In essence, positioning and clamping have only one purpose: to prevent deformation. During the machining of parts, the question arises: should clamping or positioning come first? This is a summary that industry professionals have drawn from fixture design, but reality is far from simple. We found that preliminary designs often fall short in managing positioning […]

In essence, positioning and clamping have only one purpose: to prevent deformation.

During the machining of parts, the question arises: should clamping or positioning come first?

This is a summary that industry professionals have drawn from fixture design, but reality is far from simple. We found that preliminary designs often fall short in managing positioning and clamping.

As a result, even the most innovative solutions lose their practical value. Understanding the basics of positioning and clamping can fundamentally ensure the integrity of fixture design and machining plans.

When positioning from the side of a workpiece, similarly with supports, the principle of three points is basic.

This principle, known as the three-point principle, is derived from the concept that “three non-collinear points determine a plane.” In a set of four points, three points can determine a plane, thus potentially defining four planes in total.

However, no matter how the positioning is done, aligning the fourth point on the same plane is a significant challenge.

For instance, when using four locators of fixed height, it’s highly likely that only three points will make contact with the workpiece, leaving the fourth point not touching the workpiece.

Therefore, when setting up locators, it’s common to use three points as a basis, and to maximize the distance between these three points as much as possible.

Additionally, before setting up the locators, it’s necessary to determine the direction of the machining load. The direction of the machining load corresponds to the travel direction of the tool holder/tool.

Positioning locators at the end of the tool’s travel direction can directly influence the overall precision of the workpiece.

