Ever wondered why stainless steel 304 is so resilient? This article delves into the critical role of chromium, explaining how it enhances corrosion resistance and longevity. Learn about the specific chromium content ranges according to various international standards and understand the science behind stainless steel’s durability. Discover how chromium forms a protective layer, ensuring the material’s robustness even when scratched. Dive into this concise guide to grasp the essentials of chromium’s impact on stainless steel 304.

The chromium (Cr) content in 304 stainless steel typically ranges from 17.5% to 20%.

There are slight variations in the chromium content standards for 304 stainless steel among different countries. For instance, according to Japanese standard 1S G4305-2015, the chromium content in SUS304 stainless steel must be between 18% and 20%, while the American standard ASTM A240/A240M-15a requires the chromium content in 304 stainless steel to be between 17.5% and 19.5%.

It’s worth noting that chromium is a critical component in the composition of stainless steel.

The chromium content in stainless steel 304 plays a crucial role in determining its corrosion resistance.

Chromium (Cr) is a key component in maintaining the anti-corrosive properties of stainless steel.

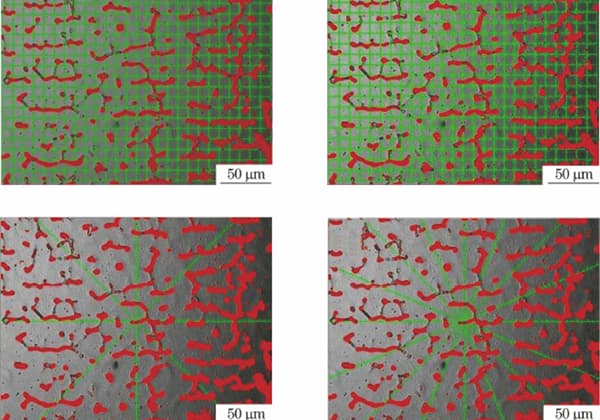

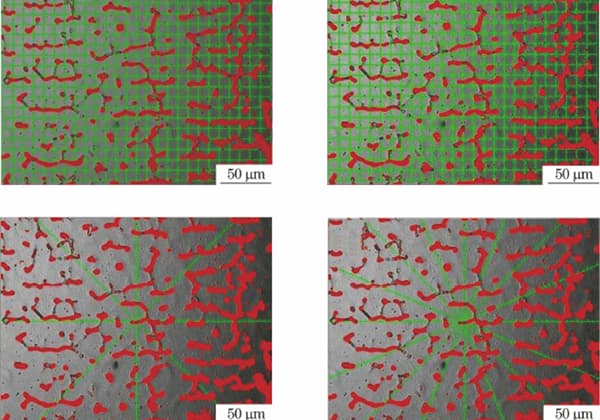

The presence of chromium and oxygen creates a passive film that protects against corrosion.

Even if the surface of stainless steel is scratched, the passive film will reform, preserving its resistance to corrosion and rust.

Comparison table of chromium content of common stainless steel materials:

Chromium content of 304 and common stainless steel materials

| Material Elements | 304① | S30408② 06Cr19Ni10 | 3304L③ | S30403④ 022Cr19Ni10 | 316L⑤ | 6S31603⑥ 022Cr17Ni12Mo2 |

| Cr | 17.5-19.5 | 18-20 | 17.5-19.5 | 18-20 | 16-18 | 16-18 |

Remarks:

1. Unit:%;

2. ①, ③ and ⑤ data source: American standard ASTM A240/A240M-15a;

3. ②, ④, ⑥ Data source: GB/T20878-2007;

Is the content of chromium and nickel in stainless steel as high as possible?

The content of chromium and nickel in stainless steel is not always proportional to quality, but should adhere to the relevant standards.

Different types of stainless steel have varying requirements for chromium and nickel content. For example, according to the table, 304 stainless steel bars should have a chromium content between 17.5% and 19.5%.

In accordance with the American standard ASTM A240M-15a, the nickel content in 304 stainless steel should fall between 8% and 10.5%.

Taking the commonly used 304 stainless steel as an example, the regulations on stainless steel materials vary across countries. However, the chromium content in 304 stainless steel typically ranges from 17.5% to 20%, while the nickel content typically falls between 8% and 10.5%.

Considering the role of alloy elements in stainless steel, it can be determined that within the specified range of the corresponding material standard, the higher the chromium and nickel content in stainless steel, the better its quality.

How much more chromium is called stainless steel?

Definition of Stainless Steel: Stainless steel is a type of steel that is known for its resistance to corrosion and staining. It is characterized by a chromium content of at least 10.5% and a carbon content of no more than 1.2%.

It is important to note that the chromium content in stainless steel plays a crucial role in determining its resistance to corrosion.