Can plastics and metals be laser welded together? This intriguing question opens up a discussion on advanced manufacturing technologies. In the quest for lightweight yet robust materials, particularly in the automotive industry, the connection of metals and plastics using laser techniques has shown promising results. This article delves into the methods, challenges, and potential of laser bonding, offering insights into its practical applications and the future of material science. Readers will gain an understanding of how laser technology could revolutionize material connections and the hurdles that still need to be overcome.

It has been demonstrated through examples that metal and plastic can be effectively “connected” using laser welding.

It should be noted that the term “welded” is not entirely accurate and should be replaced with “connected.”

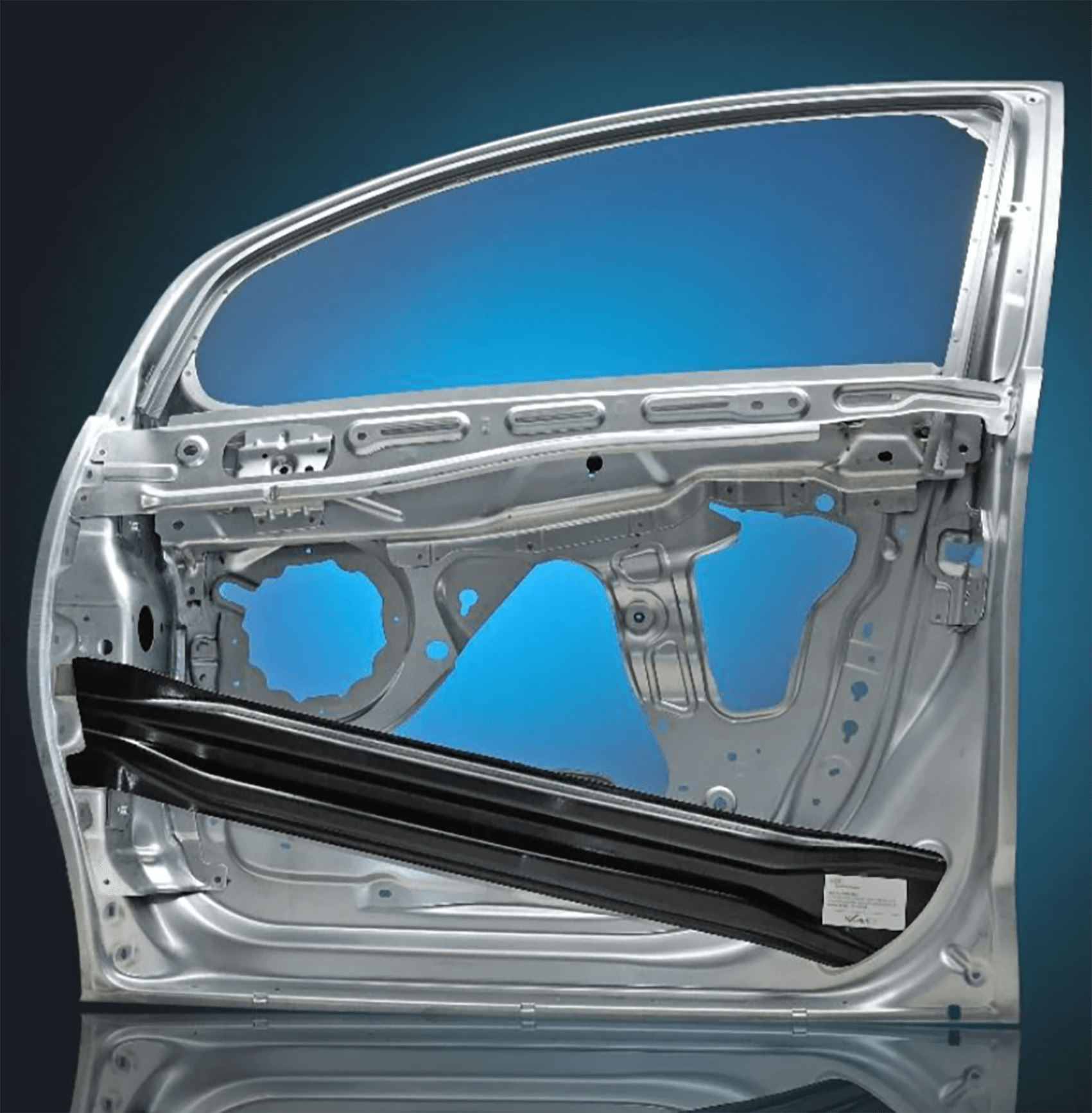

As shown in Figure 1, the car door is reinforced with glass fiber plastic.

Fig. 1 Car door reinforced with glass fiber plastic

With the increasing focus on lightweighting in the automobile industry, there is a growing need for effective connections between metal and plastic components, particularly those that contain reinforced carbon fiber or glass fiber.

To meet the demands of the fast-paced assembly line operations in the automobile industry, a solution is needed for quick, reliable, and automated connections between these materials.

The following are three of the most commonly used methods for joining composite and metal parts in industry: [list the methods].

