Have you ever wondered how to accurately calculate the weight of cast iron parts? In this insightful blog post, an experienced mechanical engineer shares their expertise on the density variations of different types of cast iron and provides practical methods for measuring volume and dimensions. Discover the key factors that influence cast iron weight calculations and learn how to apply this knowledge in real-world applications. Whether you’re a professional or a curious learner, this article will equip you with the tools to master cast iron weight calculations.

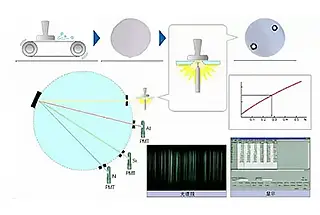

Accurately calculating the weight of cast iron is crucial for various industrial applications, including transportation, inventory management, and cost estimation. This process involves determining the volume of the casting and then combining it with the material’s density.

The first step in calculating the weight of cast iron is to determine the volume of the casting. This involves precise measurement of the casting’s dimensions and considering any machining allowances that may apply.

Volume = Length × Width x Height

Machining allowances refer to the extra material added to the casting to allow for precise machining and finishing.

After calculating the volume, the next critical factor is the density of the cast iron, which varies based on its type:

Once the volume and density are determined, the weight can be calculated using the formula:

Weight = Volume x Density

For example, if a casting has a volume of 1000 cm³ and the density is 7.3 g/cm³, the weight is calculated as:

1000 cm3 × 7.3g/cm3 = 7300 grams

To convert to kilograms:

7300 grams = 7.3 kilograms

This cast iron weight calculator is based on a cast iron density of 7g/cm³. If the density of your cast iron is not this value, you can enter your own metal density in the metal density input box.

Furthermore, you can refer to the metal density table to find the corresponding density values. For more calculations on metal weight, you can use our metal weight calculator.

Cast iron is a versatile and durable material widely used in various industrial applications due to its excellent castability, machinability, and wear resistance. Its high carbon content and the presence of graphite make it suitable for manufacturing a wide range of shapes, each serving specific functions. Understanding these shapes is essential for accurate weight calculation and material selection.

Round bars are cylindrical shapes with a uniform diameter throughout their length. They are commonly used in industries such as automotive, construction, and machinery manufacturing.

Example: For a round bar with a diameter of 10 cm and a length of 100 cm:

Rectangular bars, also known as flat bars, have a rectangular cross-section. They are used in a variety of structural and fabrication applications.

Example: For a rectangular bar with dimensions 5 cm (width), 2 cm (height), and 100 cm (length):

Cast iron plates are flat, rectangular pieces with a uniform thickness, widely used in construction and machinery.

Example: For a plate with dimensions 100 cm (length), 50 cm (width), and 1 cm (thickness):

Tubes are hollow cylindrical shapes with specified outer diameters and wall thicknesses, used in various piping and structural applications.

Example: For a tube with an outer diameter of 10 cm, an inner diameter of 8 cm, and a length of 100 cm:

Beams are structural elements with various cross-sectional shapes such as I-beams, H-beams, and T-beams, designed to bear loads.

Discs are flat, circular shapes commonly used in rotating machinery and as support bases.

Example: For a disc with a diameter of 20 cm and a thickness of 2 cm:

Rings are circular shapes with a hollow center, often used in mechanical seals and structural components.

Example: For a ring with an outer diameter of 20 cm, an inner diameter of 10 cm, and a thickness of 2 cm:

In addition to standard shapes, cast iron can be cast into custom shapes tailored to specific application needs. Custom shapes are designed and manufactured based on detailed specifications provided by engineers and manufacturers.

Understanding the various shapes of cast iron and their corresponding volume calculation formulas is crucial for accurate weight determination. This knowledge aids in selecting the right shape for specific applications and ensures precise weight calculations essential for industrial processes.

The density of cast iron varies depending on its type. The density of gray cast iron generally falls within the range of 6.6 to 7.4 g/cm³, but the specific value can vary depending on the grade. For instance, the density of gray cast iron of grade HT250 is approximately 7.35 g/cm³, while that of grade HT220 is slightly lower, around 7.2 g/cm³. The density of ductile cast iron is slightly higher than that of gray cast iron, typically about 7.3 g/cm³, although some sources suggest a range of 7.0 to 7.4 g/cm³. This indicates that the density of ductile cast iron may vary according to its specific chemical composition and manufacturing process.

Indeed, there is a difference in the density between gray cast iron and ductile cast iron, with the latter being slightly denser. These differences reflect the variations in the microstructure of the two types of cast iron, such as the graphite in ductile cast iron being spherical, while in gray cast iron it is flaky. These structural differences impact the material’s mechanical properties, including strength, toughness, and hardness.

Accurately calculating the weight of cast iron components is essential for various industrial applications. Here are some tips to ensure precise and efficient use of cast iron weight calculators.

Accurate dimension measurements are crucial for precise weight calculations. Use reliable measuring tools such as calipers, micrometers, or measuring tapes to determine the length, width, height, diameter, or thickness of the cast iron part. Ensure that measurements are taken at multiple points to account for any irregularities. For example, when measuring a cast iron plate, take readings from different areas to ensure uniform thickness.

