Have you ever wondered what sets brushless DC motors apart from permanent magnet synchronous motors? This article dives into the fascinating world of these two motor types, exploring their principles, control methods, efficiency, and response characteristics. By the end, you’ll understand which motor is best suited for your needs.

Brushless DC Motors (BLDC) and Permanent Magnet Synchronous Motors (PMSM) are two widely used types of motors in the modern electric motor field.

While they share many similarities, there are still some important differences between them. This article provides an exhaustive, factual, and detailed comparison of these two types of motors from several aspects.

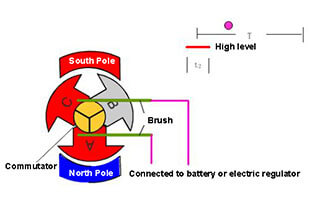

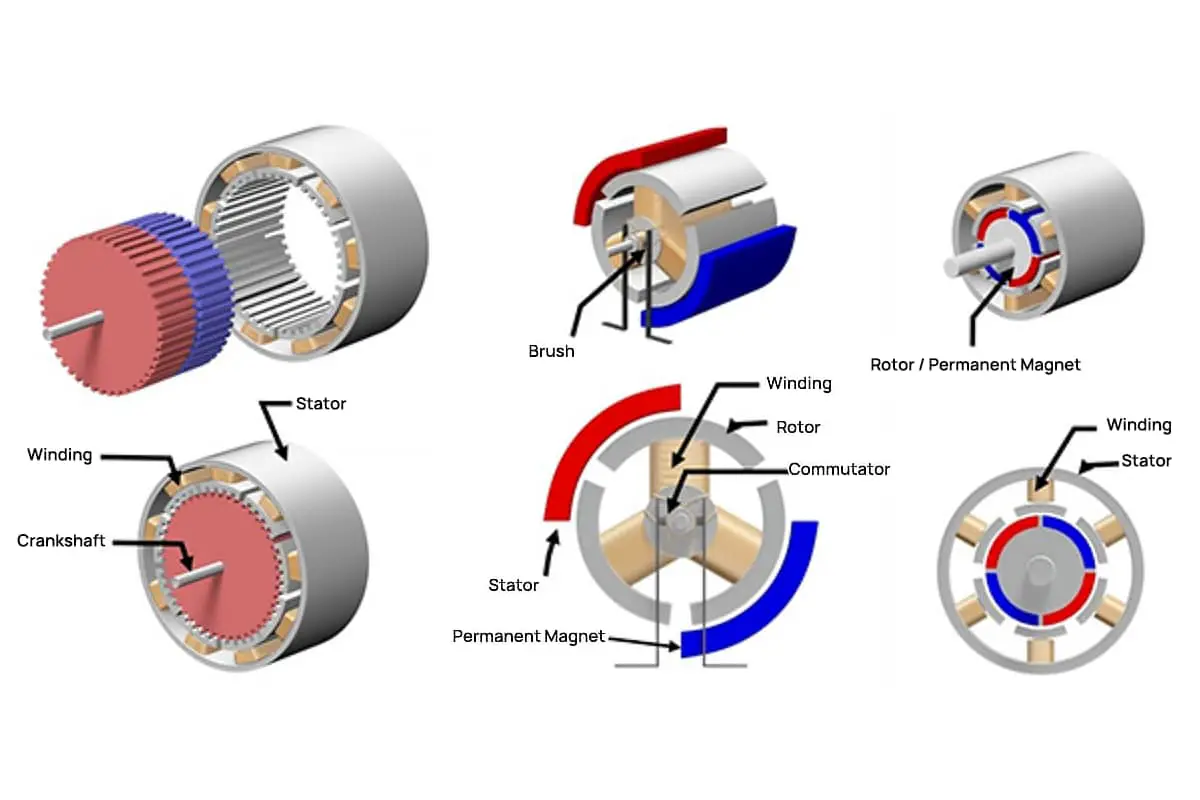

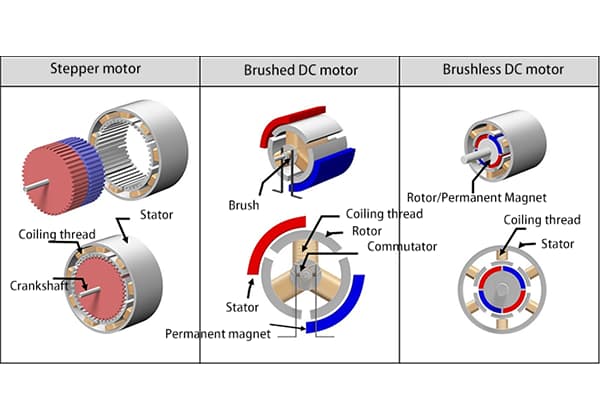

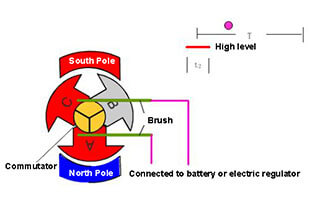

Brushless DC motor:

The brushless DC motor operates on a rotating magnetic field formed by the magnetic potential at the shaft end, synchronizing phase switching through the sensing pole to drive rotor movement.

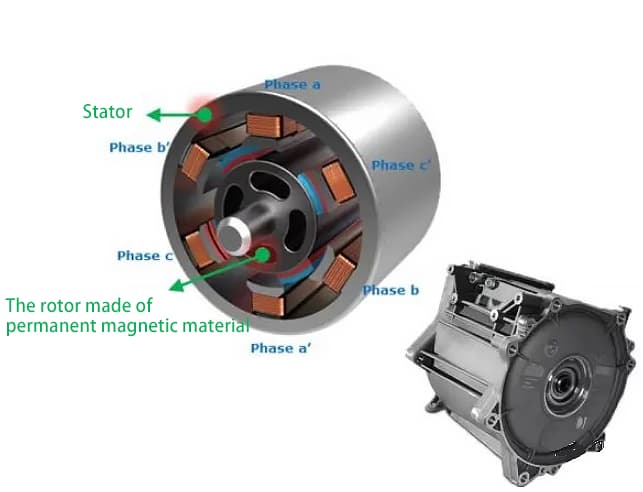

Its structure consists of a rotor formed by permanent magnets, a stator wrapped with coils, and a position sensor. By changing the direction and magnitude of the current, the movement of the rotor can be controlled.

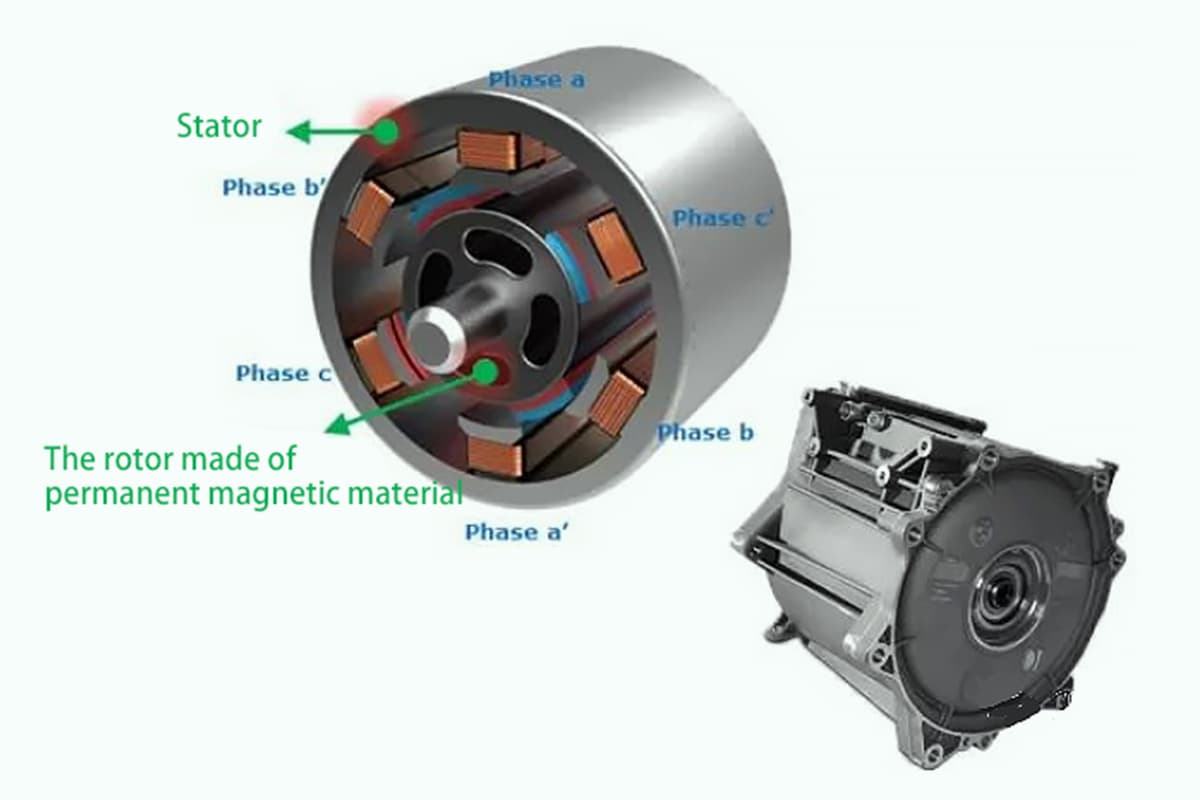

Permanent Magnet Synchronous Motor:

The permanent magnet synchronous motor works on the interaction of magnetic potentials between the stator and the rotor, generating torque to drive rotor movement.

The rotor generates a rotating magnetic field through permanent magnets, while the stator coils create an excitation magnetic field. The interaction of these two magnetic fields drives the rotor.

The structure of a permanent magnet synchronous motor is similar to that of a brushless DC motor, but the difference lies in the function of the stator coils: in brushless DC motors, they assist the magnetic field, whereas in permanent magnet synchronous motors, they generate the excitation magnetic field.

Brushless DC motor:

The control of brushless DC motors primarily involves two methods: Hall sensor feedback and back electromotive force control. The Hall sensor feedback method determines the timing of commutation by detecting the position of the rotor, controlling the direction and magnitude of the current.

The back electromotive force control method estimates the rotor position and measures the back electromotive force of the armature coils for control. This method enables high efficiency and high torque output.

Permanent Magnet Synchronous Motor:

The control methods for permanent magnet synchronous motors mainly include current control and field-oriented control. The current control method controls the motor’s torque and speed by measuring the current.

Field-oriented control estimates the rotor position and measures the back electromotive force of the rotor to control the current, achieving more precise control and response.

Brushless DC motor:

Brushless DC motors have a high power density and efficiency. Due to their simple structure, free from brushes and brush wear issues, they can achieve high power output.

Also, the use of back electromotive force control reduces copper and iron losses, enabling efficient operation.

Permanent Magnet Synchronous Motor:

Permanent magnet synchronous motors have a high power density but relatively lower efficiency. Due to their complex structure and the need to maintain an excitation magnetic field in the stator coils, copper and iron losses occur.

Additionally, the presence of a rotating magnetic field leads to extra eddy current losses. Nonetheless, efficiency can be improved through optimized control strategies and advanced material technologies.

Brushless DC motor:

Brushless DC motors exhibit good response characteristics and a wide control range. As their rotors are made of permanent magnets, they have low rotor inertia and quick response speed. Moreover, brushless DC motors can achieve precise control by adjusting the current’s magnitude and direction to meet various operational requirements.

Permanent Magnet Synchronous Motor:

Permanent magnet synchronous motors have relatively poorer response characteristics and a narrower control range. Due to the larger rotor inertia, the response speed of the rotor is slower. Additionally, the control of permanent magnet synchronous motors is more complex, requiring accurate estimation of the rotor position and back electromotive force for precise control.

In summary, brushless DC motors and permanent magnet synchronous motors have noticeable differences in aspects like principle and structure, control methods, power density and efficiency, as well as response characteristics and control range. Depending on the application requirements, the appropriate type of motor can be chosen.

Brushless DC motors are suitable for applications requiring high power output and precise control, while permanent magnet synchronous motors are fit for applications needing high power density and a wider control range.