Of these, laser-based connection technology is the most recent advancement. However, despite its potential, there are still several challenges that must be addressed in this technology, including issues related to efficiency, joint strength, and aging. This article will provide an in-depth examination of these challenges.

(1) Mechanical Connection: This method is fast, cost-effective, and provides a stable connection. However, the process of creating holes in the composite material can disrupt the fiber distribution and weaken the composite’s overall strength. Additionally, the use of connectors such as screws adds weight to the assembly.

(2) Bonding: There is a wide variety of adhesives available for connecting various materials. However, the surface must be pre-treated, the bonding process takes longer, adhesive must be used, and this increases the overall cost of the connection.

(3) Laser Connection: Laser connection is fast, reliable, and provides a strong connection without the need for any auxiliary materials. However, it is currently limited to the use with thermoplastics only.

The process of laser connecting thermoplastic and metal parts involves two steps.

In the first step, a microstructure is formed on the surface of the metal parts through laser processing. This is typically accomplished using a 1 kW fiber laser.

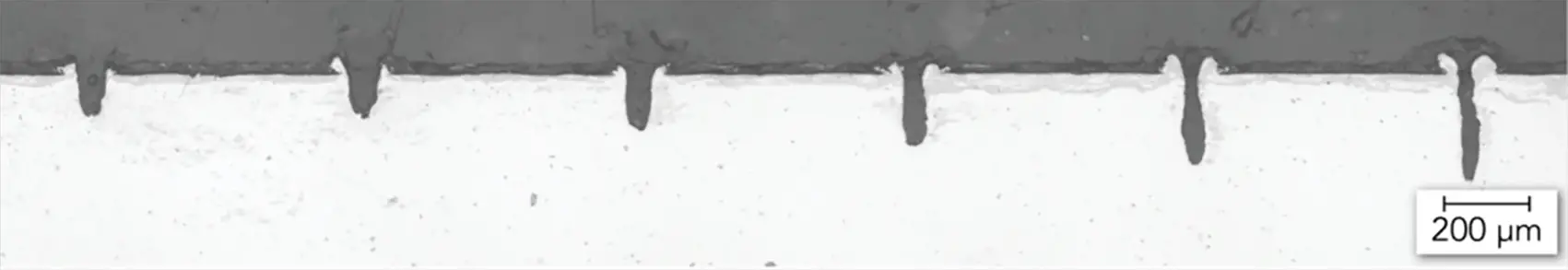

The laser scans the surface and creates a regular pattern of grooves and undercuts (as shown in Fig. 2).

Fig. 2 Laser bonding process of plastic and metal

The high power density of the laser beam causes partial melting and evaporation of the metal during ablation. The molten metal is expelled by high-pressure evaporation and solidifies at the edge of the grooves to form the undercut structure.

