How can manufacturers ensure flawless cuts in ultra-thick steel plates? This article delves into the critical process of CNC flame cutting, highlighting the challenges, such as potential cutting defects and material loss, and providing solutions to optimize gas supply, support frames, and cutting programs. By understanding these intricacies, readers will gain valuable insights into achieving precise and efficient cuts, ensuring high-quality results in large-scale manufacturing.

With the advent of large-scale equipment and the increasing utilization of steel over cast materials, ultra-thick plates have become increasingly prevalent in equipment manufacturing.

Flame cutting is the initial stage in the manufacture and processing of structural components.

Given the irreversible nature of flame cutting, the CNC flame-cutting process for ultra-thick plates has become a crucial technology for large equipment manufacturers.

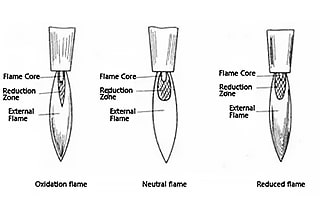

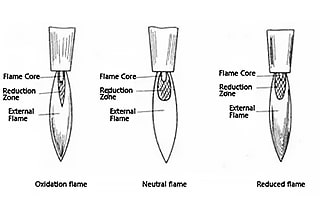

Figure 1

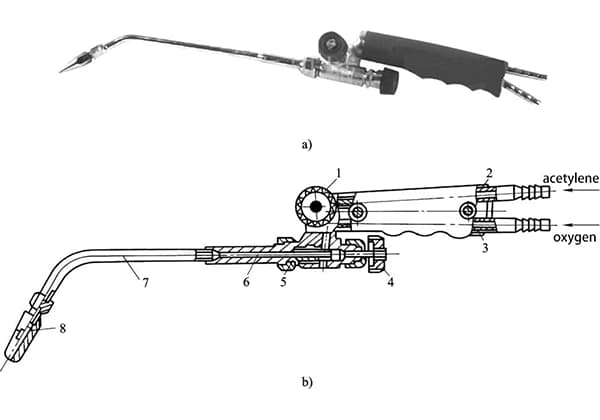

Oxygen and Acetylene for Ultra-Thick Plate Cutting

The cutting of ultra-thick plate parts requires a large amount of oxygen and acetylene, as these parts are usually larger in size. To ensure a smooth and efficient cutting process, it is crucial to have a continuous and stable supply of these gases.

Large Size and Weight of Ultra-Thick Plates

As an example, a 220mm x 2200mm x 8000mm thick plate weighs approximately 30 tons. Additionally, the weight of individual parts can be quite substantial, with the upper connecting rod number 9 steel plate, for instance, weighing more than 4 tons (refer to Figure 1).

Risk of Cutting Defects

Ultra-thick plates are more prone to cutting defects, such as impervious cutting, compared to regular plates.

Large Material Scrap Loss

The significant material loss during the edging process of ultra-thick plates makes it difficult to reuse the cut-off edges.

Cutting Distortion

The heat generated during the cutting process can cause deformation in the steel plate and result in deviation from the desired dimensions. Furthermore, sudden bouncing of the plate under high stress can lead to safety hazards. To prevent these quality and safety issues, it is essential to consider the cutting distortion when formulating the cutting process.

(1) Upper Edge Cutting Defects

The upper edge of the cut collapses or drops in the form of molten strings, resulting in rounded corners collapsing due to the upper edge of the slit melting too quickly.

Possible causes:

As illustrated in Picture 2.

Figure 2

(2) Poor Flatness of the Cutting Surface

① There is a concave defect under the edge of the cut section (refer to Figure 3). Additionally, the upper edge exhibits varying degrees of melting collapse.

This can be attributed to high cutting oxygen pressure or excessive height between the cutting nozzle and the workpiece, as well as a clogged cutting nozzle that causes wind interference.

② The cutting section has excessive roughness.

This may be due to excessive cutting speed or impurities in the steel plate that impact its formation.

As shown in Figure 3.

Figure 3

(3) Poor Verticality

① The width of the cutting seam varies, being narrow at the top and wide at the bottom or vice versa, due to a fast or slow cutting speed, a clogged cutting nozzle that interferes with the wind line, and inadequate or excessive cutting oxygen that leads to insufficient or excessive metal burning.

② The cutting torch creates an oblique angle that is not perpendicular to the workpiece surface or the wind line is incorrect.

(4) Lower-Edge Cutting Defects

① There is depression near the lower edge and the lower edge melts into rounded corners because of a fast cutting speed, a clogged or damaged cutting nozzle, and blocked or deteriorated air line.

