Ever wondered how busbars, the unsung heroes of electrical distribution, are processed and installed? This article delves into the intricate steps of busbar selection, preparation, and installation, ensuring efficient and safe power distribution. You’ll discover the essential tools and techniques needed to handle these critical components, enhancing your understanding of their role in low and high-voltage systems. By the end, you’ll have a solid grasp of busbar processing intricacies, from material inspection to final installation, ensuring optimal performance and safety in electrical applications. Dive in to power up your knowledge!

These guidelines govern the busbar processing and installation procedures for all low-voltage switchgear and power distribution enclosures manufactured by our facility. The principles outlined herein encompass a comprehensive range of busbar fabrication techniques, including but not limited to cutting, bending, drilling, and surface treatment. While primarily focused on low-voltage applications, many of these guidelines—with the exception of specific electrical clearance and creepage distance requirements—can be adapted for high-voltage cabinet manufacturing processes.

The scope of application includes:

These guidelines aim to ensure consistent quality, optimal performance, and adherence to relevant international standards such as IEC 61439 for low-voltage switchgear and controlgear assemblies. By following these procedures, we maintain the highest levels of safety, reliability, and efficiency in our busbar processing and installation operations.

Busbars should be selected based on multiple critical factors, including circuit current, long-term permissible temperature rise conditions, and dynamic thermal stability requirements. The primary materials for busbars are aluminum and copper, with copper core plastic wires also being a viable option for certain applications.

The selection process must adhere to relevant industry standards, specifically GB5584-85 “Aluminum Busbars” and GB55852-85 “Copper Busbars” for Chinese applications. International standards such as IEC 60439-1 or ANSI C37.20.1 should be considered for global projects. These standards provide guidelines for material properties, dimensional tolerances, and performance requirements.

When determining the appropriate busbar, several key considerations should be taken into account:

For detailed specifications and current carrying capacities of common busbar sizes, refer to Appendix A1. Information on copper core plastic wires, which may be suitable for smaller current applications or as flexible connectors, can be found in Appendix A2.

It is crucial to note that while these guidelines provide a solid foundation for busbar selection, specific project requirements, such as unique environmental conditions, space constraints, or client preferences, may necessitate custom solutions. In such cases, detailed calculations and possibly finite element analysis (FEA) should be employed to ensure the selected busbar meets all performance and safety criteria.

1. Fasteners and Electrical Components:

2. Machinery and Hand Tools:

1. Before processing the busbar material, it should be subjected to an external inspection. If surface cracks, blemishes, pits, or miscellaneous deposits are found, or if there are large pores on the surface (aluminum busbar diameter greater than 5mm, depth greater than 0.55mm, copper busbar diameter greater than 5mm, depth greater than 0.15mm), that section should be cut off.

2. The entire busbar should be basically straight before cutting. If there is obvious unevenness or straightness, it should be corrected.

3. Cut according to the drawing or template size (for example, cut on the cutting machine or punch press) and remove burrs during processing.

After cutting, if it is found to be uneven, not straight or twisted, it should be corrected with a wooden hammer or similar tool. After correction, there should be no obvious hammer marks on the busbar.

4. Bend the busbar according to its own requirements or the specific requirements of the switch cabinet. When the busbar is bent, care should be taken not to use too much force or speed to avoid cracking. The bending degree of the two parallel busbars of the same phase should be consistent.

(1) The minimum allowable radius for busbar bending is shown in Appendix A3.

(2) No cracks are allowed after the busbar is bent.

(3) The bending points of the same group of busbars should be basically consistent after installation.

5. Busbar Hole Drilling

(1) The pairing of the busbar hole and bolt specifications is selected according to Appendix A4.

(2) After determining the hole size according to the used busbar specifications, overlapping form, and electrical pile head form, drill or punch holes on a drilling machine or punch press.

(3) After the busbar is processed, cut-offs and hole edges should be deburred and chamfered.

6. Both the connection points between busbars and between busbars and electrical pile heads should be tinned and crimped, with neutral Vaseline applied to the tinned connection parts. Depending on the plant’s technical conditions, conductive paste can be used instead of tinning.

(1) For detailed busbar tinning procedures, refer to the “Tinning Process Guidelines”. For application of conductive paste, refer to the “Conductive Paste Application Guidelines”.

(2) Busbar crimping should be done using a dedicated crimping mold on a punch press.

(3) Before crimping, the crimping boundary should be marked (generally 20mm from the connection edge).

7. All busbars should be painted black. The painted edges should be basically on one line, without missing paint, drip marks, foreign objects, or other traces. The overlapping surface should not be painted, and the distance between the painted edge and the overlapping edge should be between 5-10mm.

