Compared to conventional press brakes, CNC press brakes have many advantages in improving working efficiency. Here, we explain these advantages in 6 aspects. Graphical user interface The user interface serves as a dialogue interface between the CNC press brake controller and the user. The graphical user interface is designed to be user-friendly for a diverse […]

Compared to conventional press brakes, CNC press brakes have many advantages in improving working efficiency. Here, we explain these advantages in 6 aspects.

The user interface serves as a dialogue interface between the CNC press brake controller and the user.

The graphical user interface is designed to be user-friendly for a diverse range of users, including non-professionals.

By utilizing windows and menus, users can perform various functions such as graphic simulation, dynamic tracking, simulation, and fast programming.

The exchange of information is no longer restricted to the use of language and words. Nowadays, visual information such as graphics, images, animations, and other visuals can be used directly to communicate.

Visualization technology can be employed for various purposes such as CAD/CAM, automatic parameter setting, tool compensation, and displaying and visualizing process simulations.

Interpolation methods include linear interpolation, circular interpolation, cylindrical interpolation, spatial elliptical surface interpolation, thread interpolation, polar coordinate interpolation, polynomial interpolation and so on.

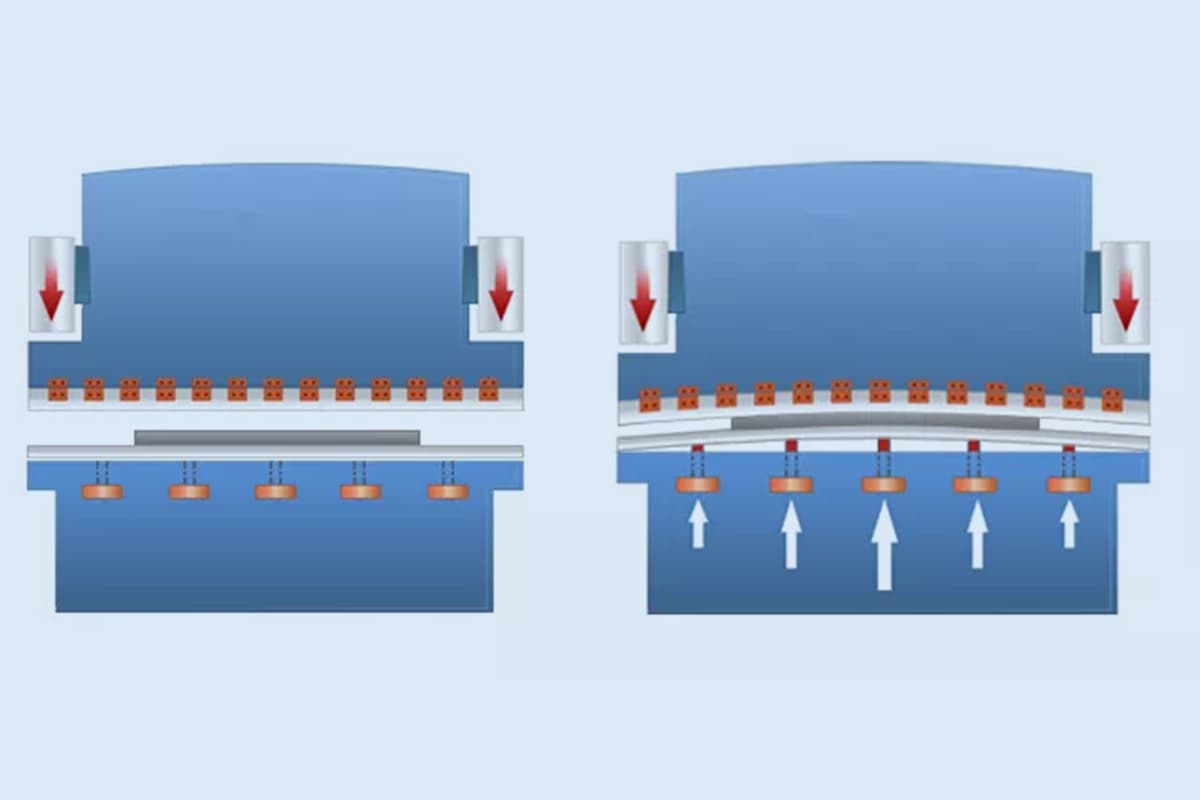

Deflection compensation function has vertical compensation, gap compensation, quadrant circular arc interpolation error compensation, pitch, and measurement system error compensation, tool radius compensation, temperature compensation and so on.

The built-in high-performance PLC of the CNC press brake controller can be programmed directly using ladder diagram or high-level language. It supports online debugging and editing, allowing you to modify and build your own applications.

The utilization of highly integrated CPUs, RISC chips, large-scale programmable integrated circuits, and application-specific integrated circuit chips has improved the density of integrated circuits, as well as the speed of software and hardware operations. This, in turn, has increased the reliability of the controller.

In order to achieve integration and standardization of CNC press brake controllers, the modules, including CPU, memory, location servo, PLC, input and output interfaces, and communications, should be transformed into a standard series of products to constitute a variety of CNC bending machine controllers of different grades.

With the continuous progress of modern industrial revolution, CNC bending machines will have broader applications.

CNC bending machine development will continue to advance, making its use more convenient, enhancing bending accuracy, increasing efficiency, and making greater contributions to the entire machining industry.