Ever wondered why some welds hold strong while others fail? This article uncovers the secrets behind welding rods, their types, and their critical role in ensuring durable welds. Learn how choosing the right welding rod can make all the difference in safety and strength.

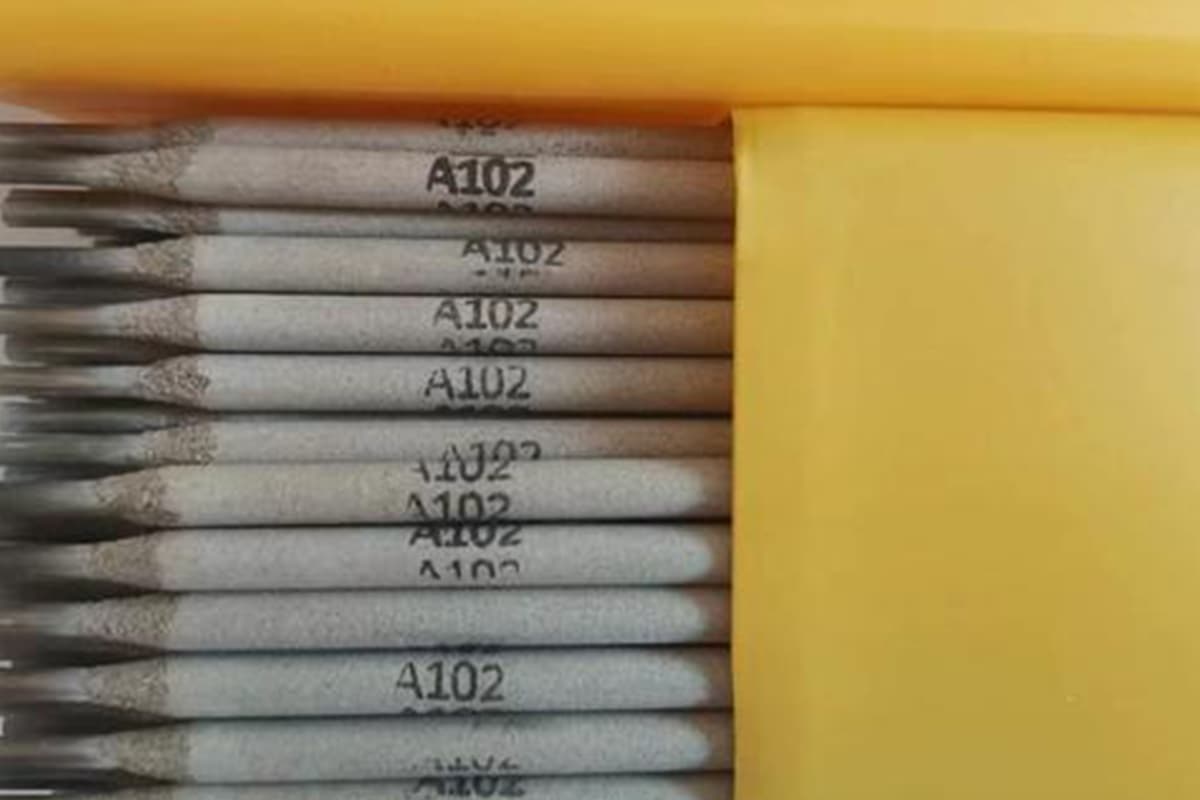

I’m sure you’re all aware that welding rods are an essential component for electric welding.

Once the welding rods have been connected, the welding tongs can begin their operation.

However, do you know what model of welding rods you’re using?

The use of welding rods is very specific.

The incorrect use of welding rods can compromise the strength of the welding, so it must be re-welded with a suitable material.

In the case of large workpieces, incorrect use of welding rods can result in cracking at the welding site, posing a threat to both life and property.

Therefore, it is important to understand the composition of the electrode.

The electrode is coated with a special material called the electrode coating.

This type of electrode, known as a shielded metal arc welding electrode, consists of two parts: the coating and the welding core.

The metal wire covered by the coating on the electrode is referred to as the welding core.

Typically, the welding core is made of steel and has a specific length and diameter.

The welding core serves two primary functions:

When welding with electrodes, a portion of the weld metal comes from the core metal.

As a result, the chemical composition of the welding core significantly impacts the quality of the weld.

For this reason, the steel wire used as the welding core must have a specific brand and composition.

When other fusion welding methods, such as submerged arc automatic welding, electroslag welding, gas shielded welding, or gas welding, are used as the filler metal, they are referred to as welding wires.

Related reading: Types of Welding

The electrode coating is the layer applied to the surface of the welding core.