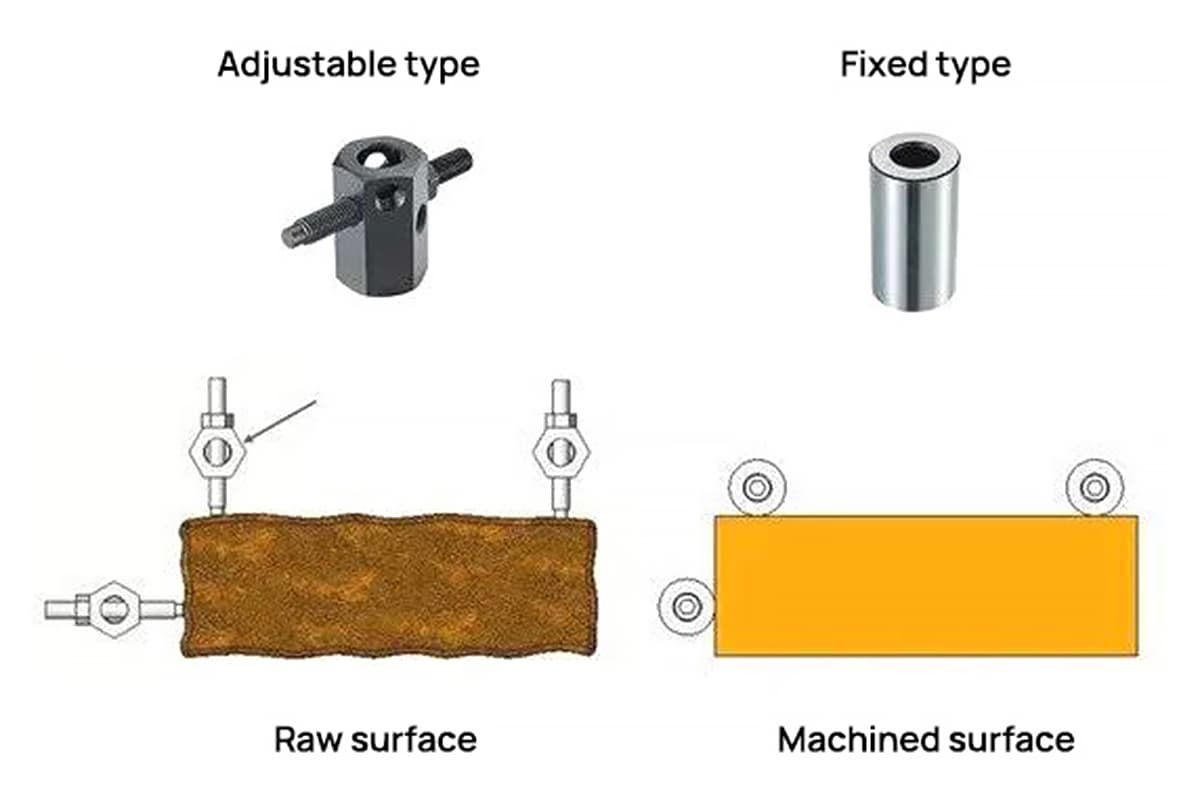

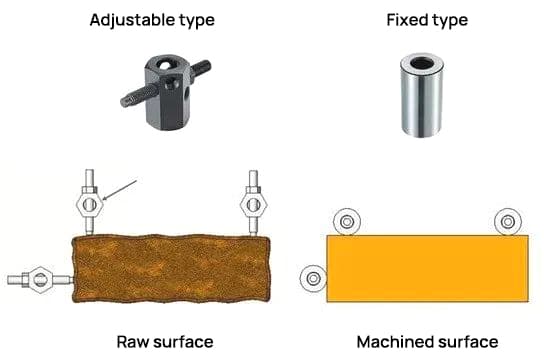

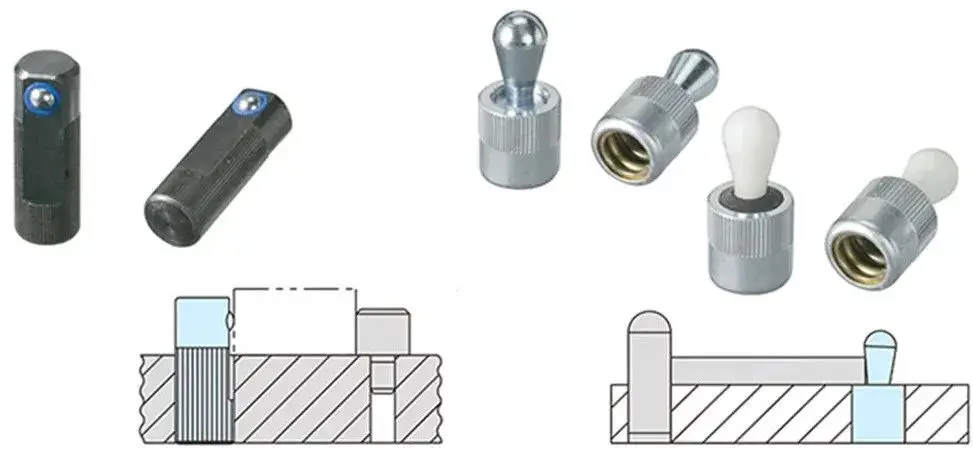

Typically, adjustable bolt-type locators are used for positioning on the rough surface of the workpiece, while fixed-type locators (with workpiece contact surfaces that have been ground) are used for positioning on the machined surface of the workpiece.

When using holes machined in previous operations of a workpiece for positioning, it is necessary to employ dowel pins with tolerance.

Through the precision coordination of the workpiece hole and the dowel pin’s external shape, and according to the fit tolerance, the positioning accuracy can meet actual requirements.

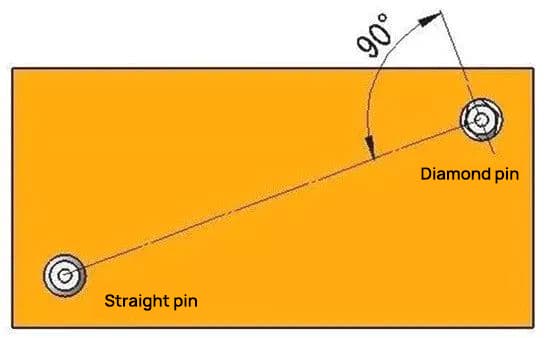

Furthermore, when using dowel pins for positioning, it is typical to use one straight dowel and one diamond dowel.

This setup makes the assembly and disassembly of workpieces more convenient, and rarely results in the workpiece getting stuck on the dowel pins.