Select a calculator specifically designed for the shape of the cast iron part you are working with. Shape-specific calculators, such as those for round bars, rectangular bars, plates, and tubes, are tailored to the geometric formulas needed for accurate volume calculations. Using a shape-specific calculator minimizes errors and ensures that the calculations are based on the correct geometric principles.

Familiarize yourself with the geometric formulas used to calculate the volume of the cast iron part. For example:

Understanding these formulas helps ensure that you input the correct dimensions and use the calculator effectively.

Ensure that all measurements and calculations are performed using consistent units. If the calculator requires inputs in centimeters, make sure to convert all measurements to centimeters before entering them. This consistency helps prevent errors and ensures accurate results.

Confirm the density value used in the calculator. For cast iron, the density typically ranges around 7.2 to 7.4 g/cm³ for grey cast iron and 7.3 g/cm³ for ductile cast iron. Some calculators may have pre-entered densities, but it’s essential to verify these values or input the correct density manually if needed.

When calculating the weight of cast iron parts that will undergo machining, consider the machining allowances. Machining allowances are additional material added to the initial dimensions to ensure the final product meets precise specifications after machining. Add the necessary machining allowance to the dimensions before calculating the volume.

Leverage online metal weight calculators for convenience and accuracy. These tools often come with pre-entered densities for various metals, including cast iron, and can handle different shapes and dimensions. Input the material type and dimensions to quickly obtain the weight.

Be aware of manufacturing tolerances and slight variations in material composition that can affect the actual weight. Manufacturing tolerances are acceptable deviations from the specified dimensions. Online calculators provide estimates, so additional checks may be necessary for precise engineering applications.

Always double-check your input values and the resulting calculations to ensure accuracy. Even small errors in dimension measurements or density values can lead to significant discrepancies in the final weight calculation.

Ensure that the calculator you are using allows you to select between metric and imperial units, depending on your needs. Consistently using the correct system of units helps maintain accuracy and simplifies the calculation process.

By following these tips, you can effectively use cast iron weight calculators to determine the accurate weight of your cast iron components, ensuring precision in your industrial applications.

Below are answers to some frequently asked questions:

To calculate the weight of cast iron, follow these steps:

By following these steps, you can accurately estimate the weight of cast iron parts, which is essential for cost estimation, mobility, and shipping considerations.

When calculating the weight of cast iron, several common shapes are typically considered:

Round bars are one of the most frequent shapes. The weight calculation for a round bar involves using the diameter of the bar. The weight per foot of a round bar can be determined through tables that list the weight based on the actual diameter.

Rectangular and square bars also require weight calculations that involve the height and width of the bar. The weight per foot for these shapes can be found using tables that provide this information based on their dimensions.

Cast iron plates are another common shape, and their weight is calculated based on their height, width, and length. Formulas or tables that consider these dimensions can be used to determine the total weight of the plate.

For tubing, the weight calculation involves the outside diameter (O.D.) and the wall thickness. This method applies to both gray iron and ductile iron tubing, including round, square, and rectangular types.

Other shapes like I-beams, channels, and beams can also be calculated, though these shapes are more commonly associated with steel. These shapes require specific formulas and tables tailored to their geometric configurations.

In general, the weight of these cast iron shapes is calculated by multiplying the cross-sectional area by the length and the density of the material. The density of cast iron typically ranges from 7.9 to 8 g/cm³, depending on the type and grade.

Using accurate cast iron weight calculators is crucial for several reasons, particularly in the context of iron and steel foundries and manufacturing processes. Accurate weight calculations directly impact production costs, as the rough weight of cast iron influences the consumption of raw materials, manpower, and electricity. These factors are key determinants of overall production costs.

Moreover, precise weight calculations are essential for pricing and quotations. Inaccurate estimates can lead to significant price discrepancies, which can affect the profitability of the foundry and the relationship between suppliers and buyers.

Accurate weight calculations also ensure correct material consumption and resource allocation, minimizing waste and avoiding the costs associated with either insufficient or excessive material usage. Additionally, they help in determining the appropriate machining allowance, reducing surface defects and dimensional deformations, which can affect the quality of the final product.

Finally, understanding the weight of cast iron is important for ensuring the quality and performance of the final product. The density of cast iron affects its machinability and overall performance in various applications. Therefore, accurate cast iron weight calculators are essential for maintaining cost efficiency, ensuring accurate pricing, optimizing resource allocation, and guaranteeing the quality and performance of the final products.

Yes, you can use a general metal weight calculator for cast iron, provided certain conditions are met. Cast iron has a specific density, typically around 7,900 kg/m³, which can vary slightly depending on the type. For accurate weight calculations, you need to ensure the calculator allows you to input this specific density.

Many metal weight calculators, such as MachineMFG Metal Weight Calculator, offer the option to select the material or input a custom density, making them suitable for cast iron. Additionally, if you are calculating the weight of specific shapes like round bars, rectangular bars, or plates, using a calculator that provides formulas for these shapes will yield more accurate results.

For the best accuracy, especially for specific cast iron shapes, consider using resources that offer dedicated formulas and tables for cast iron. Ensure that the units of measurement are consistent, such as using kg/m³ for density and cubic meters for volume.

In summary, a general metal weight calculator can be used for cast iron if it allows for the correct density input and provides formulas for the shapes you are working with. For more precise calculations, specialized resources may be preferable.