Have you ever wondered how to keep your laser cutting machine running smoothly? The cleanliness of the machine’s lenses plays a crucial role in its performance and longevity. In this article, you’ll discover essential tips and methods for cleaning laser lenses, from avoiding fingerprints to using specific cleaning agents. By following these guidelines, you can enhance your machine’s efficiency and reduce maintenance costs. Dive in to learn the best practices for maintaining the clarity and functionality of your laser cutting equipment’s lenses.

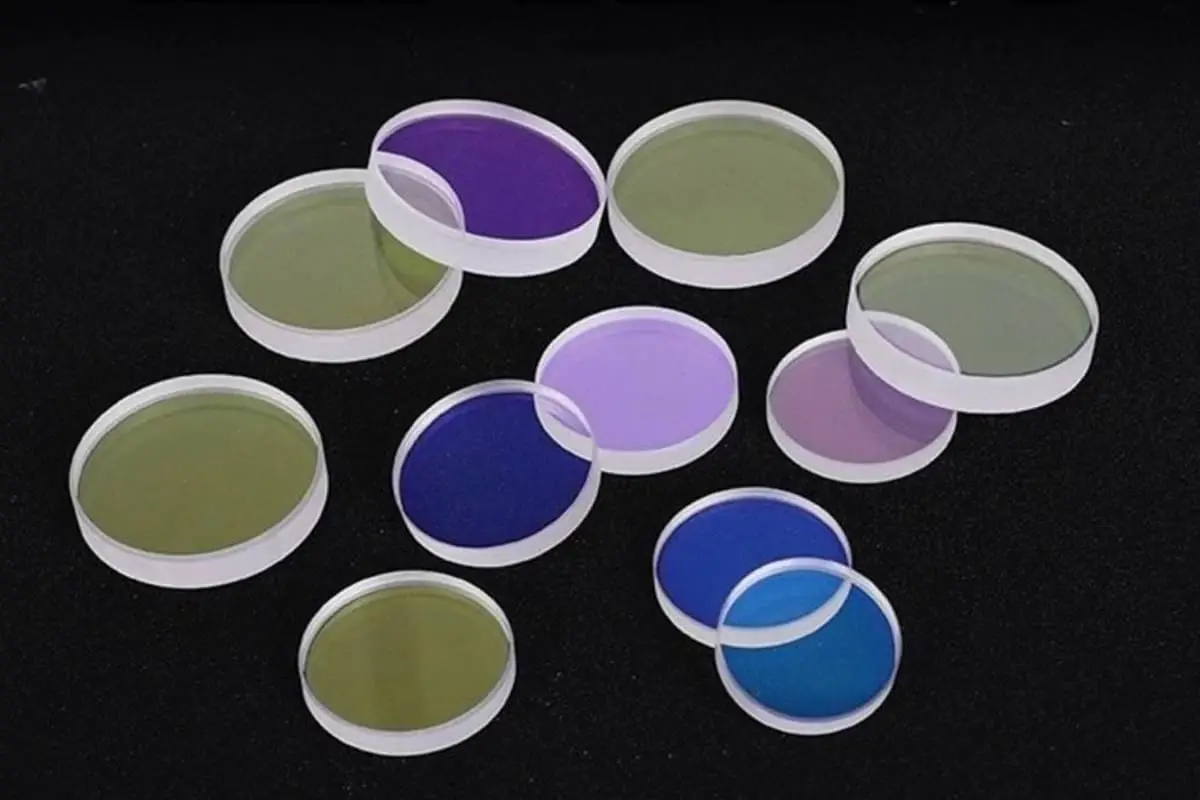

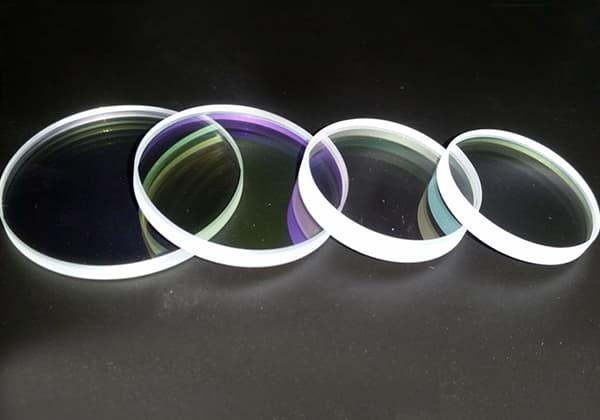

In laser systems, optical lenses are consumable items. To extend their service life and reduce operating costs as much as possible, it is essential to clean the lenses strictly following this standard.

During the replacement process, care must be taken when placing, inspecting, and installing optical lenses to avoid damage and contamination. Once a new lens is installed, it should be cleaned regularly to maintain its performance.

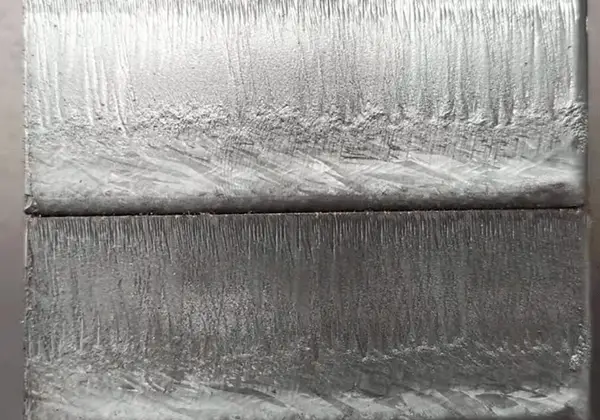

When the laser cuts materials, the working surface releases a large amount of gas and splatter, which can damage the lens. Contaminants on the lens surface can absorb energy from the laser beam, leading to the thermal lens effect.

If the lens has not yet developed thermal stress, the operator can disassemble and clean it.

During the installation and cleaning process of the lens, even a tiny bit of adhesive or a fingerprint can increase the lens’s absorption rate and decrease its service life.

For daily laser lens operation, the following preventive measures must be taken:

During the lens cleaning process, methods with relatively low risk should be adopted. The following steps are established for this purpose, and users should follow them: