Imagine transforming the toughest materials with precision and efficiency—this is the promise of brazing and diffusion welding in diamond tool manufacturing. In this article, you’ll explore how these advanced techniques create stronger, longer-lasting diamond tools by bonding them with metals under high temperatures. Discover the science behind these methods and their practical applications in industries ranging from stone cutting to aerospace. By the end, you’ll understand why these processes are game-changers in the world of manufacturing.

Preface

Diamond is known for its high hardness, strong wear resistance, high thermal conductivity, and low thermal expansion coefficient, making it the optimal material for cutting and grinding tools.

Diamond tools are widely used for cutting and grinding hard and brittle materials, including saw blades, drill bits, finishing tools, and wire-drawing dies. They are commonly used in industries such as stone cutting, 3C processing, geological exploration, automobile manufacturing, and the defense industry.

Related reading: Cutting Tools Basics

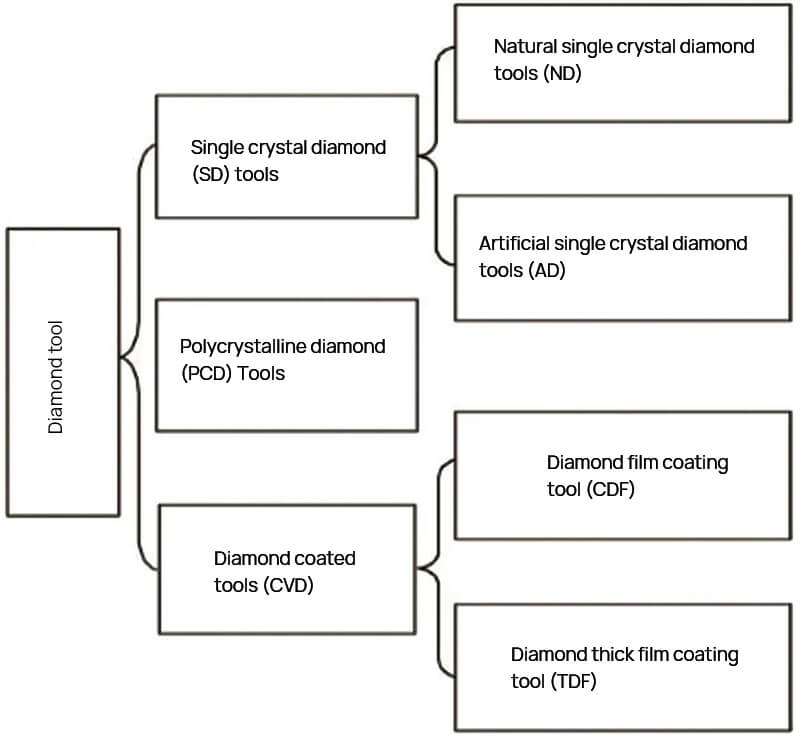

Currently, the most commonly used diamond tools are single crystal diamond tools (SD), polycrystalline diamond tools (PCD), and diamond coated tools (CVD).

Single crystal diamond tools can be made from both natural and artificial single crystal diamonds. Polycrystalline diamond tools, on the other hand, are typically made from synthetic diamonds.

Diamond coated tools are divided into two categories based on the thickness of the diamond coating: diamond thick film tools (with a diamond film thickness greater than 300 µm) and diamond film tools (with a diamond film thickness less than 20 µm).

Figure 1 illustrates the classification of diamond tools, and Figure 2 displays some common diamond tools.

The process of converting diamonds into diamond tools with specific properties is a crucial technology. This article summarizes the current methods for preparing diamond tools and provides an overview of research progress in brazing and diffusion welding of diamond tools both domestically and internationally. It also looks at the future prospects for diamond welding technology.

Fig.1 Classification of diamond tools

Fig.2 Commonly used diamond tools

A single diamond is not a suitable tool on its own and must be bonded with materials of high toughness. The production of diamond tools typically utilizes methods such as sintering, electroplating, brazing, and diffusion welding.

The sintering process involves mixing matrix powder and diamonds in a specific ratio and then pressure sintering the mixture in a sintering furnace to produce diamond tools.

Hot press sintering is a common technique used to manufacture multi-layer diamond tools such as diamond cutting heads, grinding wheels, and wire saws.

The diamond matrix created through sintering has a low bonding strength with diamonds and more diamond particles are embedded within the matrix. This method is often used for cutting and grinding materials that are both hard and brittle.