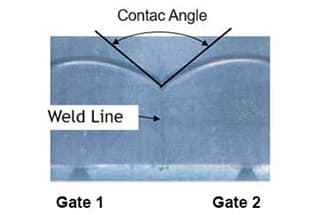

During the welding process, the coating decomposes and melts to produce gases and slag, providing mechanical protection, metallurgical treatment, and improved process performance.

The composition of the coating includes minerals (such as marble and fluorspar), ferroalloys and metal powders (such as ferromanganese and ferrotitanium), organic substances (such as wood flour and starch), and chemical products (such as titanium dioxide and sodium silicate).

The quality of the electrode coating is a crucial factor in determining the quality of the weld.

A bare welding rod, without coating, is difficult to ignite an arc.

Even if an arc is established, it will not burn consistently.

During the welding process, the immersion of oxygen, nitrogen, and water vapor from the air into the weld can have negative impacts on the weld.

This can result in the formation of pores and reduced mechanical properties, and even lead to cracking.

However, when the electrode coating is melted during welding, the large amount of gas produced covers the arc and molten pool, reducing the interaction between the molten metal and air.

After cooling, the melted coating forms a layer of slag on the weld surface, providing protection for the weld metal, slowing down the cooling process, and decreasing the risk of air pockets.

Despite the protective measures in place during the welding process, a small amount of oxygen will inevitably enter the molten pool. This can lead to oxidation of the metal and alloy elements, burning of the alloy elements, and decreased weld quality.

To counteract this, reducing agents, such as manganese, silicon, titanium, and aluminum, are added to the electrode coating to reduce the oxides present in the molten pool.

The high temperature of the arc can cause the vaporization and burning of the alloy elements in the weld metal, lowering its mechanical properties.

To compensate for this loss, appropriate alloy elements must be added to the weld through the coating to maintain or improve the mechanical properties of the weld.

For welding certain types of alloy steels, it is also necessary to introduce the alloy into the weld through the coating so that the composition of the weld metal is similar to that of the base metal, and its mechanical properties match or even surpass those of the base metal.

The electrode coating has the added benefit of increasing droplet formation and reducing spatter.

The melting point of the electrode coating is slightly lower than that of the core, but since the core is at the center of the arc and has a high temperature, it melts first, followed by the coating.

This results in reduced metal loss from spatter, an improved deposition coefficient, and increased welding productivity.

So far, we have discussed the composition of welding rods. When choosing a welding rod, it’s important to understand that there are different types of welding rods.

For example, let’s consider a J422 electrode.

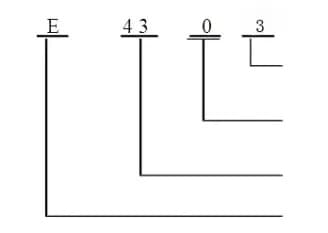

Do you see the number on the drawing?

The J422 welding rod is a common name that corresponds to the international standard grade E4303.

It is an acid welding rod with a titanium calcium coating.

The “J” in J422 represents a structural steel welding rod, and “42” represents the tensile strength of the weld metal, which is 42kg/mm2.

The international standard grade E4303 can be explained as follows:

In simpler terms, the J422 welding rod used in China is equivalent to the E4303 welding rod used internationally.

Let’s take a few models as an example.

Model and brand comparison of common welding rods

| Model | Brand | Model | Brand |

| E4303 | J422 | E5003 | T502 |

| E4316 | J426 | E5015 | J507 |

| E5016 | J506 | E6016 | T606 |

| E6015 | J607 | E7015 | 3707 |

Here’s a brief summary of the general selection criteria:

The brand names of commonly used welding rods are established by the manufacturer or industry, and the models are widely recognized internationally, with a large variety of types.

There are approximately 300 different types of welding rods.

Within the same type, different models are categorized based on their unique characteristics.

A specific type of welding rod may have one or several variations.

It’s common for welding rods of the same type to have different brand names in different welding rods.

Common welding rods mainly include:

(1) For low carbon steel structural parts, titanium calcium type E4303 (J422) or E5023 (J502) welding rods are typically used.

(2) For important structural parts with high requirements for plasticity, toughness, and crack resistance, low hydrogen E4315 (J427) or E5015 (J507) welding rods should be used.

When using an AC welding machine, AC and DC low hydrogen E4316 (J426) or E5016 (J506) welding rods can be chosen.

(3) For thin plate components that require a beautiful and smooth weld surface, titanium E4313 (J421) welding rods are preferred.

(4) When welding components that cannot remove oil, rust, and other dirt and require deep penetration, iron oxide E4320 (J424) welding rods are recommended.

(5) For components with many vertical welds, if conditions permit, special welding electrodes for vertical down welding, such as E4300 (J420) welding rods, can be selected.

