Have you ever wondered how to accurately calculate the weight of C-channel steel for your construction projects? In this blog post, we’ll dive into the world of C-channel weight calculation, providing you with a comprehensive guide and helpful tools. Whether you’re an engineer, contractor, or DIY enthusiast, understanding the weight of C-channel steel is crucial for success. Get ready to learn from industry experts and discover practical tips that will elevate your projects to new heights!

C purlins are horizontal structural members designed to support loads from the roof deck or sheathing. Their name derives from their distinctive “C” shape, achieved through the process of cold-forming steel. This shape allows for efficient load distribution and provides a stable base for various construction elements.

Calculating the weight of C-channel steel, including C-purlins, is essential for various construction and engineering projects. This guide provides a comprehensive method to accurately determine the weight based on specific dimensions and material density.

Different formulas can be used to calculate the weight of a C purlin, depending on the level of detail required and the available data.

Detailed Formula

For more precise calculations, use this formula that considers the expanded section dimensions:

Weight kg =(Sum of the dimensions of the expanded section+Thickness)×100×0.00785

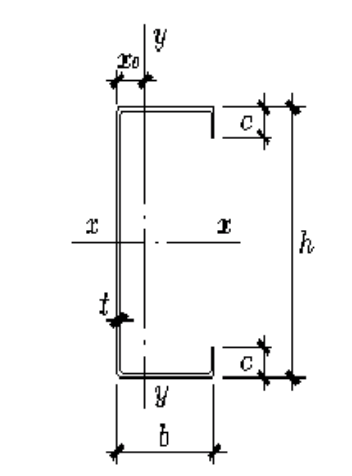

Where:

Using a C purlin weight calculator involves several steps to ensure accurate results. This process includes gathering the necessary input parameters, selecting the appropriate formula, and verifying the units of measurement. Here’s a detailed guide on how to effectively use a C purlin weight calculator for your structural engineering needs.

To use a C purlin weight calculator, you need specific dimensions and material properties of the purlin. The key input parameters include:

Common Mistakes to Avoid:

Below is a simplified version of the C-channel weight chart for quick reference:

| Model | Sizes (mm) | Cross-sectional area (cm²) | Weight (kg/m) | |||

|---|---|---|---|---|---|---|

| h | b | c | t | |||

| C80 | 80 | 40 | 20 | 2.25 | 4.29 | 3.37 |

| C80 | 80 | 40 | 20 | 2.50 | 4.75 | 3.72 |

| C80 | 80 | 40 | 20 | 2.75 | 5.19 | 4.08 |

| C80 | 80 | 40 | 20 | 3.00 | 5.64 | 4.42 |

| C80 | 80 | 50 | 20 | 2.25 | 4.74 | 3.72 |

| C80 | 80 | 50 | 20 | 2.50 | 5.25 | 4.12 |

| C80 | 80 | 50 | 20 | 2.75 | 5.74 | 4.51 |

| C80 | 80 | 50 | 20 | 3.00 | 6.24 | 4.89 |

| C100 | 100 | 50 | 20 | 2.25 | 5.19 | 4.08 |

| C100 | 100 | 50 | 20 | 2.50 | 5.75 | 4.51 |

| C100 | 100 | 50 | 20 | 2.75 | 6.29 | 4.94 |

| C100 | 100 | 50 | 20 | 3.00 | 6.84 | 5.36 |

| C120 | 120 | 50 | 20 | 2.25 | 5.64 | 4.43 |

| C120 | 120 | 50 | 20 | 2.50 | 6.25 | 4.90 |

| C120 | 120 | 50 | 20 | 2.75 | 6.84 | 5.37 |

| C120 | 120 | 50 | 20 | 3.00 | 7.44 | 5.84 |

| C140 | 140 | 50 | 20 | 2.25 | 6.09 | 4.78 |

| C140 | 140 | 50 | 20 | 2.50 | 6.75 | 5.29 |

| C140 | 140 | 50 | 20 | 2.75 | 7.39 | 5.80 |

| C140 | 140 | 50 | 20 | 3.00 | 8.03 | 6.31 |

| C140 | 140 | 60 | 20 | 2.25 | 6.54 | 5.13 |

| C140 | 140 | 60 | 20 | 2.50 | 7.25 | 5.69 |

| C140 | 140 | 60 | 20 | 2.75 | 7.94 | 6.23 |

| C140 | 140 | 60 | 20 | 3.00 | 8.64 | 6.78 |

| C160 | 160 | 50 | 20 | 2.25 | 6.54 | 5.13 |

| C160 | 160 | 50 | 20 | 2.50 | 7.25 | 5.69 |

| C160 | 160 | 50 | 20 | 2.75 | 7.94 | 6.23 |

| C160 | 160 | 50 | 20 | 3.00 | 8.64 | 6.78 |

| C160 | 160 | 60 | 20 | 2.25 | 6.99 | 5.49 |

| C160 | 160 | 60 | 20 | 2.50 | 7.75 | 6.08 |

| C160 | 160 | 60 | 20 | 2.75 | 8.49 | 6.67 |

| C160 | 160 | 60 | 20 | 3.00 | 9.24 | 7.25 |

| C160 | 160 | 70 | 20 | 2.25 | 7.44 | 5.84 |

| C160 | 160 | 70 | 20 | 2.50 | 8.25 | 6.47 |

| C160 | 160 | 70 | 20 | 2.75 | 9.04 | 7.10 |

| C160 | 160 | 70 | 20 | 3.00 | 9.84 | 7.72 |

| C180 | 180 | 50 | 20 | 2.25 | 6.99 | 5.49 |

| C180 | 180 | 50 | 20 | 2.50 | 7.75 | 6.08 |

| C180 | 180 | 50 | 20 | 2.75 | 8.49 | 6.67 |

| C180 | 180 | 50 | 20 | 3.00 | 9.24 | 7.25 |

| C180 | 180 | 60 | 20 | 2.25 | 7.44 | 5.84 |

| C180 | 180 | 60 | 20 | 2.50 | 8.25 | 6.47 |

| C180 | 180 | 60 | 20 | 2.75 | 9.04 | 7.10 |

| C180 | 180 | 60 | 20 | 3.00 | 9.84 | 7.72 |

| C180 | 180 | 70 | 20 | 2.25 | 7.89 | 6.19 |

| C180 | 180 | 70 | 20 | 2.50 | 8.75 | 6.86 |

| C180 | 180 | 70 | 20 | 2.75 | 9.59 | 7.53 |

| C180 | 180 | 70 | 20 | 3.00 | 10.44 | 8.19 |

| C180 | 180 | 80 | 20 | 2.25 | 8.34 | 6.55 |

| C180 | 180 | 80 | 20 | 2.50 | 9.25 | 7.26 |

| C180 | 180 | 80 | 20 | 2.75 | 10.14 | 7.96 |

| C180 | 180 | 80 | 20 | 3.00 | 11.04 | 8.66 |

| C200 | 200 | 50 | 20 | 2.25 | 7.44 | 5.84 |

| C200 | 200 | 50 | 20 | 2.50 | 8.25 | 6.47 |

| C200 | 200 | 50 | 20 | 2.75 | 9.04 | 7.10 |

| C200 | 200 | 50 | 20 | 3.00 | 9.84 | 7.72 |

| C200 | 200 | 60 | 20 | 2.25 | 7.89 | 6.19 |

| C200 | 200 | 60 | 20 | 2.50 | 8.75 | 6.86 |

| C200 | 200 | 60 | 20 | 2.75 | 9.59 | 7.53 |

| C200 | 200 | 60 | 20 | 3.00 | 10.44 | 8.19 |

| C200 | 200 | 70 | 20 | 2.25 | 8.34 | 6.55 |

| C200 | 200 | 70 | 20 | 2.50 | 9.25 | 7.26 |

| C200 | 200 | 70 | 20 | 2.75 | 10.14 | 7.96 |

