What makes molybdenum alloys crucial for modern industry? This article explores the classification of molybdenum and its alloys, detailing their unique properties and applications in high-temperature environments. From pure molybdenum to complex multi-component alloys, readers will gain insight into how these materials are developed and used to enhance performance in various sectors. Expect to learn about the different types of molybdenum alloys, their strengthening mechanisms, and future prospects in materials science.

With the development of refractory metal materials science, like steel, aluminum, titanium and other metal industries, the development of molybdenum and molybdenum alloys has gradually formed a relatively complex and complete structural system.

I have reviewed a large amount of domestic and foreign relevant materials, and based on this, proposes viewpoints and methods for molybdenum alloy classification, as well as predictions for the development direction of molybdenum alloys, in hopes of assisting researchers and producers engaged in molybdenum alloy studies and production.

Since the discovery of molybdenum metal in 1778, it has been widely used in metallurgy, electric light sources, electronic industry, chemical industry, glass and fiberglass industry, medical industry, and so on.

However, due to its inherent performance defects (such as low plastic-brittle transition temperature, limited strength, hardness, etc.), various methods have been attempted to improve it, thereby promoting its path to alloying.

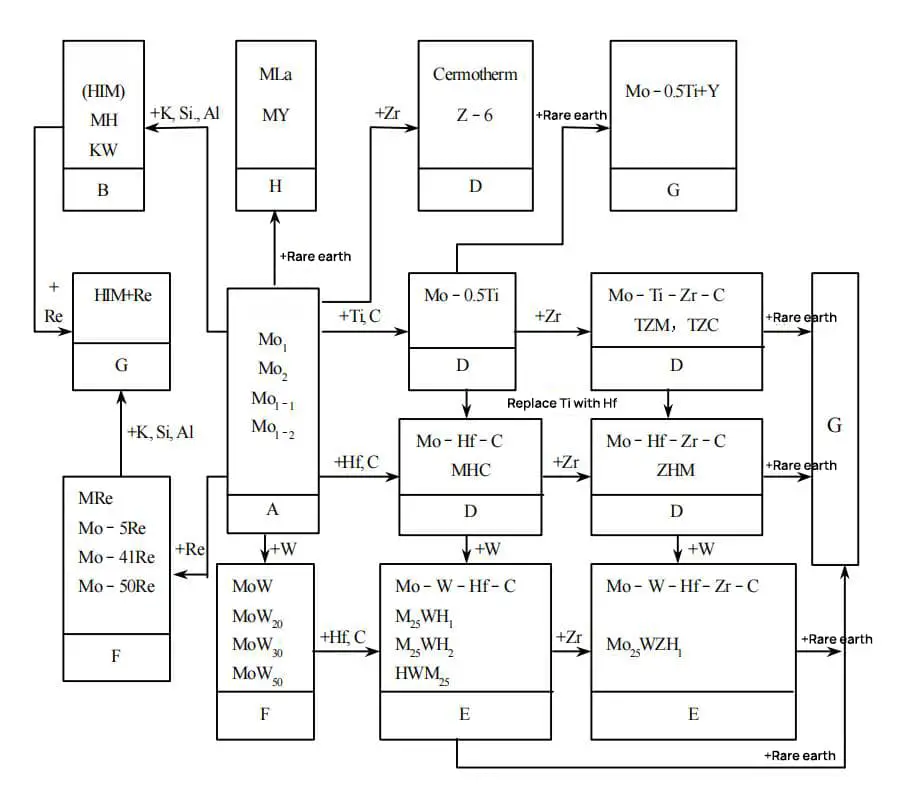

Initially, trace elements such as titanium and zirconium were added to molybdenum to form trace element alloyed alloys (such as Mo-0.5Ti, Z-6, etc.), aiming to improve its performance through solid solution strengthening of trace elements, eliminating grain boundary brittle phase, and using its reaction products (TiC, ZrC) as dispersion phases to strengthen the alloy.

