Ever wondered how to determine the perfect steel beam for your project? This article will guide you through the essentials of calculating the load-bearing capacity of H-beams and I-beams. By the end, you’ll know how to choose the right beam and ensure your structure’s safety and efficiency.

Understanding the load capacity of steel beams, particularly H-beams, is crucial for ensuring structural integrity and safety in construction projects. This section will guide you through the process of calculating beam load capacity and selecting the appropriate H-beam size for your specific requirements.

Load Capacity Calculation and Beam Selection:

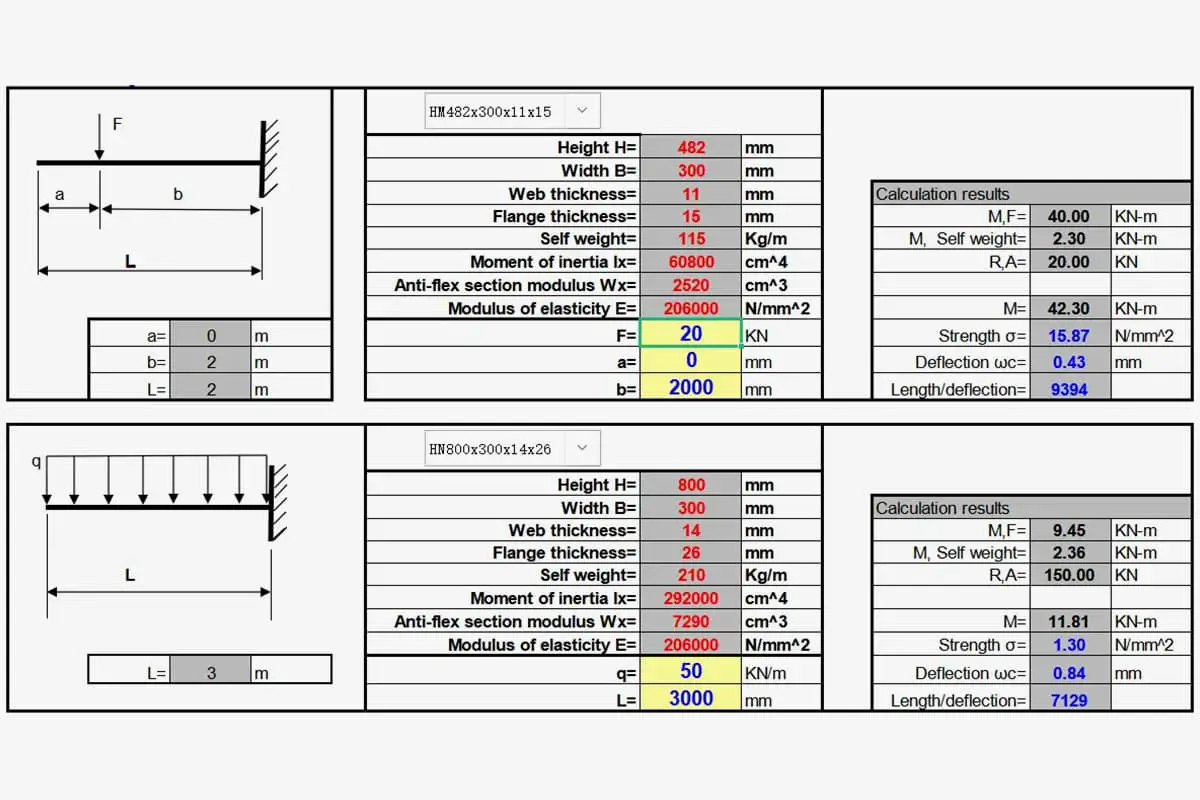

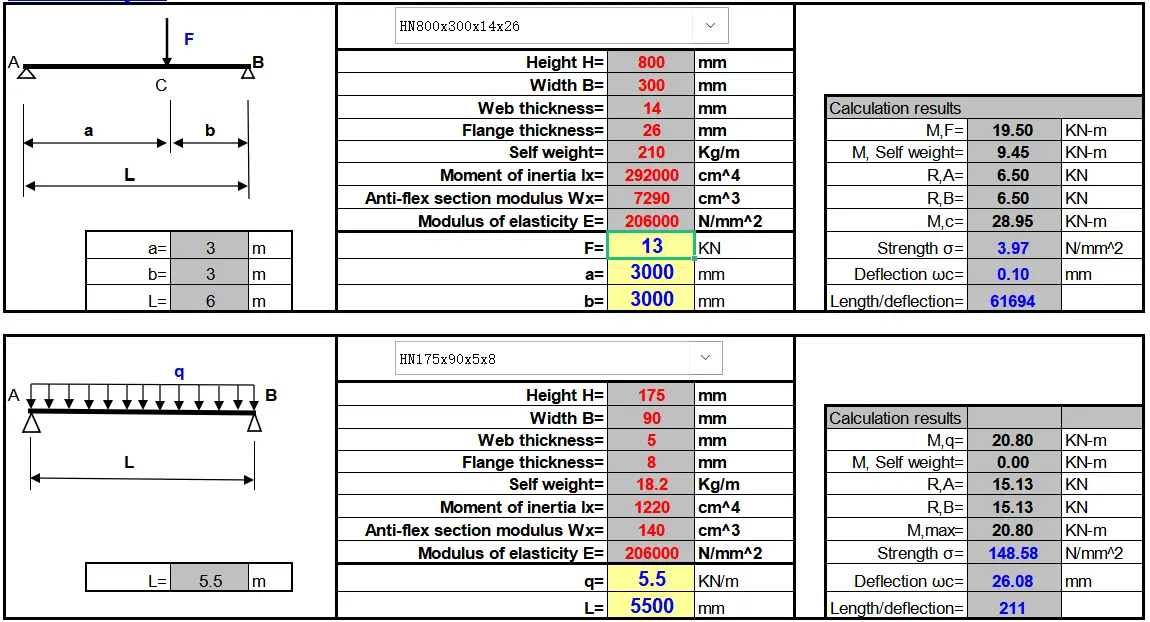

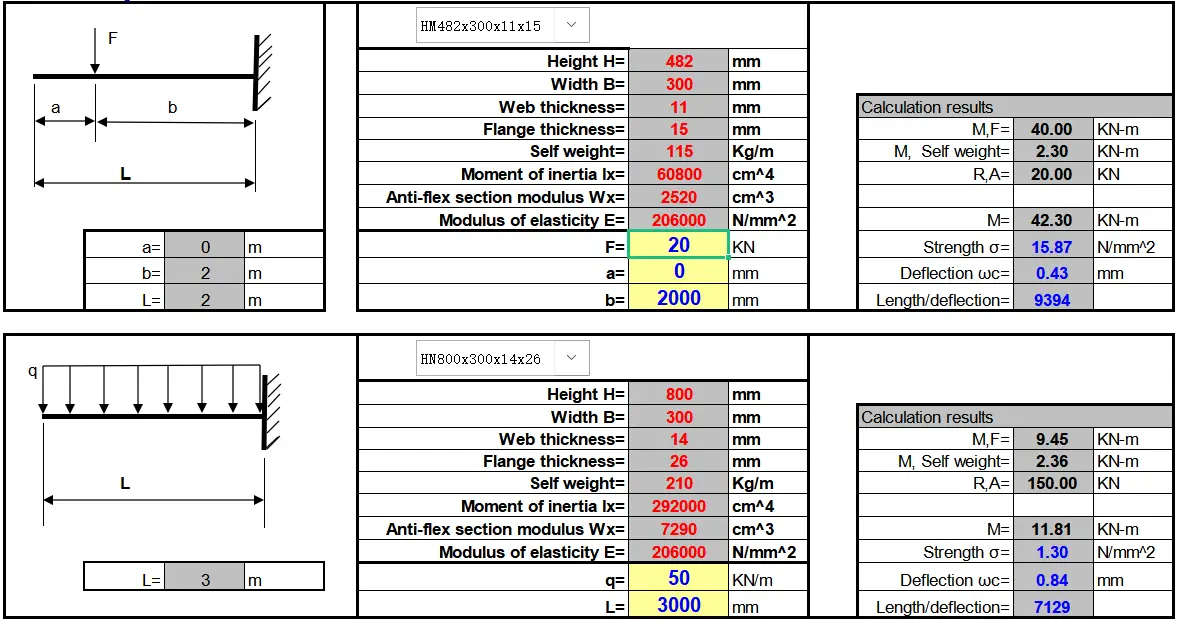

To determine the weight capacity of a steel H-beam or to select the proper size for your construction project, you can utilize our comprehensive beam load capacity calculator and reference the accompanying load capacity chart. These tools, as illustrated in the screenshot below, provide a robust and user-friendly method for making informed decisions about beam selection.

See also:

And it’s in an Excel format, which can automatically perform the calculation once you have entered the necessary information.

You can download the tool by clicking the link below. Don’t forget to enable the macro function in Excel to ensure proper functioning.

Key Factors in H-Beam Load Capacity:

The bending bearing capacity formula is:

Mu=b’*h’*f*(0.5*h-0.5*h’)+(0.5*h-h’)*b*f*0.5*(0.5*h-h’)

F – design value of yield strength

b – web thickness

b ‘- flange width

h – high

h ‘- flange thickness

As for the bearing capacity of tension and compression, I think it is not necessary for me to explain here. As for eccentric tension and compression, it is not very difficult to calculate by yourself.

For example:

How much can I-beam #25 bear when the span is 4m and the load is evenly distributed?