| C200 | 200 | 70 | 20 | 3.00 | 11.04 | 8.66 |

| C200 | 200 | 80 | 20 | 2.25 | 8.79 | 6.90 |

| C200 | 200 | 80 | 20 | 2.50 | 9.75 | 7.65 |

| C200 | 200 | 80 | 20 | 2.75 | 10.69 | 8.39 |

| C200 | 200 | 80 | 20 | 3.00 | 11.64 | 9.13 |

| C220 | 220 | 50 | 20 | 2.25 | 7.89 | 6.19 |

| C220 | 220 | 50 | 20 | 2.50 | 8.75 | 6.86 |

| C220 | 220 | 50 | 20 | 2.75 | 9.59 | 7.53 |

| C220 | 220 | 50 | 20 | 3.00 | 10.44 | 8.19 |

| C220 | 220 | 60 | 20 | 2.25 | 8.34 | 6.55 |

| C220 | 220 | 60 | 20 | 2.50 | 9.25 | 7.26 |

| C220 | 220 | 60 | 20 | 2.75 | 10.14 | 7.96 |

| C220 | 220 | 60 | 20 | 3.00 | 11.04 | 8.66 |

| C220 | 220 | 70 | 20 | 2.25 | 8.79 | 6.90 |

| C220 | 220 | 70 | 20 | 2.50 | 9.75 | 7.65 |

| C220 | 220 | 70 | 20 | 2.75 | 10.69 | 8.39 |

| C220 | 220 | 70 | 20 | 3.00 | 11.67 | 9.13 |

| C220 | 220 | 80 | 20 | 2.25 | 9.24 | 7.25 |

| C220 | 220 | 80 | 20 | 2.50 | 10.25 | 8.04 |

| C220 | 220 | 80 | 20 | 2.75 | 11.24 | 8.82 |

| C220 | 220 | 80 | 20 | 3.00 | 12.24 | 9.60 |

| C240 | 240 | 50 | 20 | 2.25 | 8.34 | 6.55 |

| C240 | 240 | 50 | 20 | 2.50 | 9.25 | 7.26 |

| C240 | 240 | 50 | 20 | 2.75 | 10.14 | 7.96 |

| C240 | 240 | 50 | 20 | 3.00 | 11.04 | 8.66 |

| C240 | 240 | 60 | 20 | 2.25 | 8.79 | 6.90 |

| C240 | 240 | 60 | 20 | 2.50 | 9.75 | 7.65 |

| C240 | 240 | 60 | 20 | 2.75 | 10.69 | 8.39 |

| C240 | 240 | 60 | 20 | 3.00 | 11.64 | 9.13 |

| C240 | 240 | 70 | 20 | 2.25 | 9.24 | 7.25 |

| C240 | 240 | 70 | 20 | 2.50 | 10.25 | 8.04 |

| C240 | 240 | 70 | 20 | 2.75 | 11.24 | 8.82 |

| C240 | 240 | 70 | 20 | 3.00 | 12.24 | 9.60 |

| C240 | 240 | 80 | 20 | 2.25 | 9.69 | 7.61 |

| C240 | 240 | 80 | 20 | 2.50 | 10.75 | 8.43 |

| C240 | 240 | 80 | 20 | 2.75 | 11.79 | 9.26 |

| C240 | 240 | 80 | 20 | 3.00 | 12.84 | 10.07 |

| C250 | 250 | 50 | 20 | 2.25 | 8.57 | 6.72 |

| C250 | 250 | 50 | 20 | 2.50 | 9.50 | 7.45 |

| C250 | 250 | 50 | 20 | 2.75 | 10.42 | 8.18 |

| C250 | 250 | 50 | 20 | 3.00 | 11.34 | 8.90 |

| C250 | 250 | 60 | 20 | 2.25 | 9.02 | 7.08 |

| C250 | 250 | 60 | 20 | 2.50 | 10.00 | 7.85 |

| C250 | 250 | 60 | 20 | 2.75 | 10.97 | 8.61 |

| C250 | 250 | 60 | 20 | 3.00 | 11.94 | 9.37 |

| C250 | 250 | 70 | 20 | 2.25 | 9.47 | 7.43 |

| C250 | 250 | 70 | 20 | 2.50 | 10.50 | 8.24 |

| C250 | 250 | 70 | 20 | 2.75 | 11.52 | 9.04 |

| C250 | 250 | 70 | 20 | 3.00 | 12.54 | 9.84 |

| C250 | 250 | 75 | 20 | 2.25 | 9.69 | 7.61 |

| C250 | 250 | 75 | 20 | 2.50 | 10.75 | 8.43 |

| C250 | 250 | 75 | 20 | 2.75 | 11.79 | 9.26 |

| C250 | 250 | 75 | 20 | 3.00 | 12.84 | 10.07 |

| C250 | 250 | 80 | 20 | 2.25 | 9.92 | 7.78 |

| C250 | 250 | 80 | 20 | 2.50 | 11.00 | 8.63 |

| C250 | 250 | 80 | 20 | 2.75 | 12.07 | 9.47 |

| C250 | 250 | 80 | 20 | 3.00 | 13.14 | 10.31 |

Related reading: Metal Weight Calculator

C purlins are structural elements commonly used in construction, particularly in roofing systems and wall framing. They provide support for loads and help maintain the integrity of structures. Understanding the material properties of C purlins is crucial for optimizing their performance and weight, which in turn affects the overall efficiency and cost of construction projects.