To increase the grip of the plastic on this surface, the number and density of grooves can be increased, as shown in Figure 3.

Fig. 3 Several laser beam scans to get a good groove shape

An alternative method involves using a special ultra-short pulse (USP) laser to create a spongy surface with conical protuberances. This technique can be applied to steel, aluminum, silicon, and titanium surfaces, resulting in better bonding strength for plastics compared to surfaces processed with fiber lasers. However, the only challenge is that the USP laser operates at a slower speed.

In step two, the plastic is heated until it melts, then pressed onto the metal surface. After cooling, the plastic is securely bonded to the metal.

There are several methods for heating plastics, such as using a hot plate, infrared radiation, or other processes to directly heat the plastic, or heating the metal parts and pressing them onto cold plastic, causing the plastic to melt and flow into small structures through heat conduction.

The first step of laser micromachining is quick and non-contact, making it ideal for integration into existing production processes and mass production.

In practical applications, the joint between metal and plastic will be subjected to loads. What is the maximum pressure that this type of composite connection can withstand, and where will it break?

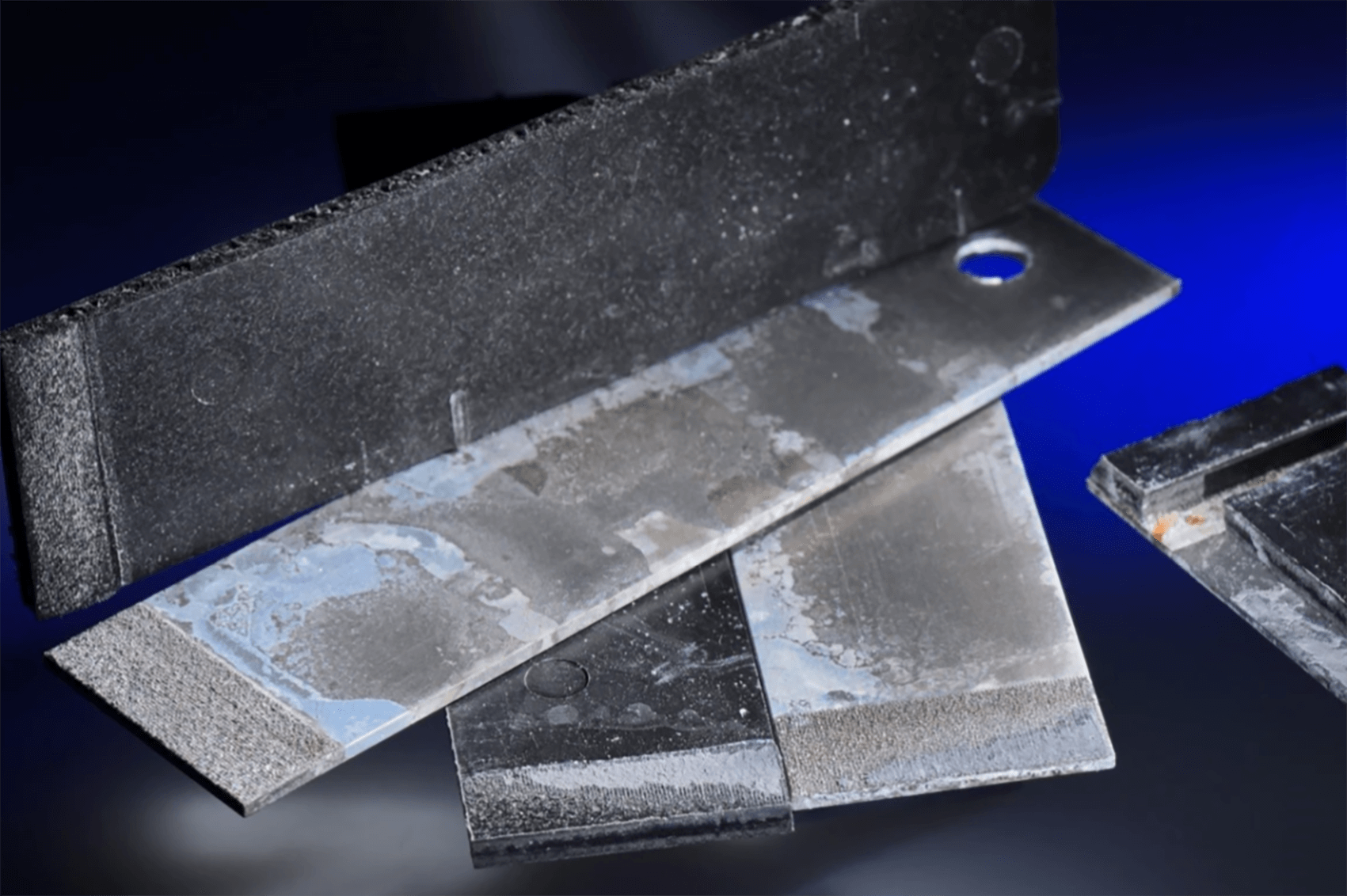

The Hoff Laser Technology Research Institute in Germany has conducted a series of stress tests on various materials to answer these questions (Figure 4).

One of the test contents is as follows:

Fig. 4 Fracture surface of metal and plastic joint after corrosion test

A 1 kW single-mode fiber laser is utilized to micro-process the metal surface, with a spot diameter of approximately 40 micrometers. The laser produces a reproducible undercut groove structure on the metal surface. The plastic is heated using a 3 kW rated power semiconductor laser, with a spot size of 7.5 mm x 25 mm. The two parts are clamped with a pressure of 0.3 MPa.

The results of the tests are as follows:

Destructive tests were performed on 5 samples of each of the above two types.

For the connection between stainless steel and PP with glass fiber, a shear strength test was conducted. The results are as follows:

For the connection between stainless steel and PP, a tensile strength test was conducted. The results are as follows:

It is evident that a dense groove distribution improves the connection strength. However, it should be noted that a dense distribution of grooves will also increase the micro-machining time.

