Have you ever wondered how bolts withstand the immense forces they’re subjected to? In this captivating article, we delve into the fascinating world of bolt shear strength. Our expert mechanical engineer will guide you through the intricacies of calculating and optimizing bolt performance, providing valuable insights to ensure your projects are built to last.

The shear strength of a bolt refers to its capacity to withstand maximum shear force without breaking when subjected to a lateral external force. We can understand the calculation method, standards, and some specific values of bolt shear strength.

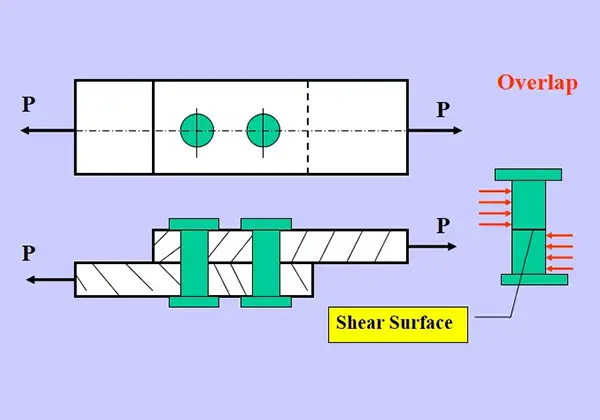

Firstly, the formula for calculating bolt shear strength is W=P/F=P/ab, where P is the load at break (N), F is the overlap area (cm^2), a is the length of the overlap (cm), and b is the width of the overlap (cm). This implies that the bolt’s shear strength is related to its size and shape. By measuring these parameters and applying the above formula, the bolt’s shear strength can be calculated.

Secondly, the shear strength of a bolt is also related to its material grade. For instance, a grade 4.8 bolt has a shear strength approximately half of its tensile strength, while a grade 12.9 bolt has a shear strength of 900 MPa. This indicates that bolts of different grades have different shear strength standards.

Furthermore, the design value of bolt shear strength is determined by statistical data from connection tests, implying that the actual shear strength of bolts in use may vary based on specific conditions and test results.

The calculation methods for the shear strength of bolts mainly include finite element analysis and experimental testing.

