Have you ever wondered how a simple piece of steel can transform into a robust cabinet? In this article, we’ll explore the fascinating nine-fold profile, its applications, and the bending process. Learn how this innovative design enhances cabinet strength and efficiency.

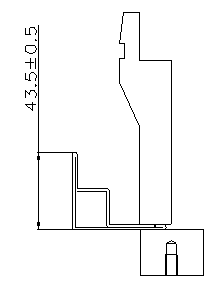

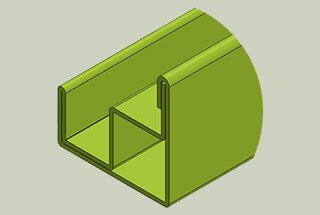

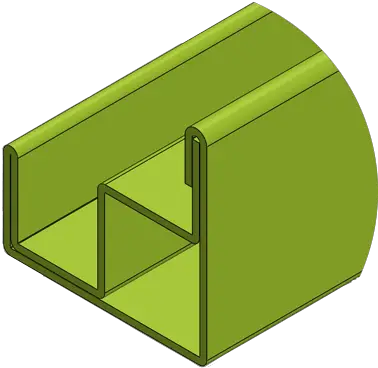

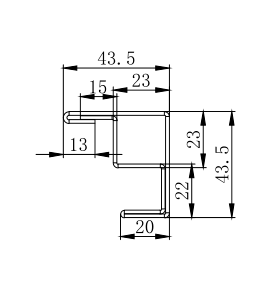

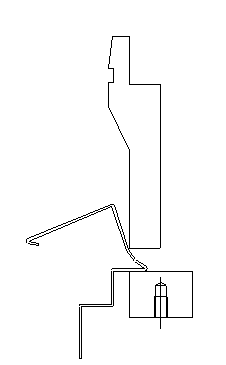

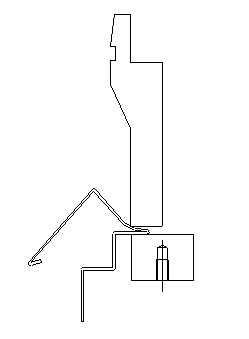

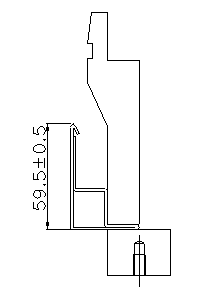

The nine-fold profile, also known as a nine-bend profile, derives its name from the distinctive nine bends in its column and beam structure. This profile is fabricated from cold-rolled steel plate, typically processed through a roll forming machine. The resulting shape offers a unique combination of strength, stability, and material efficiency.

Key characteristics of the nine-fold profile include:

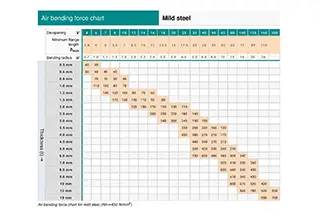

Before delving into the specific process of forming a nine-fold profile using a press brake machine, it’s crucial to understand the profile’s applications and advantages in various industrial and construction contexts. This knowledge provides essential context for the subsequent discussion on fabrication techniques.