A similar experiment was also conducted on a magnesium sheet.

All tests have demonstrated that the laser-based bonding technology creates a strong and reliable connection between metal and plastic components.

Another important concern in automotive products is their resistance to the impacts of climate change and corrosion. To address this question, experts from the Hoff Laser Technology Institute in Germany conducted various tests.

In the experiment, various metals (steel and aluminum) and plastics (PP with 30% glass fiber and PP with 40% talc) were connected using laser technology. The VW PV 1200 standard was used for the climate change test, with temperatures ranging from 80℃ to 40℃.

Each test cycle lasted 12 hours and was repeated twice, 10 times, and 30 times, respectively. The destructive shear strength of the samples was tested before and after each cycle. The results showed that all the samples had a shear strength ranging from 8 to 15 MPa.

An interesting observation was made in the test: after 30 cycles, all PP samples filled with talc powder showed cracks outside the connection area during the strength test, indicating that the joint was stronger than the bulk PP material.

A similar result was seen in the corrosion resistance test, which was conducted according to the VDA 621-415 standard for 7 days, including salt spray and high humidity conditions. Before the test, all samples had a shear strength of 8-5 MPa. After the corrosion test, the shear test showed that all PP samples containing talc powder had cracks outside the connection area, while the PP sample containing glass fiber broke at the joint area, but its strength was higher than before testing.

Corrosion was observed in stainless steel, especially in its microstructure, and the laser bonding area showed obvious corrosion penetration but had no significant effect on the bonding strength. There were also signs of corrosion in the microstructure outside the joint area, but not inside the joint area.

Therefore, it can be concluded that the microstructure should not be exposed to open environments.

The technique of connecting metal and plastic using laser technology has been tested and demonstrated to produce strong and dependable connections. The results of the climate and corrosion tests showed no impact on the joint strength. After undergoing aging, the samples showed that the fractures occurred in the plastic body, rather than at the connection point.