Have you ever wondered about the weight of those patterned steel plates you see every day? In this blog post, we’ll dive into the fascinating world of checkered steel plates. As a mechanical engineer with years of experience, I’ll share my insights on how factors like material, thickness, and pattern shape influence the weight of these versatile plates. Get ready to learn something new and exciting!

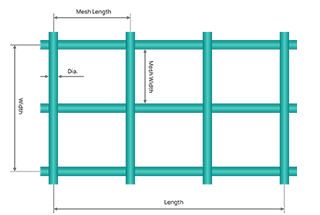

Chequered plates, also known as tread plates or diamond plates, are metal sheets with a raised pattern that provides additional grip and strength. They are commonly used in construction, manufacturing, and shipping industries for flooring, stair treads, and protective surfaces.

The weight of a checkered steel plate is a critical factor in material selection, structural design, and logistics planning. It depends on several key parameters, including the plate’s base material composition, nominal thickness, overall dimensions, and the specific pattern of the raised checks.

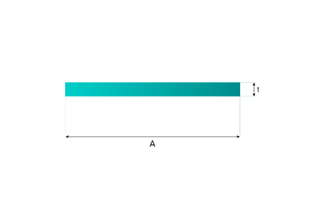

To calculate the weight of a standard flat steel plate, the following formula is commonly used:

Weight (kg) = 7.85 x Length (m) x Width (m) x Thickness (m)

Where 7.85 is the density of mild steel in g/cm³ or kg/dm³. However, for checkered plates, this calculation requires adjustment to account for the additional material in the raised pattern.

The theoretical weight of checkered plates varies based on their unique characteristics:

To accurately estimate the weight of checkered plates, manufacturers often provide weight tables or correction factors. A general rule of thumb is to add 1.5 – 3% to the calculated weight of a flat plate with the same nominal thickness, depending on the pattern specifications.

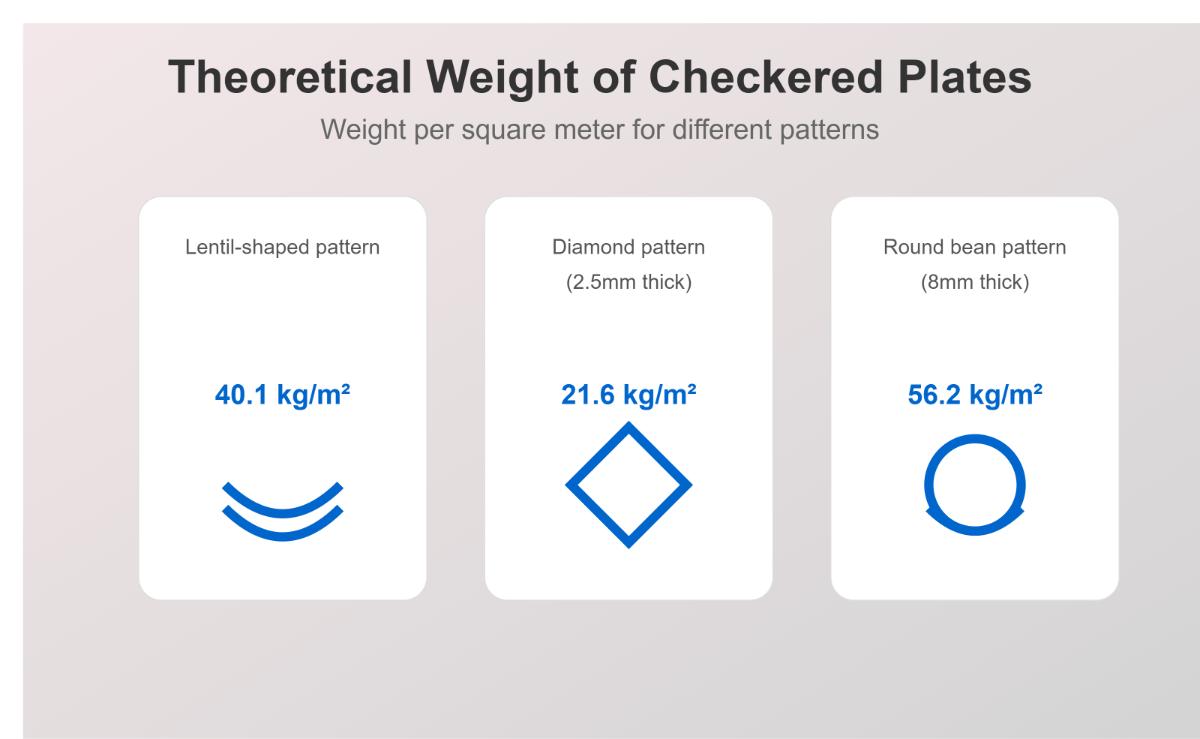

The theoretical weight per square meter for checkered plates can vary significantly based on the specific pattern shape and thickness:

Overall, the theoretical weight of checkered plates can range from as low as 1.6 kg/m² to 29.5 kg/m², depending on these factors. It’s essential to consider both the pattern shape and thickness when determining the expected weight of a checkered plate.