② The removal of slag on the cut surface or lower edge is difficult due to factors such as a fast or slow cutting speed, a small cutting nozzle, low cutting oxygen pressure, excess gas in the preheating flame, a corroded or dirty steel plate surface, excessive height between the cutting nozzle and the workpiece, and a strong preheating flame. Additionally, a high content of alloy can result in slag formation on the cross section and bottom edge (refer to Figure 4).

Figure 4

(5) Cracks

Microcracks appear in the cutting section or heat-affected zone due to high carbon equivalent in the steel plate that results in high crack sensitivity, coupled with the lack of proper preheating and slow cooling measures.

(6) Deformation

Local heating of the steel plate during cutting causes material shifting deformation, leading to dimensional deviation of the cut parts and affecting their quality.

As illustrated in Figure 5.

Figure 5

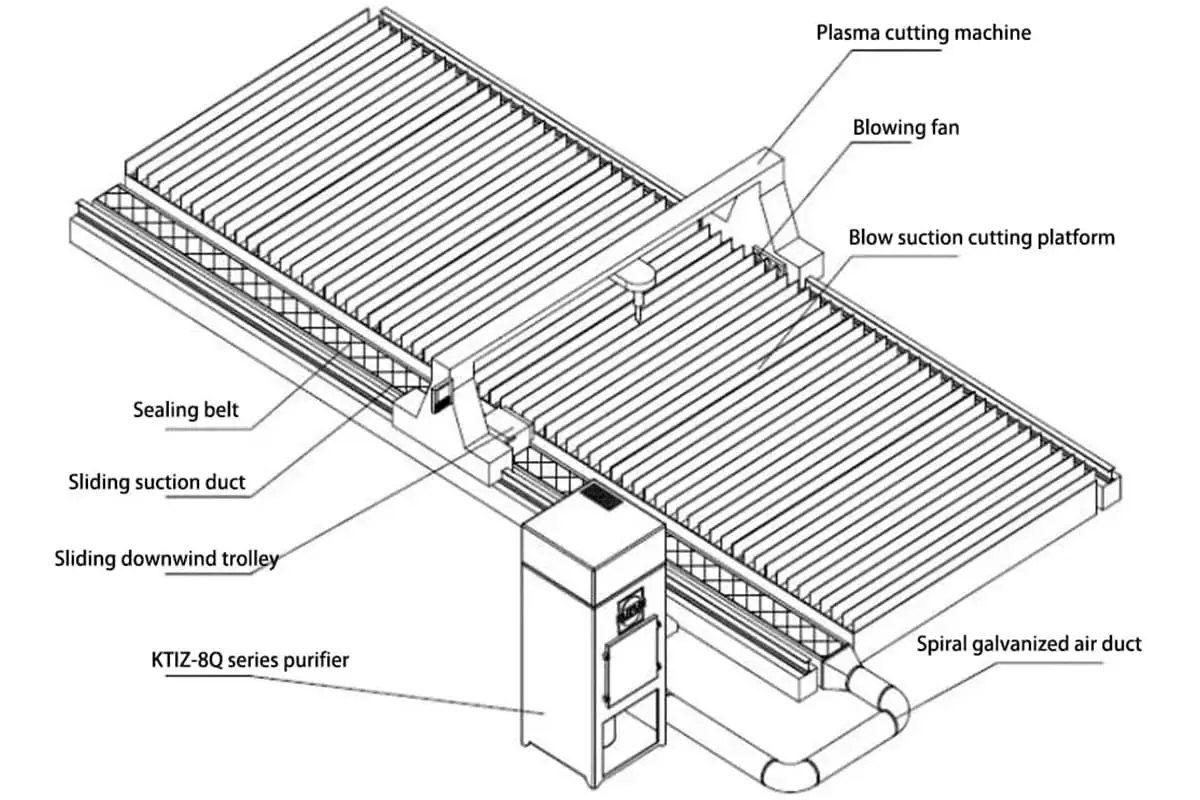

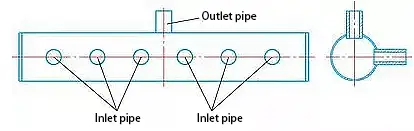

(1) Cutting Gas Supply System

To maintain a consistent and reliable supply of oxygen and acetylene gas, multiple gas bottles can be utilized in parallel. This will ensure a stable and uninterrupted flow of acetylene gas.

A parallel gas supply package can be created as shown in Figure 6. A φ100mm steel pipe is utilized as the air bag, and both ends are securely welded with steel plates.