At the same time, molybdenum was combined with tungsten, rhenium, and other metals in certain proportions to make corresponding alloys (such as Mo-5Re, Mo-25W, etc.) to improve their heat resistance through extensive alloying of solid solutions, thus forming molybdenum-tungsten and molybdenum-rhenium alloy series.

Based on the foundation of micro-alloyed alloys, the addition of a certain amount of alloying elements can improve the room temperature brittleness of molybdenum alloys after high temperature use.

This has evolved into the Mo-Ti-Zr-C series alloys. The TZM and TZC alloys in this series have become the most important molybdenum alloys currently in use and are an important part of the molybdenum alloy family.

In recent years, it has been found that using hafnium to replace titanium as an additive element, its reaction product HfC has a stronger strengthening effect than TiC, which can further improve the performance of molybdenum alloys.

Based on this, the Mo-Hf-C (MHC) and Mo-Hf-Zr-C (ZHM) series of alloys have been established.

At the same time, people are trying to combine the solid solution dispersion strengthening effect of trace elements with the solid solution strengthening effect of a large amount of alloyed molybdenum tungsten alloy, in order to achieve a fundamental breakthrough in the comprehensive performance of molybdenum alloys.

This has led to the Mo-W-Zr-Hf-C and Mo-W-Hf-C series of alloys, which are still under development.

Using a wet doping method, adding potassium, silicon, aluminum, and other trace elements to molybdenum forms doped molybdenum, which is currently reported to be the molybdenum alloy with the best high temperature performance.

Its recrystallization temperature can reach 1800 and even after recrystallization, it still has a certain strength, plasticity, and broad development prospects. At the same time, adding metallic rhenium to doped molybdenum alloys can produce alloys with even superior comprehensive performance.

Currently, there are reports of adding rare earth oxides to pure molybdenum and various types of molybdenum alloys. This has become several more mature molybdenum alloy grades. At this point, a complex evolutionary diagram of molybdenum alloys has been formed (see figure).

This article classifies molybdenum alloys in two ways: according to the alloy elements and the strengthening types of the alloy. The annex is a detailed classification table for molybdenum and molybdenum alloys.

Note :

(1) Binary Alloy

Binary alloys refer to molybdenum alloys with a single alloy element added to the molybdenum. This type of alloy can be divided into two types. One is a molybdenum alloy with tungsten and rhenium as alloy elements.

In this type of alloy, the amount of alloy elements added is large and the alloy performance is mainly characterized by good hardness and heat resistance. The other type is a molybdenum alloy with titanium, zirconium, and hafnium as alloy elements.

The characteristic of this type of alloy is that the amount added is small, and the alloy performance is slightly improved compared to pure molybdenum. The main ones are Mo0.5Ti, Z-6, and MHC.

(2) Multi-component Alloy

Multi-component molybdenum alloys are based on binary molybdenum alloys. In order to further improve the alloy performance, a second or multiple alloy components are added to form alloys with certain excellent performance. The main ones include the following series:

Mo-Ti-Zr-C series: This type of alloy is based on Mo0.5Ti, with a certain amount of zirconium and carbon elements added. It is currently the most mature and widely used excellent molybdenum alloy, often seen in plates, strips, and foil materials, and less used in wire rod materials. The main grades are TZC and TZM.

Mo-Hf-Zr-O series: This type of alloy is based on the MoTi-Zr-C series. To further improve the alloy performance, hafnium is used to replace titanium. Due to researchers’ different ratios of hafnium, multiple grades such as ZHM, ZHM4, ZHM6, ZHM7, ZHM8 have been formed. These alloys are also quite excellent, but there are currently no reports of widespread use both domestically and internationally.

The Mo-W-Hf-C series and Mo-W-Hf-Zr-C series alloys are developed to combine the strengthening effects of large amounts of alloying in the matrix solution with the dispersion strengthening of trace element carbides, thereby producing alloys with excellent comprehensive properties (high strength, hardness, and good high-temperature performance) and overcoming room temperature brittleness after high-temperature use. Currently, there are several grades such as M25WH1, M25WH2, HWM25, M25WZH1, but none are mature.

