Have you ever wondered how massive steel structures on locomotives achieve their precise curves? In this article, we reveal the secrets behind creating large bend radii in sheet metal parts. You’ll learn about innovative methods like bump bending and step bending, and how they transform flat metal sheets into complex, curved masterpieces. Get ready to uncover the engineering magic that makes these impressive structures possible!

Large arc workpieces are a prevalent component in locomotive steel structure sheet metal fabrication. Their complex geometries and variable structures present significant processing challenges compared to conventional workpieces.

This article introduces an innovative process method for achieving large bend radii in sheet metal parts, with a detailed description of its application to a specific bent workpiece. The bump bending technique, which we’ll explore, can also be effectively utilized for cone formation using a press brake.

In industrial production, three primary forming methods are typically employed for large-radius workpieces:

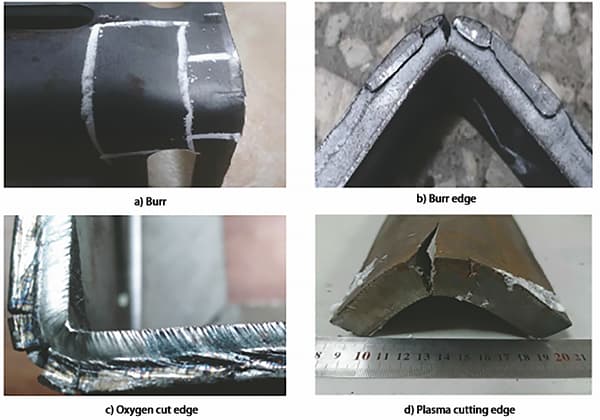

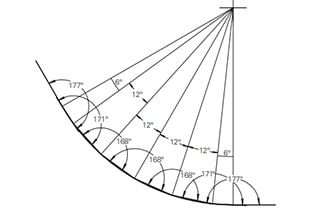

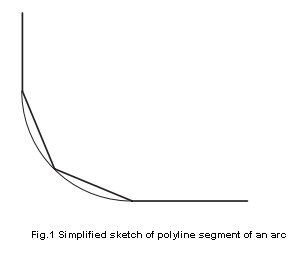

The multi-step forming process is a sophisticated technique for achieving large-radius bends in sheet metal using smaller radius punches. This method’s fundamental principle involves segmenting the desired arc into multiple polyline sections, as illustrated in Figure 1. This segmentation allows for the gradual approximation of the large radius curve through a series of smaller bends.

The accuracy and smoothness of the final formed arc are directly proportional to the number of polyline segments used in the process. Increasing the number of segments results in a closer approximation to the ideal curve, albeit at the cost of increased production time and tooling complexity.

While this method is highly effective, it inherently produces a faceted or prismatic surface structure on the workpiece. This characteristic is due to the discrete nature of the bending steps. For non-visible or non-critical surfaces, this approach offers an excellent balance between form accuracy and production efficiency. When evaluating the suitability of this method, manufacturers must consider several factors:

For applications where the prismatic structure is acceptable, this multi-step forming process provides a cost-effective solution for producing large-radius bends, especially when specialized large-radius tooling is not available or economically viable.

How to determine the polyline segmentation and bending angle of circular arc segments:

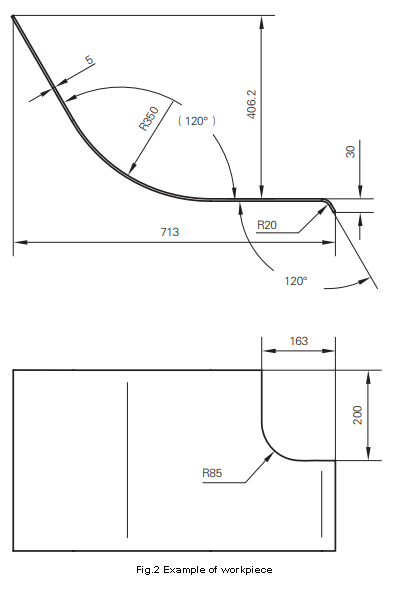

As shown in Figure 2, the inner radius of the bending arc of this workpiece is R350, the bending angle is 120°, and the plate thickness is 5mm.

Since the use environment of the workpiece satisfies the conditions of the bump bending method mentioned above, the multi-step bend forming method is used for processing.

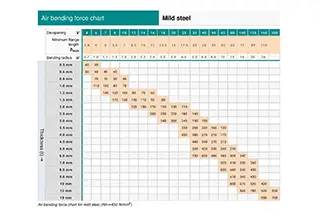

Based on past experience and the existing mold conditions in the workshop, the upper mold adopts a R120 radius punch.