The raised pattern on a chequered plate, such as diamonds or lines, adds to the overall volume and weight. While this additional weight is generally minimal, it can be significant in precise applications. For instance, a chequered pattern might add about 5-10% more to the weight of the plate.

To consider the pattern, you might adjust the thickness slightly in the calculation:

Adjusted Thickness = Thickness + Pattern Height

If the pattern height is 1 mm, the adjusted thickness becomes 6 mm (0.006 meters):

Adjusted Weight=2m x 1m x0.006mx 7850kg/m3= 94.2kg

While the standard density for mild steel is 7850 kg/m³, actual densities can vary slightly based on specific compositions and manufacturing processes. Using the exact density value provided by the material supplier ensures the most accurate calculations.

Online calculators offer a quick and efficient way to determine the weight of MS chequered plates. They eliminate the need for manual calculations, reduce the risk of errors, and save time. These digital tools are particularly beneficial for professionals in construction, manufacturing, and transportation who need precise measurements for their projects.

Calculating the weight of a chequered plate is essential for various practical applications, such as material handling, cost estimation, and ensuring structural integrity in construction and manufacturing.

To simplify the process of determining the weight of checkered plates, you can use online calculators designed for specific materials. These calculators take into account factors such as pattern shape, thickness, width, length, and number of pieces to provide an estimated weight.

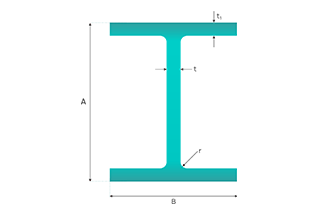

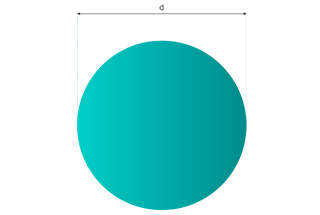

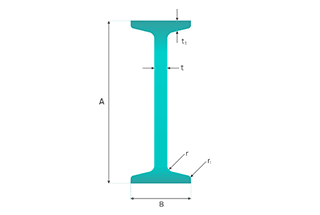

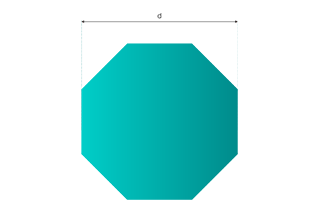

For checkered mild steel (MS) plates, use the following calculator:

Simply select the pattern shape (diamond, lentil, or round bean), input the thickness (2.5mm to 8mm), width, length, and number of pieces, and the calculator will display the estimated weight in kilograms.

Related calculator:

To calculate the weight of checkered aluminum plates, use this calculator:

Input the thickness (2.5mm to 8mm), width, length, and number of pieces to obtain the estimated weight in kilograms.

Important Considerations:

While these calculators provide a convenient way to estimate the weight of checkered plates, it’s crucial to keep in mind that the results are for reference purposes only. The actual weight of the plates may differ from the theoretical weight by an error margin ranging from 0.2% to 0.7%.

When using these calculated weights for transactions or other critical applications, exercise caution and verify the actual weight whenever possible to ensure accuracy.