Electroplated diamond tools are made by using the electroplating process to secure diamond particles to the metal coating deposited on the substrate. However, the plating metal used in these tools has a weak hold on the diamonds, resulting in a low exposed height and a tendency for the diamond abrasive grains to fall off under heavy grinding loads.

On the other hand, brazed diamond tools are created by connecting diamonds and a matrix using brazing. The bond between the diamond and matrix is strong and durable, making it less likely for the diamonds to fall off during use.

Additionally, brazed diamond tools have several advantages, including a large exposed height of abrasive particles (with a theoretical maximum of over 70% of the abrasive particle height), ample chip space, and effective heat dissipation. These tools are capable of handling heavy loads and can be used for high-speed and efficient grinding.

The brazing method for creating diamond tools was patented as early as 1975 and has since garnered attention from researchers both domestically and internationally. It is considered a promising technology for improving the connection between synthetic diamonds.

Diffusion welding, on the other hand, is a solid state connection method that involves the diffusion of atoms on the surface of the contact area under high temperature and pressure, leading to the combination of atoms and a secure connection.

Vacuum diffusion welding typically takes place at a temperature of 0.6 to 0.8 times the melting temperature (Tm) of the base metal being welded. This method is suitable for welding materials with a large difference in thermal expansion coefficients, such as cemented carbide and PDC composite sheets to cutter post matrices.

Table 1 summarizes the advantages and disadvantages of various preparation methods.

Table 1 Comparison of several preparation methods

| Preparation method | Advantage | Disadvantage |

| Powder metallurgy sintering | The preparation method is mature; Simple process operation; Low production cost; Most are multilayer diamond tools. | The diamond particles are irregularly distributed and the exposed height is uneven; The metal matrix is mechanically wrapped with diamond, so the holding force is weak, and diamond particles are easy to fall off prematurely. |

| Electroplating | The exposed height of arm particles is relatively consistent. | The depth of particles embedded in the matrix is up to 2/3, and the service life of the tool is short. |

| Brazing method | Strong adhesion between diamond and matrix; The exposed height of particles reaches 2/3, and the service life is long; The distribution of particles in the matrix is controllable. | The brazing performance of diamond is poor; High technical requirements for process operation; Diamond is easily graphitized. |

| Diffusion welding | The lower welding temperature is suitable for materials with large difference in thermal expansion coefficient. | The equipment cost is high and the scope of application is narrow. |

At present, various brazing methods are available for diamond tools, including vacuum brazing, furnace brazing, salt bath brazing, flame brazing, laser brazing, resistance brazing, high-frequency and vacuum induction brazing, and more.

The bonding strength of the diamond tool is crucial in determining its performance and lifespan.

To avoid solder oxidation, diamond tools are typically brazed in high vacuum or an inert gas environment.

This requires a specialized furnace that can maintain a vacuum or gas-shielded welding environment.

Furnace brazing typically uses resistance radiation heating for a uniform heat distribution, allowing for the brazing of diamond tools with complex structures or large sizes.

Single-layer diamond tools brazed in a vacuum are mainly used in the production of dressing tools, grinding wheels, stone tools, and glass tools.

Both vacuum brazing and furnace brazing are suitable for mass production.

Ammonia decomposition gas is commonly used in continuous atmosphere furnace brazing as a reducing agent. This method is known for its slow heating speed, which results in uniform temperature distribution. The brazed joint produced is aesthetically pleasing, reliable in quality, and has a bright workpiece surface. Additionally, this method has a high production efficiency and low welding cost.

It is commonly applied in the production of small saw blades and special-shaped diamond tools.

Salt bath brazing, on the other hand, has a low temperature and a fast and uniform heating speed, leading to a low graphitization degree of diamonds, making it suitable for mass production.

However, the salt bath brazing process is cumbersome and results in residual flux on the workpiece after welding. Additionally, the process generates a large amount of wastewater during cleaning, causing environmental pollution. The equipment for salt bath brazing is also expensive, and the production cycle is lengthy. This method of brazing diamond tools is not in line with the concept of green manufacturing.

Flame brazing, an early developed method, requires simple and lightweight equipment and has a low process cost with a wide range of gas sources. However, its heating temperature is difficult to control, leading to its gradual elimination from the mainstream market.

During laser brazing, the local heating by the laser is quick and the exposure time of diamonds in high temperatures is short, resulting in a low graphitization degree. This method has several advantages, including high heating efficiency, easy temperature control, a small heat-affected zone, the ability to process complex surfaces, an orderly arrangement of diamond particles, high degree of automation, and a favorable working environment.

