Have you ever wondered why bolts break and cause machinery failures? This article explores the critical factors behind bolt fractures, from design flaws to material issues. You’ll learn how to prevent these failures and ensure safety in your mechanical systems.

Bolts are a commonly used fastener. If a bolt breaks slightly, it needs to be shut down for maintenance. However, if it breaks badly, it can cause damage to machinery and even lead to human fatalities.

Merely replacing a broken bolt does not completely eliminate the risk of re-breaking. Therefore, it is essential to analyze the factors that contribute to the breaking of the bolt and improve them.

From an individual perspective, the factors leading to bolt fractures can vary widely. However, by examining a large number of bolt fracture samples, some common features can be identified.

The life cycle of bolts can be divided into four stages: design, manufacturing, use, and maintenance, with failure being a possible outcome. Interruption cracks are the most harmful type of failure.

To avoid bolt fracture failure, it is essential to comprehend the complete set and subset of factors that influence bolt fracture at different stages of their life cycle.

Table 1 and Table 2 are obtained after statistical analysis on the influencing factors of 227 bolts fracture.

Table 1 Statistical Analysis of Factors Affecting Fracture in Bolt Fracture Samples by Stages

| Total | 227 | |

| Single stage factor breaking | Manufacture | 81 |

| Design | 34 | |

| Material Science | 14 | |

| Use | 14 | |

| Two stage factor combination causes breakage | Design+Manufacturing | 27 |

| Manufacturing+Materials | 17 | |

| Manufacturing+use | 14 | |

| Design+use | 7 | |

| Design+Materials | 1 | |

| Use+Material | 1 | |

| Broken by combination of 3 stages+material factors | Design+Manufacture+Use | 7 |

| Design+Material+Manufacturing | 2 | |

| Material+Manufacture+Use | 7 | |

| 3 stages+materials | 1 | |

Table 2 Correlation Analysis of Bolt Fracture with Three Stages and Materials in Bolt Fracture Samples

| Correlation classification | Proportion/% | ||

| Manufacturing related | independent | 81 | |

| combination | 75 | ||

| Total | 156 | 68.7 | |

| Design related | independent | 34 | |

| combination | 45 | ||

| Total | 79 | 34.8 | |

| Related to materials | independent | 14 | |

| combination | 29 | ||

| meter | 43 | 18.9 | |

| Related to use | independent | 14 | |

| combination | 37 | ||

| Total | 51 | 22.5 | |

Bolt fracture may be caused by a single factor or a combination of multiple factors.

Table 2 shows that 77.5% of bolt fracture samples are caused by pre use factors, while 68.7% of bolt fractures are related to manufacturing.

There are numerous factors that can affect the lifespan of bolts, including their susceptibility to fracture.

However, due to space constraints, we will only be conducting a preliminary analysis of the mechanisms that have a high frequency of influence.

According to Table 3, the primary factors responsible for bolt fracture during the design stage are improper material selection, external forces acting on the bolts, design of the bolt structure, small diameter, and temperature difference caused by the use of different materials. These five factors alone account for 85 instances, which is equivalent to 82.5% of the 103 total instances observed in the design stage.

2.1.1 Effect of improper material selection on bolt fracture

The selection of materials is a crucial aspect of bolt design. Table 4 demonstrates the components impacted by inadequate material selection in bolt fracture samples.

Environmental and stress corrosion, insufficient or excessive material strength, and unsuitable heat treatment processes were the cause of 47 out of 58 incidents, representing 81.0% of cases.

Table 3 Classification and Frequency of Factors Affecting Bolt Fracture at Design Stage in Bolt Fracture Samples

| Affected Items | 103 |

| Improper material selection | 42 |

| External influence: vibration and insufficient rigidity of connectors | 17 |

| Bolt structure design | 14 |

| Small diameter | 7 |

| Temperature difference load caused by different materials | 5 |

| Number and arrangement of bolts | |

| Anti loosing | 3 |

| Length and connection method | 3 |

| Improper design requirements | 3 |

| other | 5 |

(1) Impact of environment and stress corrosion on bolt fracture

Stress corrosion is a failure phenomenon that occurs in materials when they are subjected to a combination of static stress (especially tensile stress) and corrosion.