Certainly, it’s also feasible to utilize two straight dowel pins by adjusting the fitting tolerance. However, for more precise positioning, the most effective method typically involves the use of one straight dowel pin and one diamond pin.

In situations employing one straight dowel pin and one diamond pin, the alignment direction of the diamond pin (where it contacts the workpiece) is usually at a 90° angle to the line connecting the straight dowel pin and diamond pin.

This configuration is designed for angular positioning (rotation direction of the workpiece).

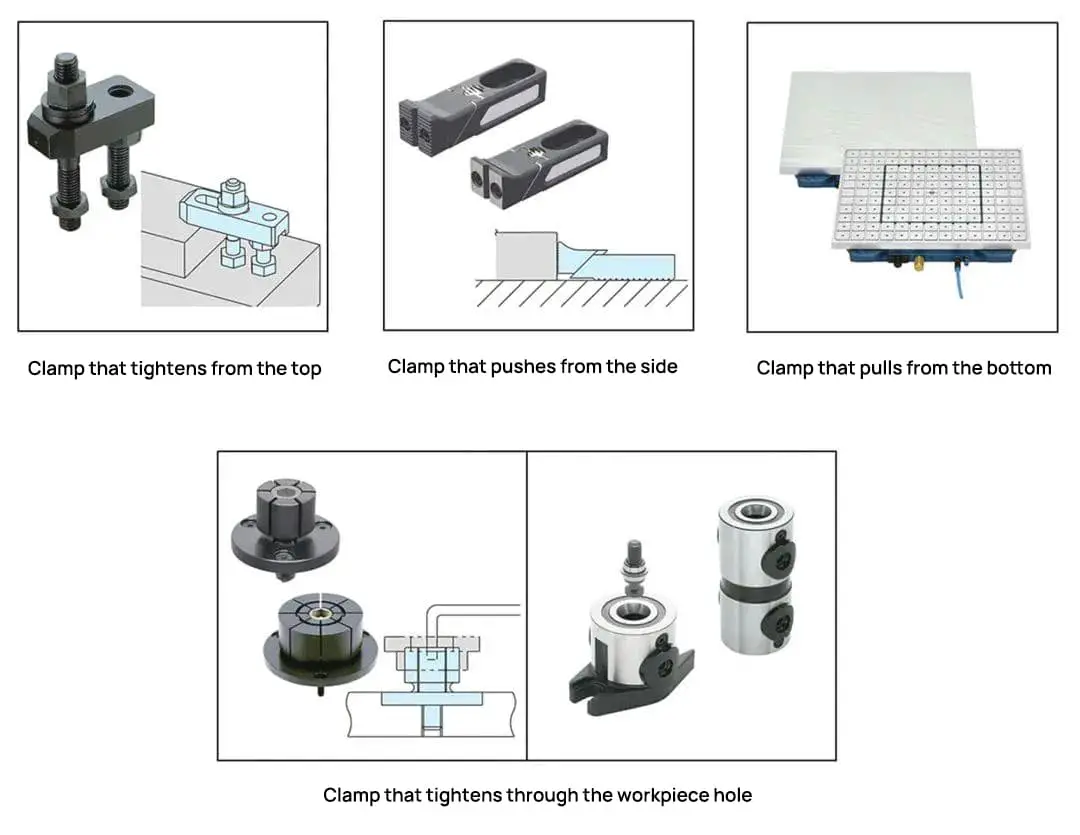

Based on the clamping direction, they are generally divided into the following categories:

Next, let’s examine the features of various clamps.

1. Top-Down Clamps

Top-down clamps, which apply pressure from above the workpiece, cause the least deformation during clamping and ensure the utmost stability during the machining process.

Therefore, in most cases, clamping from above the workpiece is the first consideration. The most common example of top-down clamping devices are manual mechanical clamps.

For instance, the clamp depicted below is known as a “maple leaf” clamp. Clamps composed of a pressure plate, double-headed bolts, a bottle jack, and nuts are referred to as “maple leaf” clamps.

Additionally, based on the shape of the workpiece, different shaped press plates can be selected to correspond with various workpiece configurations.