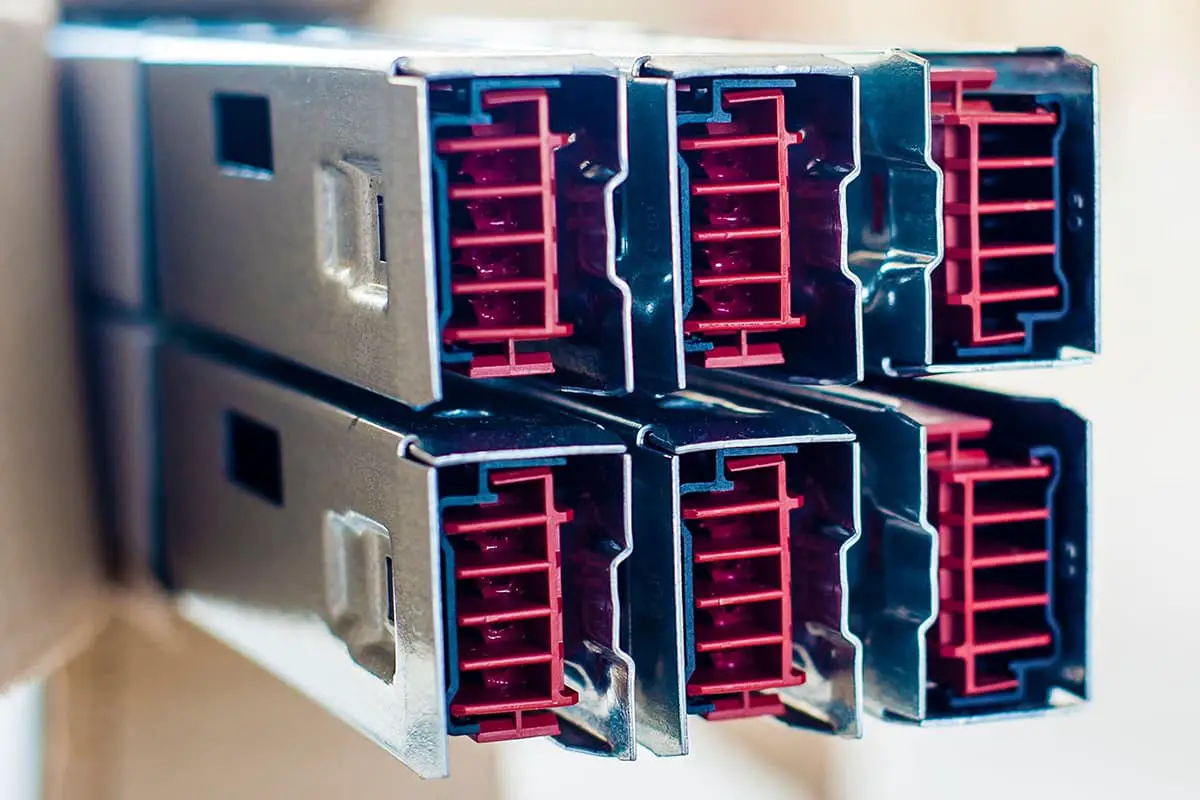

Busbars rated for currents below 200A can be effectively replaced with copper-core plastic-insulated wires, offering a flexible and cost-efficient alternative. This substitution requires precision termination using copper or aluminum connectors crimped onto both ends of the wire.

The critical parameters for proper installation, including the specific stripping length and appropriate connector selections, are detailed in Appendix A5. It is imperative to adhere to these specifications to ensure optimal electrical conductivity and mechanical strength of the connection.

After crimping, the exposed conductive area at the termination point must be thoroughly wrapped with high-quality electrical insulating tape. This step is crucial for maintaining the integrity of the insulation system, preventing short circuits, and ensuring compliance with electrical safety standards. The insulating tape should be applied with a 50% overlap and extend beyond the crimped area by at least 10mm on each side to guarantee complete coverage and protection against environmental factors.

When implementing this busbar alternative, it’s essential to consider the ampacity of the selected wire, ensuring it meets or exceeds the current-carrying capacity of the original busbar while accounting for factors such as ambient temperature, installation method, and voltage drop requirements.

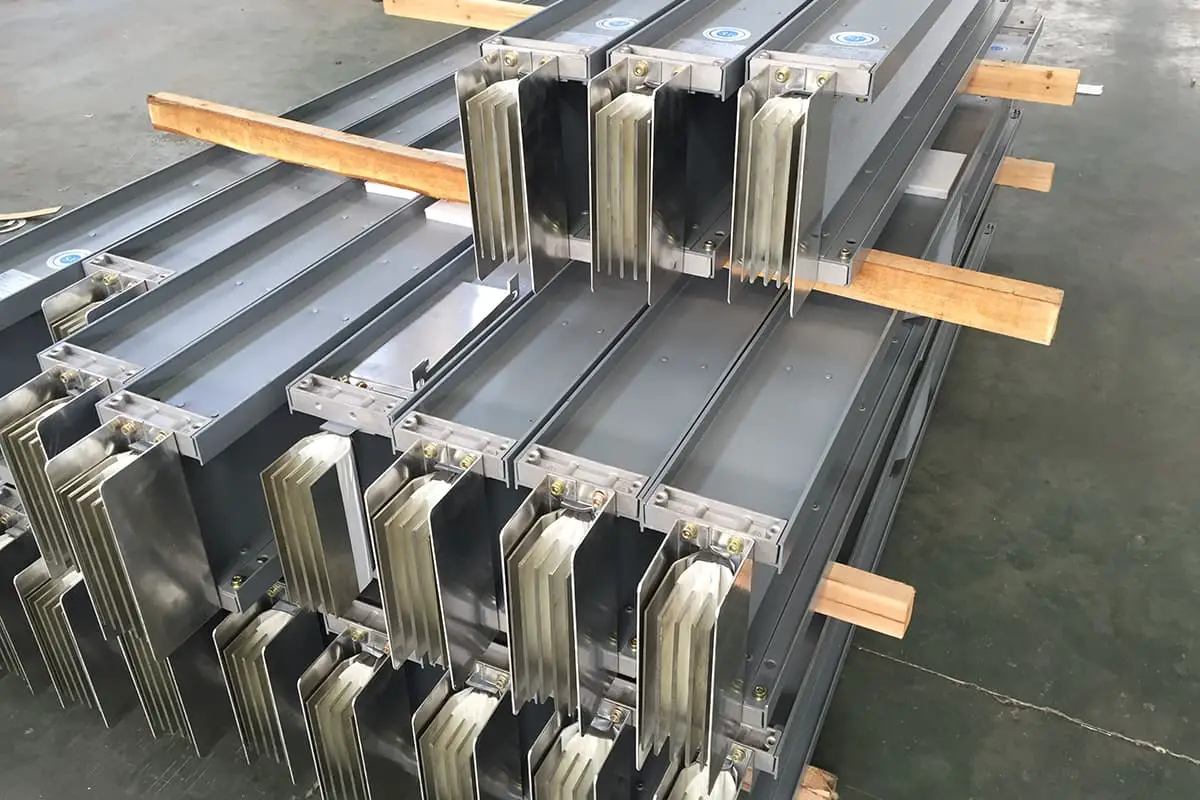

1. Before installing the busbar, inspect the quality of the busbar and its accessories. Unqualified items are not allowed to be installed.

2. When the busbar is long (generally low voltage cabinet >0.8M, GCK >0.4M), a suitable busbar clamp and insulator should be used for fixing in the middle.

3. When the main busbar overlaps, the three phases must be staggered layer by layer and not crossed. When two or more busbars are used in parallel for the same phase, there should be a row’s thickness of space between the two (to increase the heat dissipation area).

4. During installation, the overlapping surfaces of the busbar to busbar and busbar to electrical pile head must be naturally flat. No external force should be used to press it flat, causing stress on the busbar, affecting the switch components, and the busbar’s dynamic thermal stability.

5. After tightening the bolts, there must be sufficient contact pressure between the overlapping surfaces. The contact tightness can be checked with a 0.05x10mm feeler gauge.

For busbars wider than 63mm, the depth of insertion in any direction should not exceed 6mm. For those less than 56mm, the depth of insertion should not exceed 4mm. The bolt head should protrude 2-5 threads from the nut (after tightening). It should not be too short or too long.

6. When the busbar is placed flat, the bolt should be inserted from top to bottom. When vertical, it should be inserted from front to back, that is, the nut should be placed on the back.

7. If there are difficulties in the contact area or layout, a transition bar connection can be added as needed.

8. The main busbar must be firmly clamped with a busbar clamp.

9. Except for special circumstances, busbars should be installed according to drawing requirements. Their layout and installation must ensure the electrical clearance (≥12mm) and creepage distance (≥14mm) between the busbar and other components and elements, auxiliary parts.

The minimum requirements for electrical clearance and creepage distance also meet the values specified in Table A8. It also meets the requirements for arc spraying distance (see “Electrical component, auxiliary installation, tuning process rules”).