When a bolt is exposed to stress and a corrosive environment, the surface oxide film of the bolt can become damaged due to corrosion. The damaged surface becomes the anode and the undamaged surface becomes the cathode.

As a result, the anodic current density increases dramatically, causing the damaged surface to corrode further. Under the influence of tensile stress, cracks gradually appear in the damaged area, which gradually expand until the bolt fails.

To prevent stress corrosion, it is important to choose materials with strong resistance to it. For example, in environments that contain high-temperature water with sulfides, it is recommended to use chromium-nickel austenitic stainless steel with low manganese content.

In addition, the design of the bolt structure should be optimized to reduce stress concentration.

Improving the corrosion environment can also help prevent stress corrosion. This can be done by adding corrosion inhibitors to the corrosion medium or by using a metal or non-metal protective layer to isolate the corrosive medium.

(2) The influence of poor bolt material performance on bolt fracture.

Material performance encompasses various indicators, and poor performance occurs when the selected bolt material is incompatible with the service environment. Using materials beyond their engineering capacity can lead to bolt fracture.

For instance, the coupling bolt of a 200 MW unit fractured due to the original use of 35 steel that was neither quenched nor tempered and had a coarse widmanstatten or banded structure. Upon analyzing the broken bolt, it was concluded that 35 steel was not appropriate for manufacturing the coupling bolt. Instead, 40CrNiMo steel was used to enhance the bolt material’s comprehensive mechanical properties.

However, it is crucial to ensure the matching of the hardness of bolts and coupling materials when using 40CrNiMo steel. When examining the broken bolt, it was discovered that fretting wear of the bolt with hardness of (260~280) HB caused damage to the bolt hole. Therefore, using 40CrNiMo steel to improve the bolt’s hardness to achieve high fatigue strength could have adverse consequences.

Consequently, it is necessary to conduct a comprehensive mechanical property test to obtain low notch sensitivity, matching hardness, and bending fatigue strength of the bolt before transitioning to its use.

(3) Impact of excessive or insufficient strength on bolt fracture

It’s easy to understand that insufficient strength can cause bolt fractures, but it’s easy to overlook the relationship between excessive strength and bolt fracture.

High-strength bolts not only increase sensitivity to stress concentrations at notches, but they also have a higher susceptibility to hydrogen embrittlement.

Hydrogen-induced cracks typically occur when the hydrogen content in steel exceeds 5 parts per million (ppm). However, with high-strength steel, hydrogen atoms in lattice gaps will concentrate at stress concentration sites generated by notches through diffusion, even when the hydrogen content in steel is less than 1 ppm.

These hydrogen atoms interact with dislocations, causing the dislocation lines to become pinned and unable to move freely, ultimately making the body brittle.

2.1.2 External factors affect bolt fracture

(1) Effect of vibration on bolt fracture

The vibration response of the connecting bolt is primarily influenced by two factors: the modal characteristics of the connecting bolt and the vibration excitation transmitted to the bolt by the connecting piece.

Following the breakage of the connecting bolt between a transmission and a power take-off, a modal test was conducted on the long bolt. The results showed that, under the condition of 45 N·m tightening torque, the natural frequency of the first bending mode was 1155 Hz, and the modal damping ratio was 0.67.

During the vibration response test of the transmission power take-off under engine working conditions, it was observed that when the transmission system was in operation, the long bolt was excited by significant vibration with a main vibration frequency of 1000 to 1500 Hz. The first bending frequency of the long bolt was within this frequency band, and the damping ratio was very low.

