How do you ensure precise power transmission in your machinery? This article dives into the calculation and selection process of synchronous belts and pulleys. You’ll discover how to choose the right belt type, determine the correct number of teeth, and understand the essential design requirements. By the end, you’ll have a clear understanding of the key parameters needed to optimize the performance and efficiency of your mechanical systems.

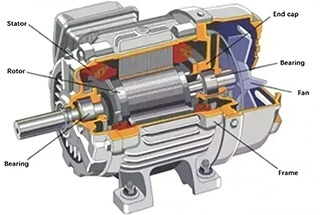

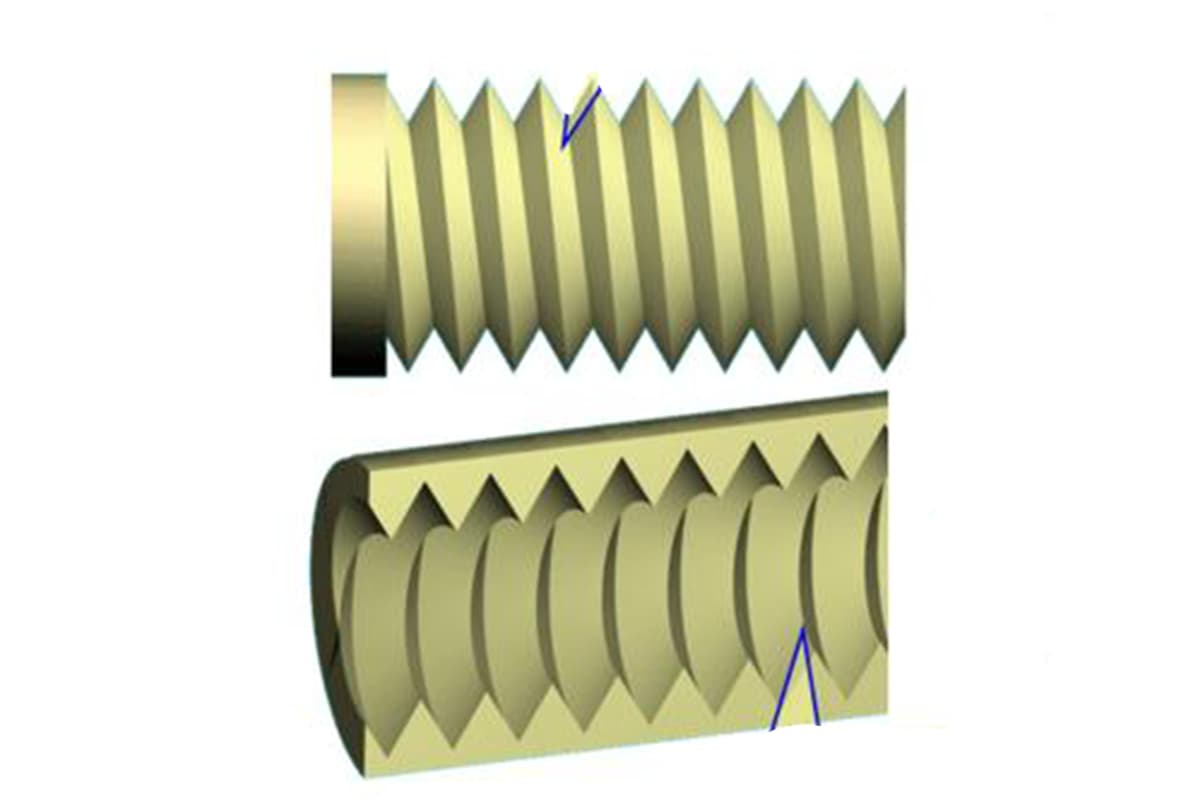

Synchronous belt transmission is a cutting-edge transmission method that utilizes the interlocking of belt teeth to transmit power.

It boasts precise synchronous transmission, requires no lubrication, prevents slippage, is eco-friendly, and operates with minimal noise.

Its transmission efficiency is impressive, reaching 0.98, and the speed ratio can range from 1:10. The maximum line speed is 50M/s, and the transmission rate can range from hundreds of watts to hundreds of kilowatts, making it suitable for multi-shaft transmission.

Synchronous belt transmission is widely used in a variety of industries, including textiles, automobiles, chemical fibers, cigarette production, papermaking, printing, and chemicals.

In recent years, there has been a growing demand for its use in the mining, metallurgy, steel machinery, and medical equipment industries.

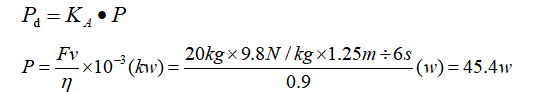

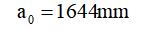

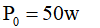

Design Requirements for Vertical Direction: The total weight of the tray and its contents is 20 kilograms (196 Newtons), and it takes 6 seconds for the slider to travel a distance of 1250 millimeters.

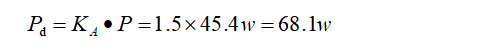

Check the table according to the working conditions and take Ka = 1.5

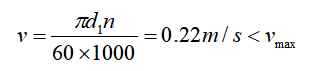

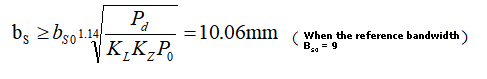

According to

And pulley speed

Select 5m arc belt after checking the table.

According to the belt speed and installation size, it is advisable to choose the larger value as much as possible. After referring to the table, a 5M belt with 26 teeth and a pitch diameter was selected.

Diameter of outer circle

The driving and driven pulleys are consistent, the transmission ratio is I = 1, and the driving and driven pulleys are of the same model.

Check the table

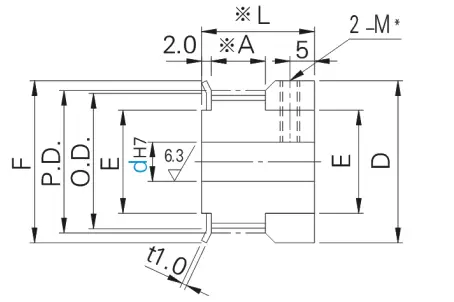

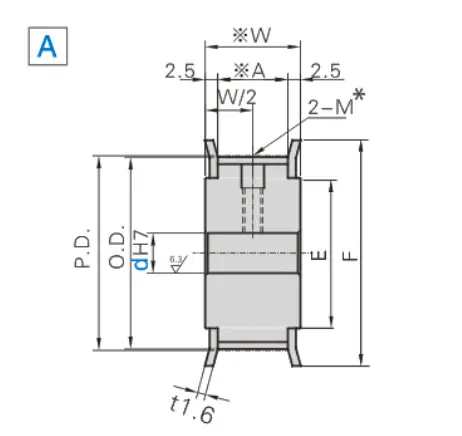

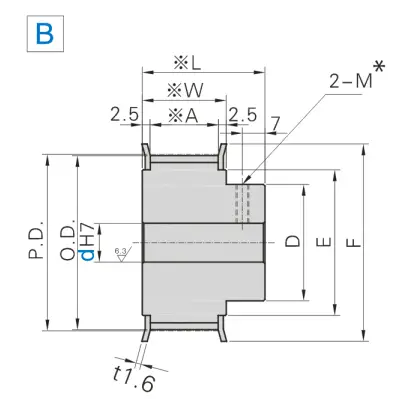

5m pulley, minimum height of retaining ring k = 2.5 ~ 3.5, r = 1.5, thickness of retaining ring t = 1.5 ~ 2

Diameter of the bend of the retaining ring

Outer diameter of retaining ring

Vertical synchronous pulley:

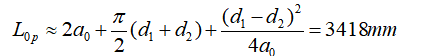

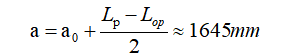

Vertical synchronous belt:

Belt type 5m arc belt, with a bandwidth of 10.3mm and a pitch length of about 3418mm