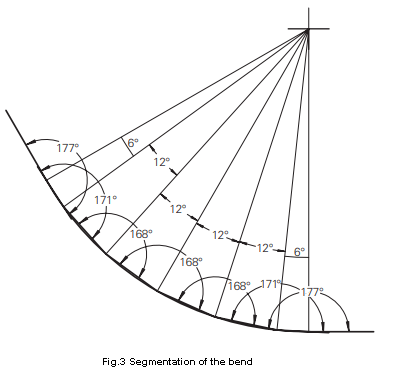

After analyzing the large arc segment of the workpiece in Figure 2, this R350 arc segment is divided into 6 polyline segments.

It should be noted that, to ensure the smooth transition of the arc segment and the straight segment of the workpiece (i.e., the two ends of the arc segment), the segmentation angle should be set to half of the other segments where the arc segment is tangent to the straight segment.

According to FIG. 3, it can be seen that the workpiece in FIG. 2 is formed by bending 7 times.

When the electro-hydraulic servo press brake machine bends sheet metal parts, three basic parameters are required: the thickness of the sheet, the bending angle, and the position of the bending line.

The first and second split angles are calculated as 6°, and the others are 12°. The bending angle after the split can be directly measured by CAD software. The specific bending angle is shown in Figure 3.

Bending line position size and unfolded size confirmation

To ensure the accuracy of the unfolded dimensions of the bend line, there are generally two methods: the neutral layer expansion calculation method and the software-assisted expansion method.

To obtain the bending data concisely, quickly, and accurately, the software-assisted expansion method is used for calculation.

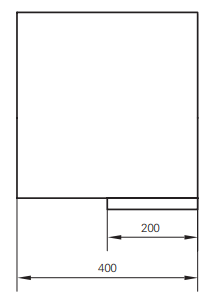

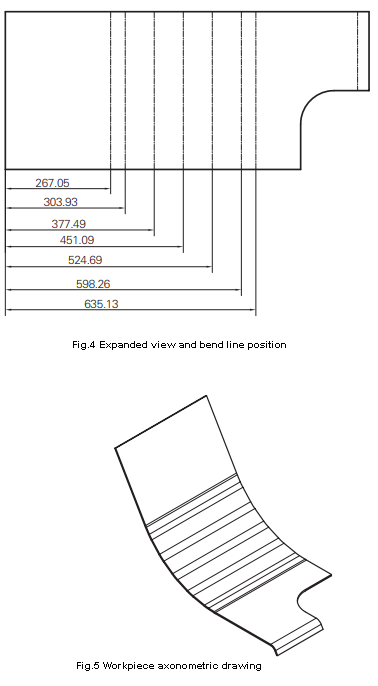

The divided part cross-section is directly imported into Catia, and the software’s Generative Sheet Metal Design module is used to generate the workpiece model. Then, the bend line and unfolded view are exported, as shown in Figure 4. The axonometric drawing of the workpiece is shown in Figure 5.

During production, it was found that some workpieces with small thickness (about 2mm) have serious deformation during processing, leading to a significant drop in processing accuracy and failure to meet design requirements. The reason for this is due to insufficient stress release in the sheet.

During laser cutting and blanking, we observed that the workpiece in this batch warped due to internal stress. This also provides a preliminary method to judge whether thin sheet metal with a large radius can be directly bent using the multi-bend process, that is, by observing the workpiece’s deformation during laser cutting.

If the deformation is serious, measures must be taken to release the internal stress, otherwise obtaining a qualified workpiece is difficult. If the production cycle allows, natural aging is an economical and effective method. However, the separated workpieces undergo aging treatment for a long time, which will inevitably produce floating rust on the surface. Therefore, they must be wiped or shot blasted with a rust remover, which increases labor and equipment costs.

Therefore, the direct use of steel plates that have undergone sufficient natural aging is the best choice. If the production cycle is not allowed, after the sheet is separated, annealing can also be used to eliminate internal stress, but the material’s hardness is reduced after annealing. Therefore, it is necessary to consider comprehensively whether annealing is performed according to the workpiece’s design requirements.

Calculation of workpiece expansion diagram in bump bending

It must be noted that when using the multi-step bending method to process sheet metal with a large radius, the actual workpiece conditions must be followed.

That is, the expanded view is calculated using the arc segment after approximating the polyline segment. The expanded view of the workpiece calculated according to the arc cannot be directly used; otherwise, the workpiece will inevitably be out of tolerance after processing.

Shape detection of workpiece using multi-step bending process

It is worth noting that when using a general comparison match sheet to detect the arc size of a workpiece processed by bump bending, the match sheet must be designed as an outer seizing type, and the outside of the workpiece arc should be used as the detection surface.

If the comparison match sheet is designed with the inner side as the detection surface, and the match sheet interferes with the polyline segment, it will inevitably lead to the match sheet not being in place, resulting in detection failure.

As an ingenious process method, large arc bump bending has its characteristics of flexibility and efficiency but also has its limitations.

Specific problems must be analyzed in accordance with the design requirements and application of the workpiece.

It is necessary to comprehensively consider the production cost and the appearance quality of the workpiece to select the processing method.