This caused a resonance amplification effect, resulting in significant bending resonance response of the bolt and a high bending dynamic stress on the threaded connection. As a result, the connecting bolt broke prematurely.

(2) Impact of insufficient rigidity of connected parts

Insufficient rigidity in connected parts not only generates vibrations but also causes uneven stress on bolts.

The anchor bolts of a marine diesel engine broke quite frequently. The analysis results revealed that the main engine had large vibrations, particularly vertical vibrations caused by poor rigidity in the base – bilge.

After the wedge positioning block of the host positioning support was welded firmly, the anchor bolt did not break anymore, as its rigidity had been strengthened.

Both ends of the steel plate of the drum shell of a hoist are connected to the flange plate with M22 bolts. However, there is no reinforcing support ring or circumferential lining ring inside the drum, which creates a simply supported beam along the axis.

As a result, the rigidity is poor, and under working conditions, the middle of the drum shell experiences the largest deformation, putting the connecting bolt M18 under maximum force and causing it to break. Meanwhile, the connecting bolts near the flange plate at both ends of the drum have not broken.

2.1.3 Effect of bolt hole structure on bolt fracture

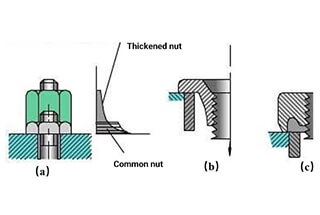

The primary factor that contributes to bolt fracture in bolt and screw hole structures is a small transition fillet. This includes the transition fillet at the thread root, screw and bolt head, and undercut. A small transition fillet not only generates stress concentration, but also leads to the generation of large internal stress during heat treatment, resulting in the appearance of microcracks or crack tendencies that reduce the bolt’s bearing capacity.

The combination of external loads and internal stress causes the bolt to bear a load that exceeds its limit, leading to breakage.

For instance, the main bearing bolt of a DF 7B locomotive diesel engine was broken due to this phenomenon.

After modification, the middle bolt hole was eliminated, resulting in a 45% increase in the bearing area of the main bearing bolt head and a substantial improvement in the strength of the thread part.

Furthermore, the elimination of the inner screw hole has eliminated the stress concentration caused by the inner hole thread structure, resulting in an increase in the bolt’s fatigue strength.

The quality of heat treatment, machining, processing transition fillet size, fitting and assembly, and the bolt forming process are the main factors that affect the risk of bolt fracture during the manufacturing stage.

There are 141 factors, accounting for 89.2% of 158. See Table 5 and Table 6.

Table 5 Classification and Items of Factors Affecting Bolt Fracture in Manufacturing Stage

| Item | 158 |

| Heat treatment quality | 71 |

| Machining quality | 40 |

| The fillet is too small | 11 |

| Fit and assembly quality | 10 |

| No integral forging or forming process defect | 9 |

| Root surface defect of screw tooth | 2 |

| Coating and corrosion fracture | 1 |

| other | 14 |

Table 6 Classification and Items of Factors Affecting Bolt Fracture by Heat Treatment

| Item | 87 |

| Heat Treatment Process Design and Process Quality | 33 |

| hydrogen embrittlement | 14 |

| Decarburization and partial overburn | 11 |

| Dysplasia | 8 |

| High hardness and low plasticity | 6 |

| Surface or center carburization | 5 |

| Quenching quality and pretreatment intelligence | 5 |

| Heat treatment and material conflict fastener leather rope | 1 |

| others | 4 |

2.2.1 Effect of heat treatment on bolt fracture

The main factors responsible for bolt fracture are heat treatment process design and process quality, hydrogen embrittlement, decarburization, local overburning, poor structure, high hardness, and low plasticity. These factors collectively account for 82.8% of the 87 cases studied.

(1) Effect of heat treatment process design and process quality on bolt fracture

An example is presented to demonstrate the impact of improper heat treatment processes on bolt fracture. When hypoeutectoid quenched and tempered steel 42CrMo is utilized as the bolt material, and the section size is large (e.g. ≥ 500 mm), achieving the yield ratio of 0.9 with traditional quenching and tempering treatment becomes challenging.

To attain the target, it is necessary to reduce the tempering temperature, i.e., use medium temperature tempering or lower-temperature tempering. However, this would result in decreased toughness, increased strength, and the metallographic structure would contain defects (the second type of temper brittleness).

The testing results of a batch of bolts are as follows: high strength (σb>1200 MPa), high hardness (HBS>400), and the metallographic structure is tempered troostite, which fully supports this observation.

Studies conducted nationally and internationally indicate that the greater the strength of the steel, the more prone it is to cracks. Therefore, if the toughness is insufficient when σb>1200 MPa, low stress brittle fracture can occur easily.

(2) Effect of hydrogen embrittlement on bolt fracture

Bolts used in corrosive environments and requiring high strength often need anti-corrosion treatment.

However, some anti-corrosion processes, like chromium plating, can lead to hydrogen embrittlement.

Research has shown that the higher the material strength, the more sensitive it is to hydrogen embrittlement, and the faster cracks will grow.

In steel microstructures, susceptibility to hydrogen embrittlement generally follows this order from high to low: martensite, upper bainite, lower bainite, sorbite, pearlite, and austenite. The high strength depends on the corresponding metallographic structure.

Hydrogen embrittlement can result from either internal or external hydrogen. Internal hydrogen is generated during manufacturing, while external hydrogen penetrates during use.

Generally, internal hydrogen will cause the bolt to crack or fracture before or after use, while external hydrogen requires an accumulation process to reach the level of damage that will cause the bolt to fracture.

Therefore, it takes time for the bolt to fracture.

To avoid hydrogen embrittlement fractures caused by electroplating, it is recommended to use hydrogen embrittlement-free coatings, such as zinc-chromium coatings commonly used in industries such as automotive and aerospace.

2.2.2 Effect of machining quality on bolt fracture

During the bolt manufacturing process, defects such as wrinkles, folds, and microcracks may form due to improper processing. These defects often lead to further cracking or expansion of bolt threads during rolling, forming, or heat treatment. In particular, such defects tend to be concentrated at the root of bolt threads.

Under cyclic stress or load, microcracks at the root of bolt threads are susceptible to stress concentration, which can trigger fatigue sources and cause multi-source fatigue fractures.

In a 350 MW gas turbine unit, a machining streak was observed on the fracture surface of the heater bolt. This streak was located at the junction of the screw and the bolt head. Additionally, a large corrosion pit was found on the streak, indicating obvious crevice corrosion before the bolt cracked.

Further appearance inspections revealed that the surface of the bolt polished rod was rough. This not only became the source of stress concentration but also provided conditions for crevice corrosion and stress corrosion.

Table 7 displays the influencing factors and material-related items that contribute to bolt fracture in the sample of broken bolts. It includes 39 items related to inclusions, material quality, metallurgical defects, and excessive chemical element content, which account for 86.7% of the total 45 items.

Table 7 Factors and Items Affecting Bolt Fracture by Materials

| Item | 45 |

| Inclusion | 16 |

| Material quality | 10 |

| Metallurgical defect | 7 |

| Chemical elements of materials | 6 |

| Segregation | 4 |

| Microcrack | 2 |

(1) Influence of inclusions on bolt fracture

When magnesium and calcium from foreign inclusions, as well as sulfur, manganese, chromium, and other elements within the material, segregate towards the grain boundary, it can cause grain boundary embrittlement. This embrittlement can occur in local areas, leading to potential cracks.

Moreover, if the size of inclusions in bolts is excessively large, especially near the surface layer, it can accelerate the initiation and propagation of fatigue cracks in bolts.

The banded distribution of MnS inclusions in steel can also increase its susceptibility to hydrogen-induced cracking.