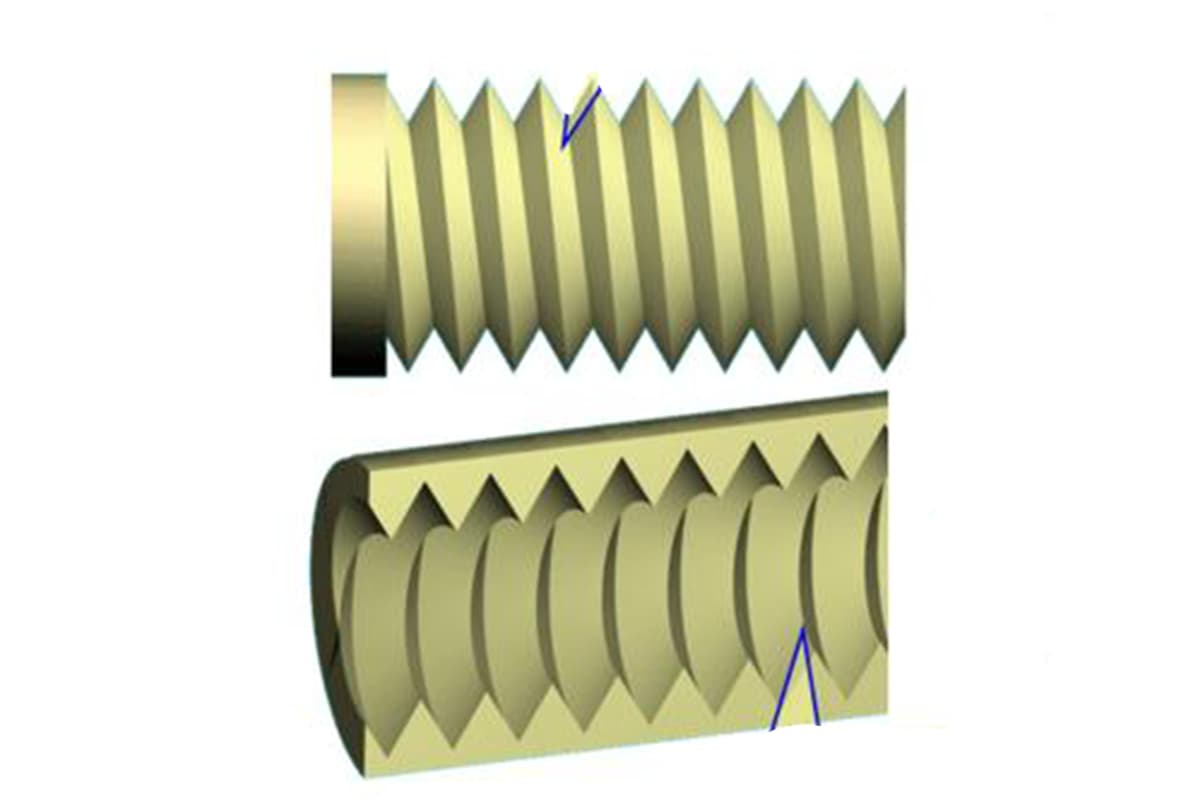

Finite element analysis is a method that predicts the behavior of materials or structures under force by establishing a mathematical model. It can evaluate the shear performance of bolts without actual destruction. This method can be used in the design and optimization of specific types of bolts such as blind bolts, by simulating the resistance behavior of bolts under pure shear force to study their load-bearing performance.

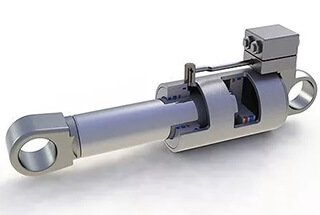

Experimental testing assesses by actually loading and observing the failure mode of the bolt, which can directly reflect the actual shear strength of the bolt.

The application scenarios of these two methods each have their own emphasis. Finite element analysis is suitable for the early stage of bolt design, needing to evaluate the impact of different design schemes on the shear performance of bolts, as well as predicting and optimizing the performance of bolts during the design process.

Experimental testing is more often applied in the later stage of product development, used to verify the accuracy and reliability of the design, ensuring that the bolt product can meet the performance requirements in actual applications.