10. For all horizontal busbars, vertical busbars, branch busbars, and live parts between main circuit connectors in drawer cabinets, and their electrical clearance and creepage distance from grounded metal parts, the rated voltage should be between 380V-660V and should not be less than 20mm.

Insulation wrapping, insulation sleeving, epoxy powder spraying or other insulation materials are allowed to be used as the insulating layer of the busbar to reduce the requirements for busbar clearance, but it should still meet the provisions of Table A8.

11. For other forms of low-voltage switchgear, the electrical clearance and creepage distance between main circuit busbars should also refer to the provisions of Article 10 when the dynamic thermal stability current passes through and may cause a reduction in electrical clearance.

12. See Appendix A6 for the typical connection forms and requirements of busbar overlaps.

After the busbar is installed, phase sequence signs should be affixed in a prominent position on the busbar, or three-color paint blocks should be painted to indicate the phase sequence (Phase A: yellow; Phase B: green; Phase C: red).

(1) See Appendix A7 for the phase sequence arrangement of the busbar in the cabinet.

(1) Check whether there are cracks at the bend of the busbar and whether the surface is smooth.

(2) Check whether the tinning place of the busbar is smooth, bright, and uniform, and use a feeler gauge to check whether the gap between the busbar overlapping surfaces meets the requirements.

(3) Check whether the busbar is firmly installed and overlapped, whether the layout is beautiful, and whether it meets the requirements for electrical clearance, creepage distance, and arc spraying distance.

(4) Whether the phase sequence mark is correct.

Appendix A1 Single rectangular busbar specifications and current carrying capacity.

| Copper Busbar TMY | |||||

| Busbar Cross-Section(㎜2) | Maximum Permissible Current (A) | ||||

| Horizontal Placement | Vertical Placement | ||||

| Specification | Area | 25℃ | 40℃ | 25℃ | 40℃ |

| 15×3 | 45 | 200 | 167 | 210 | 171 |

| 20×3 | 60 | 261 | 212 | 275 | 224 |

| 25×3 | 75 | 323 | 263 | 340 | 277 |

| 30×4 | 120 | 451 | 368 | 475 | 387 |

| 40×4 | 160 | 593 | 483 | 625 | 509 |

| 40×5 | 200 | 665 | 541 | 700 | 570 |

| 50×5 | 250 | 816 | 665 | 860 | 700 |

| 50×6 | 300 | 905 | 738 | 955 | 778 |

| 60×6 | 360 | 1069 | 893 | 1125 | 916 |

| 60×8 | 480 | 1251 | 1019 | 1320 | 1075 |

| 60×10 | 600 | 1395 | 1136 | 1475 | 1202 |

| 80×6 | 480 | 1360 | 1108 | 1480 | 1206 |

| 80×8 | 640 | 553 | 1265 | 1690 | 1377 |

| 80×10 | 800 | 17847 | 1423 | 1900 | 1548 |

| 100×6 | 600 | 1665 | 1356 | 1810 | 1475 |

| 100×8 | 800 | 1911 | 1557 | 2080 | 1695 |

| 100×10 | 1000 | 2121 | 1728 | 2310 | 1882 |

| 120×8 | 960 | 2210 | 1810 | 2400 | 1956 |

| 120×10 | 1200 | 2435 | 1984 | 2650 | 2159 |

Appendix A3: Minimum radius (R) for busbar bending (flat bend) (busbar thickness b)

| MATERIAL/Specifications | TML | LMY |

| ≤5×50 | R=2b | R=2b |

| >5×50 | R=2b | R=2.5b |

Appendix A4: Busbar, Bolt Hole, and Diameter Fitting

| Bolt Diameter | Busbar Hole | Bolt Diameter | Busbar Hole Diameter |

| M6 | ¢6.5 | M12 | ¢13 |

| M8 | ¢9 | M16 | ¢18 |

| M10 | ¢11 |

Appendix A5

| Terminal (mm) | Wire Stripping Length (mm) |

| 10 | 10 |

| 16 | 12 |

| 25 | 14 |

| 35 | 16 |

| 16 |

Note: Single-core wires less than 10mm can be installed directly using the bending circle method.