Calculation:

For #25 I-beam, W = 401.4cm3, [σ]=210N/mm2, overall stability coefficient φb=0.93

Bending moment formula M = QL2/8

Strength formula σ = M/W

According to the formula: q=8σW/L2=8*210*401400/4*4=42.1kN/m

Overall stability requirement: 42.1 * 0.93 = 39.2kn/m

Partial factor requirement (safety factor): 39.2 / 1.4 = 28kN/m

Safe use: 28kN/m

The above calculation does not consider the self-weight and deflection checking calculation of I-beam.

H-beam steel demonstrates superior load-bearing capabilities compared to I-beam steel, owing to its optimized structural design and enhanced mechanical properties.

The cross-sectional geometry of I-beam steel, characterized by its relatively high and narrow profile, results in significant disparities between the moments of inertia along its two principal axes. This asymmetry limits its application primarily to scenarios involving bending loads within the plane of its web or as components in lattice stress-bearing structures. I-beams are less suitable for axial compression or bending perpendicular to the web plane, which constrains their versatility in structural applications.

In contrast, H-beam steel presents a more efficient and economical profile due to its well-engineered cross-sectional shape. The key advantages of H-beams include:

The parallel flange design of H-beams, also known as wide flange I-beams, contributes to their improved performance. This configuration results in a more efficient distribution of material, leading to enhanced section properties and increased resistance to various loading conditions.

In summary, while both H-beam and I-beam steel have their places in structural engineering, H-beam steel generally offers superior load-bearing capabilities, greater versatility, and improved material efficiency. These characteristics make H-beams the preferred choice for many load-bearing applications in modern structural design and construction.