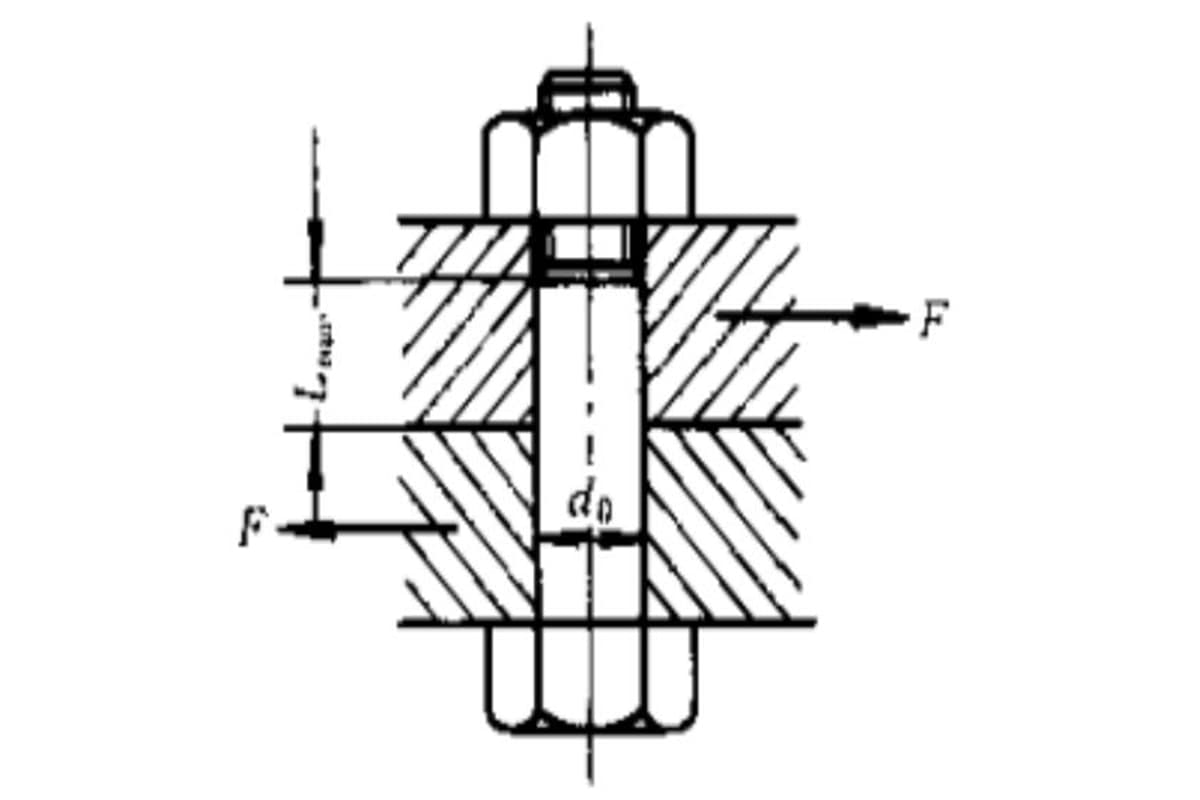

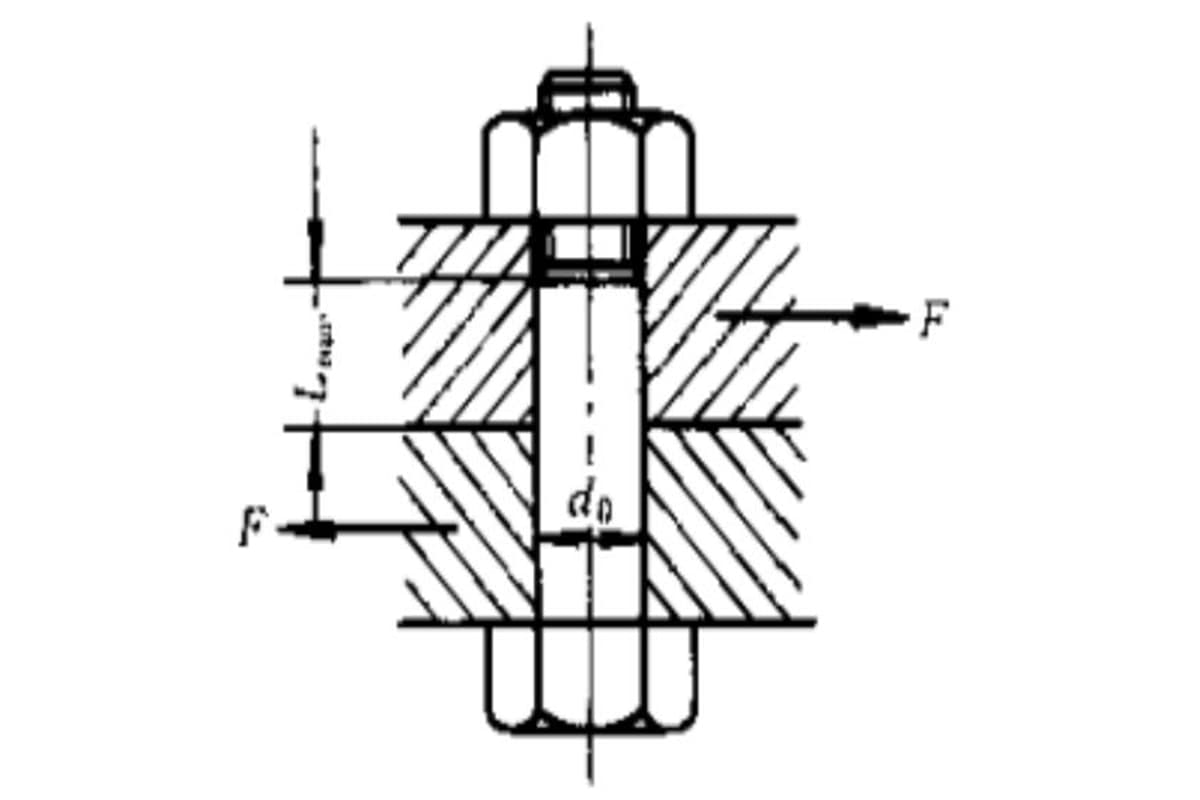

As shown in Figure 1-8, this connection uses a bolt to resist the working load F through a punched hole. Assuming each bolt receives an equal working load, the shear force received by each bolt is F.

Therefore, the compressive strength condition between the bolt rod and the hole wall is:

The conditions for the shear strength of bolts are:

In the formula:

F represents the operating shear force exerted on the bolt, in Newtons;

d0 represents the diameter of the shear face of the bolt, which can be taken as the bolt hole diameter, in millimeters;

[τ] represents the permissible shear strength of the thread, in MPa, for steel

Where:

[S]τ is the safety factor as per Table 1-9;

Lmin represents the minimum height of the bolt rod squeezed by the hole wall, in millimeters.

During design, Lmin should be greater than or equal to 1.25d; i represents the number of shear faces on the bolt rod. In Figure 1-1b, i=2, and in Figure 1-8, i=1.

The required shear stress for bolts is typically selected as 60Mpa.

| Bolt Specifications | Stress cross-sectional area (mm²) |

|---|---|

| M1 | 0.46 |

| M2 | 2.07 |

| M3 | 5.03 |

| M4 | 8.78 |

| M5 | 14.2 |

| M6 | 20.1 |

| M8 | 36.6 |

| M10 | 58.0 |

| M12 | 84.3 |

| M14 | 115 |

| M16 | 157 |

| M18 | 192 |

| M20 | 245 |

| M22 | 303 |

| M24 | 353 |

| M27 | 459 |

| M30 | 561 |

| M33 | 694 |

| M36 | 817 |

| M39 | 976 |

In practical applications, adjusting the shear strength of bolts to meet specific requirements based on usage conditions can be accomplished in several ways:

Choose the appropriate bolt type: Depending on the usage scenario, choose high-strength bolts or ordinary bolts. High-strength bolts are suitable for connecting important structures, such as bridges and steel structures, where the reliability and safety of connections need to be ensured. Ordinary bolts are more widely used in general mechanical equipment and furniture.

Calculate the shear stress of the bolt: Simplified from the formula F = A × (F / A), the shear force of the bolt equals the force the bolt is subjected to. This step helps understand the maximum shear force a bolt can withstand under a specific load, providing a basis for subsequent selection.

Consider the bolt’s deformability: To address the issue of insufficient deformability of bolt shear connectors, shear connectors with high deformability can be used to enhance their performance. This design can improve the bolt’s adaptability and reliability without sacrificing much strength.

Adjust the safety factor: Depending on the strength of the bolt and anticipated usage conditions, the safety factor should be adjusted appropriately. For example, the allowable shear stress Ít can be calculated by dividing the shear stress by the safety factor. Adjusting the safety factor can optimize bolt performance while ensuring safety.

Consider environmental factors: For high-strength fasteners that are long-term exposed to harsh environments, such as those used in wind power, special attention should be paid to their maintenance conditions and stability. In this case, special materials or coatings may be needed to enhance the bolt’s corrosion resistance and durability.

Follow technical procedures: Referring to the technical procedures for high-strength bolt connections in steel structures, measures such as increasing the coating friction surface and its slip resistance coefficient, increasing tensile connections and end plate connection joints can effectively improve the performance and reliability of bolt connections.