Furthermore, laser brazing helps to avoid the proximity and skin effects of high-frequency induction brazing when welding large and complex workpieces. However, the short heating time may not allow for the formation of a continuous reaction layer or diffusion layer between the diamond abrasive particles and filler metal, or between the filler metal and matrix, which reduces the holding force of the filler metal on the diamond particles.

Resistance brazing is often used to braze honing bars and produces good weld quality. However, due to the relatively high temperature of the cutter head during the welding process, which affects the service life of the diamonds, this method is not widely used by many enterprises.

On the other hand, high-frequency induction brazing is known for its fast heating speed, high brazing efficiency, low production cost, simple operation, low labor intensity, and the ability to braze various complex shapes and multi-tooth workpieces. When combined with automatic feeding, atmosphere protection, or vacuum induction brazing, the joint has a good appearance and brazing quality.

In conclusion, induction brazing is a promising brazing method for diamond tools.

The Vacuum Brazing Furnace is the most widely used equipment in the manufacturing of diamond tools. It allows for batch production and provides a stable, repeatable operation process.

However, the traditional vacuum furnace has limited cavity space and most domestic models only feature a single chamber, making them suitable only for small-scale production.

Thanks to advancements in technology, multi-functional vacuum furnaces have been developed, such as continuous vacuum brazing furnaces, vacuum induction brazing furnaces, and hot wall vacuum brazing furnaces.

Taking the mesh belt continuous tunnel furnace as a representative, this type of complete equipment is widely used in annealing and bright heat treatment processes. The furnace is comprised of feeding, heating, cooling, and discharging areas. During the brazing process, the workpiece is protected by an atmosphere of ammonia decomposition.

This equipment offers several advantages, including continuous heating, adjustable heating time for the workpiece, high production efficiency, ease of mass production, reduced worker labor intensity, and automation.

The fully-controllable atmosphere continuous brazing equipment integrates various professional technologies, such as those from the chemical industry, machinery, control, and electric furnace brazing, providing technical support for automatic, continuous, high-efficiency, high-quality, and low-cost brazing production in large quantities.

Laser Brazing is a brazing technology that uses a laser as the heat source, and the laser is its core component.

Based on the type of working materials, lasers can be classified into several types including gas lasers (such as CO2 gas lasers), liquid lasers, semiconductor lasers, solid state lasers (such as Nd: YAG lasers), fiber lasers, free electron lasers, etc.

Of these, fiber lasers have seen rapid development and are widely used in various fields such as communications, sensing, laser material processing, and more.

Future research on fiber lasers will focus on improving their conversion efficiency, quality, stability, and making them more compact in size.

Research areas of focus in fiber lasers will include ultra-short pulse mode-locked fiber lasers with smaller duty cycles, high-power femtosecond pulse fiber lasers, broadband output fiber lasers, and tunable fiber lasers.

The laser beam used for welding has evolved from a pulse waveform to a continuous waveform.

Initially, solid state lasers with pulse outputs were used for welding, but in recent years, high-power continuous CO2 gas lasers and solid Nd: YAG lasers have become popular as welding heat sources.

Diamond has lower absorptivity to laser beams compared to alloy filler metal, therefore, for brazing diamond tools, high energy density lasers should be selected.

When using a pulsed laser as the welding heat source, the process parameters are more complex.

Currently, the research on laser brazing diamond mainly uses CO2 continuous lasers, but there is limited research in this area.

The core component of high-frequency induction brazing equipment is an induction heating power supply.

Modern induction heating power supplies are evolving towards higher power, higher frequency, and increased intelligence.

In the future, the goal is to develop a miniaturized induction heating power supply system that is suitable for field operation, highly efficient, and energy-saving.

Due to the rising cost of labor in diamond tool manufacturing and the need for improved stability in brazing quality of diamond tools, automatic induction brazing has become the primary method for welding diamond sawing tools.

Automatic induction brazing of diamond tools allows for automatic tooth splitting, automatic identification and selection of cutter heads, and automatic delivery of welding pads.

This method offers high welding accuracy, strong brazing joints, and a long service life. One operator can manage multiple machines, significantly reducing labor costs.

The principle behind brazing diamond tools is to utilize elements with a high affinity for carbon (such as titanium, chromium, zirconium, etc.) to produce carbides through a chemical reaction during brazing, in order to achieve a metallurgical bond between the diamond, filler metal, and matrix.