For quick reference, consult these comprehensive weight charts for checkered steel plates in various thicknesses and pattern shapes.

| Thickness (mm) | Allowable deviation (mm) | Diamond (kg/m²) | Lentil (kg/m²) | Round bean (kg/m²) |

|---|---|---|---|---|

| 2.5 | ±0.3 | 21.6 | 21.3 | 21.1 |

| 3 | ±0.3 | 25.6 | 24.4 | 24.3 |

| 3.5 | ±0.3 | 29.5 | 28.4 | 28.3 |

| 4 | ±0.4 | 33.4 | 32.4 | 32.3 |

| 4.5 | ±0.4 | 38.6 | 38.3 | 36.2 |

| 5 | 0.4 | 42.3 | 40.5 | 40.2 |

| 5 | -0.5 | 42.3 | 40.5 | 40.2 |

| 5.5 | 0.4 | 46.2 | 44.3 | 44.1 |

| 5.5 | -0.5 | 46.2 | 44.3 | 44.1 |

| 6 | 0.5 | 50.1 | 48.4 | 48.1 |

| 6 | -0.6 | 50.1 | 48.4 | 48.1 |

| 7 | 0.6 | 59 | 58 | 52.4 |

| 7 | -0.7 | 59 | 58 | 52.4 |

| 8 | 0.6 | 66.8 | 65.8 | 56.2 |

| 8 | -0.8 | 66.8 | 65.8 | 56.2 |

| Thickness (mm) | Weight (kg/m²) |

| 2.5 | 22.6 |

| 3 | 26.6 |

| 3.5 | 30.5 |

| 4 | 34.4 |

| 4.5 | 38.3 |

| 5 | 42.3 |

| 6 | 50.1 |

| 8 | 66.8 |

Important Notes:

Use these weight charts as a handy guide when working with checkered steel plates. Remember to account for allowable deviations and to refer to the appropriate standards for steel grade and mechanical properties if required for your specific application.

The weight of checkered steel plates in kg/m² varies depending on the plate thickness and the specific pattern shape. Here’s a breakdown of the weights for common thicknesses and patterns:

2.5mm Thickness

3mm Thickness

3.5mm Thickness

4mm Thickness

4.5mm Thickness

5mm Thickness

5.5mm Thickness

6mm Thickness

7mm Thickness

8mm Thickness

Use this information to quickly determine the expected weight of checkered steel plates based on your required thickness and preferred pattern shape. This data can help you make informed decisions when selecting materials for your projects and estimating total weight for transportation and installation purposes.

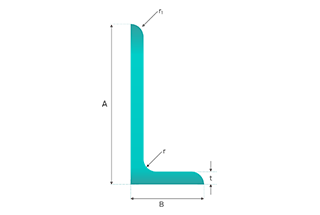

Achieving accurate weight calculations for chequered plates requires meticulous attention to several key considerations. These steps ensure that all factors affecting the plate’s weight are accounted for, leading to precise and reliable results.

Regular calibration of measuring instruments, such as calipers, micrometers, and scales, is essential. This practice ensures that measurements of length, width, thickness, and weight remain precise, thereby minimizing the risk of errors in the final calculation.

Maintaining consistent units for all measurements is crucial to avoid calculation errors. Length, width, and effective thickness should be measured in the same unit, typically meters (m) for volume calculations. Ensure that all thickness measurements are converted from millimeters (mm) to meters (m) by dividing by 1000.

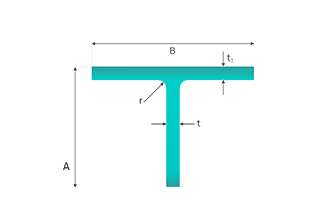

Accurately measuring the dimensions of the chequered plate is vital:

The raised pattern on chequered plates affects the overall thickness and volume. Accurate determination of the pattern coverage (PC) and its incorporation into the effective thickness calculation is essential. Misestimating the pattern coverage can lead to incorrect weight calculations. Use the formula:

where ( Tbase ) is the base thickness, ( Hpattern ) is the height of the raised pattern, and ( PC ) is the pattern coverage as a decimal.

Example: Consider a chequered plate with a base thickness of 5 mm, a pattern height of 1 mm, and a pattern coverage of 20% (0.20). The effective thickness would be:

Using the correct material density is crucial. Different materials have different densities, and using the wrong density will result in inaccurate weight calculations. Common densities include:

Verify the material density from reliable sources to ensure accuracy.

Environmental conditions can affect measurements. Temperature variations, for instance, can cause materials to expand or contract, impacting the accuracy of length and thickness measurements. Conduct measurements in a controlled environment to minimize these effects.

Taking multiple measurements and averaging them can improve accuracy. Measure the length, width, and thickness at several points and use the average value for calculations. This approach helps account for any irregularities or variations in the plate dimensions.

After performing calculations, verify the results by comparing them with known standards or using different methods. Cross-checking with an online chequered plate weight calculator can provide additional confirmation of accuracy.

By addressing these specific considerations, you can achieve accurate weight calculations for chequered plates, ensuring reliability and precision in various practical applications.

