What if you could weld metals together without any heat, just by applying pressure? Cold pressure welding does just that, achieving a solid bond by pressing metals together at room temperature. This method avoids common issues like heat-affected zones and brittleness, making it ideal for materials like aluminum and copper. In this article, we’ll explore the types of cold pressure welding, the equipment needed, and its pros and cons, providing you with practical insights into this fascinating process.

Cold pressure welding, also known as cold welding or solid-state welding, is an innovative joining technique that creates high-strength metallic bonds without the application of heat. This process relies on the principle of plastic deformation to achieve atomic-level bonding between two metal surfaces at room temperature.

During cold pressure welding, substantial compressive force is applied to the metal interfaces, typically exceeding the yield strength of the materials. This intense pressure causes localized plastic deformation, which serves two critical functions:

This process offers several advantages over traditional fusion welding methods:

Cold pressure welding is particularly effective for joining highly ductile metals and alloys, including:

The technique finds applications in various industries, including electrical and electronic manufacturing, aerospace, and jewelry production. However, it’s important to note that the process has limitations, such as the need for extremely clean surfaces and its unsuitability for joining dissimilar metals with vastly different mechanical properties.

Cold pressure welding, also known as solid-state welding, is a joining process that relies on the application of high pressure at room temperature to create a metallurgical bond between two workpieces. The principle behind this technique is fundamentally based on plastic deformation and atomic diffusion.

During the process, substantial pressure is applied to the workpieces, causing significant localized plastic deformation at the interface. This deformation serves multiple crucial functions:

For butt cold pressure welding, the procedure typically involves the following steps:

Key factors influencing the success of cold pressure welding include:

It’s important to note that cold pressure welding is most effective for materials with high room-temperature ductility. Highly work-hardened or naturally hard materials may present challenges and might require modified approaches or alternative joining methods.

In industrial applications, cold pressure welding finds use in joining similar and dissimilar metals, particularly in electrical and electronic industries where heat-affected zones are undesirable. The process offers advantages such as no heat-affected zone, no filler materials, and the ability to join dissimilar metals, but it also has limitations in terms of joint geometries and material suitability.

According to the joint configuration, cold pressure welding can be categorized into two main types: lap cold pressure welding and butt cold pressure welding.

(1) Lap Cold Pressure Welding

Lap cold pressure welding involves positioning the workpieces in an overlapping configuration and applying pressure using a specially designed indenter. The process is complete when the indenter has been pressed to the predetermined depth, creating a solid-state bond between the overlapping surfaces. This method can be further subdivided into two categories:

a) Lap Spot Welding: Utilizes a columnar indenter to create discrete welding spots.

b) Lap Seam Welding: Employs a roller-type indenter to produce continuous welding seams.

Lap seam welding can be further classified into rolling welding, sleeve welding, and extrusion welding, depending on the specific technique and tooling used.

Lap cold pressure welding is particularly effective for joining thin materials such as foils and plates, where traditional fusion welding methods might be challenging or cause distortion.

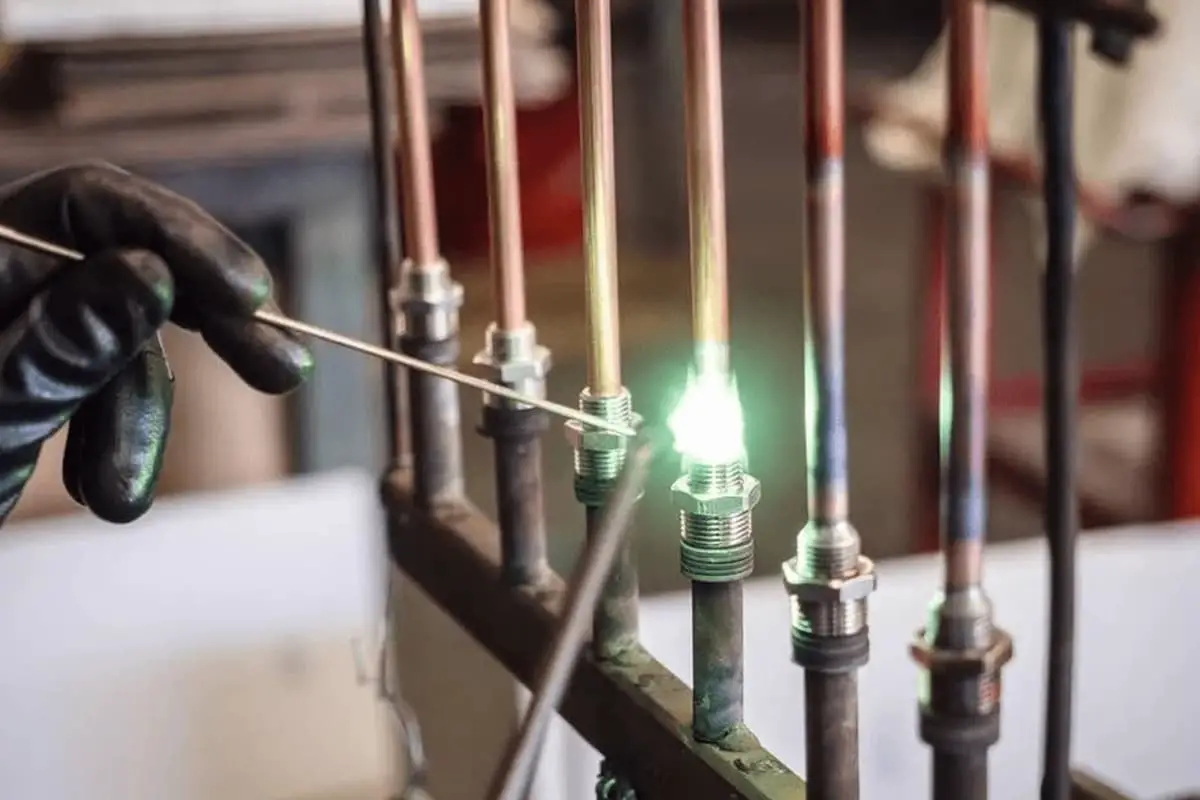

(2) Butt Cold Pressure Welding

In butt cold pressure welding, the workpieces are clamped in opposing jaws and extended slightly beyond the clamping point. Substantial upset pressure is then applied, causing radial plastic deformation in the extended portions. This deformation serves two crucial purposes:

a) It extrudes surface impurities, forming a metal flash around the joint.

b) It brings atomically clean metal surfaces into intimate contact, facilitating solid-state bonding.

The result is a high-integrity weld joint formed without melting the base materials. This technique is primarily employed for creating butt joints in metal wires, bars, or pipes, and is capable of joining both similar and dissimilar metals.

Butt cold pressure welding offers several advantages, including the ability to join materials with significantly different melting points, minimal heat-affected zones, and the preservation of the base material’s microstructure.

Cold pressure welding equipment primarily comprises cold pressure welding tongs and cold pressure welding machines, each designed for specific applications in metal joining processes.

Cold pressure welding tongs are predominantly utilized for butt cold pressure welding, particularly suitable for field installations. These tongs are capable of welding aluminum conductors with diameters ranging from 1.2 to 2.3 mm, making them widely adopted in cable welding facilities. Their portability and precision make them ideal for on-site operations where flexibility is crucial.

The cold pressure welding process encompasses two main techniques: butt welding and spot welding. Among these, the cold pressure butt welding machine is the most extensively employed. This sophisticated equipment integrates several key components, including a robust frame, a precision machine head, an advanced feeding mechanism, a high-performance scissors device, and various auxiliary components. This comprehensive design ensures optimal welding performance across a range of applications.

In communication infrastructure, power cable manufacturing, and small transformer production facilities, large cross-section weldments are typically joined using cold pressure welding machines. These machines are capable of handling substantial workpieces with high precision. A critical factor in the machine’s performance is the structure size of the cold pressure welding die, which significantly influences the welding pressure. Consequently, die design is a paramount consideration for cold pressure welding machine engineers, requiring meticulous calculations and material selection to achieve optimal results.

For end-users of cold pressure welding machines, it’s important to note that the structure size of the die is predetermined during the manufacturing process of the welding equipment. Once the machine is produced, this parameter remains fixed. However, operators can still optimize the welding process by selecting appropriate welding pressures based on the technical specifications provided by the machine manufacturer. This allows for fine-tuning of the welding operation to accommodate different materials and joint configurations within the machine’s capabilities.

To ensure consistent weld quality and efficiency, users should regularly calibrate the welding pressure according to the material properties, joint geometry, and the specific requirements of each welding task. Additionally, maintaining the dies and other critical components of the cold pressure welding machine is essential for prolonging equipment life and maintaining optimal performance.

Advantages

Cold welding is a solid-state joining process that offers several distinct advantages:

Disadvantages

Despite its advantages, cold welding has several limitations:

Equipment Cost: High-capacity cold welding machines capable of generating the required pressures can be costly, potentially limiting widespread adoption in smaller-scale operations.

Local Deformation: The high pressures required can cause significant localized deformation, particularly in lap joints, potentially affecting part geometry and surface finish.

Intermetallic Formation in Dissimilar Metals: When joining certain dissimilar metals (e.g., Cu and Al), post-weld exposure to elevated temperatures can promote the formation of brittle intermetallic compounds, compromising joint ductility and electrical conductivity. This limits the high-temperature performance of such joints.

Size and Material Limitations: The process is constrained by the capacity of the welding equipment, limiting the thickness of lap joints and the cross-sectional area of butt joints. Additionally, the hardness of the materials to be joined is restricted by the mechanical properties of the welding dies.

Surface Preparation: Successful cold welding often requires meticulous surface preparation to remove oxides and contaminants, which can increase processing time and complexity.

Limited Joint Configurations: Cold welding is primarily suitable for simple joint geometries, such as lap and butt joints, limiting its applicability in complex assemblies.