Six intake pipes and one air outlet pipe are drilled into the steel pipe, taking care to ensure proper welding quality and avoiding any air bag leaks.

A gas-tight ball valve and a connecting device should be added to each air inlet and outlet.

Figure 6

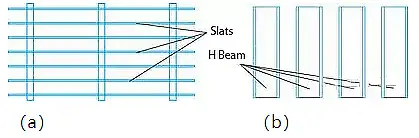

(2) Cutting Support Frame

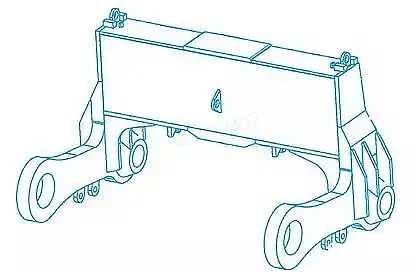

Due to the large size and weight of the thick plate, which has a maximum weight of 30 tons, and the substantial size and weight of individual parts, with a maximum weight of 4 tons, the original CNC cutting machine support frame cannot meet the cutting requirements as it provides insufficient support for the slats (as shown in Figure 7a).

To ensure stable support of the frame, modifications to the support frame are necessary. After careful analysis, research, and discussion, it was decided to utilize waste H-shaped steel as the thick plate support frame.

(A) Support Frame Before Transformation

(B) Support Frame After Transformation

Figure 7

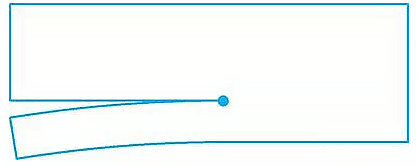

(3) Cutting Program Optimization

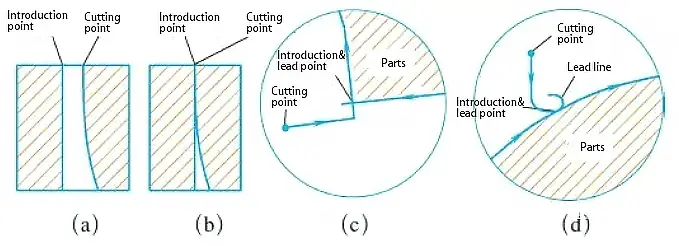

Initially, lead-out point processing is introduced.

The biggest challenge in cutting ultra-thick boards (up to 220mm) is ensuring a quality cut, especially the positioning of the lead-in and lead-out points of the parts, which often leads to cutting defects.

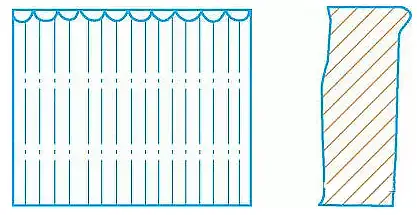

As illustrated in Figures 8a and 8b, thick plate cutting points are often not vertical.

When the cutting point coincides with the lead-in point, if the cutting line turns at this moment, the root will not be cut, causing defects due to fractures from the weight of the parts.

To prevent such defects from occurring, optimizing the lead-in and lead-out in the cutting process can be an effective solution.

Figure 8

Secondly, if proper care is not taken regarding the direction during the cutting process, it can cause deformation of the parts. This is because the expansion force will push the part away, leading to inconsistencies in the size of the part and the program size.

To address this problem, our analysis suggests that when cutting steel plates, the light weight results in low pressure and minimal friction with the support frame, causing the part to be pushed away by the expansion force. On the other hand, the heavy weight produces high pressure and significant friction with the support frame, preventing it from being pushed away by the expansion force.

It is important to take this into consideration when writing the program. During the cutting process, the part should be connected to a heavy piece as much as possible.

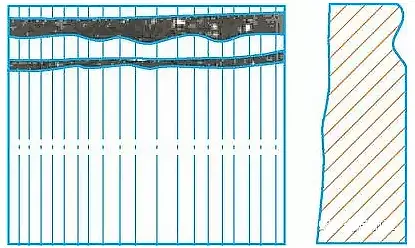

Based on this principle, the discharge, cutting sequence, and cutting direction of the upper connecting rod are depicted in Figure 9.

Figure 9

Finally, optimizing the layout can save greater costs by optimizing the size.

When designing the program, more time can be allocated towards optimizing the layout. It is best to utilize any remaining leftover material, and multiple people can collaborate to verify the size of the part and generate the program after confirming its accuracy.

For thicker parts to be cut, the torch model, cutting nozzle number, and oxygen pressure should be increased.

The oxygen pressure and cutting piece thickness, cutting torch model, and ultra-thick plate cutting parameters should be selected based on field equipment, cutting experience, and the attached table.