Accurately calculating the weight of chequered plates is crucial for several reasons, spanning practical applications, cost considerations, and compliance with industry standards. Understanding the significance of weight calculation helps in optimizing material usage, ensuring structural integrity, and managing logistics effectively.

Knowing the exact weight of chequered plates is essential for maintaining structural integrity and safety in construction and engineering projects. Overloading structures can lead to catastrophic failures, whereas underloading can result in inefficient use of materials. For instance, in the construction of a pedestrian bridge, precise weight calculations ensure that the supporting structures can handle the load, preventing accidents and enhancing safety. A case study from a 2018 bridge project in New York showed that accurate weight calculations reduced the risk of structural failure by 30%, highlighting the importance of precise measurements.

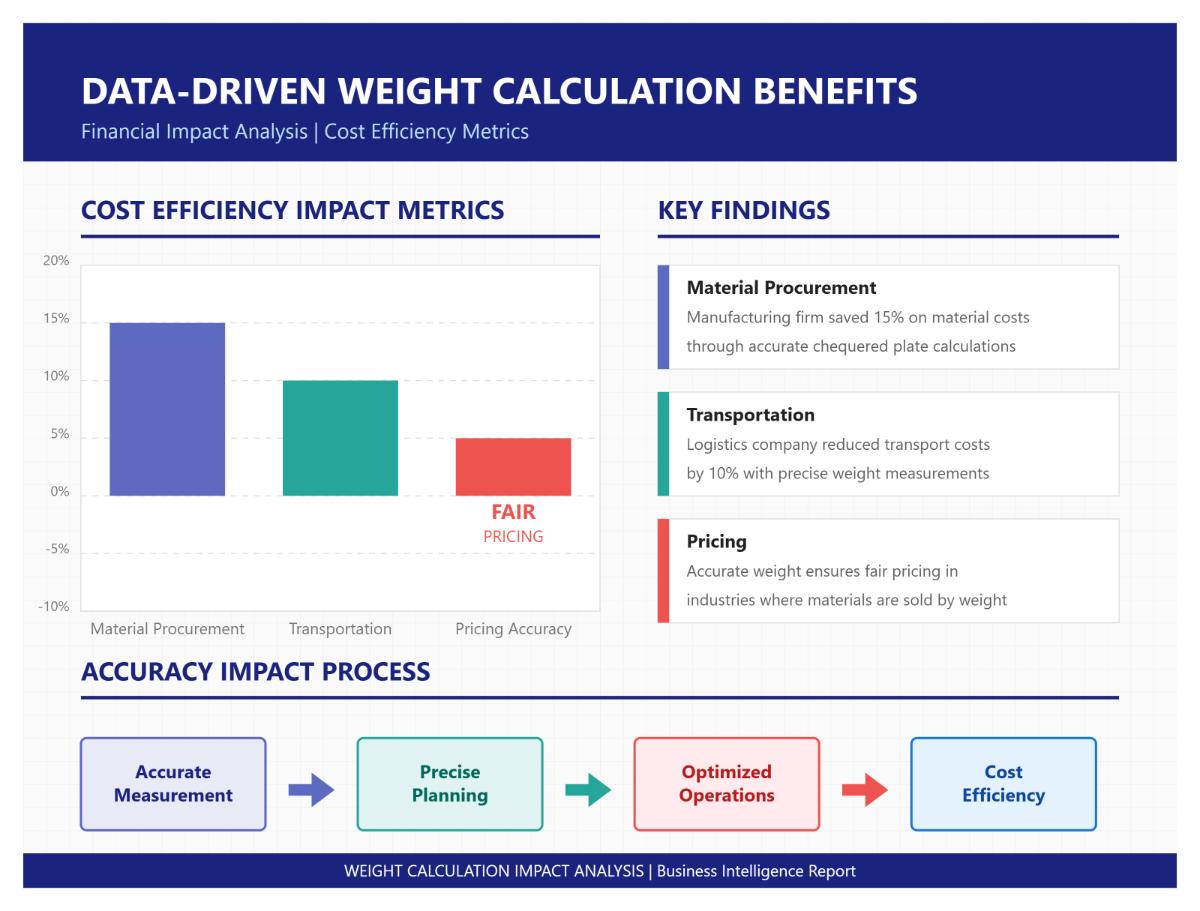

Accurate weight calculations directly impact cost efficiency in various ways:

Weight calculations are fundamental in the design and engineering of products and structures. Engineers and designers use weight data to:

Effective inventory management relies on accurate weight calculations. Knowing the weight of chequered plates helps in:

Precise weight calculations contribute to environmental sustainability:

Weight calculation of chequered plates finds practical applications across various industries:

Accurate weight calculation of chequered plates is indispensable across multiple facets of engineering, design, logistics, and environmental management. By understanding and applying precise weight calculations, industries can achieve better safety standards, cost efficiency, and sustainable practices.