When brazing diamond tools, the brazing technology and materials are of utmost importance.

Brazing diamond is challenging because it is difficult for common metal filler metals to adhere to the surface of the diamond.

Currently, active metal brazing or diamond surface metallization are the main methods used to enhance the brazing performance between the diamond and metal.

The active metal brazing method joins diamonds by incorporating active elements such as titanium, zirconium, chromium, and vanadium into the filler metal. These elements, which are known for forming strong carbides, react chemically with the filler metal to form carbides and a metallurgical bond between the diamond and the filler metal. The diamond is then attached to the metal substrate through the brazed filler metal.

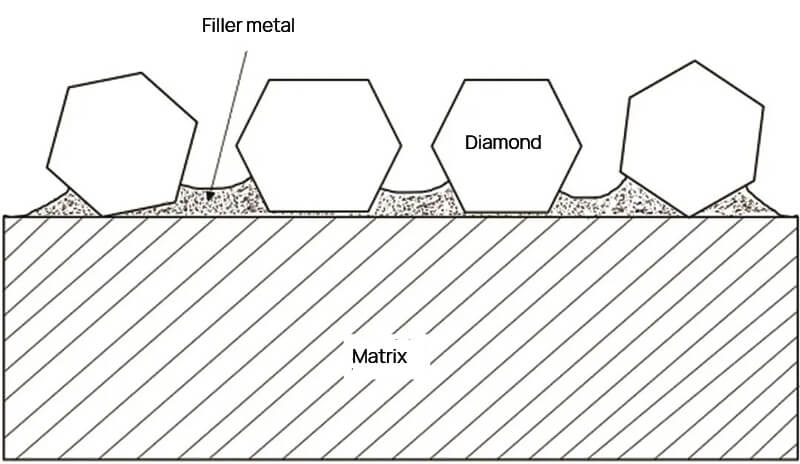

Refer to Figure 3 for the design of the diamond joint brazed with this method.

Fig.3 Interface brazed diamond joint

Alloys containing Ti, such as Ag Cu Ti and Cu Sn Ti, are commonly used as active solders. Meanwhile, Ag Cu Cr and Ni Cr alloys containing Cr are brazed using inert gas or vacuum.

Due to their relatively high chemical affinity, Ti, Cr, and C play an important role in forming carbides, such as TiC and Cr-C, at the interface. This is what ultimately leads to the metallurgical connection between the diamond, filler metal, and matrix.

Metal activation treatment of the diamond surface imparts metal-like properties, making it easier for the diamond to bond with metal fillers.

The surface metallization process can be achieved through several methods, including chemical plating and electroplating, vacuum evaporation, plasma sputtering, magnetron sputtering, chemical vapor deposition, physical vapor deposition, and mechanical coating.

Chemical plating and electroplating, as well as vacuum evaporation, are the most commonly used methods.

Typically, highly active metals such as Ti, Cr, W, and Mo are selected for metallization.

The metal coating enhances the metallurgical bond between the diamond and the matrix, thereby improving the retention of the diamond particles in the tool matrix.

The strength of a brazed joint or interface is primarily determined by two elements: the brazing material and the brazing process.

Common metal solders have difficulty wetting and spreading on diamond surfaces, and the wetting angle of nickel on diamond surfaces is limited at high temperatures.

Copper does not wet diamond surfaces at high temperatures, but its wettability on diamond surfaces is significantly improved when titanium is added to copper.

Currently, the brazing filler metals used for diamond tool brazing can be broadly divided into two categories: Ni-based high-melting-point alloy brazing filler metals (such as Ni-Cr) and Ag-based and Cu-based low-melting-point alloy brazing filler metals (such as Cu-Sn-Ti, Ag-Cu-Ti, and Ag-Cu-Cr).

The layer of nickel-based filler metal used in brazing has high hardness, excellent corrosion resistance, outstanding wear resistance, and superior high-temperature performance, making it widely utilized in the aerospace industry.

Since its inception, there have been numerous studies on nickel-based solders, both in terms of their basic properties and applications, with much attention paid to its commercial development.

One of the most commonly used filler metals for brazing diamond tools is the Ni-Cr alloy.

By combining the advantages of both the diamond tools and nickel-based filler metals, brazing with these materials results in tools that are ideal for high-strength cutting, grinding, and drilling.

In 1975, J.T. Lowder and colleagues initiated research on brazing diamond tools using Ni-Cr alloy filler metals.