(2) Effect of supplied material properties on bolt fracture

In certain service environments, it is not sufficient to solely focus on the strength and hardness of bolt materials. Comprehensive consideration must be given to factors such as plasticity, impact toughness, corrosion resistance, notch sensitivity, and the difference in performance between room temperature and working temperature.

Nonconformity in material performance refers to a situation where the supplied material does not meet the design requirements.

After the gas heater bolts of a gas turbine unit broke, it was discovered through chemical composition and metallographic analysis that the broken bolts were not made of the 304 type stainless steel specified in the design. Instead, they were cast after several different stainless steel materials were remelted, and their corrosion resistance was inadequate, leading to galvanic corrosion between the bolts and the blind plate due to differing electrode potentials at the outset.

Although the broken bolts on the flange of the intermediate pressure governing valve of a steam turbine generator passed the mechanical strength and impact toughness spot checks at room temperature, both failed to qualify in the test at the operating temperature of 540 ℃.

(3) Influence of metallurgical defects of materials on bolt fracture

The presence of looseness, bubbles, slag inclusions, and internal cracks in bolt materials significantly decreases the actual allowable stress of the materials.

Macro and micro analysis of the fracture surface of high-strength bolts shows that after the fracture begins at the crack source, the process expands rapidly and unstably until it breaks. This occurs because the material contains numerous micro defects, such as microcracks and micropores, which reduce the actual allowable stress and are also a prerequisite for rapid and unstable crack growth.

The formation of these microcracks is related to incomplete degassing and slagging during smelting, as well as incomplete elimination during subsequent forging.

The main factors that contribute to bolt fracture during use include pre-tightening force, uneven tightening force, improper tightening methods, installation issues, and other related problems.

Out of the 92 recorded occurrences, these three issues were responsible for 69 incidents, accounting for 75.0% of cases, as shown in Table 8.

(1) Effect of pre tightening force on bolt fracture

The seal structure of a clamp connection is inaccessible due to high temperature and high pressure conditions.

To tighten the clamp bolt, the operator uses a special wrench that is approximately 1 meter long until it cannot be tightened any further. However, this causes the bolt preload to exceed the allowable stress of the bolt.

Once the pipeline pressure rises, the bolt stress increases even further, ultimately resulting in the bolt breaking in a short amount of time.

In the case of a group of connecting rod bolts, if one bolt lacks sufficient preload, a large gap will form between the connecting rod journal and the bearing bush.

Under high-speed crankshaft operation, the bolt will endure large alternating impact loads and bending moments, leading to fatigue and fractures. The load must then be transferred to another bolt, which will also become overloaded and fracture in turn.

(2) Uneven fastening force and improper fastening method

During compressor maintenance, the maintenance personnel did not use a torque wrench to apply the designed pretightening force to the bolts. Instead, they used a solid head wrench and a sledgehammer to apply force, relying solely on their experience to estimate the correct amount of pressure.

As a result, the pretightening force applied to the bolts was inconsistent. The bolts located in areas that were convenient for hammering received greater pretightening force, while those in less accessible areas received less force.

After analyzing the fracture distribution of the compressor cylinder head bolts, it was found that most of the bolts located in the convenient hammering location had broken, which is consistent with the analytical results.

(1) The quality objectives for the life cycle of mechanical products are based on achieving the life cycle quality of all their parts, including bolts. An innovative approach is to establish the concept of part-level life cycle quality and identify the influencing factors of bolt fracture.

(2) The life cycle quality of bolts is influenced by multiple stages and factors. Establishing a set of factors that affect bolt fracture can aid in the overall planning and selection of these factors, thereby achieving the life cycle quality objectives of bolts.

(3) There is a need to continuously enhance the set of influencing factors of bolt fracture, as well as supplement and revise the teaching materials and relevant documents to support the practice of the concept of life cycle quality for bolts and mechanical products.