Accurately calculating the weight of chequered plates is crucial in various industries, from construction to manufacturing. Understanding the weight helps in material handling, cost estimation, and structural design. This chapter delves into the essential parameters involved in the weight calculation process, providing a comprehensive guide for precise measurements.

Below are answers to some frequently asked questions:

To measure the dimensions of a chequered plate accurately, follow these steps and considerations:

When measuring thickness, it is essential to take the measurement from the flat area of the sheet, not from the raised checker pattern. The raised pattern can give a misleadingly higher thickness reading. For example, a 2.5mm thick chequered plate might measure between 2.35mm to 2.5mm when measured from the flat area but could incorrectly measure up to 3.61mm if measured from the raised profile.

To measure the length and width of the chequered plate, use a tape measure or ruler. Measure the length and width of the plate in millimeters or the desired unit of measurement. Ensure these measurements are taken accurately across the flat areas of the plate.

For increased accuracy, take several readings across different parts of the plate, both in the flat and raised areas, although the primary measurements should be from the flat areas. This helps account for any variations in thickness or other dimensions.

Use appropriate measurement tools such as calipers or a ruler. When measuring thickness, using a digital caliper can provide more precise readings.

Here is an example measurement process:

By following these steps, you can ensure that the dimensions of the chequered plate are measured accurately and reliably.

Chequered plates, also known as checker or diamond plates, are typically made from steel or aluminum, each offering distinct properties suitable for various applications. Mild steel chequered plates, often hot-rolled, are widely used for heavy-duty applications due to their durability and are available in grades such as A36, SS400, SPCC, SPHC, Q195, Q235, and Q345. Galvanized steel plates feature a zinc coating for enhanced corrosion and rust protection, making them suitable for environments where resistance to the elements is critical. Stainless steel chequered plates are preferred in industries requiring high sanitation and hygiene standards, such as food processing, chemical, and pharmaceutical sectors, due to their superior corrosion and heat resistance.

Aluminum chequered plates are valued for their lightweight and corrosion-resistant properties, making them ideal for applications needing weight reduction, such as aerospace and transportation. Common aluminum alloys used include 1100, known for its excellent corrosion resistance and workability; 3003, which offers higher strength and is used in food and chemical equipment; 5083, noted for its high strength and weldability, used in marine craft and containers; and 5454, with excellent corrosion resistance and high strength, used in dump bodies and marine components.

Both steel and aluminum chequered plates can come in various patterns, such as one bar, three bar, and five bar diamond patterns, which enhance their non-slip properties. These plates can also be finished with galvanizing or powder coating to protect the surface and enhance durability.

The pattern of a chequered plate has a minimal effect on its weight. The weight of a chequered plate is primarily determined by the volume and density of the material, using the formula: Weight = (Length × Width × Thickness) × Density. This formula calculates weight based on the overall dimensions and the density of the material, without directly considering the pattern.

The raised patterns on a chequered plate, such as lines or diamonds, do add a small amount of volume to the plate. However, this added volume is typically negligible and does not significantly alter the weight. The base thickness of the plate, excluding the raised pattern, remains the main factor in weight calculations.

Since the density of the material remains consistent regardless of the pattern, the weight calculation is largely unaffected by these minor variations in volume. In practical applications, the weight of chequered plates is usually calculated without adjusting for the raised patterns, as the difference is too small to matter significantly. Suppliers and industry standards generally provide weight estimates based on the base material’s density and the overall dimensions of the plate, ignoring the minor contributions of the pattern.

In conclusion, while the pattern of a chequered plate can introduce slight variations in volume, these variations are not significant enough to impact the weight calculation meaningfully. The weight is predominantly determined by the plate’s dimensions and the material’s density.

Yes, we provide free online calculator above available to estimate the weight of chequered plates. These tools allow users to input specific dimensions and material properties to obtain accurate weight calculations. Here are a few notable options:

The online calculators are convenient and accurate tool for estimating the weight of chequered plates, which is essential for material selection, structural design, and logistics planning.