These are some of the common welding rods that are distinguished based on their intended use.

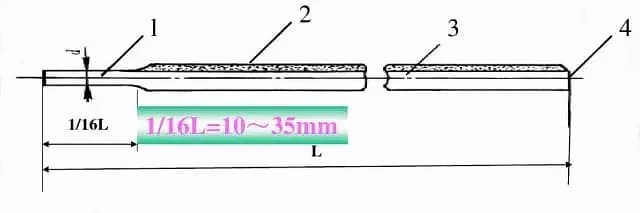

The diameter of the welding rod is determined by the thickness of the weldment, and is generally divided into 2, 2.5, 3.2, 4, 5, 6mm, and other sizes for the core.

The most commonly used sizes are 2.5, 3.2, and 4mm.

The approximate diameter and welding current are as follows:

| Welding rods diameter (mm) | Welding current (A) |

| 1.6 | 25-40 |

| 2 | 40~65 |

| 2.5 | 50~80 |

| 3.2 | 100~130 |

| 4 | 160~210 |

| 5 | 200~270 |

| 6 | 260~500 |

The method of selecting the electrode diameter based on the thickness of the weldment is as follows:

(1) If the thickness of the weldment is less than or equal to 4mm, the diameter of the selected electrode should not exceed the thickness of the weldment.

(2) For weldments with a thickness of 4mm to 12mm, the diameter of the electrode should be between 3mm and 4mm.

(3) If the thickness of the weldment is greater than 12mm, the diameter of the welding rod should be at least 4mm.

As an example, structural steel is designated as “J XXX”, where “J” represents a structural steel welding rod and the third number represents the coating type and welding current requirements. The first and second numbers indicate the tensile strength of the weld metal.

J507

The type of welding rod is determined based on relevant national and international standards. For structural steel, the letter “E” designates the welding rod. The first and second digits indicate the minimum tensile strength of the deposited metal, while the third digit represents the welding position of the electrode. The third and fourth digits indicate the type of welding current and coating used.

E4315:

Common structural steel electrodes include J421, J422, J423, J424, J506, and J507. For example, the E43 series welding rods can be used for welding low-carbon steels such as 20Mn and Q235 or steels with a tensile strength of approximately 400MPa. The E50 series welding rods can be used for welding 16Mn, 16Mng, and other steels with a tensile strength ranging from 500MPa (1MPa is approximately equal to 10kg of force).

Here’s an example.

Now let’s take Q235 as an example and discuss how to choose a 5mm thick steel. (Note: The answers to the following questions can be found in the article.)

Q235 is a low-carbon steel with a yield strength of 235 Mpa and a tensile strength of 370-500 Mpa.

For this material, we can choose E43 series welding rods. Since the requirements for the workpiece are not demanding, we can use E430 or E431 for all-position welding.

Additionally, low-carbon steel is symbolized by 3 titanium calcium type coating.

For 5mm thick materials, the recommended electrode diameter is 3.2mm.

For welding rods with a diameter of 3.2mm, the recommended current is 100-130A.

In conclusion, we should use E4303 welding rods with a diameter of 3.2mm and a current of approximately 110A for welding Q235 5mm thick steel.

For ease of use, I have provided a simple form to follow if you understand the information presented above.

Welding between the same metal materials

| Steel grade | garde | model | Remarks |

|---|---|---|---|

| Q235,10,20 | J422 | E4303 | J422 is used for general structure, with complex shape and large rigidity. |

| J426 | E4316 | J426 and J427 are used for thick weldments; | |

| J427 | E4315 | J426 and J427 are used for Q235-C and Q235D. | |

| 20R; 20g | J426 | E4316 | |

| J427 | E4315 | ||

| 16MnR | J502 | E5003 | Generally, the first three types of welding rods are selected. When the requirements for weld toughness are high, the last two types of welding rods can be selected. |

| J506 | E5016 | ||

| J507 | E5015 | ||

| J506R | E5016-G | ||

| J507R | E5015-G | ||

| 15MnVR | J506R | E5016-G | When the plate thickness is large, the first two welding rods can be selected. |

| J507R | E5015-G | ||

| J556 | E5516-G | ||

| J557 | E5515-G | ||

| 15MnVNR | J556 | E5516-G | Generally, the first three types of welding rods are selected. When the structural rigidity is small and the strength requirement is high, the last two types of welding rods can be selected. |

| J557 | E5515-G | ||

| J557MoV | E5515-G | ||

| J606 | E6016-D1 | ||

| J607 | E6015-D1 | ||

| 18MnMoNbR | J606 | E6016-D1 | Large rigid thick plate structure can be used with ultra-low gas and high toughness welding rod or welding rod containing Ni; |