Parameters for Ultra-Thick Plate Oxyacetylene Flame Cutting

| Thickness | Cutting nozzle diameter | Oxygen pressure | Acetylene pressure | Preheat time | Cutting speed | Gas flow |

|---|---|---|---|---|---|---|

| mm | mm | Mpa | Mpa | s | mm/min | L/min |

| 180 | 5 | 1.0-1.4 | 0.09-0.11 | 30-35 | 145-165 | 17-20 |

| 200 | 5 | 1.0-1.4 | 0.09-0.11 | 30-35 | 140-165 | 20-23 |

| 220 | 5 | 1.0-1.4 | 0.09-0.11 | 30-35 | 135-155 | 22-25 |

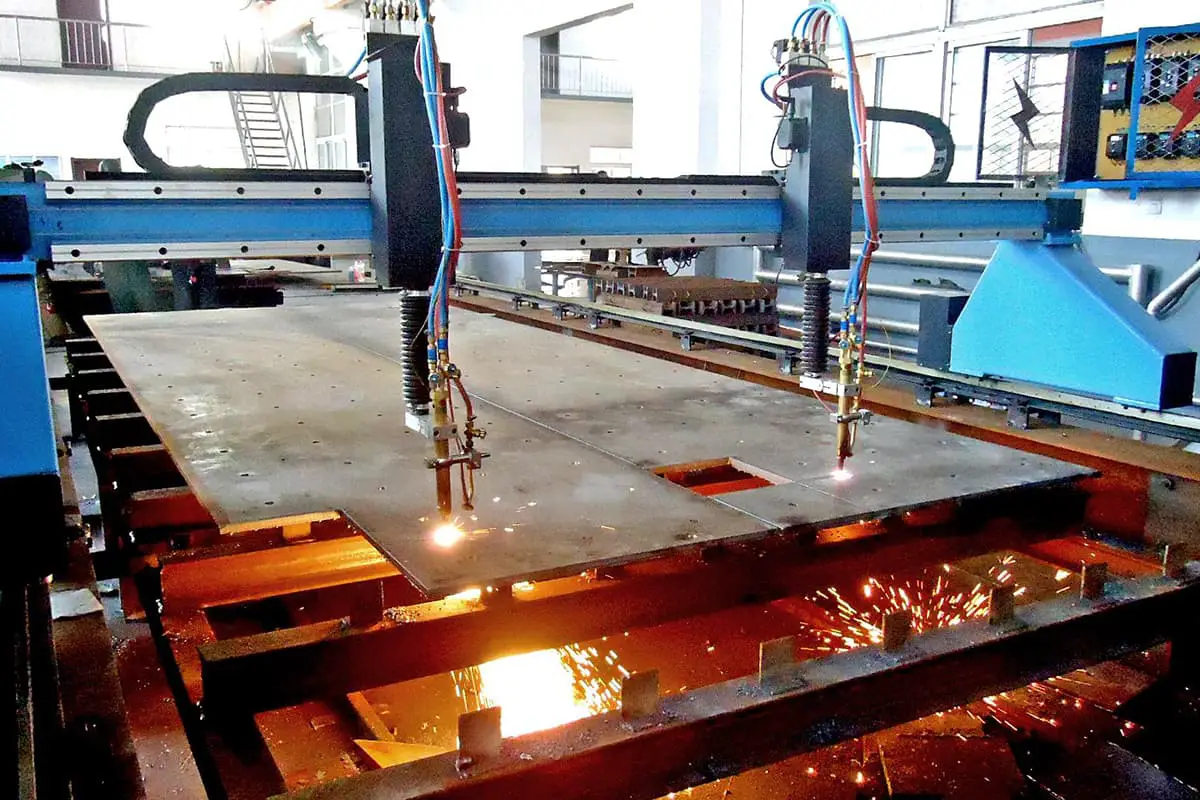

(4) Cutting Performance

When the steel plate is cut, it must be done correctly on the first attempt.

Begin by cutting the discarded corners of the steel plate, adjusting the cutting air line, and ensuring that the cut section does not have any of the mentioned defects.

It is important to closely monitor the cutting process and quickly address any issues that arise.

With proper preparation and a well-defined cutting process, ultra-thick board cutting has consistently achieved success in a single attempt. The quality and appearance of the cut products meet the process requirements, resulting in the production of qualified parts (as shown in Figure 10).

Figure 10

The production process for flame-cutting ultra-thick steel plates using the current equipment has been established, providing a technical foundation for the manufacture of similar products.