Appendix A7 Wire phase sequence arrangement

| Arrangement Method/Phase Sequence | Vertical | Horizontal | Front and Back | Sign Color |

| A | Top | Left | Far | Yellow |

| B | Middle | Middle | Medium | Green |

| C | Bottom | Right | Near | Red |

| Neutral Line | Very Bottom | Finally | Closest |

Note: The above is observed from the front of the cabinet. (Special cases may not follow this table, but must be marked)

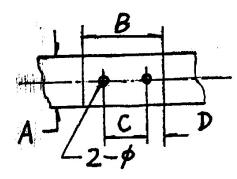

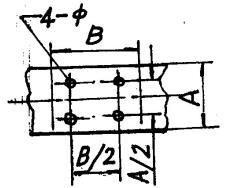

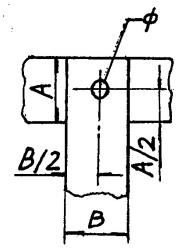

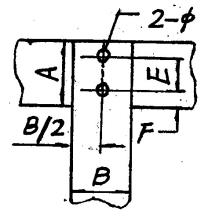

Appendix A6 Dimensions of Bolt Connection Holes for Rectangular Busbars

| Legend | Dimensions (mm) | Components | |||||||||||

| A | B | D | F | E | C | ¢ | Diameter | Bolt | Nut | Washer | Spring Washer | ||

| 15 20 25 30 40 | 40 50 50 60 80 | 10 12 12 15 20 | 20 26 26 30 40 | 7 11 11 13 13 | M6 M10 M10 M12 M12 | 2 | 2 | 42 | ||||

| 50 60 | 75 90 | 14.5 17 | 14 17 | 22 17 | 23 28 | 13 | M12 | 3 | 3 | 63 | ||

| 80 100 | 80 100 | 17 | M16 | 4 | 4 | 8 | 6 | |||||

| 15 20 25 20 25 25 35 40 30 40 | 15 15 15 20 20 25 25 25 30 30 | 7 7 7 11 11 11 11 11 13 13 | M6 M6 M6 M10 M10 M10 M10 M10 M12 M12 | 1 | 1 | 2 | 1 | |||||

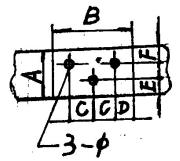

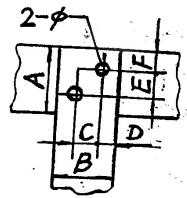

Appendix A6 (2) Hole Size for Rectangular Busbar Bolt Connection

| Legend | Dimensions (mm) | Components | ||||||||||

| A | B | D | F | E | C | ¢ | Diameter | Bolt | Nut | Washer | Spring Washer | |

| 40 50 60 60 | 40 50 50 60 | 11 14 14 17 | 11 14 17 17 | 18 22 26 26 | 18 22 22 26 | 11 13 13 13 | M10 M12 M12 M12 | 2 | 2 | 4 | 2 |

| 30 40 30 30 40 40 50 50 50 50 60 60 60 60 80 80 80 80 100 100 100 | 12 12 15 20 15 20 20 25 30 40 30 25 30 40 30 40 50 60 40 50 60 | 7 10 7 7 10 10 12 12 12 12 15 15 15 15 20 20 20 20 20 25 25 25 | 16 20 16 16 20 20 26 26 26 26 30 30 30 30 40 40 40 40 50 50 50 | 5.5 5.5 7 7 7 7 11 11 11 11 11 11 13 13 13 13 13 13 13 13 13 | M5 M5 M6 M6 M6 M6 M10 M10 M10 M10 M10 M10 M12 M12 M12 M12 M12 M12 M12 M12 M12 | 2 | 2 | 4 | 2 | ||

| 80 80 100 | 80 80 100 | 17 | M 16 | 4 | 4 | 8 | 4 | ||||

Appendix A8 Electrical Clearance, Creepage Distance, and Spacing Distance (mm)

| Rated Insulation Voltage(V) | Electrical Clearance | Creepage Distance | ||

| 63A and below | More than 63A | 63A and below | More than 63A | |

| V≤60 | 3 | 5 | 3 | 5 |

| 60<V≤300 | 5 | 6 | 6 | 8 |

| 300<V≤660 | 8 | 10 | 10 | 12 |

Minimum distance between primary circuit electrical equipment and the ground.

| 3KV | 6KV | 10KV | 35KV | ||

| The distance between bare conductors of different phases and between bare live parts to the grounded frame. | 75 | 100 | 125 | 300 | |

| The distance from the live part of the bare conductor to | Front Metal Cover Plate | 105 | 130 | 155 | 330 |

| Transmission Rod Bare Belt | 100 | 120 | 130 | 320 | |

| The portion of the energized bare conductor to the mesh sealing plate or mesh door | 175 | 200 | 225 | 400 | |

| Height of the unshielded bare conductor to the ground (floor) slab | 2500 | 2500 | 2500 | 2500 | |