| J607 | E6015-D1 | Preheat 150~250 ℃ before welding, and conduct 250~350 ℃ post heat treatment immediately after welding or when welding is interrupted, and conduct stress relief heat treatment after welding. | |

| J606RH | E6016-G | ||

| J607RH | E6015-G | ||

| J607Ni | E6015-G | ||

| 13MnNiMoNbR | J606 | E6016-D1 | Preheat 150~200 ℃ before welding, and conduct nitrogen elimination treatment at 350~400 ℃ after welding. |

| J607 | E6015-D1 | ||

| J607Ni | E6015-G | ||

| 07MnCrMoVR | J606RH | E6016-G | |

| J607RH | E6015-G | ||

| 15CrMoR 14CrMoR | R302 | E5503-B2 | Preheat 160~200 ℃ before welding, and conduct 675~705 ℃ tempering treatment after welding. |

| R307 | E5515-B2 | R302 is mainly used for cover welding. | |

| 12Cr1MoV | R312 | E5503-B2-V | Preheat 250~300 ℃ before welding, and conduct 715~745 ℃ tempering treatment after welding. |

| R317 | E5515-B2-V | R312 is mainly used for cover welding. | |

| 12Cr2Mo1 | R402 | E6000-B3 | Preheat 160~200 ℃ before welding, and 675~705 ℃ tempering treatment after welding. |

| R407 | E6015-B3 | R402 is mainly used for cover welding. | |

| 16MnDR | J506RH | E5016-G | Tempering at 600~650 ℃ after welding can reduce the brittle fracture tendency of low temperature steel welding products by eliminating welding stress. |

| J507RH | E5015-G | ||

| J507NiTiB | E5015-G | ||

| W507 | E5015-G | ||

| 15MnNiDR 09MnNiDR | W607 | E5015-G | |

| W607H | E5515-C1 | ||

| 09Mn2VDR 09MnTiCuReDR | W707 | E5015-G | |

| W707Ni | E5515-C1 | ||

| OCr18Ni9 | A102 | E308-16 | |

| A102A | E308-17 | ||

| A107 | E308-15 | ||

| 00Cr19nl10 0Cr18Ni10Ti 0Cr18Ni11Nb 1Cr18Ni9Ti | A002 | E308L-16 | |

| A002A | E308L-17 | ||

| A002Mo | E308MoL-16 | ||

| A132 | E347-16 | ||

| A132A | E347-17 | ||

| A137 | E347-15 | ||

| 0Cr17Ni12Mo2 | A202 | E316-16 | |

| A207 | E316-15 | ||

| A212 | E318-16 | ||

| 0Cr19Ni13Mo3 | A242 | E317-16 | |

| 0Cr18Ni12Mo2Ti | A212 | E318-16 | |

| 00Cr17Ni14Mo2 | A002 | E316L-16 | |

| A022L | |||

| 00Cr19Ni13Mo3 | A032 | E317MoCuL-16 | |

| 00Cr18Ni5Mo3Si2 | A022Si | E316L-16 | |

| 0Cr13 0Cr13A1 | G202 | E410-16 | When the first three kinds of welding rods are used, the weldment shall be preheated at a temperature above 300C, and tempered and slowly cooled at 700 ℃ after welding. |

| G207 | E410-15 | ||

| G217 | E410-15 | ||

| A107 | E308-15 | ||

| A207 | E316-15 | ||

| A407 | E310-15 |

Welding rods are recommended for welding different steel grades

| Joint steel grade | grade | model |

|---|---|---|

| Q235-A+16Mn | J422 | E4303 |

| 20, 20R+16Mn, 16MnRC | J427 J507 | E4315 E5015 |

| Q235-A+18MnMoNbR | J427 J507 | E4315 E5015 |

| 16MnR+18MnMoNbR | J507 | E5015 |

| Q235A+15CrMo | J427 | E4315 |

| 16MnR+15CrMo,20, 20R, 16Mn+12Cr1MoV | J507 | E5015 |

| Q235A+OCr18Ni10Ti 20R+0Cr18Ni10Ti 16MnR+0Cr18Ni10T | A302 A307 A062 | E309-16 |

| E309-15 | ||

| E309L-16 | ||

| Q235A+0Cr17Ni12Mo2 20R+0Cr17Ni12Mo2 16MnR+0Cr17Ni12Mo2 | A312 A317 A042 | E309M0-16 |

| E309M0-15 | ||

| E309MoL-16 | ||

| Q235A, 20R,16MnR+00Cr17Ni14Mo2 | A312 A317 A042 | E309M0-16 |

| E309M0-15 | ||

| E309MoE-16 |