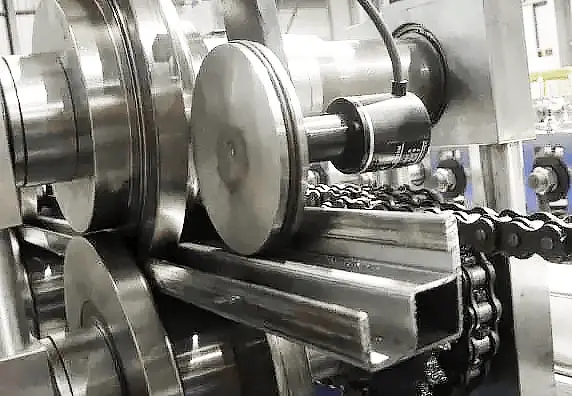

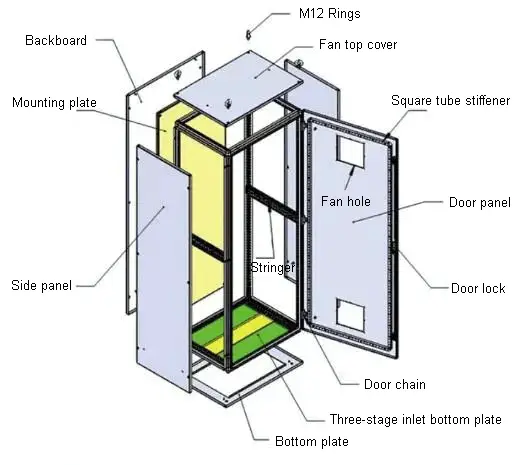

The nine-fold profiles are predominantly utilized in advanced cabinet manufacturing. These profiles form the foundation for cabinets featuring a closed column and beam structure, which offers superior structural integrity compared to conventional open beam and C-profile designs. This innovative architecture provides several key advantages:

The pioneering technology for processing these advanced cabinets was originally developed by Rittal GmbH & Co. KG, a renowned German company specializing in industrial enclosures and electrical distribution systems. Subsequently, several Chinese manufacturers have adopted and adapted this technology, contributing to its widespread availability in the global market.

This proliferation has led to continuous improvements in manufacturing techniques, material selection, and customization options, further enhancing the appeal of nine-fold profile cabinets across diverse industrial sectors.

Materials of nine-fold profile cabinet:

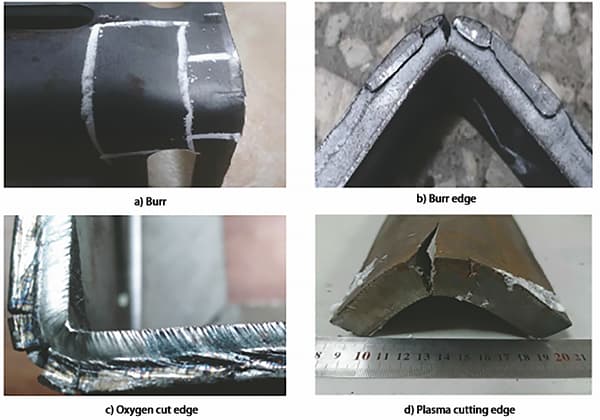

The materials used for the nine-fold profiles include national standard cold-rolled steel plates and high-grade stainless steel, such as SUS304L for the food and beverage industry, SUS316L for the medical and pharmaceutical industry, and SUS201 as an economical stainless steel option.

The thickness:

Surface treatment of the cabinet with nine-fold profile:

The steel plates for the cabinet body, base, and door undergo 12 international standard pre-treatment processes, including pickling, phosphating, dewaxing, washing, and purification. After these processes, the surface is coated with plastic and can be painted in any color as required. Stainless steel is typically treated with double-sided drawing.

Standard components of a nine-fold profile cabinet include:

Typically, the nine-fold profile can be purchased rather than made by the sheet metal shop. In special circumstances, sheet metal fabricators can also bend their own profiles.

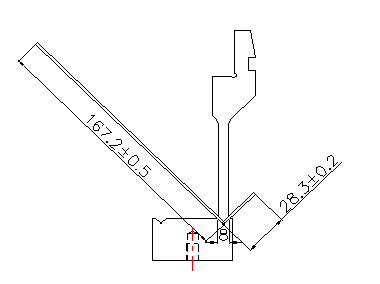

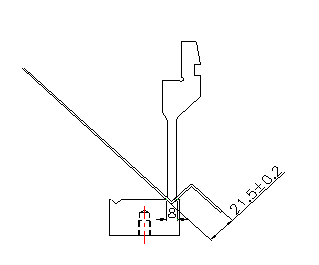

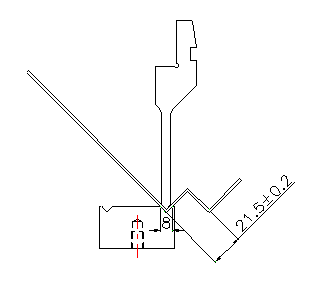

The following are two methods to bend a nine-fold profile.

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Step 7

Step 8

Step 9

Step 10

Step 11