Subsequently, Wiand and others investigated the impact of different metal powders (such as Ni, Cr, B, Si, Fe, Mo, etc.) and brazing parameters (temperature, holding time, etc.) on the strength of vacuum-brazed coated diamonds.

A team of researchers led by K. Chatopadhyay in Switzerland first sprayed a Ni-Cr alloy flame onto a steel substrate, then used induction brazing to connect the diamond and steel substrate under argon protection. They studied the relationship between the amount of filler metal and the wettability and strength.

In China, Lin Zengdong and his colleagues used Ni-Cr-P filler metals to braze diamond tools and described the brazing process.

The results indicate that the brazing temperature should be 50-100°C higher than the melting temperature of the solder alloy, the holding time should be brief, and the height of the exposed diamond is inversely proportional to the amount of solder used.

Xiao Bing, Feng Bojiang, and other scholars found that when brazing diamonds with a Ni-Cr filler metal, the interface presents a double-layer structure, with an inner layer of Cr3C2 and an outer layer of Cr7C3.

Lu Jinbin and his team showed that when diamonds are brazed with a Ni-Cr filler metal, the Cr7C3 generated at the interface takes on a shoot-like morphology, while the Cr3C2 takes on a sheet-like morphology.

The use of nickel-based filler metal for brazing has a drawback as it requires high brazing temperatures that can lead to graphitization of diamonds and harm their thermal stability.

For applications that demand a good working environment and low wear resistance, copper-based or silver-based filler metals are a better choice, as they reduce the graphitization of diamonds.

In a study by A. Khalid et al. of Pakistan, a copper-based active filler metal (Cu-14.3Sn-10.2Ti-1.5Zr) was used to achieve vacuum brazing of diamonds.

The research found that the interface between the diamond and filler metal produced a double-layer TiC structure that was 200 nm thick. This structure consisted of 50-70 nm thick TiC particles near the diamond and 100-200 nm thick columnar TiC near the filler metal.

With an increase in temperature or reaction time, columnar TiC grows on the side of the filler metal, while the TiC particle layer on the diamond side remains unchanged.

S. Buhl and colleagues utilized the Cu-14.4Sn-10.2Ti-1.5Zr filler metal to achieve brazing of single crystal diamonds and investigated the relationship between brazing parameters and the residual stress and strength of the joint.

As the brazing temperature was raised from 880 ℃ to 930 ℃, the shear strength of the diamond joints decreased from 321 MPa to 78 MPa.

W. C. Li and colleagues used the Cu-10Sn-15Ti alloy solder to braze diamonds at temperatures of 925 ℃/5 min and 1050 ℃/5 min, forming a continuous TiC layer approximately 500 nm thick at the interface. S. F. Huang and colleagues compared the effects of vacuum and laser brazing on the microstructure of the diamond interface using the Cu-10Sn-15Ti filler metal.

Under vacuum conditions, the TiC transition layer is continuous. However, due to the short reaction time during laser brazing, fewer reaction products are produced in the diamond.

Meng Weiru and colleagues from Xi’an Jiaotong University used filler metals such as BNi-2, BNi-7, and CuSnNiTi to achieve vacuum brazing of diamond tools.

Through comparison, it was found that the CuSnNiTi filler metal had a low melting temperature, good wettability on the diamond surface, caused minimal thermal damage to the diamond, had high holding power, and was highly usable for diamond tools.

The brazing filler metal used for diamond tools is typically a silver-based eutectic alloy of Ag and Cu, with active elements such as Ti and Zr added. This Ag-based alloy has a low melting point and good wetting ability with diamonds.

Researchers from Harbin University of Science and Technology, Yanshan University, Harbin University of Technology, and Nanjing University of Aeronautics and Astronautics have conducted studies on brazing diamonds with Ag-based filler metals and have reached a similar conclusion: under brazing conditions, a chemical reaction occurs between Ti and C, resulting in the formation of TiC compounds that create a metallurgical bond between the filler metal and diamond.

The team from the State Key Laboratory of Brazing at Zhengzhou Machinery Research Institute Co., Ltd. analyzed commonly used Ag-based solders. Based on the roles and characteristics of elements such as Ag, Cu, Zn, Cd, Ni, Co, and Mn in the solders, more than 10 solders were prepared and their melting temperature, strength, and brazing process were studied.

A series of solders suitable for brazing PCD tools in various working conditions were developed. However, the high cost of Ag metal and the high brazing cost due to the stringent requirements for the Ti element in terms of vacuum degree have limited its application.

Additionally, the filler metal’s grip on diamond is weak, making it prone to falling off during use, thus limiting its use in diamond tool brazing. Silver-based solders are used in exceptional cases where low wear resistance is required. Table 2 compares the pros and cons of several different solders.

Table 2 Advantages and disadvantages of several different brazing filler metals

| Type | Advantage | Disadvantage |

| Ni Cr alloy | Excellent corrosion resistance and oxidation resistance. Cr reacts with C in diamond to form Cr3C2 and Cr7C3, with high bonding strength and high holding power on diamond. | When brazing temperature is higher than 1000 ℃, diamond is easy to be graphitized and thermal damage occurs. |

| C-Sn Ti alloy solder | When TiC is generated, the brazing filler metal can realize high strength connection with diamond, the brazing temperature is low, and the thermal damage to diamond is small. | The activity of Ti element is high, and brazing requires high atmosphere. |

| Ag Cu Cr alloy solder | Cr and C in diamond form Cr-C compound, and the brazing filler metal has a high holding power on diamond. | The brazing temperature must be lower than 800 ℃ to avoid graphitization and oxidation of diamond;Too low temperature leads to too long brazing time and energy waste. |

| Ag Cu Ti alloy solder | TiC is generated, and the brazing filler metal is metallurgically connected with the diamond. The low brazing temperature has no thermal damage to the diamond. | The content of Ag is high and the cost of solder is high; The activity of Ti element is high, and brazing requires high atmosphere. |

| CuMn based Ti containing prealloyed solder | TiC is generated to achieve gold bonding, and the holding power of diamond is high. | The thickness of TiC layer is large or TiC is continuously distributed, which is easy to produce cracks and make diamond particles fall off. |

Diffusion welding has joint properties that are comparable to those of the base metal, making it ideal for welding dissimilar materials. The vacuum diffusion welding joint boasts high strength, exceptional thermal stability, and robust seismic resistance.

In the production of diamond tools, diffusion welding is commonly used to connect PDC geological bits. This not only enhances the quality of the bit and improves welding strength, but also increases the bit’s footage depth.

Diffusion welding is an effective method for enhancing the performance and prolonging the service life of PDC bits. Varnado and colleagues coated PDC with a 25-50 μm thick layer of nickel metal and performed vacuum diffusion welding at 650 ℃ and 214 MPa for 4 hours, resulting in a joint shear strength of 413-551 MPa.

Qiu Huizhong and team utilized unidirectional pressure diffusion welding and hot isostatic pressure diffusion welding to achieve a high-strength connection between PDC and tungsten carbide pillar, fulfilling the requirements of PDC bits.

The connection strength between PDC and tungsten carbide reached approximately 500 MPa at 680 ℃ with unidirectional pressure diffusion welding, and hot isostatic pressure diffusion welding ensured the stability and reliability of the cutting teeth while not significantly reducing the finished drill bit’s abrasion resistance. Field tests have verified the excellent quality of the product.

Liu Jie and colleagues conducted a vacuum diffusion welding test on PDC (polycrystalline diamond composites) bits with the aim of addressing problems and improving the performance and lifespan of these bits. Their study verified the feasibility of using vacuum diffusion welding to connect the composites to the bits.

Sun Fenglian and colleagues used a combination of diffusion welding and brazing to connect a thick film of CVD (chemical vapor deposition) diamond to cemented carbide. They used Ti foil and Ag Cu foil as the interlayer material and performed the welding process under vacuum radiation heating.

At the interface between the diamond and the interlayer, there was mutual diffusion of C and Ti elements, resulting in the formation of the compound TiC.

Qiao Peixin and colleagues improved the connection between the diamond and the matrix alloy by adding prealloyed powder through vacuum hot pressing sintering. They found that this diffusion brazing connection using prealloyed powder is an effective method for enhancing diamond tools.

The diffusion welding process is complex and time-consuming, and the necessary equipment is expensive, leading to high welding costs.

Currently, vacuum diffusion welding is mainly utilized for welding high-strength geological drill bits with demanding vibration requirements, and has not yet been applied to mass-produce general diamond tools.

Brazing and diffusion welding possess unique advantages in connecting heterogeneous materials, such as carbon and metal, due to their exceptional process characteristics. These methods are poised to become a major research area in the development of diamond tools.

Research into brazing diamond tools is flourishing and has numerous approaches. Currently, it is moving towards automation, sustainability, process integration, and a focus on quality and cost-effectiveness.

Diffusion welding of diamond tools remains limited to special tool connections and requires further development.