The relationship between the clamping torque and clamping force of a pine-leaf style clamp can be calculated via the driving force of the bolt.

The simple calculation formula for clamping force is as follows:

F (kN) = T (N×m) / 0.2d

(where d refers to the nominal diameter of the bolt).

| T(N·m) | F(KN) | F1, F2(KN) | |

| M6 | 15 | 12.5 | 6.3 |

| M8 | 25 | 16.0 | 8.0 |

| M10 | 50 | 25.0 | 12.5 |

| M12 | 80 | 33.0 | 16.5 |

| M16 | 150 | 47.0 | 23.5 |

| M20 | 200 | 50.0 | 25.0 |

| M24 | 300 | 62.5 | 31.3 |

In addition to the leaf-style clamps, there are other similar clamps that secure the workpiece from above.

2. Side-Clamping Device

Traditionally, clamping workpieces from the top has been the most stable method, resulting in the lowest workload for the workpiece.

However, when it’s necessary to work on the top of the workpiece, or when top clamping is not appropriate for various reasons, side clamping can be an alternative.

However, clamping from the side can produce an upward force on the workpiece. This force needs to be addressed when designing the clamping device.

Clamps that secure from the side, as shown above, generate a lateral force along with a downward diagonal force. This type of fixture effectively prevents the workpiece from lifting up.

There are also other similar clamps that secure from the side.

3. Utilizing a Pull-Down Clamp for Workpieces

When machining surfaces of sheet metal workpieces, it is not only inappropriate to clamp from the top, but side pressure is also unreasonable. The only viable method is to employ a pull-down approach from below.

When pulling down from underneath, if the workpiece is made of iron, a magnetic clamp is typically used. For non-iron metal workpieces, a vacuum suction cup is generally applied for pull-down clamping.

In both of these scenarios, the magnitude of the clamping force is directly proportional to the contact area between the workpiece and the magnet or vacuum suction cup.

If the machining load is too high when working on small components, the results of the machining process may not be satisfactory.

Additionally, when using magnets or vacuum suction cups, the contact surface with the magnet and suction cup needs to reach a certain level of smoothness for safe and normal operation.

4. Using hole-clamping devices

When performing multi-face simultaneous machining or mold processing with a 5-axis machine, hole-clamping is often chosen to prevent interference from clamps and tools.

Compared to clamping from the top or side of the workpiece, hole-clamping places less load on the workpiece, effectively preventing its deformation.

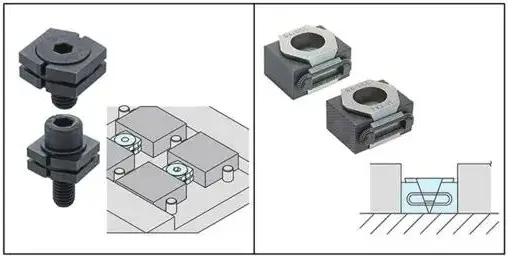

The above primarily discusses workpiece clamping fixtures and how to enhance their operability. The use of pre-clamping is also crucial for improving operability.

When vertically positioning a workpiece on the base, the workpiece will fall downwards due to gravity. At this point, one must simultaneously hold the workpiece in place and operate the clamp.

The operability significantly decreases, and the clamping time becomes lengthy when the workpiece is of substantial weight or when clamping multiple pieces simultaneously.

In such cases, using this type of spring pre-clamp product allows the operator to clamp the workpiece while it remains stationary, significantly enhancing operability and reducing clamping time.

When using various types of clamps within the same fixture, the tools for clamping and releasing should be standardized.

For instance, as shown in the left image below, when using a variety of wrenches for clamping, the overall burden on the operator increases, and the total clamping time of the workpiece extends.

As illustrated in the right image below, standardizing the wrenches and bolt sizes facilitates the on-site operator’s task.

Moreover, when setting up the clamps, the operational ease of workpiece clamping should be taken into account as much as possible. If the workpiece needs to be tilted for clamping, it becomes inconvenient to operate. Therefore, such situations should be avoided when designing the jig fixtures.