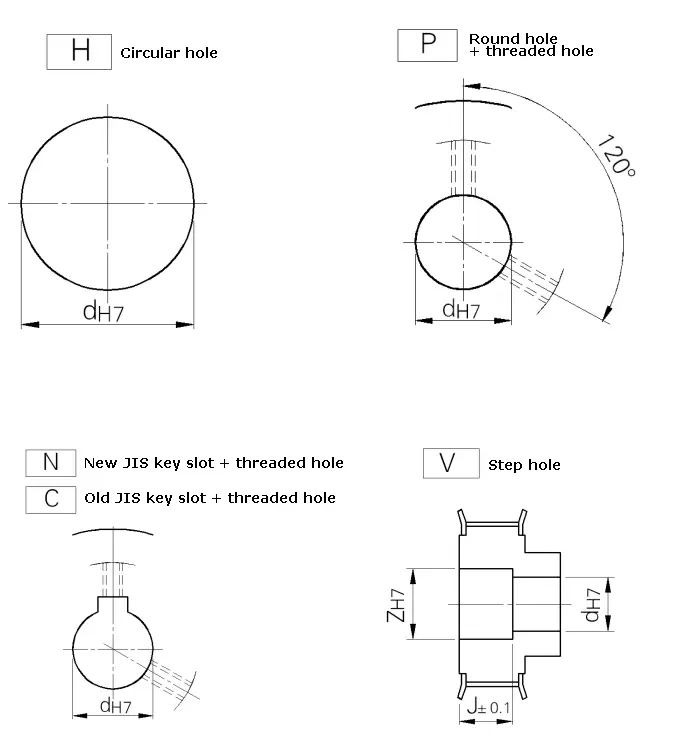

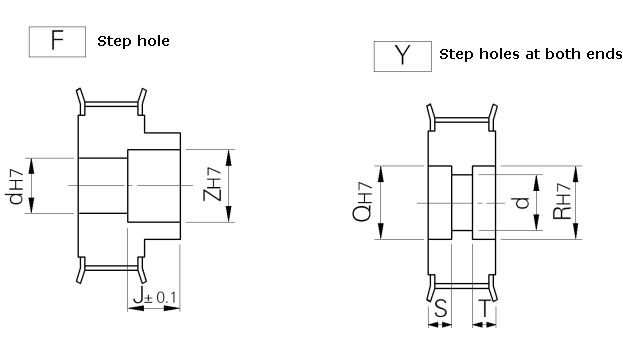

The following parameters require attention when selecting a synchronous pulley: tooth shape, number of teeth, material and surface finish, and pulley shape.

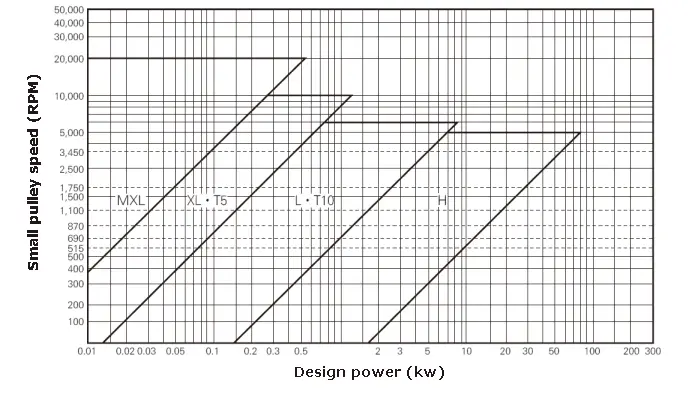

The tooth shape of synchronous belts can be categorized into several types: English (Ordinary Torque) MXL, XL, L, H; Metric (High Torque) S2M, S3M, S4M, S5M, S8M; and (Ordinary Torque) T5 and T10.

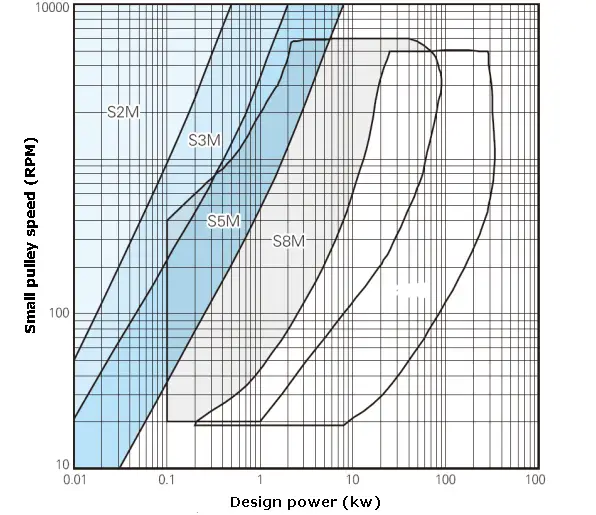

When selecting the tooth shape, refer to the following table for guidance.

Simple type selection table 1 (MXL, XL, L, H, T5, T10)

Simple type selection table 2 (S*M)

The number of teeth is an important parameter of the synchronous belt pulley.

The pitch diameter of the synchronous belt pulley = the number of teeth × Pitch / π

The common materials of synchronous pulley are aluminum alloy and 45 steel, and the surface treatment is:

K-wheel

A-wheel

B-wheel

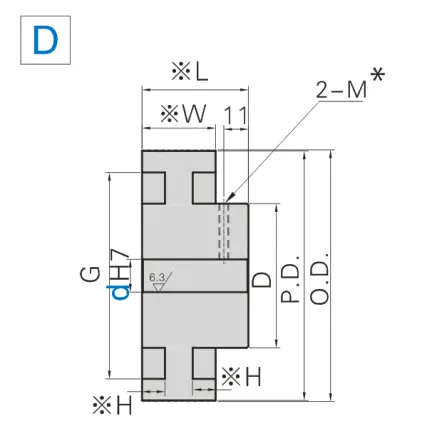

D-wheel

Specification of belt axle hole: