Ever wondered how to accurately calculate the unfolded length in groove bending? This guide breaks down the differences between grooved and non-grooved bending calculations, complete with practical examples for square tubes, Z-shapes, and multi-bend pieces. By understanding these methods, you’ll be able to ensure precision in your metalworking projects, reducing errors and improving efficiency. Dive in to uncover the exact steps and formulas necessary for mastering groove bending techniques.

Calculation of the difference between the unfolded length of grooved bending and non-grooved bending.

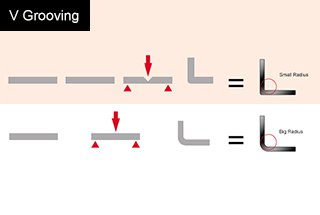

Grooved bending

For grooved bending, the total length is calculated as:

L=20-0.4+20-2X0.4+20-0.4=58.4

Non-grooved bending

For non-grooved bending, the total length is calculated as:

L=(20-1xt+k)+(20-2xt+2xk)+(20-1xt+1xk)=(20-1+0.2)+(20-2+2×0.2)+(20-1+0.2)=56.8mm

Note: “t” represents the material thickness and “k” is the coefficient.

The value of “k” is dependent on the material thickness, usually ranging between 0.2 and 0.25. The value of “k” increases as the material thickness increases.

For this particular case, “k” is selected as 0.2.

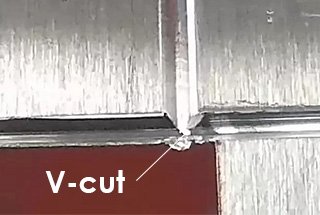

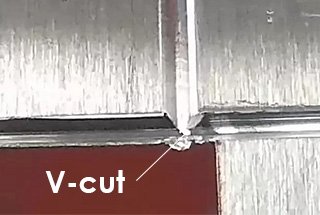

As shown in the figure, a 20 × 20mm square tube with a plate thickness of 1mm needs to be grooved and bent.

The thickness “a” of the remaining material in the groove is determined by the size of the right-angle arc after bending, as well as the material thickness “t”.

Typically, when the material thickness is less than or equal to 1mm, “a” equals 0.4mm. For materials thicker than 1mm, “a” is equal to “t/2”.

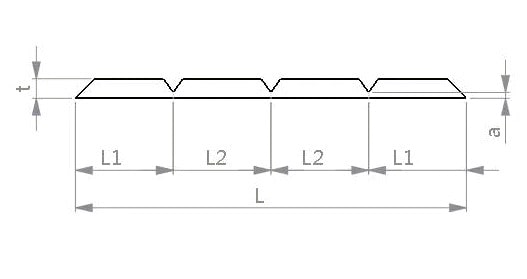

The unfolded length of the example shown is:

L=2×(L1+L2)=2x((Edge length-1xa-0.2)+(Edge length-2xa))=2x((20-1×0.4-0.2)+(20-2×0.4))=77.2mm

Note: For one end of “L1” that is grooved off, 0.2mm is deducted regardless of the material thickness.

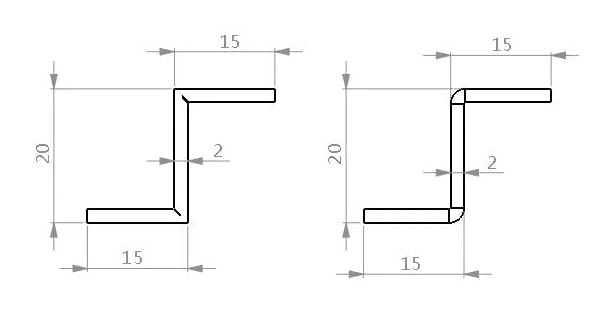

The bending unfolding length is calculated using the following combination of grooved and ungrooved Z-shapes.

For a 2mm plate, the remaining material thickness of the groove is taken as t/2 = 1mm. If the customer requires a smaller direct arc, a value less than 1mm should be chosen.

Therefore, the unfolding length is:

L=15-1+20-2×1+15-1=46mm

For a 2 mm-thick plate without groove bending, the factor k is chosen to be 0.25. Therefore, the unfolded length is:

L=(15-2+0.25)+(20-2×2+2×0.25)+(15-2+0.25)=43mm

The following calculation presents an example of a workpiece with multiple bends, both grooved and ungrooved.

Assuming that the customer requires a small rounding of the right angle, for a 3 mm-thick plate, the remaining material thickness is chosen to be 0.5 mm.

Unfolded length:

L=(40-0.5)+(30-2×0.5)+(30-2×0.5)+(10-0.5)=107mm;

For a 3 mm-thick plate, the coefficient k is chosen to be 0.25. Therefore, the unfolding length is:

L=(40-3+0.25)+(30-6+2×0.25)+(30-6+2×0.25)+(10-3+0.25)=93.5mm

The method of calculating the unfolding is presented below, using an example of reverse bending after grooving.

To calculate the length of unfolding for the reverse bend after grooving shown in the figure, use the following steps:

L=(20-2+0.2)+(30-2×2+2×0.2)+(20-2+0.2)=62.8mm