Material density, defined as mass per unit volume (kg/m³), significantly influences the weight of C purlins. For instance, steel, a common material for C purlins, has a density of approximately 7850 kg/m³, making it relatively heavy. In contrast, aluminum, with a density of around 2700 kg/m³, is much lighter. For example, a steel C purlin and an aluminum C purlin of the same dimensions will have different weights due to their densities, with the aluminum purlin being significantly lighter. This difference impacts not only the weight but also the structural performance and ease of installation.

The strength to weight ratio is a crucial factor in selecting materials for C purlins. This ratio, calculated by dividing the material’s strength by its density, indicates how well a material can support loads relative to its weight. High-strength materials like advanced high-strength steels (AHSS) and titanium alloys offer excellent strength to weight ratios. For instance, AHSS is used in automotive and aerospace industries where reducing weight without compromising strength is essential. Using a high-strength steel with a better strength to weight ratio can allow for thinner, lighter purlins that still support the required loads.

Mechanical properties such as tensile strength, yield strength, hardness, ductility, and toughness determine how a material performs under various stresses. Tensile strength is the maximum stress a material can withstand while being stretched. Yield strength is the stress at which a material begins to deform plastically. Hardness measures a material’s resistance to deformation. Ductility is the ability to undergo significant plastic deformation before rupture, and toughness is the ability to absorb energy and plastically deform without fracturing. For example, high tensile strength steel can withstand significant stress, making it ideal for load-bearing applications. Charts and data illustrating these properties help in understanding their impact on material performance.

The elastic modulus, or Young’s Modulus, measures a material’s stiffness, indicating its ability to resist deformation under load. Stiffness is crucial for structural components like C purlins, as it affects their ability to maintain shape and support loads without bending or buckling. Materials with a higher elastic modulus, such as steel, provide greater stiffness, allowing for thinner sections that reduce weight without sacrificing performance.

The thickness and cross-sectional area of C purlins significantly impact their weight and structural capacity. Thicker purlins are generally stronger and can support greater loads, but they also weigh more. Engineers must balance these factors to achieve the desired performance characteristics. For example, in applications where reducing weight is essential, such as in long-span roofs or lightweight structures, using high-strength materials that allow for thinner, lighter purlins can be advantageous.

