What if you could enhance the strength and durability of metal components with just a surface treatment? Chemical heat treatment achieves this by infusing elements into the metal’s surface, significantly improving its hardness, wear resistance, and corrosion resistance. This article explains the various methods of chemical heat treatment, their benefits, and their industrial applications. You’ll discover how these processes can extend the lifespan and performance of metal parts, making them essential in manufacturing and engineering.

Chemical heat treatment is a process that involves heating metal or alloy workpieces in an appropriate active medium for insulation, causing one or more elements to penetrate the surface layer and alter its chemical composition, structure, and performance.

Chemical heat treatment, also known as “surface diffusion” or “thermal diffusion” treatment, involves placing metal materials or parts in a solid, liquid, or gas medium containing one or more chemical elements.

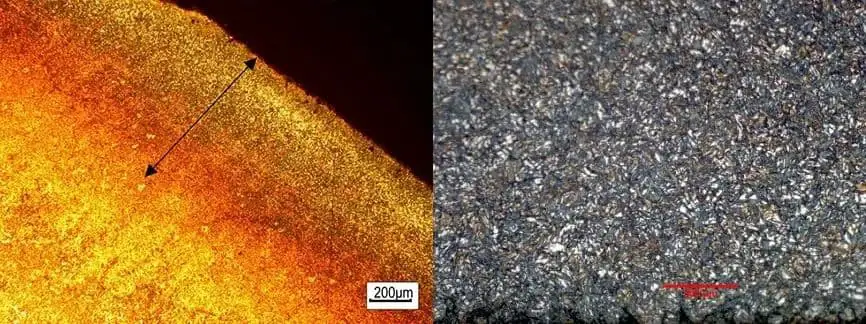

The materials are then heated to a specific temperature in a furnace, allowing these elements to enter the metal surface through the decomposition, adsorption, solid solution, and combination reaction of medium pyrolysates on the metal surface. The elements gradually penetrate into the metal material through thermal diffusion, forming a penetration layer rich in one or more alloy elements on the metal surface.

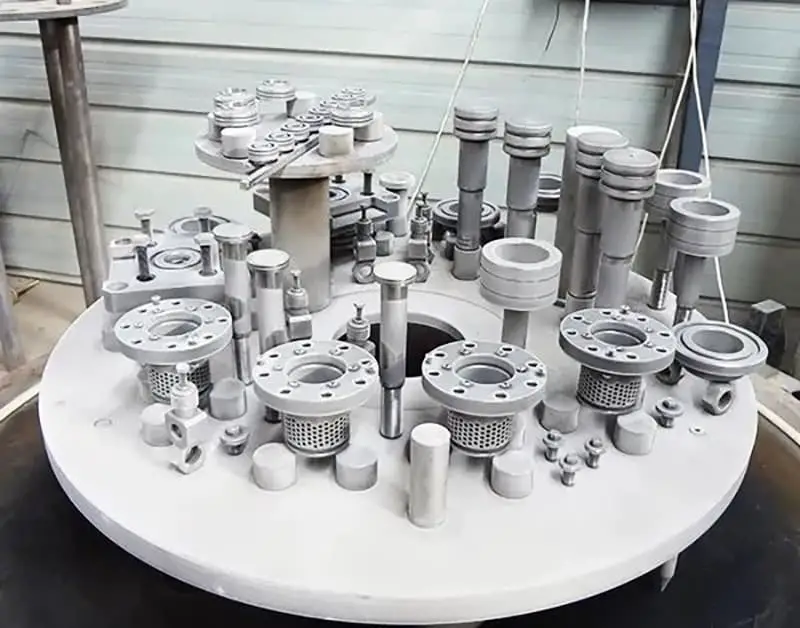

Chemical heat treatment technology plays a significant role in modern industry due to its ability to greatly improve the performance requirements of workpieces.

By creating a hard surface and tough internal surface, it can enhance various mechanical properties, including high strength, high hardness, high wear resistance, anti-seizure performance, anti-fatigue performance, and special corrosion resistance. It can also improve the physical and chemical properties of the workpiece surface, such as high temperature oxidation resistance.

It is important to note that the workpiece must maintain its original plastic and ductile properties to enhance the durability of machine parts under complex working conditions. As a result, chemical heat treatment is widely used to achieve specific requirements for a wide range of industrial applications.

The main characteristics of chemical heat treatment include:

This can be divided into several methods, including carburizing, nitriding, boronizing, aluminizing, sulfurizing, carbonitriding, carbon-chromium composite carburizing, and more.

1. Single element infiltration

Such as carburizing (unit carburizing), boronizing (unit boronizing), etc.

2. Binary penetration.

The process of infiltrating two elements simultaneously is known as dual penetration.

When carbon and nitrogen are infiltrated simultaneously, it is referred to as carbonitriding (also known as carbonitriding for short). Similarly, the process of simultaneous infiltration of boron and aluminum is called boron aluminizing (also known as boron aluminizing for short).

3. Multi element penetration.

Multi-element penetration refers to the simultaneous infiltration of more than two elements.

Specifically, when carbon, nitrogen, and boron infiltrate a material at the same time, it is referred to as carbonitriding.

