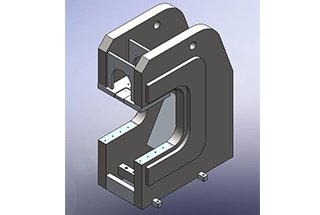

Have you ever wondered why your C-frame press suddenly stops working? In this article, we’ll explore common malfunctions, their causes, and practical solutions. By the end, you’ll know how to troubleshoot and fix these issues, ensuring your press runs smoothly.

Below is a detailed list of C-frame press malfunctions and their corresponding solutions. This list not only identifies the location of the failure, but also provides explanations for why it occurred and how to resolve it.

| Category | Faults | Reasons | Solutions |

| Main motor | Ac Contactor not work, main motor not work | 1. clutch bond | Check the switch to,adjusting microinching position Check the power supply |

| 2. power failure | |||

| 3. control circuit failure | |||

| 4. thermo relay work | |||

| 5. winding turnoff | |||

| Ac Contactor work, main motor not work | 1. main motor line broken | Repair | |

| 2. main motor fault | Repair | ||

| 3. poor contact | Repair | ||

| 4. main motor bearing fault | Repair | ||

| Main motor not stop | 1. stop button short out | Repair | |

| 2. two contacts colliquefaction | Repair | ||

| 3. contactor movable part fault | Repair | ||

| Operation | Sliding block not move | 1. auto stop button not restoration | Restoration |

| 2. sliding block not back to the top dead center | Sliding block back to top dead center | ||

| 3. pressure relay not work | Adjusting air pressure | ||

| 4. overload protector microswitch not adjusted | Readjusting | ||

| 5. power source or power fault | Repair | ||

| 6. auto stop button bad contact | Repair | ||

| 7. operating button contact | Repair | ||

| 8. clutch cylinder stroke increase | Change adjusting shim | ||

| 9. clutch get stuck or air leakage | Repair | ||

| 10. clutch magnetic valve air leakage or coil short | Repair | ||

| Sliding block stops at the bottom dead center | 1. auto stop button processing circuit due to vibration | Increase spring force | |

| 2. ac contactor off due to vibration | Change antivibration switch | ||

| 3. overload protection microswitch off due to vibration | |||

| 4. cam controller switch not work | |||

| Sliding block cannot stop at the top dead center | 1. clutch stroke increase | Change adjustable pad | |

| 2. cam adjustment fault | Readjustment | ||

| Stop position not regularly | 1. relay contact fusion | Change contactor | |

| 2. relay residual magnetism | Change relay | ||

| 3. button spring damage | Change button | ||

| 4. damage fault | Repair | ||

| 5. clutch emit heat | Reduce operation time | ||

| 6. spring force too low | Increase spring force or change | ||

| Emergency stop button cannot restoration | Button not good | Change | |

| Coil melting loss. melting loss | 1. excess temperature | Adjusting | |

| 2. supply voltage exceed specified value | |||

| 3. generate residual magnetism | |||

| 4. lead too tight | |||

| Movable iron core cannot go back when power off | 1. movable iron core Slipper part get stuck | Wipe off impurity | |

| 2. reset spring corrosion | Change spring | ||

| Actuation time error | 1. iron core and valve seat corrosion | Iron core rust removal or change, increase | |

| 2. Slipper part has dust and impurity | Voltage | ||

| Reversing valve | Leakage | 1. P-A cavitary seal ring broken | Replace sealing element part |

| 2. priority valve and main valve coupling screw loose | |||

| After reverse, O cavitary Continue to vent | 1. P-A cavitary seal ring broken | Replace sealing element part, change seal ring | |

| 2. piston seal broken | |||

| Not reversing | 1. coil bad contact | Check binding post | |

| 2. coil burning-out | change coil | ||

| 3. main valve element get stuck | Removing impurities | ||

| 4. valve slipper part large resistance | Improve lubrication | ||

| 5. poor lubrication | Change seal ring | ||

| 6. seal ring deformation | Change seal ring | ||

| Valve vibration | 1. control air supply low pressure | Increase control pressure | |

| 2. guide solenoid valve low voltage | Increase supply voltage | ||

| Reversing valve | Reversing too slow | exhaust resistance increasing due to silencer installed at the vent | Change silencer |

| Balance valve fault | 1. two guide solenoid valve electrical signal out of sync | Check electrical signal | |

| 2. travel switch not work | Check valve element dynamical friction switch, change them if necessary |