Choosing the appropriate material for C purlins involves considering various factors, including weight, strength, cost, and environmental conditions. For instance, galvanized steel purlins are commonly used due to their excellent corrosion resistance and durability. In contrast, stainless steel or aluminum purlins might be selected for environments with extreme corrosion risks or where weight reduction is a priority. Each material offers different benefits and trade-offs, impacting the overall performance and weight of the purlins.

The manufacturing process and the presence of impurities can affect the weight and performance of materials used for C purlins. Processes like hot-rolling, cold-forming, and heat treatment can alter the material’s density and mechanical properties. Additionally, impurities such as sulfur and phosphorus in steel can impact its strength and toughness. Ensuring high-quality manufacturing processes and materials with minimal impurities is essential for producing reliable and consistent C purlins.

Understanding the material properties and their impact on weight is crucial for designing effective and efficient structural components. By carefully selecting materials based on their density, strength to weight ratio, mechanical properties, and manufacturing quality, engineers can optimize the performance and weight of C purlins to meet the specific demands of their projects.

Below are answers to some frequently asked questions:

To calculate the weight of a C purlin, you need to know its size, thickness, length, and the material’s density. The size includes the width and depth of the C purlin, typically given in inches or millimeters, such as 3″ X 1 6/8″ or 75mm x 45mm. The thickness, which can range from 1.60 mm to 2.5 mm or more, is also crucial. Additionally, you need the total length of the purlin, which depends on the specific application and can range from 6 feet to 25 feet (1.83 meters to 7.62 meters). Finally, knowing the material density, often given in kg per meter, is essential.

To calculate the weight, multiply the total length of the C purlin by its weight per meter. For example, if a 100mm x 50mm x 1.6mm C purlin has a weight of 2.24 kg/m and you need 60 meters, the calculation would be 60 meters * 2.24 kg/m = 134.4 kg.

The material type of a C purlin directly impacts its weight due to the inherent properties and manufacturing methods of the materials used. Steel C purlins, especially those made from cold-formed steel, are favored for their combination of light weight and high strength. Cold-formed steel achieves its properties through a rolling and pressing process that does not require heating, making the material stronger and more efficiently used.

When galvanized steel is used for C purlins, a zinc coating provides corrosion resistance without a significant weight increase. This makes galvanized steel purlins lightweight, easy to handle, and install, while also being durable.

The thickness or gauge of the steel also influences the weight of a C purlin. Lower gauge numbers indicate thicker steel, which is heavier and offers greater structural support. Conversely, higher gauge numbers denote thinner steel, which is lighter but may need closer spacing to maintain the same level of structural integrity.

Compared to materials like wood, steel C purlins are much lighter and more durable. Wood purlins tend to be heavier due to their density and are susceptible to rot and pest damage, which can increase their weight over time as they absorb moisture.

The roll-forming manufacturing process used for steel C purlins ensures efficient material usage, minimizing waste and keeping the weight as low as possible while maintaining structural strength.

In conclusion, the choice of cold-formed and often galvanized steel for C purlins results in a lightweight yet robust structural component. The weight is further optimized by selecting the appropriate gauge and utilizing an efficient manufacturing process.

Yes, you can use a C purlin weight calculator for different grades of steel, provided the calculator allows for the input of custom material properties. C purlins can be manufactured from various grades of steel, each with unique mechanical properties such as density, yield strength, and tensile strength. To ensure accurate calculations, the weight calculator should accommodate these variations.

Most C purlin weight calculators require input parameters like the purlin’s dimensions and steel thickness. If the calculator is designed to work with different steel grades, it should also allow you to input specific material properties. Some advanced calculators offer features to enter custom properties, making it possible to calculate the weight and capacity of the purlin accurately based on the specific steel grade you are using.