4. Binary composite infiltration.

Infiltrating a material with two elements is referred to as two element composite infiltration.

For instance, if tungsten and carbon are infiltrated sequentially, the process is known as tungsten-carbon binary composite infiltration.

5. Multi element composite infiltration.

Multi-element composite infiltration involves the sequential infiltration of more than two elements.

For example, the ternary composite infiltration of nitrogen, carbon, and sulfur is a type of multi-element composite infiltration.

1. Solid method

Including powder filling method, paste (slurry) method, electric cyclone method, etc.

2. Liquid method

Including salt bath method, electrolytic salt bath method, aqueous solution electrolysis method, etc.

3. Gas method

Including vacuum method, solid gas method, indirect gas method, mobile ion furnace method, etc.

4. Ion bombardment method

It includes ion bombardment carburizing, ion bombardment nitriding, ion bombardment metallizing, etc.

Diffusion infiltration can be classified into four categories:

There are two mechanisms involved in the process of surface modification of steel. The first mechanism is the formation of solid solutions by the infiltrating elements dissolving in the lattice of solvent elements. Carburizing, carbonitriding, and similar processes fall under this category.

The second mechanism is reaction diffusion, which has two subtypes.

The first subtype involves the infiltrating elements reacting with the elements present in steel to form ordered phases, also known as metal compounds. Nitriding, commonly referred to as nitriding, is an example of this subtype.

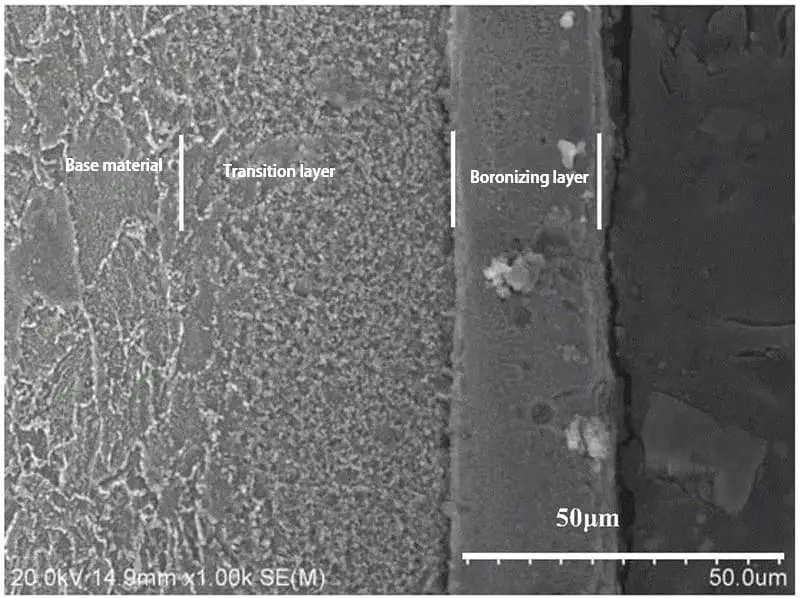

The second subtype occurs when the solubility of the infiltrating elements in the solvent element lattice is very low. In this case, the infiltrating elements react with the elements present in steel to form compound phases. Boronizing is an example of this subtype.

Table 1 Classification table formed according to the structure state of steel

| Austenitic state chemical heat treatment | Chemical heat treatment in ferrite state |

| Carburization | Nitriding |

| Carbonitriding | Nitrocarbonization |

| Boronizing, boroaluminizing, borosiliconizing, borozirconizing, boron carbon composite carburizing, boron carbon ammonia composite carburizing, etc | Oxynitriding, Oxynitrocarburizing |

| Chromizing, chromizing aluminizing, chromizing siliconizing, chromizing nitriding, chromizing titanizing | Sulphurization |

| Aluminizing, aluminum nickel penetration, aluminum rare earth penetration, etc | Oxynitriding, Oxynitrocarburizing |

| Siliconizing | Zincizing |

| Vanadium, niobium, titanium, etc |

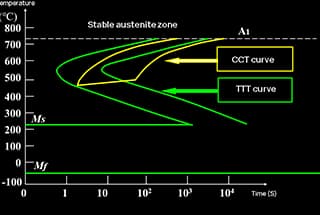

Table 1 shows that the chemical heat treatment temperature of steel in the ferrite state is generally below 600℃, which is referred to as low-temperature chemical heat treatment.

On the other hand, the chemical heat treatment temperature of steel in the austenitic state is typically above 600℃, which is known as high-temperature chemical heat treatment.

Low-temperature chemical heat treatment processes offer several advantages, including lower treatment temperature, energy efficiency, minimal distortion of the workpiece, improved corrosion resistance and anti-seizure properties, increased hardness, and better wear and anti-friction performance.

Moreover, as seen in Table 1, the chemical heat treatment of steel is typically named after the infiltration of different elements, such as carburizing, nitriding, carbonitriding, and so on.

Compared to surface hardening methods such as surface quenching and surface deformation strengthening, it exhibits the following characteristics.

This article primarily focuses on defining, classifying, and highlighting the characteristics of chemical heat treatment.

By providing this fundamental information, it is hoped that readers will gain a deeper understanding of the subject.