimensions of the bent workpiece reveals that they do not equal the dimensions of the flat sheet, as shown in the illustration.

This discrepancy is known as the bending deduction.

If the bending deduction is inaccurate, the flat pattern size will be imprecise, and regardless of the precision of subsequent operations, the final workpiece will not meet the required dimensional accuracy.

The bending deduction is complex, and a rudimentary method is to simply use twice the material thickness.

However, this approach is quite crude. A more refined method is to apply the neutral axis theory from the DIN 6935 standard, which involves calculating a factor ‘k’ and combining it with the thickness and angle of the sheet to be bent.

This formula yields a more precise bending deduction. Yet, even the bending deductions calculated according to the neutral axis theory from DIN 6935 may not be precise enough, as the actual deductions also depend on the characteristics of the material, the thickness, the bending angle, and the tooling used.

Different materials, thicknesses, and calculation methods yield varying bending deductions, as shown in Table below.

Table Deduction value for bending dimensions corresponding to different materials, thicknesses, and methods

| Plate thickness S/mm | Die | Material | -S × 2 | DIN6935 | Database |

| 1.5 | V12/78 | DC04 | -3.00 | -3.00 | -2.90 |

| 1.5 | V08/78 | DC04 | -3.00 | -2.80 | -2.70 |

| 1.5 | V1278 | X5CrNi1810 | -3.00 | -3.00 | -3.10 |

| 4 | V24/78 | S235JRG2 | -8.00 | -7.60 | -7.09 |

| 4 | V30/78 | S235JRG2 | -8.00 | -7.57 | -7.26 |

| 4 | V24/78 | X5CrNi1810 | -8.00 | -8.01 | -7.57 |

| 4 | V30/78 | X5CrNi1810 | -8.00 | -7.90 | -8.01 |

| 6 | V30/78 | S235JRG2 | -12.00 | -11.20 | -10.35 |

| 6 | V4078 | S235JRG2 | -12.00 | -11.60 | -10.62 |

| 6 | V30/78 | X5CrNi1810 | -12.00 | -11.20 | -10.89 |

| 6 | V4078 | X5CrNi1810 | -12.00 | -11.60 | -11.60 |

For example, for a 4mm thick S235JRG2 plate using a V30 lower die, the bending deduction varies by method: twice the material thickness results in 8mm, the DIN 6935 formula yields 7.57mm, and the database empirical value gives 7.26mm.

There are discrepancies between the methods, which become even more significant when workpieces require multiple bends, leading to larger cumulative deviations. The empirical values from the database are derived from extensive practical testing and are stored in the database, providing the utmost precision.