Doped molybdenum alloys are made by wet or dry doping, where a certain amount of potassium, silicon, and aluminum elements are added to pure molybdenum. This can significantly increase the recrystallization temperature of molybdenum, maintaining good plasticity even after recrystallization.

This type of molybdenum alloy has the highest reported recrystallization temperature, reaching up to 1800. It is not only used in rods and wires but also has a wide range of applications in sheets, strips, and foils.

In certain military applications, the doping effect of potassium, silicon, and aluminum is combined with the solid solution strengthening effect of rhenium to produce products that meet special high-performance requirements.

Rare earth molybdenum alloys have been extensively tested in single-component and multi-component alloys due to the recrystallization temperature and anti-sagging properties of molybdenum. The mature ones include MLa and MY alloys, which add 1%~2% La2O3 or Y2O3 to pure molybdenum.

These alloys have good high-temperature performance and a broad application prospect. Mo-0.5Ti+Y adds Y2O3 to form a dispersion alloy based on a single-element alloy, which is expected to secure a place in the field of sheets, strips, and foils.

The work of adding rare earth oxides to TZM, TZC, ZHM alloys is currently in the research and development stage. The addition of rare earth oxides can significantly enhance the stable chemical structure and good strengthening effect.

In the evolution process and strengthening method diagram of molybdenum alloy, it can be seen that the alloys can be divided into the following categories according to the type of alloy strengthening:

(1) Solid solution strengthening type alloys

Trace solid solution strengthening alloys: This type of alloy mainly refers to Mo-0.5Ti Z-6 single element system molybdenum alloy, which mainly relies on adding a small amount of alloy elements to the solid solution to improve the performance of the alloy.

This strengthening effect is very weak and the alloy performance can only be slightly higher than pure molybdenum. Therefore, a certain amount of carbon is often added to the alloy while adding trace solid solution elements, allowing carbon and alloy elements to form carbides to play a role in dispersion strengthening.

Large amount solid solution strengthening alloys: This type of alloy refers to molybdenum-tungsten and molybdenum-rhenium series alloys. They primarily rely on the addition of a large number of alloy elements to form an alloy solid solution with molybdenum to enhance the heat resistance and hardness of the alloy, but the machinability becomes worse.

(2) Dispersed-strengthened alloys

Carbide dispersed-strengthened alloys: Apart from the strengthening effect of trace elements in multi-element molybdenum alloys, carbide strengthening cannot be adopted.

Active elements like titanium, zirconium, and hafnium, added to molybdenum alloys, react with carbon to generate refractory carbides (TiC, ZrC, HfC) that exist in the form of fine dispersed phases, playing a role in dispersion strengthening at high temperatures.

The TZM, TZC alloys of the Mo-Ti-Zr-C series, and the ZHM of the Mo-Hf-Zr-C series, all belong to this category of alloys.

Rare earth oxide dispersed-strengthened alloys: These alloys enhance the strength of the alloy through the dispersion strengthening effect of fine particles of rare earth oxide. Compared with carbide strengthening, its dispersion strengthening effect is stronger. Examples of such alloys include ML10, MY, and Mo-0.5Ti+Y.

(3) Doped-strengthened alloys

This category refers to alloys with various different doping amounts of molybdenum. They not only rely on the solid solution strengthening effect of trace doping elements but also mainly rely on the presence of potassium bubbles at high temperatures to further improve the performance of the alloy.

(4) Comprehensive-strengthened alloys

Generally speaking, there is a close relationship between the various strengthening mechanisms of molybdenum alloys. The strengthening effect of trace elements mainly occurs at temperatures between 1100 and 1300.

When the temperature rises further, it fails. The dispersion strengthening effect of carbides is most evident at 1400-1500. At 1500-1800, carbides soften and become unstable. At this temperature, the strengthening effect of high-melting point rare earth oxides is significant.

Above 2000, rare earth oxides begin to soften, while the strengthening effect of doped potassium and silicon bubbles is evident. The pursuit of higher performance materials has always been ongoing, and comprehensive-strengthened alloys are currently one of the hotspots in the research and development of molybdenum alloys.

