Have you ever wondered why your sheet metal bends aren’t turning out as expected? Mastering the art of press brake bending involves understanding the nuances that can make or break your work. This article offers seven expert tips to enhance precision, avoid deformation, and ensure consistent results. By following these guidelines, you’ll improve your bending techniques and achieve professional-quality bends every time. Dive in to uncover practical advice and solutions for common bending challenges.

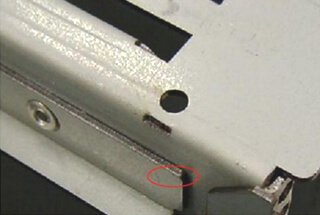

(1) After bending the sheet metal on both sides of the corner, there will be metal material protruding due to extrusion. This leads to an increased width compared to the original size, and the protruding size is dependent on the thickness of the material used. The thicker the material, the larger the protruding point.

To avoid this phenomenon, a semicircle can be made on both sides of the bend line beforehand. The diameter of the semicircle should preferably be 1.5 times the thickness of the material.

The same method is applied when folding back leftover material.

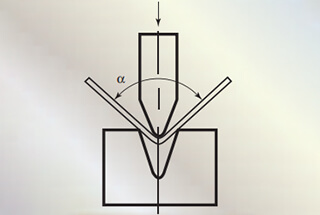

(2) When using a press brake machine to bend sheet metal, it is preferable for the internal R angle to be greater than or equal to 1/2 of the material thickness.

If the R angle is not initially made, the right angle will gradually disappear after multiple punches and the R angle will naturally form. After that, the length of one or both sides of the R angle will become slightly longer.

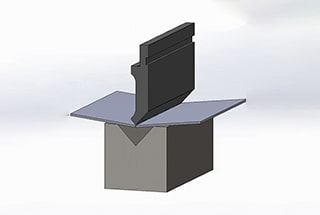

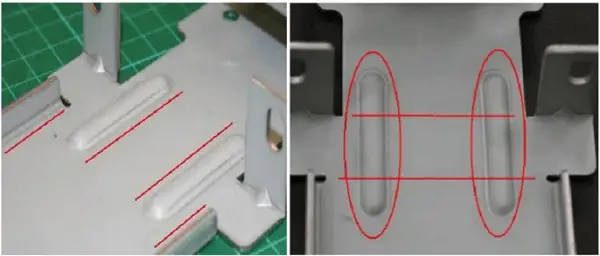

(3) Sheet metal is easily deformed when bent.

To prevent deformation, an appropriate amount of 45-degree reinforcement ribs can be added to the bends to increase their strength, without interfering with other parts.

(4) Generally, it is difficult to maintain the straightness of a narrow and elongated sheet metal part, and it is prone to deformation under stress. To maintain its strength and straightness, one side can be folded into an L-shape or two sides can be folded into a 冂-shape.

However, it’s often not possible to connect the L and 冂-shapes from beginning to end. So, what should be done if they get interrupted due to some factors?

In such cases, adding an appropriate amount of ribs can help increase the strength of the sheet metal part.

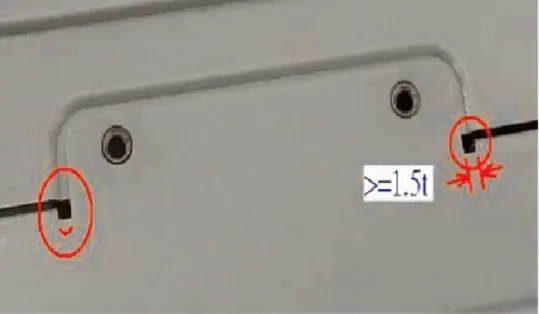

(5) It is best to have narrow openings in the bend between the flat surface and the bending surface, or the edge of the opening should be retracted after bending, otherwise, burrs may occur.

The width of the opening should be at least 1.5 times greater than the thickness of the sheet.

Additionally, it is essential to mark the R corner when creating drawings, and avoid negligence or laziness in this regard.

Right-angle or acute-angle male and female molds are susceptible to cracking, which may lead to additional expenses for suspension and repairs in the future.

(6) Unless there is a specific requirement for a 90-degree angle, please process the corner of the metal sheet to an appropriate R angle.

A right angle on the edge of the metal sheet can create sharp points that can cut staff.

The die’s right-angled tip is prone to cracking due to stress concentration.

The tip of the top punch is also susceptible to cracking, leading to mold repair and production delays.

Furthermore, even if the mold does not crack, over time, the R angle will wear down, resulting in burrs on the product and defective items.

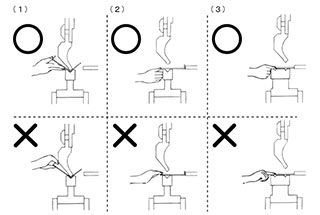

(7) Edge bending

There are two types of bending: unilateral and bilateral. For greater precision, it is recommended to use bilateral bending as it provides better accuracy.

It is advisable to ensure that the height of the folded edge is greater than 3mm (with a tolerance of T: 1.0 ~ 1.2mm), as insufficient clamping dimensions may result in unstable dimensions.

When folding edges, ensure that the parts on the side walls or internal protrusions are not too close to the bottom surface. It is recommended to keep a distance of more than 10mm. This is because if the distance is too small, the bending radius of the corners below the protrusions will be larger than the radius of the left and right sides, as there will be no punch.

This can result in an irregular shape, which affects the overall appearance. Therefore, it is crucial to maintain a consistent R angle throughout the folding process.

Solution:

A suitable indentation length can be made on the fold line before bending, which will enhance its appearance.

When folding the edges, it is important to ensure that the openings on the side walls are not too close to the bottom surface. Ideally, there should be a distance of 3mm or more between the two to prevent any deformation of the openings during the bending process.

Solution

Prior to bending, a long hole with a length equal to 1.5 times the thickness of the material is punched along the folding line. The purpose of this hole is to allow for easy removal of excess material without affecting the appearance of the opening.