If the calculator does not allow for inputting custom material properties or selecting specific steel grades, it might only provide a general estimate based on standard formulas. In such cases, the results may not be accurate for different grades of steel.

Therefore, when using a C purlin weight calculator for different steel grades, ensure it:

By verifying these features, you can ensure that the weight and capacity calculations of the purlin accurately reflect the properties of the steel grade you are working with.

Using an online C purlin weight calculator provides multiple benefits for engineers, architects, and construction professionals. One key advantage is the accuracy and efficiency it offers; these calculators use precise formulas and material properties to deliver reliable results, reducing the likelihood of human error and saving time compared to manual calculations. The process is simplified, as users only need to enter dimensions and material properties into a straightforward interface, which automatically computes the weight.

Customization and flexibility are also notable benefits, as many calculators allow for input of various sizes and materials, making them suitable for a wide range of C purlins. Integration with other design tools is another advantage, enabling seamless workflow transitions and easy data transfer for further structural analysis.

Compliance with industry standards and codes, such as AISI, ASCE, and AISC, is often built into these calculators, ensuring that calculations meet regulatory requirements and contribute to the structural integrity and safety of the design. Additionally, automating the calculation process saves significant time, allowing professionals to focus on other critical project aspects.

Finally, the accessibility and convenience of online calculators are important, as they can be used from any device with an internet connection, facilitating productivity and collaboration in various settings, whether in the office or on-site. Overall, these calculators enhance the design and analysis process by providing accurate, efficient, and compliant weight calculations for C purlins.

To accurately calculate the unit weight of C-channel steel, including C-purlins, you first need to understand the basic calculation formulas. The key points are summarized below:

The weight of C-channel steel can be calculated using the dimensions of its expanded section, thickness, and the density of the material.

The specific formula is:

Weight of C-channel steel = (Sum of the dimensions of the expanded section + Thickness) * 100 * 0.00785 = kg/m.

Here, “dimensions of the expanded section” refer to the width and height, while “Thickness” refers to the thickness of the C-channel steel. All these dimensions must be in centimeters.

Another method involves adding the dimensions of the C-channel steel’s expanded section, multiplying by the thickness, and then by the density (7.85). This method also applies to the calculation of the weight of C-purlins.

For C-purlins, the weight calculation formula is: Length × Width × Thickness × Density = Weight of the purlin. This indicates that, in addition to considering the basic parameters of the C-channel steel, the specific length of the purlin must also be taken into account.

The theoretical weight of the steel can also be calculated based on the density of the steel, the cross-sectional area, and the length, where the density of the steel is usually expressed in kilograms per cubic meter (kg/m³).

To accurately calculate the unit weight of C-channel steel, including C-purlins, it’s necessary to use the formulas mentioned above based on their specific dimensions (including width, height, and thickness), as well as the density of the material (usually 7.85 or 7.86 kg/m³). For C-purlins, the effect of the length on the weight must also be considered. In practice, you can choose the appropriate calculation method based on specific design drawings and specifications.

The density of C-section steel (especially C purlins) is 7.85kg/m³. This value applies to the general density of steel, including C-section steel and C purlins. There is no direct evidence in the data that the density of C purlins differs significantly from that of other types of steel or materials. Therefore, it can be assumed that the density of C purlins is the same as that of C-section steel, which is 7.85kg/m³.

The weight variation of C-purlins under different materials primarily reflects in their specifications and thickness. The actual weight of a C-purlin can be calculated through the product of its width, thickness, and 0.00785.

This indicates that with the change in width and thickness of the C-purlin, its actual weight will also vary. In addition, C-purlins of different specifications but the same thickness have a considerable difference in weight per meter, and the greater the difference in specification data, the larger their weight per meter difference.

This implies that, apart from the material (such as galvanized or non-galvanized) possibly impacting the weight, the specific specifications of the C-purlin (like its height) also play a significant role in determining its weight difference.