(1) As the production process of molybdenum alloys and pure molybdenum is very similar, with the development of refractory materials, pure molybdenum materials will gradually be replaced by high-performance molybdenum alloy materials.

(2) For a considerable period, the Mo-Ti-Zr-C series of TZM, TZC alloys, with their excellent performance and mature technology, will remain mainstream in the application of plates, strips, and foils. Rare earth molybdenum with good sag resistance and high-temperature performance will gradually replace pure molybdenum in rods and wires.

(3) Doped molybdenum and doped molybdenum with added rhenium elements, these two types of molybdenum alloys, with their excellent comprehensive performance, will gradually develop and grow in both civilian and military products, having a promising development prospect.

(4) Comprehensive strengthened molybdenum alloys will be the new target people are pursuing.

| Classification | Alloy Series | Grade | Nominal Composition | Recrystallization Temperature |

| Pure Molybdenum | Powder Metallurgy Molybdenum | Mo1Mo2 | Pure Molybdenum | 1000℃-1100℃ |

| Melted Molybdenum | Mo1-1Mo1-2 | |||

| Belongs to Ceramic Material | Molybdenum-Tungsten Alloy | MoW20 | Mo-25%W | ~1200℃ |

| MoW25 | Mo-25%W | |||

| MoW30 | Mo-30%W | |||

| MoW5o | Mo-50%W | |||

| Molybdenum-Rhenium Alloy | Mo-5Re | Mo-5%Re | 1200℃-1300℃ | |

| Mo-41Re | Mo-41%Re | |||

| Mo-50Re | Mo-50%Re | |||

| Molybdenum-Zirconium Alloy | Z-6 | Mo-0.5ZrO | ~1250℃ | |

| Cermatherm | 40%-90%Mo-60%-10%ZrO | Belongs to Ceramic Materials | ||

| Molybdenum-Titanium Alloy | Mo-0.5Ti | Mo-0.5Ti-0.01-0.04C | 1100℃-1300℃ | |

| Molybdenum-Hafnium Alloy | MHC | Mo-1.2Hf-0.005C | 1550℃ | |

| Doping with Molybdenum | HIM Alloy | MH(HD) | Mo-0.0015K-0.002Si | -1800℃ |

| KW | Mo-0.002K-0.003Si-0.001A1 | |||

| Rare Earth Molybdenum Alloy | Molybdenum-Titanium-Yttrium Alloy | Mo-0.5Ti-Y | Mo-0.5Ti-1.6%Y | 1500℃ |

| Molybdenum Alloy | MLa | Mo-1%-2%La2O3 | 1400℃-1500℃ | |

| Molybdenum-Yttrium Alloy | HY | Mo-0.5%-1.5%Y | 1500℃-1600℃ | |

| Multi-element Molybdenum Alloy | Mo-Ti-Zr-C | TZM | Mo-0.5Ti-0.07~0.12%Zr-0.01~0.04C | 1300 ℃~1500℃ |

| TZC | Mo-1.0~1.5Ti-0.1~0.3Zr-0.02~0.04C | |||

| Mo-Hf-Zr-C | ZHM | Mo-0.5Zr-1.5Hf-0.2C | 1550℃ | |

| ZHM4 | Mo-1.2Hf-0.4Zr-0.15C* | |||

| ZHM6 | Mo-1.5Hf-0.5Zr-0.19C* | |||

| ZHM7 | Mo-1.8Hf-0.6Zr-0.23C* | |||

| ZHM8 | Mo-2.1Hf-0.7Zr-0.27C* | |||

| Mo-W-Hf-C | HWM25 | Mo-1.0Hf-25W-0.07C | ~1650℃ | |

| M25WH1 | Mo-23.72W-1.2Hf-0.08C* | |||

| M25WH2 | Mo-23.9W-1.0Hf-0.006C* | |||

| Mo-W-Hf-Zr-C | Mo25WZH1 | Mo-23.3W-1.2Hf-0.4Zr-0.1C* | ||

| Note: * indicates that the research has not yet been fully established domestically. | ||||